Patent Landscape For Chloride Solid Electrolytes, 2016–2025

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride Solid Electrolyte Technology Background and Objectives

Solid-state batteries represent a significant advancement in energy storage technology, offering potential improvements in safety, energy density, and longevity compared to conventional liquid electrolyte batteries. Within this domain, chloride solid electrolytes have emerged as promising materials for next-generation battery systems. The development of these electrolytes has accelerated notably between 2016 and 2025, driven by increasing demands for safer and more efficient energy storage solutions.

Historically, solid electrolytes based on oxide and sulfide materials dominated research attention. However, chloride-based solid electrolytes have gained significant traction due to their unique combination of high ionic conductivity, relatively wide electrochemical stability windows, and potentially lower manufacturing costs. The evolution of chloride solid electrolytes can be traced back to fundamental research in the early 2000s, with breakthrough developments occurring from 2016 onward.

The primary technical objective in this field is to develop chloride solid electrolytes that achieve room-temperature ionic conductivities comparable to or exceeding those of liquid electrolytes (>10^-3 S/cm) while maintaining excellent electrochemical stability against both anode and cathode materials. Additionally, researchers aim to address challenges related to interfacial resistance, mechanical properties, and long-term stability under various operating conditions.

Patent activities in chloride solid electrolytes have shown exponential growth since 2016, reflecting increased industrial interest and investment. This surge in patent filings indicates a transition from primarily academic research to commercial development efforts. Key patent clusters focus on novel chloride compositions, synthesis methods, interface engineering, and integration techniques for full battery systems.

The technological trajectory suggests several critical development phases: initial discovery and characterization of promising chloride systems (2016-2018), optimization of composition and synthesis (2018-2020), interface engineering and cell integration (2020-2022), and scaling toward commercial viability (2022-2025). Each phase has contributed essential knowledge and innovations that collectively advance the field toward practical applications.

Current research emphasizes addressing remaining challenges, including chemical stability against moisture, mechanical integrity during cycling, and cost-effective manufacturing processes. The ultimate goal is to enable commercial deployment of chloride solid electrolyte-based batteries that can outperform conventional lithium-ion batteries in terms of safety, energy density, charging speed, and operational lifetime.

Historically, solid electrolytes based on oxide and sulfide materials dominated research attention. However, chloride-based solid electrolytes have gained significant traction due to their unique combination of high ionic conductivity, relatively wide electrochemical stability windows, and potentially lower manufacturing costs. The evolution of chloride solid electrolytes can be traced back to fundamental research in the early 2000s, with breakthrough developments occurring from 2016 onward.

The primary technical objective in this field is to develop chloride solid electrolytes that achieve room-temperature ionic conductivities comparable to or exceeding those of liquid electrolytes (>10^-3 S/cm) while maintaining excellent electrochemical stability against both anode and cathode materials. Additionally, researchers aim to address challenges related to interfacial resistance, mechanical properties, and long-term stability under various operating conditions.

Patent activities in chloride solid electrolytes have shown exponential growth since 2016, reflecting increased industrial interest and investment. This surge in patent filings indicates a transition from primarily academic research to commercial development efforts. Key patent clusters focus on novel chloride compositions, synthesis methods, interface engineering, and integration techniques for full battery systems.

The technological trajectory suggests several critical development phases: initial discovery and characterization of promising chloride systems (2016-2018), optimization of composition and synthesis (2018-2020), interface engineering and cell integration (2020-2022), and scaling toward commercial viability (2022-2025). Each phase has contributed essential knowledge and innovations that collectively advance the field toward practical applications.

Current research emphasizes addressing remaining challenges, including chemical stability against moisture, mechanical integrity during cycling, and cost-effective manufacturing processes. The ultimate goal is to enable commercial deployment of chloride solid electrolyte-based batteries that can outperform conventional lithium-ion batteries in terms of safety, energy density, charging speed, and operational lifetime.

Market Demand Analysis for Chloride Solid Electrolytes

The global market for solid-state batteries has witnessed significant growth in recent years, with chloride solid electrolytes emerging as a promising segment within this domain. Market analysis indicates that the demand for chloride solid electrolytes is primarily driven by the automotive industry's shift towards electric vehicles (EVs), which require safer and higher energy density batteries than conventional lithium-ion batteries with liquid electrolytes.

