PVDF in Robotics: Superior Actuator Technologies

PVDF Actuator Evolution

The evolution of PVDF actuators in robotics represents a significant advancement in the field of smart materials and their application in advanced robotic systems. Initially developed in the 1960s, polyvinylidene fluoride (PVDF) has undergone substantial improvements in its piezoelectric properties and manufacturing processes, leading to its increased adoption in robotic actuators.

In the early stages of PVDF actuator development, researchers focused on enhancing the material's piezoelectric response. This was achieved through various techniques, including mechanical stretching and electrical poling. These processes aligned the polymer chains and dipoles within the material, significantly improving its electromechanical coupling efficiency.

The 1980s and 1990s saw a surge in research activities aimed at optimizing PVDF film fabrication methods. Advances in thin-film deposition techniques, such as spin coating and electrospinning, enabled the production of PVDF films with controlled thickness and uniformity. This breakthrough allowed for the creation of more precise and responsive actuators, opening up new possibilities in micro-robotics and soft robotics applications.

A major milestone in PVDF actuator evolution came with the development of copolymers and nanocomposites. The introduction of trifluoroethylene (TrFE) to create P(VDF-TrFE) copolymers in the late 1990s resulted in materials with enhanced piezoelectric properties and lower operating voltages. This advancement made PVDF actuators more suitable for a wider range of robotic applications, particularly in biomedical and microfluidic devices.

The turn of the millennium brought about significant progress in PVDF actuator design and integration. Researchers began exploring multi-layer structures and novel electrode configurations to amplify the actuation response. The development of interdigitated electrodes and stack actuators allowed for greater force output and displacement, addressing some of the limitations of earlier PVDF actuator designs.

Recent years have seen a focus on improving the overall performance and durability of PVDF actuators. Innovations in material science have led to the creation of self-healing PVDF composites, enhancing the longevity and reliability of these actuators in demanding robotic applications. Additionally, the integration of PVDF actuators with other smart materials, such as shape memory alloys and magnetorheological fluids, has resulted in hybrid systems with enhanced functionality and adaptability.

The miniaturization trend in robotics has driven the development of micro- and nano-scale PVDF actuators. Advanced fabrication techniques, including 3D printing and nanoimprinting, have enabled the creation of intricate PVDF structures with unprecedented precision. These developments have paved the way for highly sophisticated microrobots and nanorobots capable of performing complex tasks in confined spaces.

As we look to the future, the evolution of PVDF actuators continues to accelerate. Ongoing research in areas such as molecular engineering and artificial intelligence promises to further enhance the capabilities of these actuators. The integration of machine learning algorithms for real-time adaptation and self-optimization of PVDF actuators represents an exciting frontier in the field, potentially leading to more intelligent and responsive robotic systems.

Robotics Market Demand

The robotics market has been experiencing significant growth and transformation, driven by advancements in actuator technologies. The demand for more sophisticated, efficient, and versatile robots across various industries has created a substantial market opportunity for innovative actuator solutions, particularly those utilizing PVDF (Polyvinylidene Fluoride) technology.

In the industrial sector, there is a growing need for robots capable of performing complex tasks with high precision and adaptability. Manufacturing companies are increasingly adopting robotics to enhance productivity, improve quality control, and reduce operational costs. This trend has led to a surge in demand for actuators that can provide precise movements, rapid response times, and durability in harsh industrial environments.

The healthcare industry represents another significant market for robotics, with applications ranging from surgical assistance to rehabilitation and patient care. In this sector, there is a strong demand for actuators that can offer gentle, controlled movements and high sensitivity, making PVDF-based solutions particularly attractive.

The consumer robotics market, including household robots and personal assistants, is also expanding rapidly. Consumers are seeking more interactive and capable robots, driving the need for actuators that can provide smooth, natural movements and tactile feedback. PVDF actuators, with their ability to mimic human-like movements, are well-positioned to meet these requirements.

In the aerospace and defense sectors, there is an increasing demand for lightweight, high-performance actuators for use in unmanned aerial vehicles (UAVs), exoskeletons, and other advanced robotic systems. PVDF actuators offer significant advantages in terms of weight reduction and energy efficiency, making them highly desirable for these applications.

