How to Enhance PVDF in Polarization Applications?

PVDF Polarization Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in various polarization applications due to its unique ferroelectric properties. The development of PVDF and its copolymers has spanned several decades, with significant advancements in understanding its molecular structure and enhancing its piezoelectric and pyroelectric characteristics. The evolution of PVDF technology has been driven by the growing demand for high-performance sensors, actuators, and energy harvesting devices across multiple industries.

The primary objective in enhancing PVDF for polarization applications is to maximize its electroactive properties while maintaining its mechanical flexibility and chemical stability. This involves optimizing the crystalline structure of PVDF, particularly increasing the content of the β-phase, which is responsible for its ferroelectric behavior. Researchers and engineers are focusing on developing novel processing techniques and incorporating various additives to achieve this goal.

Another critical aspect of PVDF enhancement is improving its overall polarization efficiency. This includes increasing the degree of polarization, reducing the required electric field for polarization, and enhancing the stability of the polarized state. These improvements are essential for expanding the range of applications and improving the performance of PVDF-based devices in challenging environments.

The technological trajectory of PVDF polarization has been marked by several key milestones. These include the discovery of its piezoelectric properties in the 1960s, the development of PVDF copolymers in the 1970s and 1980s, and more recent advancements in nanocomposite formulations. Each of these breakthroughs has contributed to the expansion of PVDF's applicability and the enhancement of its polarization characteristics.

Current research efforts are focused on several promising avenues for further improvement. These include the exploration of new copolymer compositions, the integration of nanoparticles and nanostructures to enhance polarization, and the development of advanced poling techniques. Additionally, there is growing interest in leveraging computational modeling and machine learning algorithms to predict and optimize PVDF properties for specific applications.

The enhancement of PVDF in polarization applications is not only a scientific pursuit but also a response to market demands. Industries such as aerospace, automotive, medical devices, and renewable energy are driving the need for more efficient and reliable piezoelectric materials. As such, the objectives for PVDF enhancement are closely aligned with the requirements of these sectors, including improved sensitivity, broader operating temperature ranges, and enhanced durability.

Market Analysis for Enhanced PVDF Applications

The global market for enhanced PVDF (Polyvinylidene Fluoride) in polarization applications is experiencing significant growth, driven by increasing demand across various industries. The unique properties of PVDF, including its high dielectric strength, excellent chemical resistance, and piezoelectric characteristics, make it a valuable material for polarization applications.

In the electronics sector, enhanced PVDF is gaining traction in the production of sensors, actuators, and transducers. The growing adoption of smart devices and the Internet of Things (IoT) is fueling the demand for these components, consequently boosting the market for enhanced PVDF. The automotive industry is another key driver, with PVDF being used in fuel systems, battery separators for electric vehicles, and various sensor applications.

The energy sector presents substantial opportunities for enhanced PVDF, particularly in renewable energy applications. PVDF's durability and resistance to harsh environments make it ideal for solar panel components and wind turbine blades. As countries worldwide push for cleaner energy sources, this segment is expected to witness robust growth in the coming years.

In the medical field, enhanced PVDF is finding applications in ultrasound transducers, surgical implants, and drug delivery systems. The material's biocompatibility and ability to be sterilized without degradation are driving its adoption in this sector. The growing emphasis on personalized medicine and non-invasive diagnostic techniques is likely to further propel the demand for enhanced PVDF in medical applications.

The water treatment industry is another significant market for enhanced PVDF, particularly in membrane filtration systems. As water scarcity becomes a global concern, the demand for efficient water purification technologies is rising, benefiting the enhanced PVDF market.

Geographically, Asia-Pacific is emerging as a key market for enhanced PVDF, driven by rapid industrialization, increasing electronics manufacturing, and growing investments in renewable energy. North America and Europe continue to be strong markets, particularly in high-tech applications and medical devices.

Despite the positive outlook, the market faces challenges such as high production costs and competition from alternative materials. However, ongoing research and development efforts aimed at improving PVDF's properties and reducing production costs are expected to address these challenges and open up new application areas.

Current PVDF Polarization Challenges

Polyvinylidene fluoride (PVDF) has gained significant attention in polarization applications due to its unique ferroelectric properties. However, several challenges persist in enhancing PVDF's performance for these applications. One of the primary obstacles is the difficulty in achieving a high degree of crystallinity and optimal molecular orientation, which are crucial for maximizing the material's piezoelectric and ferroelectric responses.

The β-phase of PVDF, known for its superior ferroelectric properties, is often challenging to obtain in high purity. Current manufacturing processes struggle to consistently produce PVDF films with a high percentage of β-phase content, which directly impacts the material's polarization capabilities. This limitation hinders the development of high-performance sensors, actuators, and energy harvesting devices.

Another significant challenge lies in the control of domain structures within PVDF. The alignment and size of ferroelectric domains play a critical role in determining the material's overall polarization response. However, achieving precise control over these nanoscale structures remains a complex task, often resulting in suboptimal device performance and reliability issues.

