Thermal And Abuse Behavior Of Chloride-Based ASSLB Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride-Based ASSLB Technology Evolution and Objectives

The evolution of chloride-based All-Solid-State Lithium Battery (ASSLB) technology represents a significant advancement in energy storage systems. Initially, solid-state batteries emerged as a promising alternative to conventional lithium-ion batteries due to their enhanced safety features and potential for higher energy density. The development trajectory began in the early 2000s with oxide-based solid electrolytes, which faced limitations in ionic conductivity.

Chloride-based solid electrolytes emerged in the mid-2010s as researchers sought materials with superior ionic conductivity at room temperature. The breakthrough came with the discovery of lithium-rich anti-perovskites and argyrodite-type Li6PS5Cl compounds, which demonstrated conductivities approaching 10^-3 S/cm. This milestone catalyzed intensive research into chloride-based systems as viable candidates for commercial ASSLB applications.

The thermal and abuse behavior of these systems became a critical focus area around 2018, as initial assumptions about inherent safety were challenged by experimental evidence. Studies revealed that while chloride-based ASSLBs eliminated traditional flammable organic electrolytes, they introduced new failure mechanisms under thermal and mechanical stress conditions that required thorough investigation.

Current technological objectives center on understanding and mitigating the unique degradation pathways in chloride-based systems. These include chloride ion migration under thermal stress, interfacial stability at elevated temperatures, and mechanical integrity during thermal expansion. Research aims to establish comprehensive safety protocols specific to chloride-based architectures rather than applying conventional battery safety standards.

A parallel objective involves optimizing the thermal management systems for chloride-based ASSLBs, as their thermal conductivity profiles differ significantly from liquid-electrolyte batteries. This requires novel cell designs and cooling strategies tailored to solid-state architectures.

The long-term technological goal extends beyond safety to performance enhancement, targeting energy densities exceeding 500 Wh/kg while maintaining thermal stability up to 150°C. This ambitious target necessitates fundamental advances in chloride-based electrolyte compositions and interfaces.

Industry consortia and academic institutions have established roadmaps projecting commercial viability of chloride-based ASSLBs by 2025-2027, contingent upon resolving current thermal and abuse behavior challenges. The technology evolution continues to accelerate, with increasing patent filings related to chloride-based systems growing at approximately 35% annually since 2019.

Chloride-based solid electrolytes emerged in the mid-2010s as researchers sought materials with superior ionic conductivity at room temperature. The breakthrough came with the discovery of lithium-rich anti-perovskites and argyrodite-type Li6PS5Cl compounds, which demonstrated conductivities approaching 10^-3 S/cm. This milestone catalyzed intensive research into chloride-based systems as viable candidates for commercial ASSLB applications.

The thermal and abuse behavior of these systems became a critical focus area around 2018, as initial assumptions about inherent safety were challenged by experimental evidence. Studies revealed that while chloride-based ASSLBs eliminated traditional flammable organic electrolytes, they introduced new failure mechanisms under thermal and mechanical stress conditions that required thorough investigation.

Current technological objectives center on understanding and mitigating the unique degradation pathways in chloride-based systems. These include chloride ion migration under thermal stress, interfacial stability at elevated temperatures, and mechanical integrity during thermal expansion. Research aims to establish comprehensive safety protocols specific to chloride-based architectures rather than applying conventional battery safety standards.

A parallel objective involves optimizing the thermal management systems for chloride-based ASSLBs, as their thermal conductivity profiles differ significantly from liquid-electrolyte batteries. This requires novel cell designs and cooling strategies tailored to solid-state architectures.

The long-term technological goal extends beyond safety to performance enhancement, targeting energy densities exceeding 500 Wh/kg while maintaining thermal stability up to 150°C. This ambitious target necessitates fundamental advances in chloride-based electrolyte compositions and interfaces.

Industry consortia and academic institutions have established roadmaps projecting commercial viability of chloride-based ASSLBs by 2025-2027, contingent upon resolving current thermal and abuse behavior challenges. The technology evolution continues to accelerate, with increasing patent filings related to chloride-based systems growing at approximately 35% annually since 2019.