Between 2016 and 2025, the market demand for chloride solid electrolytes has been projected to grow at a compound annual growth rate exceeding 25%, reflecting the increasing interest in this technology. This growth trajectory correlates with the surge in patent filings observed during this period, particularly from major automotive manufacturers and battery technology companies.

Consumer electronics represents another substantial market segment driving demand for chloride solid electrolytes. The need for longer-lasting, faster-charging, and safer batteries in smartphones, laptops, and wearable devices has created significant market pull for advanced solid electrolyte technologies, including chloride-based systems.

Market research indicates that Asia-Pacific, particularly Japan, South Korea, and China, dominates the demand landscape for chloride solid electrolytes. This regional concentration aligns with the patent filing patterns observed during 2016-2025, where Asian corporations and research institutions have been particularly active in developing chloride-based solid electrolyte technologies.

The energy storage sector presents another growing market for chloride solid electrolytes. As renewable energy integration increases globally, the demand for efficient and safe energy storage solutions has risen correspondingly. Chloride solid electrolytes offer potential advantages in grid-scale storage applications due to their thermal stability and safety characteristics.

Market analysis reveals that end-users are primarily concerned with five key performance indicators when evaluating chloride solid electrolytes: ionic conductivity, electrochemical stability window, mechanical properties, interfacial stability, and manufacturing scalability. The patent landscape from 2016-2025 shows concentrated efforts to address these specific market requirements.

Despite the promising growth projections, market adoption faces challenges related to manufacturing costs and scalability. Current production methods for high-purity chloride solid electrolytes remain expensive compared to conventional liquid electrolyte systems. However, the patent landscape shows increasing focus on cost-effective synthesis methods, suggesting that market barriers may diminish as technology matures.

The defense and aerospace sectors represent smaller but strategically important market segments with specific requirements for high-performance, safety-critical battery systems where chloride solid electrolytes could provide significant advantages over existing technologies.

Between 2016 and 2025, the market demand for chloride solid electrolytes has been projected to grow at a compound annual growth rate exceeding 25%, reflecting the increasing interest in this technology. This growth trajectory correlates with the surge in patent filings observed during this period, particularly from major automotive manufacturers and battery technology companies.

Consumer electronics represents another substantial market segment driving demand for chloride solid electrolytes. The need for longer-lasting, faster-charging, and safer batteries in smartphones, laptops, and wearable devices has created significant market pull for advanced solid electrolyte technologies, including chloride-based systems.

Market research indicates that Asia-Pacific, particularly Japan, South Korea, and China, dominates the demand landscape for chloride solid electrolytes. This regional concentration aligns with the patent filing patterns observed during 2016-2025, where Asian corporations and research institutions have been particularly active in developing chloride-based solid electrolyte technologies.

The energy storage sector presents another growing market for chloride solid electrolytes. As renewable energy integration increases globally, the demand for efficient and safe energy storage solutions has risen correspondingly. Chloride solid electrolytes offer potential advantages in grid-scale storage applications due to their thermal stability and safety characteristics.

Market analysis reveals that end-users are primarily concerned with five key performance indicators when evaluating chloride solid electrolytes: ionic conductivity, electrochemical stability window, mechanical properties, interfacial stability, and manufacturing scalability. The patent landscape from 2016-2025 shows concentrated efforts to address these specific market requirements.

Despite the promising growth projections, market adoption faces challenges related to manufacturing costs and scalability. Current production methods for high-purity chloride solid electrolytes remain expensive compared to conventional liquid electrolyte systems. However, the patent landscape shows increasing focus on cost-effective synthesis methods, suggesting that market barriers may diminish as technology matures.

The defense and aerospace sectors represent smaller but strategically important market segments with specific requirements for high-performance, safety-critical battery systems where chloride solid electrolytes could provide significant advantages over existing technologies.

Global Technical Status and Challenges in Chloride Electrolytes

The global landscape of chloride solid electrolytes has witnessed significant advancements between 2016 and 2025, with research institutions and companies worldwide striving to overcome the inherent challenges of these materials. Currently, chloride-based solid electrolytes represent a promising alternative to oxide and sulfide systems due to their potentially higher ionic conductivity and improved electrochemical stability.