The interfacial properties of PVDF in composite systems present additional hurdles. When combined with other materials to enhance its properties or create multifunctional composites, PVDF often exhibits poor adhesion and compatibility. This can lead to reduced polarization efficiency and compromised mechanical integrity in the final device.

Temperature sensitivity is another critical issue facing PVDF in polarization applications. The material's ferroelectric properties can significantly degrade at elevated temperatures, limiting its use in high-temperature environments or applications that generate heat during operation. This thermal instability narrows the operational range of PVDF-based devices and restricts their potential applications.

Furthermore, the long-term stability of PVDF's polarization remains a concern. Over time, the material can experience depolarization, leading to a gradual decrease in performance. This aging effect is particularly problematic in applications requiring sustained and consistent polarization responses over extended periods.

Scaling up the production of high-quality PVDF films for large-area applications presents additional challenges. Current manufacturing techniques often struggle to maintain uniform properties across large surface areas, leading to inconsistencies in device performance and yield issues in mass production scenarios.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, processing techniques, and device engineering. Innovations in polymer chemistry, nanoscale fabrication methods, and composite design are needed to overcome these limitations and fully harness the potential of PVDF in polarization applications.

Existing PVDF Enhancement Techniques

01 PVDF film preparation and polarization methods

Various techniques for preparing and polarizing PVDF films are explored. These methods include stretching, annealing, and applying electric fields to enhance the piezoelectric properties of PVDF. The processes aim to optimize the β-phase content and alignment of dipoles within the polymer structure.- PVDF film preparation and polarization methods: Various techniques for preparing and polarizing PVDF films are explored. These methods include stretching, annealing, and applying electric fields to enhance the piezoelectric properties of PVDF. The processes aim to optimize the β-phase content and alignment of dipoles within the polymer structure.

- PVDF-based composite materials for enhanced polarization: Composite materials incorporating PVDF and other components are developed to improve polarization characteristics. These composites may include nanoparticles, other polymers, or functional additives to enhance the overall piezoelectric response and stability of the material.

- Applications of polarized PVDF in sensors and actuators: Polarized PVDF films find applications in various sensing and actuating devices. These include pressure sensors, vibration detectors, and energy harvesting systems. The unique properties of polarized PVDF enable the development of flexible and highly sensitive electronic components.

- Characterization and measurement of PVDF polarization: Techniques for characterizing and measuring the polarization of PVDF materials are discussed. These methods may involve spectroscopic analysis, thermal analysis, or electrical measurements to determine the degree of polarization and the distribution of dipoles within the polymer structure.

- Polarization stability and long-term performance of PVDF: Research focuses on improving the long-term stability of polarized PVDF materials. This includes studying the effects of environmental factors, aging, and repeated use on the polarization state. Strategies for maintaining and enhancing the polarization stability over time are explored.

02 PVDF-based composite materials for enhanced polarization

Composite materials incorporating PVDF and other components are developed to improve polarization characteristics. These composites may include nanoparticles, other polymers, or functional additives that synergistically enhance the overall polarization and piezoelectric response of the material.Expand Specific Solutions03 Applications of polarized PVDF in sensors and actuators

Polarized PVDF films and composites find applications in various sensing and actuating devices. These include pressure sensors, accelerometers, energy harvesters, and tactile feedback systems. The unique properties of polarized PVDF enable the development of flexible and highly sensitive devices.Expand Specific Solutions04 Characterization and measurement of PVDF polarization

Techniques for characterizing and measuring the polarization of PVDF materials are discussed. These methods include dielectric spectroscopy, piezoelectric coefficient measurements, and thermal analysis. Advanced imaging techniques may also be employed to visualize the polarization distribution within the material.Expand Specific Solutions05 Polarization stability and retention in PVDF

Research focuses on improving the long-term stability and retention of polarization in PVDF materials. This includes investigating the effects of environmental factors, aging, and mechanical stress on polarization. Strategies for enhancing polarization stability through material modifications and protective measures are explored.Expand Specific Solutions

Key Players in PVDF Industry

The enhancement of PVDF in polarization applications is a rapidly evolving field, currently in its growth stage. The market size is expanding, driven by increasing demand in energy storage, electronics, and sensor technologies. Technologically, the maturity level varies across different enhancement approaches. Companies like Arkema, Solvay Specialty Polymers, and LG Energy Solution are at the forefront, developing advanced PVDF formulations and processing techniques. Academic institutions such as Nanyang Technological University and Shandong University are contributing significant research. Emerging players like Sansan Intelligent Technology and Tianmu Lake Institute are introducing innovative solutions, intensifying competition. The industry is characterized by a mix of established chemical companies and specialized technology firms, with ongoing collaborations between industry and academia driving progress.

Arkema France SA

Solvay Specialty Polymers Italy SpA

Innovative PVDF Polarization Methods

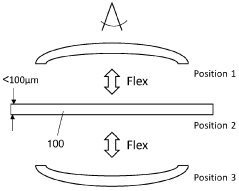

- An electrophoretic display film less than 100 μm thick, comprising a layer of electrophoretic material, a patterned piezoelectric layer with differential polarization, and a flexible, light-transmissive electrode layer, which eliminates the need for external power sources by using piezoelectric material to drive the electrophoretic medium through mechanical flexing.