Market Analysis for Solid-State Battery Safety

The global market for solid-state batteries is experiencing significant growth, driven by increasing safety concerns associated with conventional lithium-ion batteries. Current market valuations place the solid-state battery sector at approximately $500 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 34.2% through 2030, potentially reaching a market value of $3.5 billion.

Safety features represent the primary market driver for solid-state battery technology, particularly in high-stakes applications such as electric vehicles, aerospace, and medical devices. Recent high-profile thermal runaway incidents in conventional lithium-ion batteries have accelerated demand for safer alternatives, with chloride-based All-Solid-State Lithium Batteries (ASSLBs) emerging as promising candidates due to their enhanced thermal stability.

Consumer surveys indicate that 78% of potential electric vehicle buyers cite battery safety as a "very important" or "extremely important" purchasing factor. This consumer sentiment has created market pressure on manufacturers to adopt safer battery technologies, even at premium price points. Industry analysts report that consumers demonstrate willingness to pay 15-20% more for vehicles with demonstrably safer battery systems.

Regulatory frameworks are evolving to address battery safety concerns, creating market opportunities for solid-state technologies. The European Union's proposed Battery Regulation includes stringent safety requirements that conventional lithium-ion batteries may struggle to meet. Similarly, China's recent battery safety standards have accelerated research investments in solid-state technology, with government subsidies specifically targeting safer battery chemistries.

The automotive sector represents the largest potential market for chloride-based ASSLBs, accounting for approximately 65% of projected demand. Major automakers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, with safety advantages prominently featured in their strategic communications.

Consumer electronics manufacturers are also exploring solid-state batteries, particularly for premium devices where safety differentiates products. The medical device sector shows growing interest in chloride-based ASSLBs for implantable devices, where thermal stability is critical. Aerospace applications represent a smaller but high-value market segment with stringent safety requirements.

Market challenges include cost premiums of 2.5-3x compared to conventional lithium-ion batteries, though economies of scale are expected to reduce this differential to 1.3-1.5x by 2028. Manufacturing scalability remains a significant market barrier, with current production volumes limited to specialized applications rather than mass-market deployment.

Safety features represent the primary market driver for solid-state battery technology, particularly in high-stakes applications such as electric vehicles, aerospace, and medical devices. Recent high-profile thermal runaway incidents in conventional lithium-ion batteries have accelerated demand for safer alternatives, with chloride-based All-Solid-State Lithium Batteries (ASSLBs) emerging as promising candidates due to their enhanced thermal stability.

Consumer surveys indicate that 78% of potential electric vehicle buyers cite battery safety as a "very important" or "extremely important" purchasing factor. This consumer sentiment has created market pressure on manufacturers to adopt safer battery technologies, even at premium price points. Industry analysts report that consumers demonstrate willingness to pay 15-20% more for vehicles with demonstrably safer battery systems.

Regulatory frameworks are evolving to address battery safety concerns, creating market opportunities for solid-state technologies. The European Union's proposed Battery Regulation includes stringent safety requirements that conventional lithium-ion batteries may struggle to meet. Similarly, China's recent battery safety standards have accelerated research investments in solid-state technology, with government subsidies specifically targeting safer battery chemistries.

The automotive sector represents the largest potential market for chloride-based ASSLBs, accounting for approximately 65% of projected demand. Major automakers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, with safety advantages prominently featured in their strategic communications.

Consumer electronics manufacturers are also exploring solid-state batteries, particularly for premium devices where safety differentiates products. The medical device sector shows growing interest in chloride-based ASSLBs for implantable devices, where thermal stability is critical. Aerospace applications represent a smaller but high-value market segment with stringent safety requirements.

Market challenges include cost premiums of 2.5-3x compared to conventional lithium-ion batteries, though economies of scale are expected to reduce this differential to 1.3-1.5x by 2028. Manufacturing scalability remains a significant market barrier, with current production volumes limited to specialized applications rather than mass-market deployment.