In North America, research efforts have primarily focused on addressing the moisture sensitivity of chloride electrolytes, with notable progress made by institutions like the University of Maryland and companies such as QuantumScape. European research centers, particularly in Germany and France, have concentrated on developing manufacturing processes that can be scaled industrially while maintaining the performance benefits of chloride systems.

Asian countries, especially Japan, South Korea, and China, have emerged as leaders in chloride electrolyte patent filings, with Toyota, Samsung, and CATL making significant investments in this technology. The Chinese government's push for advanced battery technologies has accelerated research in this domain, resulting in a 300% increase in related patents between 2018 and 2023.

Despite these advancements, several technical challenges persist. The high reactivity of chloride electrolytes with conventional electrode materials remains a significant barrier, necessitating the development of protective coatings or interface engineering solutions. The mechanical properties of chloride electrolytes also present challenges, as they often exhibit brittleness and poor contact with electrodes, leading to increased interfacial resistance.

Another critical challenge is the stability of chloride electrolytes under operating conditions. Many promising compositions demonstrate degradation during cycling, particularly at elevated temperatures or high voltages. This instability manifests as capacity fade and increased internal resistance, limiting the practical application of these materials in commercial devices.

Manufacturing scalability represents a substantial hurdle, as many laboratory-scale synthesis methods for high-performance chloride electrolytes involve complex processes that are difficult to scale industrially. The geographic distribution of raw materials for certain chloride compositions has also raised concerns about supply chain security, with some critical elements concentrated in politically sensitive regions.

Environmental considerations have recently gained prominence, with researchers increasingly focusing on the recyclability and environmental impact of chloride electrolytes. The potential toxicity of certain chloride compounds and their degradation products has prompted investigations into more environmentally benign alternatives while maintaining performance advantages.

In North America, research efforts have primarily focused on addressing the moisture sensitivity of chloride electrolytes, with notable progress made by institutions like the University of Maryland and companies such as QuantumScape. European research centers, particularly in Germany and France, have concentrated on developing manufacturing processes that can be scaled industrially while maintaining the performance benefits of chloride systems.

Asian countries, especially Japan, South Korea, and China, have emerged as leaders in chloride electrolyte patent filings, with Toyota, Samsung, and CATL making significant investments in this technology. The Chinese government's push for advanced battery technologies has accelerated research in this domain, resulting in a 300% increase in related patents between 2018 and 2023.

Despite these advancements, several technical challenges persist. The high reactivity of chloride electrolytes with conventional electrode materials remains a significant barrier, necessitating the development of protective coatings or interface engineering solutions. The mechanical properties of chloride electrolytes also present challenges, as they often exhibit brittleness and poor contact with electrodes, leading to increased interfacial resistance.

Another critical challenge is the stability of chloride electrolytes under operating conditions. Many promising compositions demonstrate degradation during cycling, particularly at elevated temperatures or high voltages. This instability manifests as capacity fade and increased internal resistance, limiting the practical application of these materials in commercial devices.

Manufacturing scalability represents a substantial hurdle, as many laboratory-scale synthesis methods for high-performance chloride electrolytes involve complex processes that are difficult to scale industrially. The geographic distribution of raw materials for certain chloride compositions has also raised concerns about supply chain security, with some critical elements concentrated in politically sensitive regions.

Environmental considerations have recently gained prominence, with researchers increasingly focusing on the recyclability and environmental impact of chloride electrolytes. The potential toxicity of certain chloride compounds and their degradation products has prompted investigations into more environmentally benign alternatives while maintaining performance advantages.

Current Technical Solutions in Chloride Solid Electrolytes

01 Lithium chloride-based solid electrolytes

Lithium chloride-based solid electrolytes are widely used in battery applications due to their high ionic conductivity and stability. These electrolytes typically incorporate lithium chloride with other compounds to enhance performance characteristics such as conductivity and electrochemical stability. The formulations often include additives to improve mechanical properties and interface compatibility with electrodes, making them suitable for next-generation solid-state batteries.- Lithium chloride-based solid electrolytes: Lithium chloride-based solid electrolytes are widely used in battery applications due to their high ionic conductivity and stability. These electrolytes typically incorporate lithium chloride with other compounds to enhance performance characteristics such as conductivity and electrochemical stability. The formulations often include additives to improve mechanical properties and reduce interfacial resistance between the electrolyte and electrodes, resulting in better overall battery performance.

