PVDF in Smart Grids: Reliability Enhancement Strategies

PVDF Smart Grid Evolution

The evolution of PVDF (Polyvinylidene Fluoride) in smart grids represents a significant advancement in enhancing the reliability and efficiency of power distribution systems. This journey began in the early 2000s when researchers first recognized the potential of PVDF as a piezoelectric material for sensing applications in electrical infrastructure. Initially, PVDF was primarily used in small-scale sensor deployments to monitor vibrations and structural health of power transmission lines and transformers.

As smart grid technologies gained momentum in the mid-2000s, PVDF found its way into more sophisticated applications. The material's unique properties, including its flexibility, durability, and ability to generate electrical charge under mechanical stress, made it an ideal candidate for developing self-powered sensors. These sensors could harvest energy from the ambient vibrations in the grid, eliminating the need for external power sources and reducing maintenance requirements.

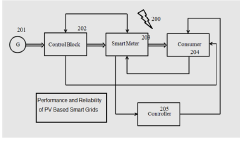

By the early 2010s, PVDF-based sensors had evolved to incorporate wireless communication capabilities, enabling real-time monitoring of grid conditions. This development marked a crucial step in the transition towards more responsive and adaptive smart grid systems. The integration of PVDF sensors with advanced data analytics platforms allowed utilities to predict potential failures and optimize grid performance proactively.

The mid-2010s saw a shift towards the use of PVDF in energy harvesting applications beyond sensing. Researchers began exploring ways to utilize PVDF's piezoelectric properties to capture and convert mechanical energy from various sources within the grid, such as vibrations from transformers or wind-induced oscillations in power lines. This innovation opened up new possibilities for powering remote monitoring devices and reducing the overall energy consumption of smart grid infrastructure.

In recent years, the focus has shifted towards enhancing the reliability of PVDF-based systems in smart grids. This includes developing more robust PVDF composites that can withstand harsh environmental conditions and improving the long-term stability of PVDF sensors. Additionally, researchers are exploring ways to integrate PVDF with other advanced materials and technologies, such as graphene and artificial intelligence, to create more intelligent and responsive grid monitoring systems.

The latest developments in PVDF smart grid applications involve the creation of large-area, flexible PVDF films that can be easily integrated into existing infrastructure. These films serve multiple purposes, including energy harvesting, sensing, and even self-healing capabilities for power cables and insulators. This multifunctional approach represents a significant step towards creating more resilient and self-sustaining smart grid systems.

Smart Grid Reliability Demand

The increasing integration of renewable energy sources, distributed generation, and advanced technologies in power systems has led to a growing demand for enhanced reliability in smart grids. As electricity becomes an indispensable part of modern life, consumers and businesses expect uninterrupted power supply with minimal outages and fluctuations. This heightened expectation has placed significant pressure on utility companies and grid operators to improve the overall reliability of smart grid infrastructure.

Smart grid reliability encompasses various aspects, including power quality, system stability, and resilience against both natural and man-made disruptions. The demand for reliability is driven by several factors, such as the economic impact of power outages, the need for consistent energy supply in critical infrastructure, and the growing dependence on electricity for daily activities and industrial processes.

One of the primary drivers of reliability demand is the economic cost associated with power outages. Businesses, particularly those in manufacturing, healthcare, and data centers, require a constant and stable power supply to maintain operations. Even brief interruptions can lead to significant financial losses, productivity declines, and potential safety hazards. As a result, there is a strong push for smart grid technologies that can minimize downtime and quickly restore power in the event of an outage.

Another crucial factor is the increasing complexity of power systems due to the integration of renewable energy sources. The intermittent nature of solar and wind power introduces new challenges in maintaining grid stability and power quality. Smart grids are expected to effectively manage these fluctuations, ensuring a smooth and reliable power supply even with a high penetration of renewable energy sources.

The growing trend of electrification in various sectors, including transportation and heating, further amplifies the demand for smart grid reliability. As more electric vehicles enter the market and buildings shift towards electric heating systems, the grid must be capable of handling increased loads while maintaining stability and power quality.

