Pouch-Cell Integration Of Chloride SSEs: Stack Pressure And Cycling

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride SSEs Background and Integration Objectives

Solid-state electrolytes (SSEs) have emerged as a promising alternative to conventional liquid electrolytes in lithium-ion batteries, offering enhanced safety and potential for higher energy density. Among various SSE materials, chloride-based solid-state electrolytes have gained significant attention in recent years due to their high ionic conductivity, comparable to that of sulfide-based SSEs, while demonstrating improved air stability.

The development of chloride-based SSEs can be traced back to the early 2010s, when researchers began exploring alternatives to oxide and sulfide electrolytes. The breakthrough came in 2018 with the discovery of Li3YCl6 and related materials, which exhibited room temperature ionic conductivities exceeding 10^-3 S/cm. This milestone catalyzed intensive research efforts worldwide, focusing on optimizing composition, synthesis methods, and integration techniques.

The evolution of chloride SSEs has followed a trajectory of continuous improvement in ionic conductivity, mechanical properties, and electrochemical stability. Recent advancements have focused on addressing the critical challenges of interfacial resistance and chemical compatibility with electrode materials, particularly at the cathode interface where oxidative decomposition remains problematic.

The primary objective of chloride SSE integration into pouch cells is to develop commercially viable all-solid-state batteries that overcome the limitations of conventional lithium-ion technology. Specifically, the goals include enhancing safety by eliminating flammable liquid electrolytes, increasing energy density through compatibility with lithium metal anodes, and extending cycle life by mitigating dendrite formation.

A particular focus of current research is understanding and optimizing stack pressure requirements during both cell assembly and cycling. Unlike liquid-based systems, solid-state batteries require careful pressure management to maintain intimate contact between electrolyte and electrode materials while accommodating volume changes during cycling. Insufficient pressure leads to contact loss and increased resistance, while excessive pressure may cause mechanical degradation of components.

The integration objectives also encompass developing scalable manufacturing processes compatible with existing production infrastructure. This includes adapting conventional pouch cell assembly techniques to accommodate the unique requirements of chloride SSEs, such as moisture-free environments and precise pressure control mechanisms.

Additionally, researchers aim to establish optimal cycling protocols that maximize performance while minimizing degradation mechanisms specific to chloride-based systems. This involves understanding the complex interplay between electrochemical processes, mechanical stress evolution, and interfacial stability during repeated charge-discharge cycles.

The development of chloride-based SSEs can be traced back to the early 2010s, when researchers began exploring alternatives to oxide and sulfide electrolytes. The breakthrough came in 2018 with the discovery of Li3YCl6 and related materials, which exhibited room temperature ionic conductivities exceeding 10^-3 S/cm. This milestone catalyzed intensive research efforts worldwide, focusing on optimizing composition, synthesis methods, and integration techniques.

The evolution of chloride SSEs has followed a trajectory of continuous improvement in ionic conductivity, mechanical properties, and electrochemical stability. Recent advancements have focused on addressing the critical challenges of interfacial resistance and chemical compatibility with electrode materials, particularly at the cathode interface where oxidative decomposition remains problematic.

The primary objective of chloride SSE integration into pouch cells is to develop commercially viable all-solid-state batteries that overcome the limitations of conventional lithium-ion technology. Specifically, the goals include enhancing safety by eliminating flammable liquid electrolytes, increasing energy density through compatibility with lithium metal anodes, and extending cycle life by mitigating dendrite formation.

A particular focus of current research is understanding and optimizing stack pressure requirements during both cell assembly and cycling. Unlike liquid-based systems, solid-state batteries require careful pressure management to maintain intimate contact between electrolyte and electrode materials while accommodating volume changes during cycling. Insufficient pressure leads to contact loss and increased resistance, while excessive pressure may cause mechanical degradation of components.

The integration objectives also encompass developing scalable manufacturing processes compatible with existing production infrastructure. This includes adapting conventional pouch cell assembly techniques to accommodate the unique requirements of chloride SSEs, such as moisture-free environments and precise pressure control mechanisms.