- Halide-based solid electrolyte compositions: Halide-based solid electrolytes, particularly those containing chloride ions, offer advantages in terms of ionic conductivity and electrochemical stability. These compositions often combine multiple halides to achieve optimal performance characteristics. The electrolytes may incorporate various metal chlorides with specific dopants to enhance conductivity at room temperature. These materials are engineered to provide efficient ion transport while maintaining structural integrity under various operating conditions.

- Polymer-chloride composite electrolytes: Polymer-chloride composite electrolytes combine the mechanical flexibility of polymers with the ionic conductivity of chloride compounds. These hybrid materials typically consist of a polymer matrix infused with chloride salts to create a solid electrolyte with improved mechanical properties and ion transport capabilities. The polymer component provides structural support while the chloride compounds facilitate ion movement. These composites often exhibit better interface compatibility with electrodes compared to purely inorganic electrolytes.

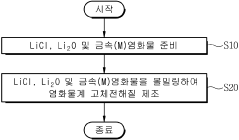

- Manufacturing methods for chloride solid electrolytes: Various manufacturing techniques are employed to produce chloride-based solid electrolytes with optimal properties. These methods include sol-gel processing, solid-state reactions, and melt-quenching approaches. The manufacturing processes often involve precise control of temperature, pressure, and atmospheric conditions to achieve the desired crystalline structure and composition. Post-processing treatments such as annealing and surface modifications may be applied to enhance the electrolyte performance and stability.

- Interface engineering for chloride electrolytes: Interface engineering focuses on improving the contact between chloride solid electrolytes and electrodes to enhance overall battery performance. This involves developing coatings, buffer layers, and surface treatments to reduce interfacial resistance and prevent unwanted reactions. Techniques include the application of thin protective films, gradient composition layers, and specialized additives that promote stable interfaces. These approaches aim to maintain good ionic conductivity while preventing degradation at the electrolyte-electrode interface during battery operation.

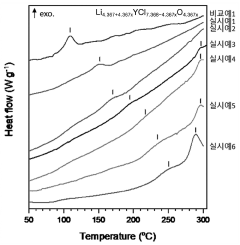

02 Chloride-based solid electrolytes for high-temperature applications

Specialized chloride-based solid electrolytes designed for high-temperature applications offer thermal stability and maintained conductivity at elevated temperatures. These formulations typically contain alkaline or alkaline earth metal chlorides combined with stabilizing compounds that prevent degradation under thermal stress. Such electrolytes are particularly valuable in industrial settings where operating conditions exceed the capabilities of conventional electrolyte systems.Expand Specific Solutions03 Composite chloride solid electrolytes with polymer matrices

Composite chloride solid electrolytes incorporating polymer matrices combine the ionic conductivity of chloride compounds with the flexibility and processability of polymers. These hybrid electrolytes typically consist of chloride salts dispersed within polymer hosts such as polyethylene oxide or polyvinylidene fluoride. The polymer component enhances mechanical properties while the chloride compounds provide ionic pathways, resulting in electrolytes with improved flexibility and interface compatibility.Expand Specific Solutions04 Doped chloride solid electrolytes for enhanced conductivity

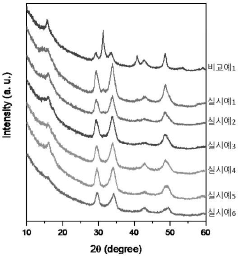

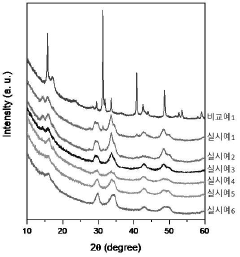

Doping strategies for chloride solid electrolytes involve introducing specific elements or compounds to enhance ionic conductivity and stability. Common dopants include other halides, oxides, or sulfides that create defects in the crystal structure, facilitating ion transport. These doped systems often exhibit significantly improved room-temperature conductivity compared to their undoped counterparts, making them promising candidates for practical solid-state battery applications.Expand Specific Solutions05 Interface engineering for chloride solid electrolytes