Cybersecurity concerns also play a significant role in driving reliability demand. As smart grids become more interconnected and reliant on digital technologies, they become potential targets for cyber attacks. Ensuring the reliability of smart grids now includes protecting against these digital threats, which could potentially disrupt power supply on a large scale.

Climate change and the increasing frequency of extreme weather events have also heightened the need for grid resilience. Smart grids are expected to withstand and quickly recover from natural disasters, minimizing the duration and extent of power outages during critical times.

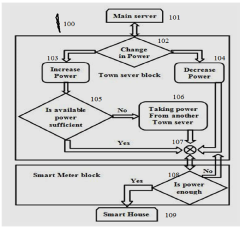

In response to these demands, utility companies and grid operators are investing in advanced technologies and strategies to enhance smart grid reliability. These include the implementation of advanced monitoring and control systems, the deployment of energy storage solutions, and the development of self-healing grid capabilities. The focus is on creating a more adaptive, responsive, and resilient power infrastructure that can meet the evolving needs of a modern, electricity-dependent society.

PVDF Challenges in Grids

Polyvinylidene fluoride (PVDF) has emerged as a promising material for enhancing the reliability of smart grids. However, its implementation faces several challenges that need to be addressed for widespread adoption. One of the primary obstacles is the high cost associated with PVDF production and integration into existing grid infrastructure. The material's complex manufacturing process and limited availability contribute to its elevated price point, making it less economically viable for large-scale deployment.

Another significant challenge is the limited understanding of PVDF's long-term performance and durability in diverse environmental conditions. Smart grids are exposed to various weather extremes, electromagnetic interference, and mechanical stresses. While PVDF shows promising initial results, there is a lack of comprehensive data on its behavior over extended periods, particularly in harsh operating environments. This uncertainty raises concerns about the material's ability to maintain its reliability-enhancing properties throughout the grid's lifecycle.

The integration of PVDF into existing grid components and systems poses technical difficulties. Retrofitting older infrastructure with PVDF-based solutions requires careful engineering and may necessitate significant modifications to current designs. This integration challenge is further complicated by the need to ensure compatibility with other materials and technologies already in use within the grid.

Scalability is another hurdle in the widespread adoption of PVDF in smart grids. As power networks expand and become more complex, scaling up PVDF applications while maintaining consistent performance across diverse grid topologies becomes increasingly challenging. This scalability issue is closely tied to manufacturing capabilities and the need for standardized production processes to ensure uniform quality and properties of PVDF materials.

Regulatory and standardization challenges also impede the rapid adoption of PVDF in smart grids. The lack of comprehensive standards and guidelines specific to PVDF applications in electrical infrastructure creates uncertainty for utilities and manufacturers. This regulatory gap can slow down the approval and implementation processes, as well as hinder interoperability between different PVDF-based solutions.

Lastly, there are concerns regarding the environmental impact of PVDF production and disposal. While the material offers significant benefits in terms of grid reliability, its production process can be energy-intensive and involve potentially harmful chemicals. Additionally, the end-of-life management and recycling of PVDF components from decommissioned grid infrastructure present challenges that need to be addressed to ensure the technology's sustainability.

PVDF Reliability Solutions

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their reliability. This includes methods for improving membrane structure, surface properties, and overall performance in different applications.- PVDF membrane fabrication techniques: Various techniques are employed to fabricate PVDF membranes with improved reliability. These methods include phase inversion, electrospinning, and blending with other polymers. The focus is on creating membranes with enhanced mechanical strength, chemical resistance, and long-term stability for applications in filtration and separation processes.

- PVDF-based energy harvesting devices: PVDF's piezoelectric properties are utilized in energy harvesting devices. Research focuses on improving the reliability of these devices by optimizing the PVDF film structure, incorporating nanoparticles, and developing novel electrode designs. These advancements aim to enhance the efficiency and durability of PVDF-based energy harvesters for various applications.

- PVDF in lithium-ion battery separators: PVDF is widely used in lithium-ion battery separators due to its excellent chemical stability and mechanical properties. Research focuses on improving the reliability of PVDF-based separators by modifying the polymer structure, incorporating additives, and optimizing the manufacturing process to enhance thermal stability, electrolyte uptake, and overall battery performance.