Additionally, researchers aim to establish optimal cycling protocols that maximize performance while minimizing degradation mechanisms specific to chloride-based systems. This involves understanding the complex interplay between electrochemical processes, mechanical stress evolution, and interfacial stability during repeated charge-discharge cycles.

Market Analysis for Chloride Solid-State Electrolytes

The global market for solid-state batteries is experiencing significant growth, with chloride-based solid-state electrolytes (SSEs) emerging as a promising segment. Current market projections indicate that the solid-state battery market will reach $8 billion by 2026, with a compound annual growth rate of 34% between 2021 and 2026. Within this expanding market, chloride-based SSEs are gaining attention due to their superior ionic conductivity and potential cost advantages over other SSE chemistries.

The demand for chloride SSEs is primarily driven by the electric vehicle (EV) sector, where manufacturers are seeking safer, higher energy density alternatives to conventional lithium-ion batteries with liquid electrolytes. Major automotive companies including Toyota, Volkswagen, and BMW have made substantial investments in solid-state battery technology, with particular interest in chloride-based systems for their promising performance characteristics.

Consumer electronics represents another significant market segment, with manufacturers looking to incorporate solid-state batteries to enable slimmer device profiles and eliminate safety concerns associated with traditional batteries. The wearable technology sector is especially interested in chloride SSEs due to their potential for flexible form factors and higher energy density.

Market analysis reveals regional variations in chloride SSE development and adoption. Asia-Pacific, particularly Japan, South Korea, and China, leads in research and commercialization efforts, with North America and Europe following closely. China's battery manufacturers are making substantial investments in chloride SSE production capacity, potentially positioning the country as a manufacturing hub for this technology.

From a supply chain perspective, chloride SSEs face challenges related to raw material availability and processing. The technology requires high-purity chloride compounds, and scaling up production while maintaining quality remains a significant hurdle. However, chloride-based systems generally utilize more abundant and less expensive materials compared to oxide or sulfide alternatives, presenting a long-term cost advantage.

Investor interest in chloride SSE technology has grown substantially, with venture capital funding for startups in this space increasing by 150% between 2019 and 2021. Strategic partnerships between material suppliers, battery manufacturers, and end-users are becoming more common as the industry recognizes the need for vertical integration to overcome technical challenges related to pouch-cell integration and stack pressure optimization.

Market forecasts suggest that chloride-based SSEs could capture approximately 25% of the overall solid-state electrolyte market by 2030, contingent upon successful resolution of current technical challenges related to cycling stability and manufacturing scalability.

The demand for chloride SSEs is primarily driven by the electric vehicle (EV) sector, where manufacturers are seeking safer, higher energy density alternatives to conventional lithium-ion batteries with liquid electrolytes. Major automotive companies including Toyota, Volkswagen, and BMW have made substantial investments in solid-state battery technology, with particular interest in chloride-based systems for their promising performance characteristics.

Consumer electronics represents another significant market segment, with manufacturers looking to incorporate solid-state batteries to enable slimmer device profiles and eliminate safety concerns associated with traditional batteries. The wearable technology sector is especially interested in chloride SSEs due to their potential for flexible form factors and higher energy density.

Market analysis reveals regional variations in chloride SSE development and adoption. Asia-Pacific, particularly Japan, South Korea, and China, leads in research and commercialization efforts, with North America and Europe following closely. China's battery manufacturers are making substantial investments in chloride SSE production capacity, potentially positioning the country as a manufacturing hub for this technology.

From a supply chain perspective, chloride SSEs face challenges related to raw material availability and processing. The technology requires high-purity chloride compounds, and scaling up production while maintaining quality remains a significant hurdle. However, chloride-based systems generally utilize more abundant and less expensive materials compared to oxide or sulfide alternatives, presenting a long-term cost advantage.

