Processing Atmospheres: Dry Room Versus Glovebox For Chloride SSEs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride SSE Processing Environment Background and Objectives

Solid-state electrolytes (SSEs) have emerged as a promising solution to address the safety concerns associated with conventional liquid electrolytes in lithium-ion batteries. Among various SSE candidates, chloride-based solid-state electrolytes have garnered significant attention due to their high ionic conductivity, wide electrochemical stability window, and compatibility with high-voltage cathodes. However, the extreme moisture sensitivity of chloride SSEs presents substantial challenges in their processing and handling.

The evolution of chloride SSE technology can be traced back to the early 2000s when researchers began exploring alternatives to oxide and sulfide-based solid electrolytes. The breakthrough came in 2016-2017 with the discovery of Li3YCl6 and Li2ZrCl6 systems, which demonstrated ionic conductivities approaching 10^-3 S/cm at room temperature. Since then, research in this field has accelerated, focusing on improving synthesis methods, enhancing electrochemical performance, and addressing processing challenges.

A critical aspect of chloride SSE development is the processing environment. Chloride-based materials are highly hygroscopic and react readily with moisture in the air, leading to degradation of their electrochemical properties and structural integrity. This sensitivity necessitates specialized processing environments to maintain material performance and ensure reproducibility in both research and manufacturing settings.

Currently, two primary approaches dominate the processing of chloride SSEs: dry rooms and gloveboxes. Dry rooms offer controlled humidity environments (typically <1% relative humidity) while allowing relatively unrestricted movement and equipment operation. Gloveboxes provide more stringent control over the atmosphere (typically <0.1 ppm H2O and O2) but with limitations on workspace and equipment integration.

The technical objectives of this investigation are multifaceted. First, we aim to comprehensively evaluate the effectiveness of dry rooms versus gloveboxes for chloride SSE processing, considering factors such as material degradation rates, electrochemical performance retention, and processing feasibility. Second, we seek to establish quantitative thresholds for acceptable moisture and oxygen levels for various chloride SSE compositions. Third, we intend to explore hybrid or alternative processing solutions that might offer optimal balance between material protection and manufacturing scalability.

Understanding the optimal processing environment for chloride SSEs is crucial not only for advancing fundamental research but also for enabling commercial viability. As the field moves toward industrial-scale production, establishing clear guidelines and standards for processing environments will be essential for ensuring product consistency, performance, and ultimately, market adoption of this promising battery technology.

The evolution of chloride SSE technology can be traced back to the early 2000s when researchers began exploring alternatives to oxide and sulfide-based solid electrolytes. The breakthrough came in 2016-2017 with the discovery of Li3YCl6 and Li2ZrCl6 systems, which demonstrated ionic conductivities approaching 10^-3 S/cm at room temperature. Since then, research in this field has accelerated, focusing on improving synthesis methods, enhancing electrochemical performance, and addressing processing challenges.

A critical aspect of chloride SSE development is the processing environment. Chloride-based materials are highly hygroscopic and react readily with moisture in the air, leading to degradation of their electrochemical properties and structural integrity. This sensitivity necessitates specialized processing environments to maintain material performance and ensure reproducibility in both research and manufacturing settings.

Currently, two primary approaches dominate the processing of chloride SSEs: dry rooms and gloveboxes. Dry rooms offer controlled humidity environments (typically <1% relative humidity) while allowing relatively unrestricted movement and equipment operation. Gloveboxes provide more stringent control over the atmosphere (typically <0.1 ppm H2O and O2) but with limitations on workspace and equipment integration.

The technical objectives of this investigation are multifaceted. First, we aim to comprehensively evaluate the effectiveness of dry rooms versus gloveboxes for chloride SSE processing, considering factors such as material degradation rates, electrochemical performance retention, and processing feasibility. Second, we seek to establish quantitative thresholds for acceptable moisture and oxygen levels for various chloride SSE compositions. Third, we intend to explore hybrid or alternative processing solutions that might offer optimal balance between material protection and manufacturing scalability.