The automotive industry is another key market driver, with the rise of autonomous vehicles and advanced driver assistance systems (ADAS) creating new opportunities for robotic actuators. These applications require actuators that can provide rapid, precise responses to ensure vehicle safety and performance.

Environmental concerns and sustainability initiatives are also influencing market demand. There is a growing preference for energy-efficient and environmentally friendly actuator technologies, aligning well with the characteristics of PVDF-based solutions.

As robotics continues to penetrate new industries and applications, the demand for advanced actuator technologies is expected to grow substantially. The versatility, performance, and potential cost-effectiveness of PVDF actuators position them as a promising solution to meet the diverse and evolving needs of the robotics market across multiple sectors.

PVDF Tech Challenges

Despite the promising potential of PVDF (Polyvinylidene Fluoride) in robotics actuators, several technical challenges persist in its widespread adoption and optimal performance. These challenges span material properties, manufacturing processes, and integration complexities.

One of the primary challenges lies in enhancing the electromechanical coupling coefficient of PVDF. While PVDF exhibits good flexibility and responsiveness, its piezoelectric properties are not as strong as some ceramic alternatives. Researchers are working on improving the molecular alignment and crystalline structure of PVDF to boost its piezoelectric response, but achieving significant improvements without compromising other beneficial properties remains a hurdle.

The manufacturing of PVDF actuators with consistent and reliable performance is another significant challenge. The piezoelectric properties of PVDF are highly dependent on the processing conditions, including stretching, poling, and thermal treatment. Ensuring uniformity in these processes across large-scale production is difficult, leading to variations in actuator performance.

Integration of PVDF actuators into robotic systems presents its own set of challenges. The soft and flexible nature of PVDF, while advantageous in many applications, can complicate its incorporation into traditional rigid robotic structures. Developing robust interfaces between PVDF actuators and other robotic components, such as sensors and structural elements, requires innovative design solutions.

The long-term stability and durability of PVDF actuators in diverse operating conditions is another area of concern. Exposure to high temperatures, humidity, and mechanical stress can degrade PVDF's piezoelectric properties over time. Enhancing the material's resistance to environmental factors without sacrificing its actuator performance is a key research focus.

Power requirements and energy efficiency pose additional challenges. While PVDF actuators generally require lower voltages compared to ceramic piezoelectrics, achieving high force outputs often necessitates the use of stacked or multi-layer configurations. This increases complexity and can lead to higher power consumption, which is particularly problematic for battery-powered robotic systems.

Lastly, the development of advanced control systems tailored for PVDF actuators remains a challenge. The non-linear behavior of PVDF, especially under varying environmental conditions, complicates precise control. Creating robust algorithms that can adapt to these variations while maintaining accurate and responsive actuation is an ongoing area of research in the field of soft robotics.

Current PVDF Solutions

01 Improved PVDF actuator performance through material composition

Enhancing the performance of PVDF actuators by optimizing the material composition. This includes incorporating additives, nanoparticles, or other polymers to improve the piezoelectric properties, flexibility, and durability of the actuator. These modifications can lead to increased displacement, force output, and overall efficiency of the PVDF actuator.- Improved PVDF actuator performance through material composition: Enhancing the performance of PVDF actuators by modifying the material composition. This includes incorporating additives, nanoparticles, or other polymers to improve the piezoelectric properties, flexibility, and durability of the actuator. These modifications can lead to increased displacement, force output, and overall efficiency of the PVDF actuator.

- Optimized PVDF actuator design and structure: Developing innovative designs and structures for PVDF actuators to enhance their performance. This involves creating multi-layer configurations, optimizing electrode patterns, and implementing novel geometries to maximize the actuator's displacement and force output. Advanced manufacturing techniques, such as 3D printing or precision molding, may be utilized to achieve these complex structures.

- Integration of PVDF actuators in smart systems: Incorporating PVDF actuators into smart systems and devices to leverage their unique properties. This includes applications in wearable technology, soft robotics, and energy harvesting systems. The integration focuses on maximizing the actuator's performance within the constraints of the overall system design, often involving miniaturization and power optimization techniques.