- PVDF coatings for corrosion protection: PVDF coatings are developed to enhance the reliability of various materials against corrosion. Research focuses on improving the adhesion, durability, and chemical resistance of PVDF coatings. Techniques such as surface modification, incorporation of nanoparticles, and development of multi-layer coating systems are explored to enhance the long-term performance of PVDF-based protective coatings.

- PVDF in flexible electronics: PVDF's flexibility and piezoelectric properties make it suitable for flexible electronics applications. Research focuses on improving the reliability of PVDF-based flexible devices by optimizing the polymer structure, developing novel fabrication techniques, and enhancing the interface between PVDF and other materials. These advancements aim to create more durable and efficient flexible sensors, actuators, and energy harvesting devices.

02 PVDF-based energy storage devices

Development of reliable PVDF-based components for energy storage applications, such as batteries and capacitors. This involves optimizing PVDF properties to enhance the performance and longevity of these devices.Expand Specific Solutions03 PVDF in sensor and actuator applications

Utilization of PVDF in sensors and actuators, focusing on improving their reliability and performance. This includes enhancing the piezoelectric properties of PVDF and developing novel sensor designs.Expand Specific Solutions04 PVDF composite materials

Creation of PVDF-based composite materials with enhanced reliability and specific properties. This involves combining PVDF with other materials to improve its mechanical, thermal, and electrical characteristics for various applications.Expand Specific Solutions05 PVDF coating and film technologies

Development of reliable PVDF coatings and films for various industrial applications. This includes improving adhesion, durability, and chemical resistance of PVDF-based protective layers and thin films.Expand Specific Solutions

Smart Grid PVDF Players

The integration of PVDF in Smart Grids for reliability enhancement is in a growth phase, with increasing market size driven by the global push for grid modernization. The technology's maturity is advancing, with key players like State Grid Corp. of China, Siemens Corp., and China Electric Power Research Institute Ltd. leading research and implementation efforts. Universities such as Southeast University and Massachusetts Institute of Technology are contributing to technological advancements. The competitive landscape is diverse, including power utilities, technology providers, and research institutions, all working towards improving grid resilience and efficiency through PVDF applications.

State Grid Corp. of China

Siemens Corp.

PVDF Innovations Analysis

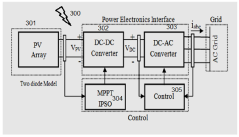

- The implementation of Phasor Measurement Units (PMUs) for real-time voltage monitoring, combined with meta-heuristic calculations and OPF methods, enables the computation of Voltage Stability Indices (VSI) and dynamic power flow management, addressing the stochasticity and irregularity in renewable energy integration and load patterns.

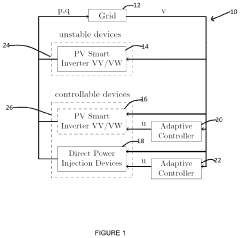

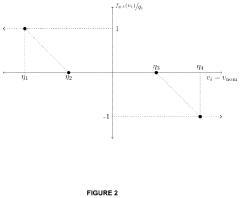

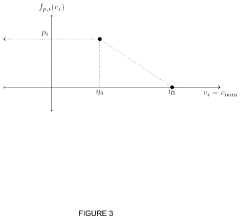

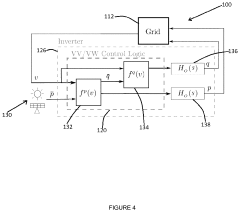

- An adaptive control approach using a Model Reference Adaptive Controller (MRAC) with a low-pass filtered AC grid voltage magnitude as a stable reference model is employed to derive a stabilizing control law for VV/VW control functions of stable PV systems and active/reactive power injections, making the algorithm decentralized, model-free, and communications-free.

Grid Cybersecurity Measures

In the context of PVDF in Smart Grids and reliability enhancement strategies, grid cybersecurity measures play a crucial role in ensuring the resilience and stability of the power infrastructure. As smart grids increasingly rely on advanced communication and control systems, they become more vulnerable to cyber threats. Implementing robust cybersecurity measures is essential to protect the grid from potential attacks and maintain its reliability.