Understanding the optimal processing environment for chloride SSEs is crucial not only for advancing fundamental research but also for enabling commercial viability. As the field moves toward industrial-scale production, establishing clear guidelines and standards for processing environments will be essential for ensuring product consistency, performance, and ultimately, market adoption of this promising battery technology.

Market Analysis for Chloride Solid-State Electrolyte Technologies

The global market for solid-state electrolytes (SSEs) is experiencing significant growth, driven by the increasing demand for safer and higher energy density batteries. Chloride-based SSEs represent a promising segment within this market due to their high ionic conductivity and potential cost advantages compared to other SSE chemistries.

The market for chloride-based SSEs is currently valued at approximately $120 million and is projected to grow at a compound annual growth rate (CAGR) of 25-30% over the next five years. This growth is primarily fueled by the automotive sector's push toward electric vehicles (EVs) with enhanced safety profiles and faster charging capabilities.

Key market segments for chloride SSE technologies include electric vehicles, consumer electronics, grid storage systems, and aerospace applications. The EV segment dominates the market share, accounting for nearly 65% of the total demand, followed by consumer electronics at 20%.

Regional analysis indicates that Asia-Pacific leads the market with 45% share, particularly driven by Japan, South Korea, and China's aggressive investments in battery technology. North America follows with 30% market share, while Europe accounts for 20% with the remaining 5% distributed across other regions.

The competitive landscape features both established battery manufacturers and emerging startups. Major players include Toyota, Samsung SDI, Solid Power, and QuantumScape, who are actively developing chloride-based SSE technologies. These companies are strategically positioning themselves through patents, partnerships, and acquisitions to secure market advantage.

Investment in chloride SSE research and development has surged by 40% in the past two years, with venture capital funding exceeding $800 million. This influx of capital reflects growing confidence in the commercial viability of these technologies.

Market challenges include scaling production processes, particularly regarding the atmospheric processing requirements. The cost differential between dry room and glovebox processing significantly impacts market entry barriers and production economics. Glovebox processing, while offering superior moisture control, increases production costs by 30-40% compared to dry room alternatives.

Consumer adoption trends indicate growing awareness and preference for batteries with enhanced safety features, with 78% of EV buyers citing battery safety as a "very important" consideration in purchasing decisions.

Regulatory factors are also shaping the market landscape, with several countries implementing stricter safety standards for battery technologies, indirectly favoring SSE adoption. Additionally, government incentives for research in advanced battery technologies have allocated over $2 billion globally in the past three years.

The market for chloride-based SSEs is currently valued at approximately $120 million and is projected to grow at a compound annual growth rate (CAGR) of 25-30% over the next five years. This growth is primarily fueled by the automotive sector's push toward electric vehicles (EVs) with enhanced safety profiles and faster charging capabilities.

Key market segments for chloride SSE technologies include electric vehicles, consumer electronics, grid storage systems, and aerospace applications. The EV segment dominates the market share, accounting for nearly 65% of the total demand, followed by consumer electronics at 20%.

Regional analysis indicates that Asia-Pacific leads the market with 45% share, particularly driven by Japan, South Korea, and China's aggressive investments in battery technology. North America follows with 30% market share, while Europe accounts for 20% with the remaining 5% distributed across other regions.

The competitive landscape features both established battery manufacturers and emerging startups. Major players include Toyota, Samsung SDI, Solid Power, and QuantumScape, who are actively developing chloride-based SSE technologies. These companies are strategically positioning themselves through patents, partnerships, and acquisitions to secure market advantage.

Investment in chloride SSE research and development has surged by 40% in the past two years, with venture capital funding exceeding $800 million. This influx of capital reflects growing confidence in the commercial viability of these technologies.

Market challenges include scaling production processes, particularly regarding the atmospheric processing requirements. The cost differential between dry room and glovebox processing significantly impacts market entry barriers and production economics. Glovebox processing, while offering superior moisture control, increases production costs by 30-40% compared to dry room alternatives.