- Enhanced control and driving methods for PVDF actuators: Developing advanced control algorithms and driving methods to improve the performance of PVDF actuators. This includes implementing precise voltage control, frequency modulation, and feedback systems to optimize the actuator's response and efficiency. These methods aim to enhance the accuracy, speed, and reliability of PVDF actuator operations in various applications.

- PVDF actuator performance characterization and testing: Developing comprehensive characterization and testing methodologies for PVDF actuators to accurately assess and improve their performance. This includes creating standardized testing procedures, implementing advanced measurement techniques, and utilizing simulation tools to predict and optimize actuator behavior under various operating conditions.

02 Novel PVDF actuator structures and designs

Developing innovative structures and designs for PVDF actuators to enhance their performance. This includes creating multi-layer configurations, implementing unique electrode patterns, or designing specialized shapes to maximize the actuator's response to electrical stimuli. These structural improvements can result in increased actuation range, faster response times, and improved control over the actuator's movement.Expand Specific Solutions03 Integration of PVDF actuators in smart systems

Incorporating PVDF actuators into smart systems and devices to leverage their unique properties. This involves developing control algorithms, sensor integration, and feedback mechanisms to optimize the actuator's performance in various applications. The integration can lead to improved precision, adaptability, and functionality in fields such as robotics, biomedical devices, and energy harvesting systems.Expand Specific Solutions04 Fabrication techniques for high-performance PVDF actuators

Advancing manufacturing processes and fabrication techniques to produce high-performance PVDF actuators. This includes developing new methods for polymer processing, electrode deposition, and surface treatment to enhance the actuator's properties. Improved fabrication techniques can result in more consistent performance, increased durability, and better scalability for mass production.Expand Specific Solutions05 Characterization and modeling of PVDF actuator performance

Developing advanced characterization methods and modeling techniques to better understand and predict PVDF actuator performance. This includes creating accurate simulation models, implementing novel testing procedures, and analyzing the actuator's behavior under various conditions. Improved characterization and modeling can lead to optimized designs, more efficient control strategies, and enhanced overall performance of PVDF actuators.Expand Specific Solutions

Key PVDF Players

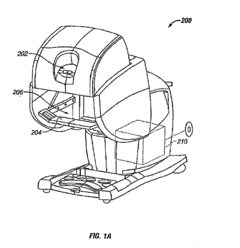

The PVDF in robotics actuator technology market is in a growth phase, with increasing adoption across various industries. The market size is expanding rapidly due to the superior properties of PVDF actuators, such as high precision and responsiveness. Technologically, PVDF actuators are reaching maturity, with companies like Intuitive Surgical Operations, Inc. and Applied Materials, Inc. leading innovation in medical robotics and semiconductor manufacturing applications. Universities such as Shanghai Jiao Tong University and Zhejiang University are contributing to research advancements. Companies like Arkema France SA and LG Energy Solution Ltd. are developing advanced PVDF materials, while Siemens Healthineers AG is integrating this technology into medical devices, indicating a competitive and diverse landscape.

Arkema France SA

Polytronics Technology Corp.

PVDF Actuator Patents

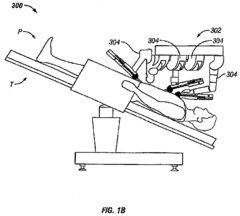

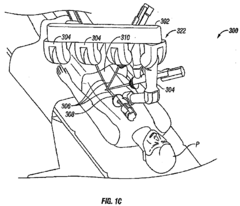

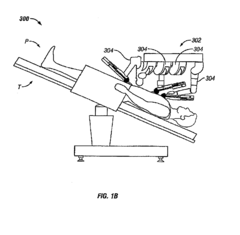

- A hydraulic robotic arm integrated with a Linear Variable Differential Transformer (LVDT) sensor for real-time position feedback, enabling precise control and adaptability across various tasks.

- The development of highly configurable surgical robotic manipulators with redundant degrees of freedom, enabled by processors that calculate and control joint movements to prevent collisions and adjust to patient movement, allowing for easier setup and operation through software centering and collision avoidance mechanisms.