Investor interest in chloride SSE technology has grown substantially, with venture capital funding for startups in this space increasing by 150% between 2019 and 2021. Strategic partnerships between material suppliers, battery manufacturers, and end-users are becoming more common as the industry recognizes the need for vertical integration to overcome technical challenges related to pouch-cell integration and stack pressure optimization.

Market forecasts suggest that chloride-based SSEs could capture approximately 25% of the overall solid-state electrolyte market by 2030, contingent upon successful resolution of current technical challenges related to cycling stability and manufacturing scalability.

Technical Challenges in Pouch-Cell Integration

The integration of chloride solid-state electrolytes (SSEs) into pouch-cell configurations presents several significant technical challenges that must be addressed for successful commercialization. One of the primary obstacles is achieving and maintaining optimal stack pressure throughout the cell's operational lifetime. Unlike conventional liquid electrolyte systems, SSEs require intimate contact between electrodes and the electrolyte to facilitate ion transport across interfaces, necessitating precise pressure management.

Stack pressure optimization represents a delicate balance - insufficient pressure leads to high interfacial resistance and poor ion transport, while excessive pressure can cause mechanical degradation of cell components. This challenge is exacerbated by the inherent brittleness of many chloride SSEs, making them susceptible to fracture under mechanical stress during assembly and cycling.

The dynamic nature of lithium-ion batteries during charge-discharge cycles introduces additional complexity. Volume changes in electrode materials, particularly in high-capacity anodes like lithium metal, can reach up to 300% during cycling. These dimensional fluctuations create variable pressure distributions within the cell, potentially leading to contact loss, increased impedance, and accelerated degradation of the solid electrolyte.

Temperature variations further complicate pressure management due to the different thermal expansion coefficients of cell components. This mismatch can induce mechanical stress at interfaces, potentially creating microcracks in the SSE that compromise ionic conductivity and cell safety. The challenge is particularly pronounced during rapid charging or in extreme environmental conditions.

Manufacturing considerations add another layer of complexity. Traditional pouch cell production lines are designed for liquid electrolyte systems and require significant modification to accommodate the unique assembly requirements of SSEs. The need to apply and maintain uniform pressure during sealing processes demands specialized equipment and precise process control.

Long-term cycling stability represents perhaps the most critical challenge. Initial performance metrics may be promising, but maintaining consistent pressure distribution and interfacial contact over thousands of cycles remains problematic. Gradual relaxation of stack pressure, coupled with microstructural changes at interfaces, can lead to capacity fade and eventual cell failure.

The integration of pressure regulation mechanisms within the confined space of a pouch cell presents design challenges. External pressure fixtures used in laboratory settings are impractical for commercial applications, necessitating innovative internal solutions that can maintain optimal pressure without significantly increasing cell thickness or weight.

Stack pressure optimization represents a delicate balance - insufficient pressure leads to high interfacial resistance and poor ion transport, while excessive pressure can cause mechanical degradation of cell components. This challenge is exacerbated by the inherent brittleness of many chloride SSEs, making them susceptible to fracture under mechanical stress during assembly and cycling.

The dynamic nature of lithium-ion batteries during charge-discharge cycles introduces additional complexity. Volume changes in electrode materials, particularly in high-capacity anodes like lithium metal, can reach up to 300% during cycling. These dimensional fluctuations create variable pressure distributions within the cell, potentially leading to contact loss, increased impedance, and accelerated degradation of the solid electrolyte.

Temperature variations further complicate pressure management due to the different thermal expansion coefficients of cell components. This mismatch can induce mechanical stress at interfaces, potentially creating microcracks in the SSE that compromise ionic conductivity and cell safety. The challenge is particularly pronounced during rapid charging or in extreme environmental conditions.

Manufacturing considerations add another layer of complexity. Traditional pouch cell production lines are designed for liquid electrolyte systems and require significant modification to accommodate the unique assembly requirements of SSEs. The need to apply and maintain uniform pressure during sealing processes demands specialized equipment and precise process control.

Long-term cycling stability represents perhaps the most critical challenge. Initial performance metrics may be promising, but maintaining consistent pressure distribution and interfacial contact over thousands of cycles remains problematic. Gradual relaxation of stack pressure, coupled with microstructural changes at interfaces, can lead to capacity fade and eventual cell failure.