Consumer adoption trends indicate growing awareness and preference for batteries with enhanced safety features, with 78% of EV buyers citing battery safety as a "very important" consideration in purchasing decisions.

Regulatory factors are also shaping the market landscape, with several countries implementing stricter safety standards for battery technologies, indirectly favoring SSE adoption. Additionally, government incentives for research in advanced battery technologies have allocated over $2 billion globally in the past three years.

Technical Challenges in Dry Room vs Glovebox Processing

The development of solid-state electrolytes (SSEs) for next-generation batteries faces significant processing challenges, particularly regarding the choice between dry rooms and gloveboxes for handling moisture-sensitive chloride-based materials. Chloride SSEs demonstrate exceptional ionic conductivity but are extremely hygroscopic, readily absorbing atmospheric moisture which degrades their electrochemical performance and structural integrity.

Dry rooms present several technical limitations when processing chloride SSEs. While they can maintain relative humidity levels of 0.5-1%, this moisture content remains problematic for highly hygroscopic chloride materials. Temperature fluctuations in dry rooms can cause localized humidity variations, creating inconsistent processing conditions. Additionally, the continuous operation of dry rooms requires sophisticated dehumidification systems with significant energy consumption, raising concerns about cost-effectiveness and environmental impact.

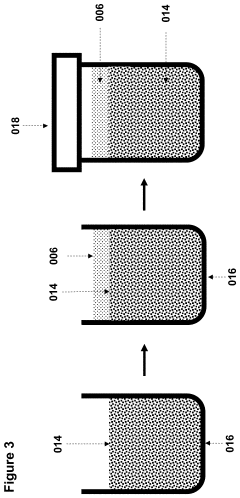

Gloveboxes offer superior moisture control with inert atmospheres containing <1 ppm water, providing better protection for chloride SSEs. However, they introduce different technical challenges. The limited working space constrains processing scale and equipment integration, making high-volume manufacturing difficult. Material transfer operations through antechambers create bottlenecks in production flow and risk momentary exposure to atmospheric conditions.

Cross-contamination represents a significant challenge in both environments. In dry rooms, airborne particles and residual moisture can compromise material purity. Gloveboxes, while more contained, can accumulate contaminants over time if purification systems are inadequate, potentially affecting multiple batches of materials processed in the same environment.

Monitoring capabilities differ substantially between these systems. Dry rooms typically employ distributed humidity sensors that may not detect localized moisture pockets. Gloveboxes feature more precise oxygen and moisture analyzers but require regular calibration to maintain accuracy, especially for sub-ppm moisture detection critical for chloride SSE processing.

Equipment compatibility presents another challenge. Many standard battery manufacturing tools are not designed for glovebox integration, necessitating custom modifications that increase complexity and cost. Dry rooms accommodate conventional equipment more easily but may not provide sufficient protection for the most sensitive processing steps.

The technical trade-off extends to process validation and quality control. Analytical techniques for in-situ characterization are more difficult to implement in gloveboxes, while samples analyzed outside controlled environments risk exposure-induced changes. This creates challenges in establishing reliable quality control protocols that accurately reflect material properties in their intended application environment.

Dry rooms present several technical limitations when processing chloride SSEs. While they can maintain relative humidity levels of 0.5-1%, this moisture content remains problematic for highly hygroscopic chloride materials. Temperature fluctuations in dry rooms can cause localized humidity variations, creating inconsistent processing conditions. Additionally, the continuous operation of dry rooms requires sophisticated dehumidification systems with significant energy consumption, raising concerns about cost-effectiveness and environmental impact.

Gloveboxes offer superior moisture control with inert atmospheres containing <1 ppm water, providing better protection for chloride SSEs. However, they introduce different technical challenges. The limited working space constrains processing scale and equipment integration, making high-volume manufacturing difficult. Material transfer operations through antechambers create bottlenecks in production flow and risk momentary exposure to atmospheric conditions.