PVDF Manufacturing

The manufacturing process of Polyvinylidene Fluoride (PVDF) for robotics applications involves several critical steps to ensure the production of high-quality actuator materials. The process typically begins with the polymerization of vinylidene fluoride monomers, which can be achieved through various methods such as suspension, emulsion, or solution polymerization. The choice of polymerization technique significantly influences the final properties of the PVDF, including its crystallinity, molecular weight, and piezoelectric response.

Following polymerization, the PVDF undergoes a series of post-processing steps to enhance its piezoelectric properties. One crucial step is the stretching of the PVDF film, which aligns the polymer chains and promotes the formation of the β-phase crystal structure responsible for the material's piezoelectric behavior. This stretching process is typically performed at elevated temperatures and can be uniaxial or biaxial, depending on the desired final properties.

The next stage in PVDF manufacturing for robotics applications involves the poling process. This step is essential for maximizing the piezoelectric response of the material. During poling, a strong electric field is applied to the PVDF film at elevated temperatures, typically near the material's Curie point. This process aligns the dipoles within the polymer structure, enhancing its piezoelectric properties.

To improve the mechanical and electrical properties of PVDF for robotic actuators, various additives and fillers may be incorporated during the manufacturing process. These can include conductive particles, such as carbon nanotubes or metallic nanoparticles, which enhance the material's electromechanical coupling. Additionally, plasticizers may be added to improve flexibility and processability.

The final stages of PVDF manufacturing for robotics applications involve precision cutting and shaping of the material to meet specific actuator design requirements. This may include techniques such as laser cutting, die-cutting, or 3D printing for more complex geometries. The integration of electrodes onto the PVDF surface is also a critical step, often achieved through methods like sputtering or vapor deposition of conductive materials.

Quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability of the PVDF actuators. These may include spectroscopic analysis to verify crystal structure, mechanical testing to assess strength and flexibility, and electrical characterization to evaluate piezoelectric performance. Advanced manufacturing techniques, such as roll-to-roll processing, are being explored to increase production efficiency and scalability for large-scale robotic applications.

PVDF Environmental Impact

The environmental impact of Polyvinylidene Fluoride (PVDF) in robotics actuator technologies is a crucial consideration for sustainable development in the field. PVDF, a fluoropolymer with exceptional piezoelectric properties, offers significant advantages in robotic applications. However, its production and disposal processes raise important environmental concerns.

The manufacturing of PVDF involves the use of fluorine-based chemicals, which can contribute to greenhouse gas emissions and potential environmental contamination if not properly managed. The production process requires substantial energy inputs, leading to indirect carbon emissions. Additionally, the synthesis of PVDF monomers often involves the use of chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs), which have been linked to ozone depletion.

Despite these challenges, PVDF actuators in robotics offer potential environmental benefits. Their high efficiency and low power consumption can lead to reduced energy usage in robotic systems, potentially offsetting some of the environmental costs associated with production. Furthermore, the durability and long lifespan of PVDF actuators may result in less frequent replacements, reducing overall material consumption and waste generation.

End-of-life management for PVDF actuators presents another environmental consideration. While PVDF is recyclable, the recycling process is complex and energy-intensive due to the material's high chemical resistance. Improper disposal can lead to long-term environmental persistence, as PVDF does not readily biodegrade. This raises concerns about potential accumulation in ecosystems and the food chain.

Research into more environmentally friendly production methods for PVDF is ongoing. Some promising approaches include the development of green synthesis routes using supercritical CO2 as a solvent, which could significantly reduce the use of harmful chemicals and minimize waste generation. Additionally, efforts are being made to improve recycling technologies for PVDF, aiming to create a more circular economy for this material in robotics applications.

The use of PVDF in robotics actuators also intersects with broader sustainability goals in the field of robotics. As robots become increasingly prevalent in various industries, the environmental impact of their components becomes more significant. PVDF actuators, with their potential for energy efficiency and longevity, could play a role in developing more sustainable robotic systems. However, this potential must be balanced against the environmental costs of production and end-of-life management.

In conclusion, while PVDF offers superior performance in robotics actuator technologies, its environmental impact is complex and multifaceted. Balancing the material's benefits with its environmental costs requires ongoing research, innovation in production and recycling methods, and careful consideration of lifecycle impacts in robotic system design.