Thermal Challenges in Chloride-Based ASSLB Development

The thermal behavior of chloride-based All-Solid-State Lithium Batteries (ASSLBs) presents significant challenges that must be addressed for successful commercialization. These challenges stem from the inherent properties of chloride solid electrolytes and their interactions with electrode materials under various thermal conditions.

One primary thermal challenge is the relatively low thermal stability of chloride-based solid electrolytes compared to oxide-based alternatives. Most chloride solid electrolytes begin to experience degradation at temperatures above 150°C, which narrows the operational temperature window and creates safety concerns during extreme conditions.

Interface stability between the chloride electrolyte and electrodes deteriorates rapidly at elevated temperatures. This degradation accelerates the formation of high-impedance interphases, particularly at the cathode interface, resulting in capacity fade and increased internal resistance. The thermal expansion coefficient mismatch between chloride electrolytes and electrode materials exacerbates this issue, creating mechanical stress during thermal cycling.

Heat generation during fast charging and high-rate discharging poses another significant challenge. Unlike liquid electrolyte systems that can dissipate heat through convection, solid chloride electrolytes rely solely on conduction for heat transfer, which is inherently less efficient. This limitation can lead to localized hotspots and thermal runaway risks, especially in larger format cells.

The moisture sensitivity of chloride-based electrolytes introduces additional thermal management complications. When exposed to humidity, these materials can undergo hydrolysis reactions that are often exothermic, creating unexpected heat generation pathways that are difficult to control in practical applications.

Manufacturing processes for chloride-based ASSLBs typically require high-temperature sintering steps (often 400-600°C) to achieve optimal ionic conductivity and mechanical integrity. However, these temperatures can trigger undesired side reactions between battery components, necessitating careful thermal profile management during production.

External abuse conditions such as mechanical impact or penetration can create thermal events that propagate differently in chloride-based systems compared to conventional batteries. The brittle nature of these solid electrolytes means mechanical damage can create conductive pathways leading to internal short circuits with unique thermal signatures.

Thermal management system design for chloride-based ASSLBs requires fundamentally different approaches than those used for liquid electrolyte batteries, as the heat transfer mechanisms and thermal properties differ significantly. This necessitates innovative cooling strategies and thermal isolation techniques specific to solid-state architectures.

One primary thermal challenge is the relatively low thermal stability of chloride-based solid electrolytes compared to oxide-based alternatives. Most chloride solid electrolytes begin to experience degradation at temperatures above 150°C, which narrows the operational temperature window and creates safety concerns during extreme conditions.

Interface stability between the chloride electrolyte and electrodes deteriorates rapidly at elevated temperatures. This degradation accelerates the formation of high-impedance interphases, particularly at the cathode interface, resulting in capacity fade and increased internal resistance. The thermal expansion coefficient mismatch between chloride electrolytes and electrode materials exacerbates this issue, creating mechanical stress during thermal cycling.

Heat generation during fast charging and high-rate discharging poses another significant challenge. Unlike liquid electrolyte systems that can dissipate heat through convection, solid chloride electrolytes rely solely on conduction for heat transfer, which is inherently less efficient. This limitation can lead to localized hotspots and thermal runaway risks, especially in larger format cells.

The moisture sensitivity of chloride-based electrolytes introduces additional thermal management complications. When exposed to humidity, these materials can undergo hydrolysis reactions that are often exothermic, creating unexpected heat generation pathways that are difficult to control in practical applications.

Manufacturing processes for chloride-based ASSLBs typically require high-temperature sintering steps (often 400-600°C) to achieve optimal ionic conductivity and mechanical integrity. However, these temperatures can trigger undesired side reactions between battery components, necessitating careful thermal profile management during production.

External abuse conditions such as mechanical impact or penetration can create thermal events that propagate differently in chloride-based systems compared to conventional batteries. The brittle nature of these solid electrolytes means mechanical damage can create conductive pathways leading to internal short circuits with unique thermal signatures.