- A mixture of PVDF grafted by irradiation with an unsaturated polar monomer and a TFE-based polymer or PVF is developed, enhancing adhesion while maintaining mechanical and chemical properties, using a radiation grafting process that allows for higher grafting levels and simpler implementation compared to conventional methods.

Environmental Impact of PVDF Production

The production of Polyvinylidene Fluoride (PVDF) has significant environmental implications that warrant careful consideration. The manufacturing process of PVDF involves the use of various chemicals and energy-intensive procedures, which can contribute to environmental pollution and resource depletion if not managed properly.

One of the primary environmental concerns associated with PVDF production is the emission of greenhouse gases. The synthesis of PVDF typically requires high temperatures and pressures, leading to substantial energy consumption. This energy demand is often met through the burning of fossil fuels, resulting in the release of carbon dioxide and other greenhouse gases into the atmosphere. Additionally, the production process may emit volatile organic compounds (VOCs) and other air pollutants, potentially impacting local air quality and contributing to smog formation.

Water pollution is another critical environmental issue related to PVDF manufacturing. The production process generates wastewater containing various chemical compounds, including unreacted monomers, solvents, and other byproducts. If not treated adequately, these effluents can contaminate water bodies, affecting aquatic ecosystems and potentially entering the food chain.

The use of fluorine-containing compounds in PVDF production raises concerns about the potential release of persistent organic pollutants (POPs) into the environment. These substances can accumulate in living organisms and have long-lasting effects on ecosystems and human health. Proper handling and disposal of fluorinated waste products are essential to mitigate these risks.

Furthermore, the production of PVDF relies on non-renewable resources, particularly petroleum-based feedstocks. This dependence contributes to the depletion of fossil fuel reserves and raises questions about the long-term sustainability of PVDF production. As global efforts to reduce reliance on fossil fuels intensify, the PVDF industry may face pressure to explore alternative, more sustainable raw materials.

Land use and habitat disruption are additional environmental considerations. The establishment and operation of PVDF production facilities can lead to land clearing, potentially impacting local ecosystems and biodiversity. Moreover, the transportation of raw materials and finished products contributes to carbon emissions and may pose risks of chemical spills during transit.

To address these environmental challenges, the PVDF industry is increasingly focusing on developing more sustainable production methods. This includes exploring bio-based alternatives for raw materials, implementing closed-loop manufacturing systems to minimize waste and emissions, and investing in energy-efficient technologies. Additionally, advancements in recycling technologies for PVDF products are being pursued to reduce the environmental impact of end-of-life disposal.

As environmental regulations become more stringent globally, PVDF manufacturers are likely to face increased pressure to adopt cleaner production practices and demonstrate improved environmental performance. This may drive innovation in production technologies and encourage the development of more environmentally friendly alternatives to traditional PVDF formulations.

PVDF Polarization Testing Standards

Standardization plays a crucial role in ensuring the reliability and consistency of PVDF polarization testing across different applications and industries. The development of comprehensive testing standards for PVDF polarization is essential for accurately assessing and enhancing the material's performance in various polarization applications.

Current PVDF polarization testing standards encompass a range of methodologies and parameters to evaluate the material's polarization characteristics. These standards typically include guidelines for sample preparation, testing conditions, and measurement techniques. One of the primary aspects addressed in these standards is the assessment of the degree of polarization, which is often measured through techniques such as thermally stimulated current (TSC) analysis or piezoelectric coefficient measurements.

Testing standards also outline procedures for evaluating the stability and durability of PVDF's polarization under different environmental conditions. This includes thermal cycling tests, humidity exposure assessments, and long-term aging studies to determine the material's ability to maintain its polarization over time. Additionally, standards may specify methods for characterizing the polarization response of PVDF under various electric field strengths and frequencies.

The electrical properties of polarized PVDF are another critical aspect covered by testing standards. These may include protocols for measuring dielectric constant, dissipation factor, and breakdown strength. Such measurements are essential for understanding the material's behavior in different electrical applications and for optimizing its performance in specific use cases.

Mechanical testing standards for polarized PVDF are also crucial, as they help assess the material's structural integrity and its ability to maintain polarization under mechanical stress. These standards may include guidelines for tensile testing, flexural testing, and impact resistance evaluations, all of which contribute to a comprehensive understanding of the material's behavior in real-world applications.

As PVDF continues to find new applications in areas such as energy harvesting, sensors, and actuators, testing standards are evolving to address emerging requirements. This includes the development of standards for evaluating PVDF's performance in nanocomposite forms or when integrated into complex multi-material systems. Furthermore, efforts are being made to harmonize testing standards across different regions and industries to facilitate global collaboration and ensure consistent quality control.

The ongoing refinement and expansion of PVDF polarization testing standards are essential for driving innovation in material development and application design. By providing a common framework for evaluation and comparison, these standards enable researchers and manufacturers to more effectively enhance PVDF's properties and optimize its use in polarization applications.