The integration of pressure regulation mechanisms within the confined space of a pouch cell presents design challenges. External pressure fixtures used in laboratory settings are impractical for commercial applications, necessitating innovative internal solutions that can maintain optimal pressure without significantly increasing cell thickness or weight.

Current Stack Pressure Management Solutions

01 Pressure optimization for chloride SSE interfaces

Applying optimal stack pressure to chloride solid-state electrolytes improves interfacial contact between the electrolyte and electrodes, reducing resistance and enhancing ion transport. The pressure must be carefully controlled to maintain mechanical stability while ensuring sufficient contact area. Various pressure application methods and measurement techniques are employed to determine the optimal pressure range for different chloride-based SSE compositions.- Optimization of stack pressure for chloride SSEs: Stack pressure is a critical parameter in solid-state electrolyte systems that affects the interfacial contact between electrodes and the chloride electrolyte. Optimizing the stack pressure can enhance ionic conductivity and reduce interfacial resistance in chloride-based SSEs. Research shows that controlled pressure application improves the mechanical stability and electrochemical performance of the battery cells by maintaining intimate contact between components while preventing excessive stress that could lead to electrolyte fracture.

- Mechanical properties of chloride solid-state electrolytes under pressure: Chloride-based solid-state electrolytes exhibit unique mechanical properties under applied pressure. These materials often show a balance between rigidity and plasticity that can be advantageous for battery applications. Under appropriate stack pressure, chloride SSEs can deform to maintain contact with electrodes while resisting fracture. Understanding the mechanical response of these materials to pressure is essential for designing robust battery systems with extended cycle life and improved safety characteristics.

- Interface engineering for chloride SSEs under stack pressure: Interface engineering techniques are employed to optimize the contact between chloride solid-state electrolytes and electrodes under stack pressure. These methods include surface modifications, buffer layers, and gradient structures that can accommodate pressure-induced stresses. Properly engineered interfaces help prevent dendrite formation and reduce interfacial resistance, leading to improved battery performance. The interface stability under various pressure conditions is crucial for maintaining consistent electrochemical performance throughout battery operation.

- Manufacturing processes for pressure-optimized chloride SSEs: Specialized manufacturing processes have been developed to create chloride solid-state electrolytes that perform optimally under stack pressure. These include controlled sintering techniques, hot pressing methods, and composite formation approaches that enhance the mechanical and electrochemical properties of the electrolytes. The manufacturing processes focus on creating uniform microstructures that can withstand operational pressures while maintaining high ionic conductivity. Advanced fabrication methods also address issues of scalability and cost-effectiveness for commercial applications.

- Pressure monitoring and control systems for chloride SSE batteries: Advanced pressure monitoring and control systems are essential for maintaining optimal stack pressure in chloride solid-state electrolyte batteries. These systems include pressure sensors, mechanical constraints, and adaptive pressure regulation mechanisms that respond to changes during battery operation. Proper pressure management prevents mechanical degradation while ensuring consistent electrochemical performance. The integration of these control systems into battery pack designs enables long-term stability and safety under various operating conditions.

02 Mechanical properties of chloride SSEs under pressure

Chloride solid-state electrolytes exhibit specific mechanical behaviors under applied stack pressure, including creep, deformation, and fracture mechanisms. Understanding these properties is crucial for battery design as they directly impact long-term cycling stability. Research focuses on measuring and improving the mechanical robustness of chloride SSEs through compositional modifications, structural reinforcements, and pressure distribution techniques to prevent mechanical degradation during battery operation.Expand Specific Solutions03 Pressure effects on ionic conductivity in chloride SSEs

Stack pressure significantly influences the ionic conductivity of chloride solid-state electrolytes by affecting grain boundary resistance and bulk properties. Moderate pressure can enhance conductivity by improving particle-to-particle contact and reducing void spaces, while excessive pressure may cause material degradation. The relationship between applied pressure and ionic conductivity is non-linear and depends on the specific chloride composition, crystallinity, and microstructure of the electrolyte material.Expand Specific Solutions04 Manufacturing processes for pressure-optimized chloride SSEs