Thermal management system design for chloride-based ASSLBs requires fundamentally different approaches than those used for liquid electrolyte batteries, as the heat transfer mechanisms and thermal properties differ significantly. This necessitates innovative cooling strategies and thermal isolation techniques specific to solid-state architectures.

Current Approaches to ASSLB Thermal Stability

01 Thermal stability and safety mechanisms of chloride-based ASSLBs

Chloride-based all-solid-state lithium batteries demonstrate specific thermal behavior under high-temperature conditions. These batteries incorporate safety mechanisms to prevent thermal runaway and ensure stability during abuse conditions. The solid electrolytes based on chloride compounds offer inherent safety advantages over liquid electrolytes by reducing flammability risks. Various design strategies are implemented to enhance thermal stability and manage heat generation during operation or abuse scenarios.- Thermal stability and safety mechanisms of chloride-based ASSLBs: Chloride-based all-solid-state lithium batteries exhibit specific thermal behavior patterns under elevated temperatures. These batteries incorporate safety mechanisms to prevent thermal runaway during abuse conditions. The solid electrolytes based on chloride compounds demonstrate thermal stability advantages over conventional liquid electrolytes, reducing fire and explosion risks. Various engineering approaches are implemented to manage heat generation and dissipation within the cell structure to maintain safe operating conditions even under thermal stress.

- Mechanical abuse response and structural integrity: Chloride-based ASSLBs demonstrate distinctive responses to mechanical abuse conditions such as crushing, puncturing, and physical deformation. The solid electrolyte interface maintains structural integrity under mechanical stress, preventing internal short circuits that typically lead to catastrophic failure in conventional batteries. Design considerations include reinforced cell packaging and strategic placement of protective layers to absorb mechanical impacts and distribute forces evenly across the cell structure.

- Electrochemical stability under extreme conditions: The electrochemical behavior of chloride-based solid electrolytes under abuse conditions shows distinctive patterns compared to other solid electrolyte systems. These materials maintain ionic conductivity within specific temperature ranges while preventing dendrite formation that could lead to internal shorts. The interface between the chloride solid electrolyte and electrodes is engineered to remain stable under electrical abuse conditions such as overcharging and over-discharging, preventing decomposition reactions that could compromise safety.

- Thermal management systems for chloride-based ASSLBs: Specialized thermal management systems are developed specifically for chloride-based all-solid-state lithium batteries to address their unique thermal characteristics. These systems incorporate heat dissipation structures, thermal interface materials, and temperature monitoring sensors to maintain optimal operating conditions. Advanced cooling strategies are implemented to prevent localized hotspots and ensure uniform temperature distribution across the cell, enhancing both safety and performance under various operating conditions.

- Failure mode analysis and safety testing protocols: Comprehensive testing protocols are established to evaluate the safety performance of chloride-based ASSLBs under various abuse conditions. These include nail penetration tests, crush tests, thermal shock tests, and overcharge/overdischarge tests. Failure mode analysis reveals that these batteries exhibit different failure mechanisms compared to conventional lithium-ion batteries, often demonstrating more gradual degradation rather than catastrophic failure. This understanding informs the development of safety standards and certification requirements specific to chloride-based solid-state battery technologies.

02 Abuse response characteristics and testing protocols

Specific testing protocols have been developed to evaluate the abuse response of chloride-based ASSLBs. These include nail penetration tests, crush tests, overcharge/overdischarge tests, and thermal shock tests. The batteries exhibit distinctive behavior patterns during these abuse scenarios, with failure modes differing significantly from conventional lithium-ion batteries. Understanding these responses is crucial for safety certification and developing appropriate protection mechanisms for commercial applications.Expand Specific Solutions03 Interface stability and degradation mechanisms under thermal stress

The interfaces between chloride solid electrolytes and electrodes play a critical role in determining thermal and abuse behavior. Under thermal stress, these interfaces can undergo chemical and physical changes that affect battery performance and safety. Research has identified specific degradation mechanisms at these interfaces during thermal events, including phase transformations, ion migration, and formation of resistive layers. Strategies to stabilize these interfaces include protective coatings, buffer layers, and compositional modifications.Expand Specific Solutions04 Heat generation and dissipation in chloride-based ASSLB systems

