PVDF in Environmental Sensors: Monitoring for Change

PVDF Sensor Evolution

The evolution of PVDF (Polyvinylidene Fluoride) sensors in environmental monitoring has been marked by significant technological advancements and expanding applications. Initially developed in the 1960s, PVDF's piezoelectric properties were first recognized for their potential in sensing applications.

In the 1970s and 1980s, PVDF sensors began to find their way into environmental monitoring, primarily for detecting mechanical stress and vibrations. These early sensors were relatively simple in design and limited in their capabilities, mainly used for basic measurements such as pressure and force detection in controlled environments.

The 1990s saw a surge in research and development, leading to more sophisticated PVDF sensor designs. This period marked the beginning of PVDF's use in more complex environmental monitoring applications, such as water quality assessment and air pollution detection. The sensors became more sensitive and capable of detecting a wider range of environmental parameters.

The turn of the millennium brought about miniaturization and integration of PVDF sensors. This advancement allowed for the development of compact, portable environmental monitoring devices. The improved designs enabled real-time data collection in various environmental settings, from urban air quality monitoring to marine ecosystem assessment.

In the 2010s, PVDF sensor technology experienced a significant leap forward with the advent of nanotechnology. Nanostructured PVDF sensors exhibited enhanced sensitivity and selectivity, enabling the detection of trace amounts of pollutants and environmental changes. This period also saw the integration of PVDF sensors with wireless technology and IoT platforms, facilitating remote environmental monitoring and big data analysis.

Recent years have witnessed the emergence of flexible and wearable PVDF sensors for environmental monitoring. These innovations have opened up new possibilities for personal environmental monitoring, allowing individuals to track their exposure to various environmental factors in real-time.

The latest developments in PVDF sensor technology focus on multi-parameter sensing capabilities. Modern PVDF sensors can simultaneously monitor multiple environmental factors such as temperature, humidity, air quality, and various pollutants. This holistic approach to environmental monitoring provides a more comprehensive understanding of environmental conditions and their interrelationships.

Looking ahead, the evolution of PVDF sensors in environmental monitoring is expected to continue, with trends pointing towards even greater sensitivity, durability, and integration with AI and machine learning technologies. These advancements promise to enhance our ability to detect and respond to environmental changes with unprecedented precision and speed.

Environmental Monitoring Market Analysis

The environmental monitoring market has experienced significant growth in recent years, driven by increasing awareness of environmental issues, stringent regulations, and technological advancements. This market encompasses a wide range of sensors and systems designed to measure and monitor various environmental parameters, including air quality, water quality, soil conditions, and climate factors.

The global environmental monitoring market was valued at approximately $19.6 billion in 2020 and is projected to reach $28.9 billion by 2026, growing at a CAGR of 6.8% during the forecast period. This growth is attributed to several factors, including the rising need for environmental protection, government initiatives to control environmental pollution, and the increasing adoption of environmental monitoring systems across industries.

Key market segments within environmental monitoring include air quality monitoring, water quality monitoring, soil monitoring, and noise monitoring. Among these, air quality monitoring holds the largest market share due to growing concerns over air pollution and its impact on human health. The water quality monitoring segment is also experiencing rapid growth, driven by the need for clean water resources and stringent regulations on water pollution.

Geographically, North America dominates the environmental monitoring market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, primarily due to rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market is characterized by the presence of both established players and innovative startups. Major companies in the environmental monitoring market include Agilent Technologies, Danaher Corporation, Thermo Fisher Scientific, and Siemens AG. These companies are continuously investing in research and development to introduce advanced monitoring solutions and gain a competitive edge.

Emerging trends in the environmental monitoring market include the integration of Internet of Things (IoT) and artificial intelligence (AI) technologies, the development of miniaturized and portable monitoring devices, and the increasing use of remote sensing and satellite-based monitoring systems. These advancements are enabling more accurate, real-time, and cost-effective environmental monitoring solutions.

The COVID-19 pandemic has also impacted the environmental monitoring market, highlighting the importance of air quality monitoring in indoor spaces and accelerating the adoption of remote monitoring solutions. This has created new opportunities for market growth and innovation in environmental sensing technologies.