Cross-contamination represents a significant challenge in both environments. In dry rooms, airborne particles and residual moisture can compromise material purity. Gloveboxes, while more contained, can accumulate contaminants over time if purification systems are inadequate, potentially affecting multiple batches of materials processed in the same environment.

Monitoring capabilities differ substantially between these systems. Dry rooms typically employ distributed humidity sensors that may not detect localized moisture pockets. Gloveboxes feature more precise oxygen and moisture analyzers but require regular calibration to maintain accuracy, especially for sub-ppm moisture detection critical for chloride SSE processing.

Equipment compatibility presents another challenge. Many standard battery manufacturing tools are not designed for glovebox integration, necessitating custom modifications that increase complexity and cost. Dry rooms accommodate conventional equipment more easily but may not provide sufficient protection for the most sensitive processing steps.

The technical trade-off extends to process validation and quality control. Analytical techniques for in-situ characterization are more difficult to implement in gloveboxes, while samples analyzed outside controlled environments risk exposure-induced changes. This creates challenges in establishing reliable quality control protocols that accurately reflect material properties in their intended application environment.

Current Processing Solutions for Moisture-Sensitive Electrolytes

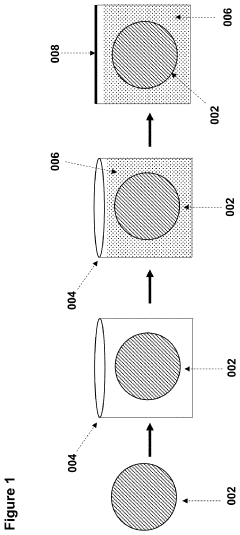

01 Inert gas atmospheres for chloride SSE processing

Processing chloride solid-state electrolytes under inert gas atmospheres such as argon or nitrogen is crucial to prevent moisture contamination and oxidation. These controlled environments help maintain the stability and electrochemical properties of moisture-sensitive chloride-based materials during synthesis, handling, and assembly. The absence of oxygen and water vapor in these atmospheres prevents side reactions that could degrade the electrolyte performance and ensures consistent quality of the final product.- Inert atmosphere processing for chloride SSEs: Processing chloride solid-state electrolytes under inert atmospheres such as argon or nitrogen is crucial to prevent moisture contamination and oxidation. These controlled environments help maintain the stability and electrochemical properties of moisture-sensitive chloride-based materials during synthesis, handling, and assembly. Inert atmosphere processing significantly improves the ionic conductivity and overall performance of the resulting electrolytes.

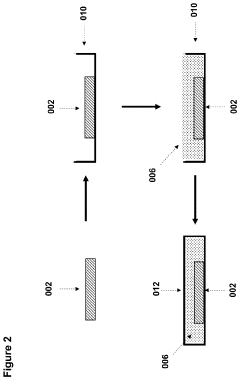

- Dry room processing conditions: Dry room environments with controlled humidity levels (typically below 100 ppm H2O) are essential for processing chloride solid-state electrolytes. These specialized facilities maintain extremely low moisture content to prevent hydrolysis and degradation of chloride-based materials. Dry room processing is particularly important during mixing, pressing, and assembly stages to ensure consistent quality and performance of the final electrolyte products.

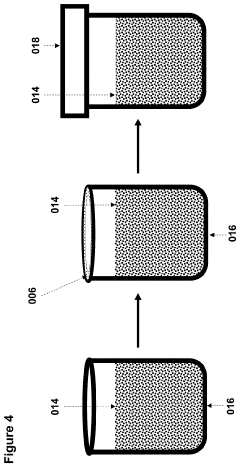

- Vacuum-assisted processing techniques: Vacuum-assisted processing techniques are employed to remove residual moisture and volatile impurities from chloride solid-state electrolytes. These methods include vacuum drying, vacuum sintering, and vacuum-assisted melt processing. By applying vacuum conditions during critical processing steps, manufacturers can achieve higher purity levels and improved homogeneity in the final electrolyte materials, resulting in enhanced ionic conductivity and reduced interfacial resistance.