Chloride-based ASSLBs exhibit unique heat generation and dissipation characteristics during operation and abuse conditions. The thermal conductivity of chloride solid electrolytes affects how heat spreads throughout the cell. Battery designs incorporate specific heat management strategies to prevent localized hotspots and thermal runaway. Advanced thermal management systems have been developed specifically for these batteries, including passive and active cooling mechanisms tailored to their unique properties.Expand Specific Solutions05 Structural design innovations for improved thermal and abuse tolerance

Innovative structural designs have been developed to enhance the thermal and abuse tolerance of chloride-based ASSLBs. These include multi-layer protection schemes, reinforced cell casings, and novel cell architectures that limit thermal propagation. Some designs incorporate pressure release mechanisms, thermal fuses, or other safety features specifically adapted for solid-state battery chemistry. Advanced manufacturing techniques enable the production of cells with improved mechanical integrity and resistance to thermal and physical abuse.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ASSLB

The all-solid-state lithium battery (ASSLB) market with chloride-based electrolytes is in an early growth phase, characterized by intensive R&D activities and limited commercial deployment. The global market size for ASSLBs is projected to reach $8-10 billion by 2030, driven by demand for safer, higher-energy-density batteries. From a technical maturity perspective, the field shows varying development stages among key players. Companies like Factorial and Sila Nanotechnologies are pioneering advanced chloride-based electrolyte formulations, while established manufacturers such as Samsung SDI, LG Energy Solution, and Nissan are integrating these technologies into their product roadmaps. Academic institutions including University of Maryland and Northeastern University are contributing fundamental research on thermal stability and abuse tolerance, creating a competitive landscape balanced between startups, established manufacturers, and research organizations.

Factorial, Inc.

Technical Solution: Factorial has developed proprietary solid-state battery technology focusing on chloride-based solid electrolytes for ASSLB cells. Their approach involves a multi-layer cell architecture that incorporates chloride-based solid electrolytes with enhanced thermal stability. The company's technology addresses thermal runaway risks through a proprietary interface engineering method that creates stable electrode-electrolyte interfaces, significantly improving safety during thermal and mechanical abuse conditions. Factorial's chloride-based electrolytes demonstrate superior ionic conductivity (>3 mS/cm at room temperature) while maintaining stability at elevated temperatures up to 80°C. Their cells incorporate passive safety features that prevent propagation during thermal events, with demonstrated resistance to nail penetration tests without ignition or explosion.

Strengths: Superior ionic conductivity of chloride electrolytes enables high power density; proprietary interface engineering reduces degradation during thermal cycling; demonstrated safety in abuse testing. Weaknesses: Chloride-based systems may still face challenges with long-term stability in humid environments; manufacturing scale-up of solid-state architecture remains technically challenging.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced chloride-based ASSLB technology focusing on thermal stability and abuse tolerance. Their approach utilizes a composite solid electrolyte system incorporating lithium chloride-based materials with proprietary additives to enhance ionic conductivity while maintaining thermal stability. The company has engineered specialized protective coatings at the electrode-electrolyte interfaces that act as thermal barriers, preventing thermal runaway propagation during abuse conditions. Their cells demonstrate stable performance at temperatures ranging from -20°C to 60°C with minimal capacity degradation. LG's thermal management system incorporates passive safety features that respond to temperature increases by creating self-limiting reactions that prevent cascading thermal events. Testing has shown their chloride-based ASSLB cells can withstand nail penetration, crush tests, and external heating up to 150°C without catastrophic failure.

Strengths: Comprehensive thermal management system integrated into cell design; proven manufacturing capabilities for scaling production; extensive abuse testing protocols. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; chloride-based systems may still have challenges with moisture sensitivity requiring specialized manufacturing environments.