Specialized manufacturing techniques are employed to produce chloride solid-state electrolytes that perform optimally under stack pressure. These include controlled sintering processes, hot pressing, cold isostatic pressing, and tape casting methods that consider the final pressure conditions in the battery. The processing parameters significantly influence the microstructure, density, and mechanical properties of the electrolyte, which in turn affect how the material responds to applied pressure during battery operation.Expand Specific Solutions05 Cell design considerations for pressure management in chloride SSE batteries

Battery cell designs incorporating chloride solid-state electrolytes must account for pressure distribution and management throughout the battery stack. This includes the development of specialized compression systems, pressure-homogenizing layers, and cell housing designs that maintain optimal pressure during thermal cycling and volume changes. Advanced pressure monitoring systems and adaptive compression mechanisms are being integrated to ensure consistent performance and prevent localized pressure points that could lead to electrolyte failure.Expand Specific Solutions

Leading Companies in Chloride SSE Development

The solid-state electrolyte (SSE) chloride pouch-cell integration market is currently in its early growth phase, characterized by significant R&D investments but limited commercial deployment. The global market for chloride SSEs is projected to expand rapidly as part of the broader $6-8 billion solid-state battery market by 2030. Technologically, pressure management and cycling stability remain key challenges. Leading automotive manufacturers like Toyota, BMW, and GM are actively developing proprietary solutions, while specialized battery companies including LG Energy Solution, Microvast, and 24M Technologies are advancing integration techniques. Research institutions such as Central South University and Forschungszentrum Jülich are contributing fundamental innovations in stack pressure optimization. The technology remains at TRL 4-6, with most players focusing on laboratory-scale demonstrations while preparing for pilot production within 2-3 years.

LG Energy Solution Ltd.

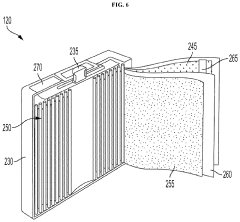

Technical Solution: LG Energy Solution has developed advanced pouch-cell integration technology for chloride solid-state electrolytes (SSEs) that addresses key challenges in stack pressure management and cycling stability. Their approach utilizes a gradient pressure distribution system within pouch cells that maintains optimal contact between electrodes and the chloride SSE during cycling. The technology incorporates specialized pressure-regulating layers that accommodate volume changes during lithium-ion intercalation/deintercalation processes. LG's solution includes a proprietary interface engineering method that creates stable electrode-electrolyte interfaces specifically designed for chloride-based SSEs, reducing interfacial resistance and preventing dendrite formation. Their pouch cells employ a multi-layer composite structure with controlled thickness variations to ensure uniform pressure distribution across the entire cell area, even during thousands of charge-discharge cycles. Additionally, LG has developed specialized sealing techniques for chloride SSE pouch cells that maintain hermeticity while allowing for minimal mechanical stress transfer to the brittle electrolyte components.

Strengths: Superior pressure distribution system that maintains consistent electrode-electrolyte contact; advanced interface engineering that reduces resistance and prevents dendrite formation; specialized sealing techniques compatible with chloride SSEs. Weaknesses: Higher manufacturing complexity compared to conventional lithium-ion batteries; potential challenges with scaling production to commercial volumes; relatively higher cost due to specialized materials and processing requirements.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered an innovative approach to pouch-cell integration of chloride solid-state electrolytes (SSEs) focused on optimizing stack pressure and cycling performance. Their technology utilizes a dynamic pressure regulation system that automatically adjusts compression forces throughout the battery's operational lifetime. Toyota's solution incorporates a composite chloride electrolyte structure with engineered grain boundaries that enhance ion conductivity while maintaining mechanical integrity under varying pressure conditions. The company has developed specialized pouch cell designs with reinforced edge sealing that prevents moisture ingress—critical for chloride SSEs which are typically hygroscopic. Their system employs thin, flexible pressure distribution plates made from proprietary alloys that maintain uniform compression across the cell stack while accommodating volumetric changes during cycling. Toyota's approach also features a thermal management system specifically designed for chloride SSE pouch cells, which maintains optimal operating temperatures to maximize conductivity while preventing degradation of the chloride electrolyte interfaces. Additionally, they've implemented advanced manufacturing processes that enable precise control of stack pressure during cell assembly and formation.