PVDF Sensor Challenges

Despite the numerous advantages of PVDF in environmental sensing applications, several challenges persist in its widespread adoption and optimal performance. One of the primary obstacles is the inherent sensitivity of PVDF to temperature fluctuations, which can lead to inaccurate readings in dynamic environmental conditions. This temperature dependence necessitates complex compensation algorithms or additional temperature sensors, increasing system complexity and cost.

Another significant challenge lies in the long-term stability and durability of PVDF sensors, particularly in harsh environmental conditions. Exposure to extreme temperatures, humidity, and corrosive substances can degrade the polymer structure over time, affecting sensor reliability and lifespan. This degradation can result in drift in sensor output, requiring frequent recalibration or replacement, which is not ideal for long-term environmental monitoring applications.

The manufacturing process of PVDF sensors also presents challenges, particularly in achieving consistent piezoelectric properties across large-scale production. The piezoelectric response of PVDF is highly dependent on its crystalline structure, which can be affected by various factors during fabrication. Ensuring uniformity in the poling process and maintaining precise control over the polymer's molecular orientation are critical yet difficult to achieve consistently in mass production.

Signal-to-noise ratio (SNR) is another area of concern for PVDF sensors, especially when detecting low-amplitude environmental signals. The relatively low piezoelectric coefficient of PVDF compared to some ceramic alternatives can result in weaker output signals, making it challenging to distinguish genuine environmental changes from background noise. This issue is particularly pronounced in applications requiring high sensitivity, such as trace gas detection or subtle vibration monitoring.

Integration challenges also exist when incorporating PVDF sensors into complex environmental monitoring systems. The need for specialized signal conditioning circuits, impedance matching, and data processing algorithms can complicate system design and increase overall power consumption. This is particularly problematic for remote or battery-operated environmental sensing applications where energy efficiency is crucial.

Lastly, the cost-effectiveness of PVDF sensors in certain applications remains a challenge. While PVDF offers advantages in flexibility and ease of processing, the overall system cost, including necessary signal processing and compensation components, can sometimes exceed that of alternative sensing technologies. This economic factor can limit the adoption of PVDF sensors in large-scale environmental monitoring projects where cost is a significant consideration.

Addressing these challenges requires ongoing research and development efforts, focusing on improving material properties, enhancing manufacturing processes, and developing advanced signal processing techniques. Overcoming these hurdles will be crucial in fully realizing the potential of PVDF in environmental sensing applications and enabling more widespread adoption of this versatile material in monitoring for environmental change.

Current PVDF Sensor Solutions

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties, such as hydrophilicity, fouling resistance, and mechanical strength. These methods may include blending with other polymers, surface modification, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes are explored, including blending with other polymers, surface treatments, and incorporation of nanoparticles. These modifications aim to enhance properties such as hydrophilicity, fouling resistance, and mechanical strength for applications in water treatment and filtration.

- PVDF-based piezoelectric and energy harvesting devices: PVDF's piezoelectric properties are utilized in the development of sensors, actuators, and energy harvesting devices. Research focuses on improving the piezoelectric performance through various processing methods, additives, and device structures for applications in wearable electronics and self-powered systems.

- PVDF composites for enhanced properties: PVDF is combined with various materials such as carbon nanotubes, graphene, and inorganic particles to create composites with improved mechanical, thermal, and electrical properties. These composites find applications in areas such as electromagnetic shielding, thermal management, and high-performance coatings.

- PVDF in battery and energy storage applications: PVDF is used as a binder material in lithium-ion batteries and other energy storage devices. Research focuses on improving the adhesion, stability, and electrochemical performance of PVDF-based electrode materials and separators to enhance overall battery performance and safety.

- PVDF processing and manufacturing techniques: Advanced processing and manufacturing techniques for PVDF are developed, including electrospinning, phase inversion, and melt processing. These methods aim to control the crystalline structure, morphology, and properties of PVDF materials for various applications in industries such as aerospace, automotive, and electronics.