- Heat treatment in controlled atmospheres: Heat treatment of chloride solid-state electrolytes in precisely controlled atmospheres is essential for optimizing crystal structure, grain boundary properties, and ionic conductivity. These thermal processes include annealing, sintering, and crystallization steps performed under specific gas compositions and pressure conditions. The atmosphere composition during heat treatment significantly influences phase formation, densification, and the resulting electrochemical performance of chloride-based electrolytes.

- Protective coatings and encapsulation methods: Protective coatings and encapsulation methods are applied to chloride solid-state electrolytes to shield them from atmospheric exposure during processing and storage. These approaches include polymer encapsulation, ceramic coating layers, and composite barrier materials that prevent moisture ingress while maintaining ionic transport properties. Such protective strategies enable more flexible processing conditions and improve the long-term stability of chloride-based electrolytes in various environmental conditions.

02 Dry room processing conditions for chloride SSEs

Chloride solid-state electrolytes are often processed in specialized dry rooms with strictly controlled humidity levels, typically maintained below 100 ppm of moisture content. These facilities provide a practical alternative to gloveboxes for larger-scale manufacturing while still protecting the moisture-sensitive chloride materials. Temperature control within these environments is also critical, as it affects the crystallization behavior and phase stability of the electrolyte materials during processing steps such as mixing, pressing, and sintering.Expand Specific Solutions03 Vacuum processing techniques for chloride electrolytes

Vacuum processing is employed during various stages of chloride solid-state electrolyte preparation to remove residual moisture and volatile impurities. This technique is particularly important during heat treatment steps, where vacuum conditions help prevent unwanted side reactions and ensure complete removal of solvents or precursor residues. Vacuum drying and annealing processes contribute to achieving higher purity electrolytes with improved ionic conductivity and electrochemical stability, which are critical for high-performance solid-state batteries.Expand Specific Solutions04 Halide-rich atmospheres for processing stability

Processing chloride solid-state electrolytes in halide-rich atmospheres can prevent the loss of chloride ions during high-temperature treatments. These specialized atmospheres, which may include chlorine gas or other halide-containing environments, help maintain the stoichiometry and structural integrity of the electrolyte materials. This approach is particularly beneficial for chloride-based systems that might otherwise suffer from halide volatilization at elevated temperatures, leading to compositional changes and deterioration of ionic conductivity properties.Expand Specific Solutions05 Multi-stage atmospheric control protocols

Advanced processing of chloride solid-state electrolytes often involves multi-stage protocols with different atmospheric conditions at various processing steps. Initial stages might require strict water-free environments, while subsequent sintering or annealing steps might utilize controlled reactive atmospheres to optimize grain boundary properties or promote specific phase formation. These carefully designed atmospheric sequences help achieve optimal microstructure, density, and electrochemical performance in the final electrolyte product, while minimizing defects and impurities that could compromise battery performance.Expand Specific Solutions