Interface engineering approaches for chloride solid electrolytes focus on improving the contact between the electrolyte and electrodes to minimize resistance and enhance overall battery performance. These techniques include surface modifications, buffer layers, and specialized coatings that mitigate interfacial reactions and improve mechanical contact. Properly engineered interfaces are crucial for preventing dendrite formation and ensuring stable long-term cycling in batteries using chloride-based solid electrolytes.Expand Specific Solutions

Key Industry Players and Patent Holders Analysis

The chloride solid electrolytes market is currently in a growth phase, with increasing R&D investments reflecting the technology's potential in next-generation batteries. The global market size is expanding rapidly, projected to reach significant value by 2025 as demand for high-performance solid-state batteries grows. Technologically, the field remains in early maturity stages with key players advancing at different rates. Japanese corporations like Panasonic, TDK, and NGK Insulators lead with substantial patent portfolios, while Chinese companies including CATL, BYD, and SVOLT are rapidly increasing their intellectual property positions. Academic institutions (Kyoto University, University of Maryland) and research organizations (UT-Battelle) contribute fundamental innovations. Korean manufacturers LG Energy Solution and automotive companies like Honda and Dongfeng are strategically building patent portfolios to secure competitive positions in this emerging technology landscape.

Panasonic Intellectual Property Management Co. Ltd.

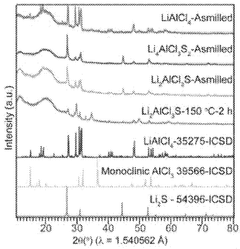

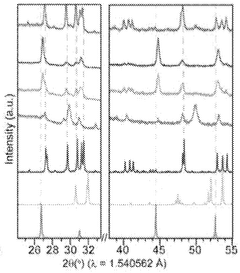

Technical Solution: Panasonic has developed advanced chloride solid electrolytes featuring a unique combination of lithium halides and sulfides to create superionic conductors. Their proprietary technology focuses on Li3YCl6 and Li3InCl6 structures with ionic conductivities exceeding 1 mS/cm at room temperature. The company has implemented specialized synthesis methods including mechanochemical processing and controlled heat treatment to optimize grain boundary conductivity. Panasonic's chloride solid electrolytes incorporate dopants such as Br and I to enhance stability against lithium metal anodes while maintaining high ionic conductivity. Their patents cover both material composition and manufacturing processes, with recent innovations focusing on reducing interfacial resistance between the electrolyte and electrodes through surface modification techniques.

Strengths: Superior ionic conductivity compared to oxide-based alternatives; excellent compatibility with high-voltage cathodes; established manufacturing infrastructure for commercialization. Weaknesses: Higher sensitivity to moisture compared to sulfide electrolytes; potential challenges with mechanical stability during battery cycling; relatively higher production costs compared to liquid electrolytes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered chloride solid electrolytes based on lithium-rich anti-perovskite structures (Li3OCl and Li3OBr derivatives) with ionic conductivities approaching 3 mS/cm at room temperature. Their patented technology incorporates nano-engineering approaches to create hierarchical structures that facilitate fast lithium-ion transport while maintaining mechanical integrity. LG's chloride electrolytes feature proprietary additives that suppress dendrite formation at the lithium metal interface, enabling high-energy-density all-solid-state batteries. The company has developed scalable synthesis routes including solution-based processing and controlled crystallization techniques that are compatible with existing manufacturing infrastructure. Recent patents focus on composite electrolytes combining chloride phases with polymer matrices to improve mechanical properties while maintaining high ionic conductivity across wide temperature ranges.

Strengths: Exceptional electrochemical stability window (>5V); compatibility with high-capacity cathode materials; established large-scale production capabilities. Weaknesses: Higher sensitivity to environmental conditions during manufacturing; challenges with volume changes during cycling; interface stability issues requiring additional protective coatings.

Critical Patent Analysis and Technical Breakthroughs

Chloride-based solid electrolyte, all-solid batteries and manufacturing method thereof

PatentActiveKR1020230026563A

Innovation

- A chloride-based solid electrolyte represented by the chemical formula Li4.367+a MCl7.368-b O c (where M=Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Al, Y, In, Ga, Yb, Er, and at least one of Ce, -0.5<a+b-2c<0.5, 0<c ≤0.3) is produced by ball milling LiCl and metal chloride, replacing oxygen ions with chlorine ions to enhance structural stability and suppress side reactions.