Strengths: Dynamic pressure regulation system that adapts throughout battery life; composite electrolyte structure with enhanced ion conductivity; superior moisture protection critical for chloride SSEs; excellent thermal management integration. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; complex manufacturing process requiring specialized equipment; potential challenges with long-term stability of pressure regulation components under extreme temperature conditions.

Key Patents in Pouch-Cell Pressure Optimization

Solvent-reagent based synthesis of solid-state electrolytes

PatentPendingUS20240039038A1

Innovation

- A process involving contacting a lithium source with a phosphorus source in a solvent-reagent at 80° C to 120° C to form a precipitate of Li7-xPS6-xYx, where Y is Cl, Br, or I, using a solvent-reagent SyYw, and then collecting the precipitate, which can include Li7-xPS6-xClx, Li7-xPS6-xBrx, or Li7-xPS6-xIx, under controlled conditions to achieve phase purity and scalability.

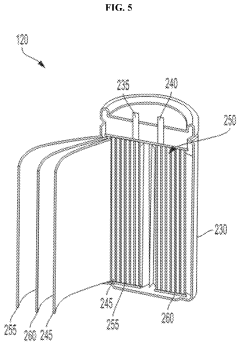

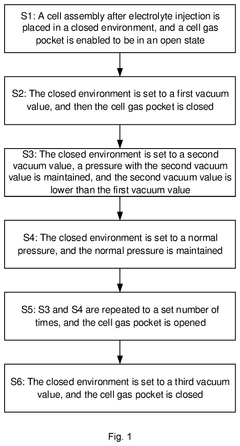

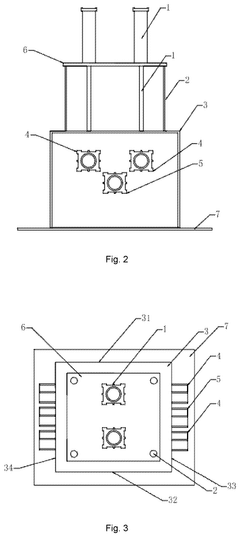

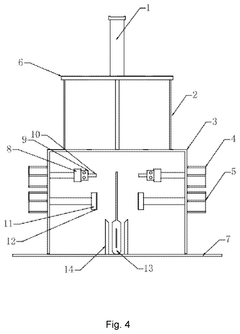

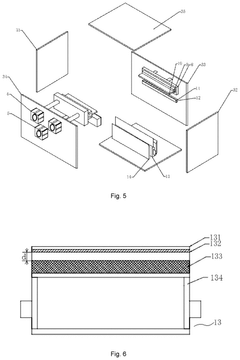

Electrolyte Infiltration Method and Apparatus for Pouch Cell, and Electrolyte Injection Machine

PatentPendingUS20240339740A1

Innovation

- An electrolyte infiltration method involving a series of vacuum pressure cycles within a closed environment to facilitate expansion and contraction of the cell, accelerating electrolyte infiltration by creating a pressure difference that enhances electrolyte penetration to the middle electrode sheet, combined with an infiltration apparatus utilizing splint cylinders and a lifting mechanism for precise control.

Safety and Reliability Assessment Framework

The safety and reliability assessment framework for pouch-cell integration of chloride solid-state electrolytes (SSEs) requires a comprehensive approach addressing both immediate operational risks and long-term performance stability. This framework must account for the unique challenges posed by stack pressure variations during cycling, which significantly impact cell performance and safety profiles.