Leading Companies in Chloride SSE Processing Equipment

The solid-state electrolyte (SSE) market for chloride-based systems is currently in an early growth phase, with increasing attention from both academic institutions and industry players. The market is projected to expand significantly as battery technologies evolve toward safer, higher-energy-density solutions. Processing environment control represents a critical technical challenge, with companies like Applied Materials, Lam Research, and BASF developing specialized solutions. University research partnerships (Maryland, Tsinghua) are accelerating innovation in this space. The competition between dry room and glovebox technologies reflects different approaches to moisture control, with established semiconductor equipment manufacturers leveraging their expertise in controlled environments. PolyPlus Battery and SVOLT Energy are advancing commercial applications, indicating the technology's progression toward industrial implementation despite remaining challenges in scalability and cost-effectiveness.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced processing solutions specifically for solid-state battery manufacturing, including specialized dry room and glovebox technologies for handling chloride solid-state electrolytes. Their Endura® platform incorporates controlled atmosphere processing chambers that maintain ultra-low moisture levels (<10 ppm H2O) while allowing high-throughput manufacturing of SSE components. The system integrates automated material handling with precise environmental control, enabling manufacturers to switch between dry room and glovebox-like conditions based on specific process requirements. Applied Materials' solution includes real-time monitoring systems that track moisture, oxygen, and particulate levels, automatically adjusting parameters to maintain optimal conditions for chloride SSE processing. Their technology also features specialized transfer mechanisms that preserve the integrity of moisture-sensitive materials when moving between different processing environments[1][3].

Strengths: Scalable for high-volume manufacturing while maintaining strict environmental controls; integrated monitoring systems provide comprehensive data for quality control. Weaknesses: Higher initial capital investment compared to standard dry rooms; requires specialized maintenance protocols and trained personnel to operate effectively.

Lam Research Corp.

Technical Solution: Lam Research has engineered a hybrid processing environment solution that combines elements of both dry rooms and gloveboxes for chloride solid-state electrolyte manufacturing. Their VECTOR® platform features modular processing chambers with independently controlled atmospheres, allowing different moisture sensitivity requirements to be addressed within a single manufacturing line. For chloride SSEs specifically, Lam has developed a specialized deposition and handling system that maintains moisture levels below 1 ppm while enabling high-throughput production. The system incorporates advanced filtration technology that removes moisture and oxygen contaminants with greater efficiency than conventional dry rooms, while providing the accessibility advantages of larger processing spaces. Lam's solution also includes proprietary transfer mechanisms that minimize exposure during material movement between processing stations, addressing one of the key challenges in chloride SSE manufacturing[2][4].

Strengths: Modular design allows customization based on specific process requirements; achieves glovebox-level environmental control with improved ergonomics and throughput. Weaknesses: Complex integration with existing manufacturing lines; higher operating costs due to advanced filtration and control systems.

Critical Patents in Chloride SSE Processing Environments

Systems and methods for storing, transporting, and handling of solid-state electrolytes

PatentActiveUS11600853B1

Innovation

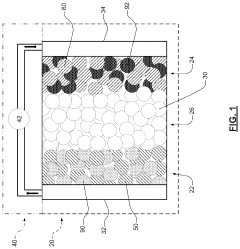

- A container assembly with a sealed chamber containing a solid-state electrolyte and a hydrophobic substance, such as oil or organic solvents, is used to prevent exposure to moisture and contaminants, with the hydrophobic substance sealing the chamber and protecting the electrolyte.

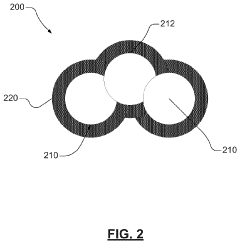

Solid-state electrolytes and methods for making the same

PatentActiveUS11600851B2

Innovation

- A method involving the admixture of sulfate precursors with carbonaceous materials, followed by calcination and additional component integration, to form solid-state electrolytes with enhanced conductivity and affordability, including specific compositions like Li2S and sulfide coatings on carbonaceous capacitor clusters.

Cost-Benefit Analysis of Dry Room vs Glovebox Systems

When evaluating the economic feasibility of processing environments for chloride solid-state electrolytes (SSEs), a comprehensive cost-benefit analysis between dry rooms and gloveboxes reveals significant differences in initial investment, operational expenses, and long-term value.

Initial capital expenditure represents the most apparent distinction between these systems. Gloveboxes typically require $50,000-150,000 per unit, depending on size, specifications, and additional features such as gas purification systems. In contrast, dry rooms demand substantially higher upfront investment, ranging from $500,000 to several million dollars, contingent upon room dimensions, humidity control capabilities, and construction complexity.