One key aspect of grid cybersecurity is the implementation of advanced intrusion detection and prevention systems (IDPS). These systems continuously monitor network traffic and system activities, identifying and responding to potential security breaches in real-time. By leveraging machine learning algorithms and artificial intelligence, modern IDPS can detect even sophisticated and previously unknown threats, providing an additional layer of protection for smart grid infrastructure.

Encryption technologies are another critical component of grid cybersecurity. Secure communication protocols, such as Transport Layer Security (TLS) and IPsec, are employed to protect data transmission between various components of the smart grid. This includes communication between smart meters, substations, and control centers. Encryption ensures that sensitive information, such as power consumption data and control commands, remains confidential and tamper-proof during transmission.

Access control and authentication mechanisms form an integral part of grid cybersecurity measures. Multi-factor authentication, role-based access control, and least privilege principles are implemented to ensure that only authorized personnel can access critical systems and data. These measures help prevent unauthorized access and reduce the risk of insider threats.

Regular security assessments and penetration testing are essential practices in maintaining grid cybersecurity. These evaluations help identify vulnerabilities in the system and allow for proactive mitigation of potential security risks. By simulating real-world attack scenarios, utilities can assess the effectiveness of their security measures and make necessary improvements.

Cybersecurity awareness training for employees is another crucial aspect of grid protection. Human error remains a significant factor in security breaches, and educating staff about best practices, social engineering tactics, and the importance of cybersecurity can significantly reduce the risk of successful attacks.

Lastly, the implementation of a comprehensive incident response plan is vital for minimizing the impact of potential cyber incidents. This plan outlines the steps to be taken in the event of a security breach, including containment, eradication, and recovery procedures. Regular drills and simulations help ensure that the response team is well-prepared to handle various cyber threats effectively.

Environmental Impact of PVDF

The environmental impact of PVDF (Polyvinylidene Fluoride) in smart grid applications is a crucial consideration as the technology becomes more widespread. PVDF, a fluoropolymer known for its excellent electrical properties and durability, plays a significant role in enhancing the reliability of smart grids. However, its production, use, and disposal have various environmental implications that must be carefully evaluated.

The manufacturing process of PVDF involves the use of fluorine-based chemicals, which can potentially contribute to greenhouse gas emissions if not properly managed. The production of PVDF requires energy-intensive processes, leading to indirect environmental impacts through increased energy consumption. However, advancements in manufacturing techniques have led to more efficient production methods, reducing the overall carbon footprint associated with PVDF production.

In terms of its application in smart grids, PVDF contributes to improved energy efficiency and grid reliability. This indirectly benefits the environment by reducing energy losses and optimizing power distribution. The enhanced durability of PVDF components also leads to longer lifespans for grid infrastructure, potentially reducing the need for frequent replacements and associated environmental impacts.

During its operational life, PVDF exhibits excellent chemical resistance and stability, minimizing the risk of environmental contamination through leaching or degradation. This characteristic is particularly important in outdoor applications where exposure to various environmental factors is constant. The material's resistance to UV radiation and weathering further extends its lifespan, reducing the frequency of replacement and associated waste generation.

End-of-life considerations for PVDF in smart grid applications are an area of growing focus. While PVDF is not biodegradable, research into recycling and repurposing methods is ongoing. Advanced recycling techniques are being developed to recover and reuse PVDF, potentially creating a more circular economy for this material. However, the current limitations in recycling infrastructure pose challenges to widespread implementation of these practices.

The use of PVDF in smart grids also indirectly contributes to environmental protection by enabling better integration of renewable energy sources. By enhancing grid stability and reliability, PVDF-based components facilitate the incorporation of intermittent renewable energy, supporting the transition to cleaner energy systems. This aspect aligns with global efforts to reduce carbon emissions and combat climate change.

In conclusion, while the environmental impact of PVDF in smart grids is multifaceted, its benefits in terms of grid reliability and efficiency often outweigh the potential drawbacks. Ongoing research and development efforts are focused on further minimizing the environmental footprint of PVDF throughout its lifecycle, from production to disposal or recycling. As smart grid technologies continue to evolve, the environmental considerations surrounding PVDF will remain a critical aspect of sustainable infrastructure development.