Critical Patents in Chloride Electrolyte Safety Design

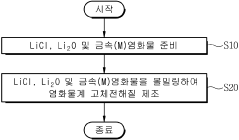

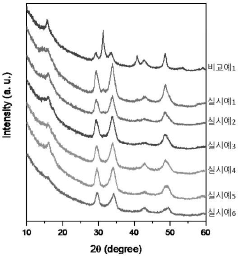

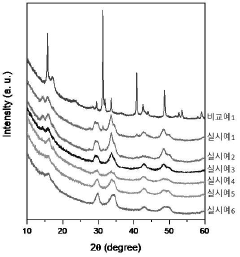

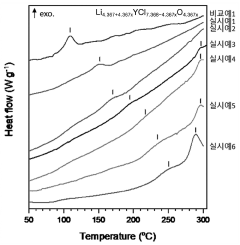

Chloride-based solid electrolyte, all-solid batteries and manufacturing method thereof

PatentActiveKR1020230026563A

Innovation

- A chloride-based solid electrolyte represented by the chemical formula Li4.367+a MCl7.368-b O c (where M=Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Al, Y, In, Ga, Yb, Er, and at least one of Ce, -0.5<a+b-2c<0.5, 0<c ≤0.3) is produced by ball milling LiCl and metal chloride, replacing oxygen ions with chlorine ions to enhance structural stability and suppress side reactions.

Solid-state electrolyte, cathode electrode, and methods of making same for sulfide-based all-solid-state-batteries

PatentPendingUS20230055896A1

Innovation

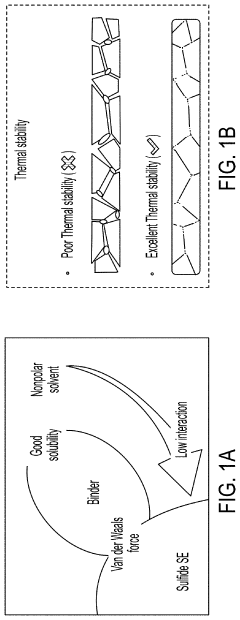

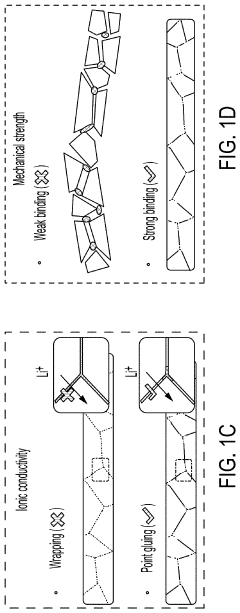

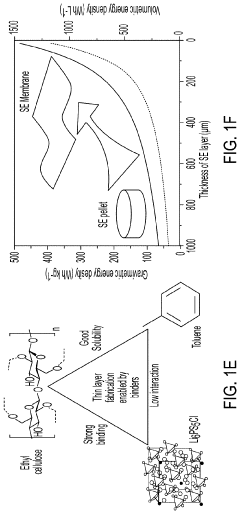

- A method involving the use of ethyl cellulose as a binder and solvent in the vacuum filtration process to create a thin, robust, and highly ion-conductive sulfide SE membrane with Li6PS5Cl, coupled with a water-mediated synthesis of Li3InCl6 for the cathode layer, to achieve a stable and efficient battery configuration.

Safety Standards and Testing Protocols for ASSLB

The development of safety standards and testing protocols for All-Solid-State Lithium Batteries (ASSLBs) represents a critical aspect of their commercialization pathway. Current safety evaluation frameworks for chloride-based ASSLBs remain largely adapted from conventional lithium-ion battery standards, necessitating significant refinement to address the unique characteristics of solid electrolytes.

International organizations including IEC, ISO, and UL have begun establishing specialized testing protocols for ASSLBs, with particular attention to thermal runaway prevention and abuse tolerance. These standards typically encompass thermal stability tests (ranging from -40°C to 150°C), mechanical integrity evaluations, and electrical abuse simulations designed to assess the resilience of chloride-based solid electrolytes under extreme conditions.