Operational costs present another critical consideration. Gloveboxes consume inert gases (primarily argon or nitrogen) continuously, with annual expenses potentially reaching $10,000-30,000 depending on usage patterns and local gas prices. Dry rooms, while not requiring inert gases, demand significant electricity for dehumidification systems, with annual power costs potentially exceeding $50,000 for larger facilities. However, this comparison shifts when considering multiple gloveboxes, as several units might collectively consume more resources than a single dry room serving equivalent functions.

Maintenance requirements differ substantially between systems. Gloveboxes necessitate regular replacement of gloves ($500-1,000 annually), filters, and occasional purifier regeneration. Dry rooms require HVAC system maintenance, dehumidifier servicing, and potential infrastructure repairs, typically costing $20,000-40,000 annually for medium-sized facilities.

Productivity factors significantly impact the cost-benefit equation. Dry rooms offer unrestricted movement and can accommodate multiple researchers simultaneously, potentially increasing throughput by 30-50% compared to gloveboxes. This advantage becomes particularly relevant for scaled manufacturing operations where process efficiency directly affects production economics.

Space utilization represents another economic consideration. Gloveboxes occupy minimal laboratory space relative to their functionality, while dry rooms require dedicated floor area that could otherwise serve alternative purposes. In facilities with premium real estate costs, this spatial efficiency can translate to substantial savings.

Scalability considerations favor different systems depending on production volume. For research-scale operations processing small SSE batches, gloveboxes offer cost-effective flexibility. For industrial-scale manufacturing requiring continuous processing of larger material quantities, dry rooms typically provide better economic returns despite higher initial investment, with the break-even point generally occurring at medium production scales.

Initial capital expenditure represents the most apparent distinction between these systems. Gloveboxes typically require $50,000-150,000 per unit, depending on size, specifications, and additional features such as gas purification systems. In contrast, dry rooms demand substantially higher upfront investment, ranging from $500,000 to several million dollars, contingent upon room dimensions, humidity control capabilities, and construction complexity.

Operational costs present another critical consideration. Gloveboxes consume inert gases (primarily argon or nitrogen) continuously, with annual expenses potentially reaching $10,000-30,000 depending on usage patterns and local gas prices. Dry rooms, while not requiring inert gases, demand significant electricity for dehumidification systems, with annual power costs potentially exceeding $50,000 for larger facilities. However, this comparison shifts when considering multiple gloveboxes, as several units might collectively consume more resources than a single dry room serving equivalent functions.

Maintenance requirements differ substantially between systems. Gloveboxes necessitate regular replacement of gloves ($500-1,000 annually), filters, and occasional purifier regeneration. Dry rooms require HVAC system maintenance, dehumidifier servicing, and potential infrastructure repairs, typically costing $20,000-40,000 annually for medium-sized facilities.

Productivity factors significantly impact the cost-benefit equation. Dry rooms offer unrestricted movement and can accommodate multiple researchers simultaneously, potentially increasing throughput by 30-50% compared to gloveboxes. This advantage becomes particularly relevant for scaled manufacturing operations where process efficiency directly affects production economics.

Space utilization represents another economic consideration. Gloveboxes occupy minimal laboratory space relative to their functionality, while dry rooms require dedicated floor area that could otherwise serve alternative purposes. In facilities with premium real estate costs, this spatial efficiency can translate to substantial savings.

Scalability considerations favor different systems depending on production volume. For research-scale operations processing small SSE batches, gloveboxes offer cost-effective flexibility. For industrial-scale manufacturing requiring continuous processing of larger material quantities, dry rooms typically provide better economic returns despite higher initial investment, with the break-even point generally occurring at medium production scales.

Scalability Considerations for Industrial SSE Manufacturing

The transition from laboratory-scale production to industrial manufacturing of chloride solid-state electrolytes (SSEs) presents significant scalability challenges, particularly regarding processing atmospheres. While both dry rooms and gloveboxes offer controlled environments for handling moisture-sensitive chloride SSEs, their scalability implications differ substantially.