02 PVDF in energy storage applications

Utilization of PVDF in energy storage devices, particularly in lithium-ion batteries and supercapacitors. PVDF serves as a binder material for electrodes or as a separator, improving the overall performance and stability of these devices.Expand Specific Solutions03 PVDF-based piezoelectric materials

Development of PVDF and its copolymers as piezoelectric materials for various applications, including sensors, actuators, and energy harvesters. Methods to enhance the piezoelectric properties through different processing techniques or additives are explored.Expand Specific Solutions04 PVDF in water treatment and filtration

Application of PVDF membranes in water treatment and filtration processes. Research focuses on improving membrane performance, reducing fouling, and enhancing selectivity for various contaminants in water purification systems.Expand Specific Solutions05 PVDF composites and blends

Creation of PVDF-based composites and blends with other materials to achieve enhanced properties such as thermal stability, mechanical strength, or specific functionalities. These composites find applications in various fields including coatings, electronics, and aerospace.Expand Specific Solutions

Key PVDF Sensor Manufacturers

The PVDF in environmental sensors market is in a growth phase, driven by increasing demand for accurate and reliable environmental monitoring solutions. The market size is expanding rapidly, with a diverse range of players entering the field. Technologically, PVDF sensors are maturing, offering improved sensitivity and durability. Companies like Arkema France SA, Murata Manufacturing Co. Ltd., and 3M Innovative Properties Co. are leading in PVDF sensor development, while research institutions such as Southeast University and University of Maryland Baltimore County are pushing the boundaries of PVDF applications. Emerging players like GRID20/20 Inc. and Valencell, Inc. are introducing innovative solutions, intensifying competition and driving technological advancements in environmental sensing capabilities.

Arkema France SA

Murata Manufacturing Co. Ltd.

PVDF Sensor Innovations

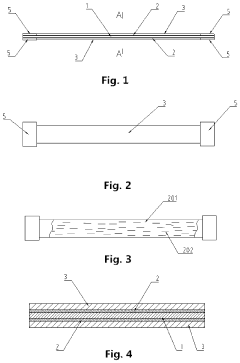

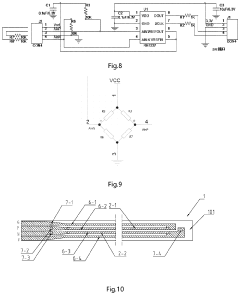

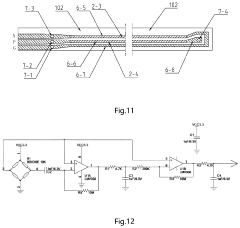

- A flexible sensor comprising a strain film with a flexible substrate, electrically conductive layers, and a signal amplifying circuit, featuring a Wheatstone bridge configuration and using carbon or metal powders, carbon fibers, or graphene for high sensitivity and ease of wiring, replacing the need for PVDF piezoelectric film sensors.

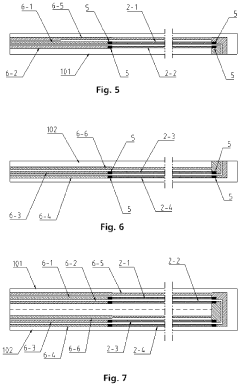

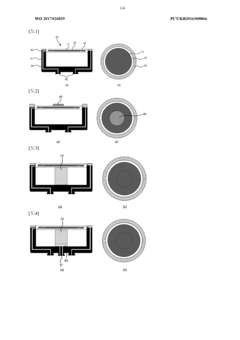

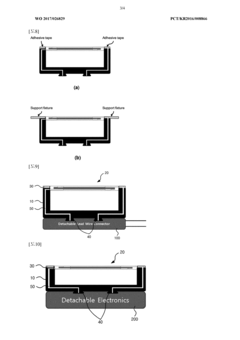

- A low-cost, disposable or semi-permanent vibration detection device equipped with a PVDF sensor, adhesive fixing parts, and an internal space that can be filled with air, liquid, or gel to adjust internal pressure, allowing for efficient vibration detection and signal amplification, featuring a signal line for external connection and an elastic body to support the sensor and select detectable frequency bands.