A multi-tiered assessment methodology begins with baseline safety testing protocols specifically adapted for chloride-based SSEs, which exhibit distinct mechanical and chemical properties compared to oxide or sulfide alternatives. These protocols must include thermal runaway resistance evaluation, mechanical integrity assessment under various stack pressure conditions, and chemical stability testing at electrode-electrolyte interfaces where chloride species may participate in side reactions.

Reliability metrics must be established with particular attention to pressure distribution uniformity across the pouch cell architecture. Current data indicates that chloride SSEs demonstrate pressure-dependent ionic conductivity, with performance degradation observed at both insufficient and excessive stack pressures. The framework should incorporate in-situ pressure monitoring systems capable of detecting localized pressure variations that may lead to dendrite formation or mechanical failure.

Accelerated aging protocols represent another critical component, designed to simulate extended cycling under controlled pressure conditions. These tests should evaluate capacity retention, impedance growth, and mechanical integrity over projected lifetime usage patterns. Special consideration must be given to pressure relaxation phenomena observed in chloride SSEs, where initial compression settings may diminish over time, potentially compromising cell performance.

Failure mode and effects analysis (FMEA) specific to chloride SSE pouch cells constitutes an essential element of the framework. This analysis should catalog potential failure mechanisms including electrolyte fracture, delamination at interfaces, and chemical degradation pathways unique to chloride chemistry. Each failure mode must be assigned risk priority numbers based on severity, occurrence probability, and detection difficulty.

Statistical reliability models incorporating Weibull distribution analysis can provide valuable insights into failure patterns and lifetime predictions. These models should be calibrated using data from cells cycled under various pressure conditions to establish clear correlations between stack pressure management strategies and cell longevity.

Implementation of this framework requires specialized equipment capable of maintaining precise pressure control during cycling while simultaneously monitoring electrical performance parameters. The resulting data set will enable manufacturers to establish optimal pressure specifications and cycling protocols that maximize both safety margins and operational lifetime for chloride SSE pouch cells.

A multi-tiered assessment methodology begins with baseline safety testing protocols specifically adapted for chloride-based SSEs, which exhibit distinct mechanical and chemical properties compared to oxide or sulfide alternatives. These protocols must include thermal runaway resistance evaluation, mechanical integrity assessment under various stack pressure conditions, and chemical stability testing at electrode-electrolyte interfaces where chloride species may participate in side reactions.

Reliability metrics must be established with particular attention to pressure distribution uniformity across the pouch cell architecture. Current data indicates that chloride SSEs demonstrate pressure-dependent ionic conductivity, with performance degradation observed at both insufficient and excessive stack pressures. The framework should incorporate in-situ pressure monitoring systems capable of detecting localized pressure variations that may lead to dendrite formation or mechanical failure.

Accelerated aging protocols represent another critical component, designed to simulate extended cycling under controlled pressure conditions. These tests should evaluate capacity retention, impedance growth, and mechanical integrity over projected lifetime usage patterns. Special consideration must be given to pressure relaxation phenomena observed in chloride SSEs, where initial compression settings may diminish over time, potentially compromising cell performance.

Failure mode and effects analysis (FMEA) specific to chloride SSE pouch cells constitutes an essential element of the framework. This analysis should catalog potential failure mechanisms including electrolyte fracture, delamination at interfaces, and chemical degradation pathways unique to chloride chemistry. Each failure mode must be assigned risk priority numbers based on severity, occurrence probability, and detection difficulty.

Statistical reliability models incorporating Weibull distribution analysis can provide valuable insights into failure patterns and lifetime predictions. These models should be calibrated using data from cells cycled under various pressure conditions to establish clear correlations between stack pressure management strategies and cell longevity.

Implementation of this framework requires specialized equipment capable of maintaining precise pressure control during cycling while simultaneously monitoring electrical performance parameters. The resulting data set will enable manufacturers to establish optimal pressure specifications and cycling protocols that maximize both safety margins and operational lifetime for chloride SSE pouch cells.