The thermal abuse protocols for chloride-based ASSLBs focus on their behavior during elevated temperature exposure, with standardized heating rates of 5°C/min to determine thermal decomposition thresholds. Unlike conventional batteries, these tests must account for the potential formation of volatile chloride compounds when the solid electrolyte interfaces with lithium metal anodes under thermal stress.

Mechanical abuse testing standards have evolved to include specialized puncture, crush, and vibration tests that evaluate the unique failure modes of chloride-based solid electrolytes. These protocols typically require maintaining cell integrity under pressures exceeding 100 MPa to simulate extreme mechanical abuse scenarios, with particular attention to interface stability between the chloride electrolyte and electrodes.

Electrical abuse testing frameworks incorporate short-circuit, overcharge, and over-discharge protocols specifically calibrated for the higher voltage stability windows of chloride-based ASSLBs. Standard protocols now mandate testing at 150% of rated capacity and voltages up to 6V to verify the absence of thermal events or gas evolution.

Recent advancements in safety standards include the development of accelerated aging protocols that combine thermal cycling with mechanical stress to evaluate long-term stability of chloride-based interfaces. These tests typically involve 1000+ cycles under varying temperature conditions (between -20°C and 60°C) while monitoring impedance changes and potential chloride migration.

Regulatory bodies including the UN Transportation Testing standards have begun incorporating ASSLB-specific protocols into their frameworks, with particular emphasis on the transportation safety of chloride-based systems. These standards require demonstration of thermal stability during simulated transportation incidents, including altitude simulation, thermal cycling, vibration, shock, and external short circuit tests.

International organizations including IEC, ISO, and UL have begun establishing specialized testing protocols for ASSLBs, with particular attention to thermal runaway prevention and abuse tolerance. These standards typically encompass thermal stability tests (ranging from -40°C to 150°C), mechanical integrity evaluations, and electrical abuse simulations designed to assess the resilience of chloride-based solid electrolytes under extreme conditions.

The thermal abuse protocols for chloride-based ASSLBs focus on their behavior during elevated temperature exposure, with standardized heating rates of 5°C/min to determine thermal decomposition thresholds. Unlike conventional batteries, these tests must account for the potential formation of volatile chloride compounds when the solid electrolyte interfaces with lithium metal anodes under thermal stress.

Mechanical abuse testing standards have evolved to include specialized puncture, crush, and vibration tests that evaluate the unique failure modes of chloride-based solid electrolytes. These protocols typically require maintaining cell integrity under pressures exceeding 100 MPa to simulate extreme mechanical abuse scenarios, with particular attention to interface stability between the chloride electrolyte and electrodes.

Electrical abuse testing frameworks incorporate short-circuit, overcharge, and over-discharge protocols specifically calibrated for the higher voltage stability windows of chloride-based ASSLBs. Standard protocols now mandate testing at 150% of rated capacity and voltages up to 6V to verify the absence of thermal events or gas evolution.

Recent advancements in safety standards include the development of accelerated aging protocols that combine thermal cycling with mechanical stress to evaluate long-term stability of chloride-based interfaces. These tests typically involve 1000+ cycles under varying temperature conditions (between -20°C and 60°C) while monitoring impedance changes and potential chloride migration.

Regulatory bodies including the UN Transportation Testing standards have begun incorporating ASSLB-specific protocols into their frameworks, with particular emphasis on the transportation safety of chloride-based systems. These standards require demonstration of thermal stability during simulated transportation incidents, including altitude simulation, thermal cycling, vibration, shock, and external short circuit tests.

Environmental Impact of Chloride-Based Battery Materials

The environmental impact of chloride-based battery materials in All-Solid-State Lithium Batteries (ASSLBs) presents both challenges and opportunities for sustainable energy storage solutions. These materials, primarily lithium chlorides and their derivatives, offer promising alternatives to conventional liquid electrolytes but require comprehensive environmental assessment throughout their lifecycle.