Environmental Regulations Impact

Environmental regulations have a significant impact on the development and deployment of PVDF-based environmental sensors. As governments worldwide increasingly prioritize environmental protection, stringent regulations are being implemented to monitor and control various pollutants. This regulatory landscape has created a growing demand for advanced sensing technologies, particularly in air and water quality monitoring.

In the United States, the Environmental Protection Agency (EPA) has established National Ambient Air Quality Standards (NAAQS) for six criteria pollutants, including particulate matter, ozone, and nitrogen dioxide. These standards have driven the need for more accurate and reliable sensors capable of detecting low concentrations of these pollutants. PVDF sensors, with their high sensitivity and stability, are well-positioned to meet these regulatory requirements.

Similarly, the European Union's Air Quality Directive sets limits for various air pollutants, necessitating continuous monitoring in urban areas. This has led to increased adoption of PVDF-based sensors in smart city initiatives across Europe. The sensors' ability to provide real-time data on air quality helps local authorities comply with regulatory standards and implement timely interventions.

Water quality regulations have also influenced the development of PVDF sensors. The EU Water Framework Directive and the US Clean Water Act mandate regular monitoring of water bodies for contaminants. PVDF sensors' resistance to harsh environments and their ability to detect a wide range of pollutants make them ideal for compliance with these regulations.

Emerging regulations in developing countries are creating new markets for environmental sensors. For instance, China's recent environmental protection laws have spurred significant investment in air and water quality monitoring systems, presenting opportunities for PVDF sensor manufacturers.

The regulatory push for continuous monitoring has led to the development of integrated sensor networks. PVDF sensors, with their low power consumption and compatibility with wireless technologies, are increasingly being incorporated into these networks to provide comprehensive environmental data.

As regulations evolve to address emerging contaminants and lower detection limits, PVDF sensor technology is likely to advance further. Research is already underway to enhance the selectivity and sensitivity of these sensors to meet future regulatory requirements. This ongoing development ensures that PVDF sensors will continue to play a crucial role in environmental monitoring and regulatory compliance.

PVDF Sensor Data Management

The management of data generated by PVDF environmental sensors is a critical aspect of their implementation and effectiveness in monitoring environmental changes. As these sensors become more widespread and sophisticated, the volume and complexity of data they produce increase exponentially. Effective data management strategies are essential to harness the full potential of PVDF sensors in environmental monitoring applications.

One of the primary challenges in PVDF sensor data management is the sheer volume of data generated. These sensors often operate continuously, producing real-time data streams that require robust storage and processing capabilities. Cloud-based storage solutions have emerged as a popular option, offering scalability and accessibility. However, considerations must be made for data security, particularly when dealing with sensitive environmental information.

Data integration is another crucial aspect of PVDF sensor data management. Environmental monitoring often involves multiple sensor types and data sources. Integrating PVDF sensor data with other environmental data sets, such as satellite imagery or weather station data, can provide a more comprehensive understanding of environmental changes. This integration requires standardized data formats and protocols to ensure seamless communication between different systems.

Data quality assurance is paramount in environmental monitoring. PVDF sensors, like all sensing devices, can be subject to errors or malfunctions. Implementing automated data validation algorithms can help identify anomalies or inconsistencies in the data stream. These algorithms can flag potential issues for human review, ensuring the integrity of the collected data.

Real-time data processing and analysis capabilities are increasingly important in environmental monitoring applications. Edge computing solutions, where data is processed closer to the source, can reduce latency and enable faster response times to environmental changes. This is particularly crucial in applications such as early warning systems for natural disasters or pollution events.

Visualization tools play a significant role in making PVDF sensor data accessible and understandable to a wide range of stakeholders. Interactive dashboards and GIS-based mapping tools can help translate complex data sets into actionable insights. These tools are essential for decision-makers who may not have a technical background but need to interpret environmental trends and patterns.

Long-term data archiving and retrieval systems are necessary for tracking environmental changes over extended periods. This requires careful consideration of data storage formats and metadata standards to ensure that data remains accessible and interpretable in the future. Additionally, implementing version control systems can help track changes in data processing algorithms or calibration methods over time.