Manufacturing Scalability Considerations

The scalability of manufacturing processes for pouch-cell integration of chloride solid-state electrolytes (SSEs) presents significant challenges that must be addressed for commercial viability. Current laboratory-scale production methods typically involve manual assembly processes that are difficult to translate to high-volume manufacturing environments. The application and maintenance of appropriate stack pressure during both assembly and long-term cycling requires specialized equipment and precise control systems that add complexity to production lines.

Material handling represents a critical bottleneck in scaling production. Chloride SSEs are often sensitive to environmental conditions, particularly moisture, necessitating controlled atmosphere environments throughout the manufacturing process. This requirement substantially increases facility costs and operational complexity compared to conventional lithium-ion battery production. Additionally, the brittle nature of many chloride SSEs creates challenges for high-speed handling equipment, potentially leading to higher material waste rates during scale-up.

Layer uniformity and thickness control become increasingly important at industrial scales. Minor variations that might be acceptable in laboratory settings can lead to significant performance inconsistencies across large production batches. Advanced quality control systems, including real-time monitoring of layer deposition and stack pressure distribution, will be essential for maintaining product consistency. These systems represent additional capital investment requirements for manufacturers.

The integration of chloride SSEs into existing battery production infrastructure presents another scaling challenge. Most current battery gigafactories are optimized for liquid electrolyte systems, requiring substantial modification to accommodate solid-state assembly processes. The specialized equipment needed for maintaining stack pressure during pouch cell sealing and formation cycles does not exist in conventional production lines, necessitating custom engineering solutions.

Cycle time optimization represents a significant economic hurdle. Laboratory-scale production often involves extended processing times that would be prohibitively expensive at industrial scales. Accelerating these processes without compromising the integrity of the chloride SSE layers or the critical interfaces between components will require substantial process engineering innovation. Current estimates suggest that production cycle times may be 2-3 times longer than conventional lithium-ion cells, significantly impacting manufacturing economics.

Supply chain considerations also impact scalability. The availability of high-purity precursor materials for chloride SSEs at industrial volumes remains limited, with few suppliers capable of meeting potential demand. Developing robust supply chains with appropriate quality control measures will be essential for supporting large-scale manufacturing operations and ensuring consistent product performance.

Material handling represents a critical bottleneck in scaling production. Chloride SSEs are often sensitive to environmental conditions, particularly moisture, necessitating controlled atmosphere environments throughout the manufacturing process. This requirement substantially increases facility costs and operational complexity compared to conventional lithium-ion battery production. Additionally, the brittle nature of many chloride SSEs creates challenges for high-speed handling equipment, potentially leading to higher material waste rates during scale-up.

Layer uniformity and thickness control become increasingly important at industrial scales. Minor variations that might be acceptable in laboratory settings can lead to significant performance inconsistencies across large production batches. Advanced quality control systems, including real-time monitoring of layer deposition and stack pressure distribution, will be essential for maintaining product consistency. These systems represent additional capital investment requirements for manufacturers.

The integration of chloride SSEs into existing battery production infrastructure presents another scaling challenge. Most current battery gigafactories are optimized for liquid electrolyte systems, requiring substantial modification to accommodate solid-state assembly processes. The specialized equipment needed for maintaining stack pressure during pouch cell sealing and formation cycles does not exist in conventional production lines, necessitating custom engineering solutions.

Cycle time optimization represents a significant economic hurdle. Laboratory-scale production often involves extended processing times that would be prohibitively expensive at industrial scales. Accelerating these processes without compromising the integrity of the chloride SSE layers or the critical interfaces between components will require substantial process engineering innovation. Current estimates suggest that production cycle times may be 2-3 times longer than conventional lithium-ion cells, significantly impacting manufacturing economics.

Supply chain considerations also impact scalability. The availability of high-purity precursor materials for chloride SSEs at industrial volumes remains limited, with few suppliers capable of meeting potential demand. Developing robust supply chains with appropriate quality control measures will be essential for supporting large-scale manufacturing operations and ensuring consistent product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!