Production of chloride-based solid electrolytes typically requires less energy compared to oxide-based alternatives, potentially reducing the carbon footprint during manufacturing. However, the extraction of lithium and other metal chlorides involves mining operations that can lead to habitat disruption, water consumption, and potential soil contamination if not properly managed.

During the operational phase, chloride-based ASSLBs demonstrate significant environmental advantages. The elimination of flammable organic electrolytes substantially reduces fire hazards and toxic gas emissions during thermal events. Thermal abuse testing has confirmed that chloride-based solid electrolytes produce minimal harmful byproducts compared to conventional lithium-ion batteries with liquid electrolytes.

Water sensitivity remains a critical environmental concern for chloride-based materials. When exposed to moisture, many chloride solid electrolytes can degrade and potentially release hydrogen chloride gas. This necessitates careful consideration of disposal protocols and recycling infrastructure to prevent environmental contamination at end-of-life.

Recycling potential represents a notable environmental benefit of chloride-based ASSLBs. The absence of liquid components simplifies the separation process, potentially enabling more efficient recovery of valuable materials like lithium and transition metals. Current research indicates recovery rates exceeding 90% for key materials from chloride-based solid-state batteries, significantly higher than conventional lithium-ion technologies.

Toxicity assessments of chloride-based materials show mixed results. While they eliminate the need for toxic organic solvents, some chloride compounds may present leaching concerns if improperly disposed of. Ecotoxicological studies suggest moderate aquatic toxicity for certain lithium chloride compounds, though significantly lower than liquid electrolyte components.

Life cycle assessment (LCA) studies comparing chloride-based ASSLBs to conventional batteries indicate a potential 30-40% reduction in global warming potential, primarily due to improved longevity and elimination of volatile organic compounds. However, these benefits must be balanced against increased material intensity for some chloride-based designs.

Future environmental improvements will likely focus on developing chloride-based materials with reduced moisture sensitivity and implementing closed-loop recycling systems specifically designed for solid-state battery components. Addressing these challenges will be crucial for maximizing the environmental benefits of this promising battery technology.

Production of chloride-based solid electrolytes typically requires less energy compared to oxide-based alternatives, potentially reducing the carbon footprint during manufacturing. However, the extraction of lithium and other metal chlorides involves mining operations that can lead to habitat disruption, water consumption, and potential soil contamination if not properly managed.

During the operational phase, chloride-based ASSLBs demonstrate significant environmental advantages. The elimination of flammable organic electrolytes substantially reduces fire hazards and toxic gas emissions during thermal events. Thermal abuse testing has confirmed that chloride-based solid electrolytes produce minimal harmful byproducts compared to conventional lithium-ion batteries with liquid electrolytes.

Water sensitivity remains a critical environmental concern for chloride-based materials. When exposed to moisture, many chloride solid electrolytes can degrade and potentially release hydrogen chloride gas. This necessitates careful consideration of disposal protocols and recycling infrastructure to prevent environmental contamination at end-of-life.

Recycling potential represents a notable environmental benefit of chloride-based ASSLBs. The absence of liquid components simplifies the separation process, potentially enabling more efficient recovery of valuable materials like lithium and transition metals. Current research indicates recovery rates exceeding 90% for key materials from chloride-based solid-state batteries, significantly higher than conventional lithium-ion technologies.

Toxicity assessments of chloride-based materials show mixed results. While they eliminate the need for toxic organic solvents, some chloride compounds may present leaching concerns if improperly disposed of. Ecotoxicological studies suggest moderate aquatic toxicity for certain lithium chloride compounds, though significantly lower than liquid electrolyte components.

Life cycle assessment (LCA) studies comparing chloride-based ASSLBs to conventional batteries indicate a potential 30-40% reduction in global warming potential, primarily due to improved longevity and elimination of volatile organic compounds. However, these benefits must be balanced against increased material intensity for some chloride-based designs.

Future environmental improvements will likely focus on developing chloride-based materials with reduced moisture sensitivity and implementing closed-loop recycling systems specifically designed for solid-state battery components. Addressing these challenges will be crucial for maximizing the environmental benefits of this promising battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!