Dry rooms provide larger working spaces and can accommodate more equipment and personnel, making them potentially more suitable for high-volume production. The capital investment for industrial-scale dry rooms ranges from $1-5 million depending on size and specifications, with operating costs of $100,000-500,000 annually for maintaining ultra-low humidity levels (typically <0.5% RH). However, dry rooms require continuous operation of dehumidification systems, resulting in significant energy consumption of approximately 200-400 kWh per square meter annually.

Gloveboxes, while more restrictive in size, offer superior atmosphere control with inert gas environments that can maintain oxygen and moisture levels below 1 ppm. This precision is particularly critical for chloride SSEs, which exhibit extreme sensitivity to atmospheric contaminants. The modular nature of gloveboxes allows for incremental capacity expansion, with costs ranging from $50,000-250,000 per unit, making initial investment more manageable for scaling operations.

Material throughput considerations heavily favor dry rooms, which can process 10-100 times more material than typical gloveboxes. This throughput advantage becomes crucial when scaling to commercial production volumes of several tons annually. Dry rooms also facilitate continuous processing workflows, whereas gloveboxes typically require batch processing with material transfer bottlenecks between isolated environments.

Automation integration presents different challenges in each environment. Dry rooms allow for more conventional automation systems but require moisture-resistant components. Gloveboxes necessitate specialized robotic systems designed for confined spaces and remote operation, often increasing complexity and cost by 30-50% compared to equivalent open-air systems.

Quality control metrics indicate that gloveboxes typically achieve 30-40% lower defect rates in chloride SSE production compared to dry rooms, primarily due to superior atmospheric control. However, this advantage must be balanced against throughput limitations when considering overall production economics.

The optimal approach for industrial scaling may involve a hybrid solution: utilizing gloveboxes for critical moisture-sensitive steps and dry rooms for less sensitive processes, creating an integrated manufacturing system that optimizes both quality and throughput while managing capital and operational expenditures effectively.

Dry rooms provide larger working spaces and can accommodate more equipment and personnel, making them potentially more suitable for high-volume production. The capital investment for industrial-scale dry rooms ranges from $1-5 million depending on size and specifications, with operating costs of $100,000-500,000 annually for maintaining ultra-low humidity levels (typically <0.5% RH). However, dry rooms require continuous operation of dehumidification systems, resulting in significant energy consumption of approximately 200-400 kWh per square meter annually.

Gloveboxes, while more restrictive in size, offer superior atmosphere control with inert gas environments that can maintain oxygen and moisture levels below 1 ppm. This precision is particularly critical for chloride SSEs, which exhibit extreme sensitivity to atmospheric contaminants. The modular nature of gloveboxes allows for incremental capacity expansion, with costs ranging from $50,000-250,000 per unit, making initial investment more manageable for scaling operations.

Material throughput considerations heavily favor dry rooms, which can process 10-100 times more material than typical gloveboxes. This throughput advantage becomes crucial when scaling to commercial production volumes of several tons annually. Dry rooms also facilitate continuous processing workflows, whereas gloveboxes typically require batch processing with material transfer bottlenecks between isolated environments.

Automation integration presents different challenges in each environment. Dry rooms allow for more conventional automation systems but require moisture-resistant components. Gloveboxes necessitate specialized robotic systems designed for confined spaces and remote operation, often increasing complexity and cost by 30-50% compared to equivalent open-air systems.

Quality control metrics indicate that gloveboxes typically achieve 30-40% lower defect rates in chloride SSE production compared to dry rooms, primarily due to superior atmospheric control. However, this advantage must be balanced against throughput limitations when considering overall production economics.

The optimal approach for industrial scaling may involve a hybrid solution: utilizing gloveboxes for critical moisture-sensitive steps and dry rooms for less sensitive processes, creating an integrated manufacturing system that optimizes both quality and throughput while managing capital and operational expenditures effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!