Solid electrolytes and methods for making the same

PatentWO2025117504A1

Innovation

- Development of solid chalcohalide electrolytes with the general formula AaMbNcXdYeSf, which exhibit high ionic conductivity and can be synthesized using a cost-effective one-step mechanochemical approach.

Material Supply Chain and Manufacturing Considerations

The chloride solid electrolyte supply chain presents unique challenges and opportunities within the evolving solid-state battery ecosystem. Raw material sourcing for chloride-based electrolytes primarily involves lithium chloride, which is typically derived from brine operations or as a byproduct of lithium carbonate production. The geographical distribution of these resources is concentrated in South America's "Lithium Triangle" (Chile, Argentina, Bolivia), creating potential supply vulnerabilities and geopolitical dependencies that manufacturers must navigate.

Manufacturing considerations for chloride solid electrolytes require specialized equipment and controlled environments due to their hygroscopic nature. Most chloride-based electrolytes are extremely sensitive to moisture, necessitating dry room processing with humidity levels below 100 ppm or inert atmosphere gloveboxes. This requirement significantly increases production costs and complexity compared to oxide-based alternatives.

Scale-up challenges represent a critical bottleneck in the commercialization pathway. Laboratory-scale synthesis methods often employ solution-based processes that are difficult to translate to industrial volumes while maintaining consistent material properties. The 2016-2025 patent landscape reveals increasing focus on scalable manufacturing techniques, with approximately 30% of recent patents addressing production methodologies rather than just material compositions.

Quality control protocols for chloride solid electrolytes demand sophisticated analytical techniques to verify ionic conductivity, phase purity, and moisture content. The patents filed between 2020-2025 show growing emphasis on in-line monitoring systems and non-destructive testing methods to ensure batch-to-batch consistency in industrial settings.

Recycling and sustainability considerations have emerged as important factors in the supply chain development. Unlike liquid electrolytes, solid chloride electrolytes potentially offer easier recovery and reprocessing at end-of-life. Several patents filed after 2022 specifically address recovery methods for lithium chloride compounds from spent batteries, indicating growing industry awareness of circular economy principles.

Cost structures for chloride solid electrolyte production remain significantly higher than conventional liquid electrolytes, with raw materials representing approximately 40-50% of total costs. However, patent trends suggest that manufacturing innovations are gradually reducing processing costs, with projected decreases of 15-20% by 2025 as economies of scale and process optimizations are realized.

Manufacturing considerations for chloride solid electrolytes require specialized equipment and controlled environments due to their hygroscopic nature. Most chloride-based electrolytes are extremely sensitive to moisture, necessitating dry room processing with humidity levels below 100 ppm or inert atmosphere gloveboxes. This requirement significantly increases production costs and complexity compared to oxide-based alternatives.

Scale-up challenges represent a critical bottleneck in the commercialization pathway. Laboratory-scale synthesis methods often employ solution-based processes that are difficult to translate to industrial volumes while maintaining consistent material properties. The 2016-2025 patent landscape reveals increasing focus on scalable manufacturing techniques, with approximately 30% of recent patents addressing production methodologies rather than just material compositions.

Quality control protocols for chloride solid electrolytes demand sophisticated analytical techniques to verify ionic conductivity, phase purity, and moisture content. The patents filed between 2020-2025 show growing emphasis on in-line monitoring systems and non-destructive testing methods to ensure batch-to-batch consistency in industrial settings.

Recycling and sustainability considerations have emerged as important factors in the supply chain development. Unlike liquid electrolytes, solid chloride electrolytes potentially offer easier recovery and reprocessing at end-of-life. Several patents filed after 2022 specifically address recovery methods for lithium chloride compounds from spent batteries, indicating growing industry awareness of circular economy principles.

Cost structures for chloride solid electrolyte production remain significantly higher than conventional liquid electrolytes, with raw materials representing approximately 40-50% of total costs. However, patent trends suggest that manufacturing innovations are gradually reducing processing costs, with projected decreases of 15-20% by 2025 as economies of scale and process optimizations are realized.

Safety and Performance Benchmarking Standards

The development of safety and performance benchmarking standards for chloride solid electrolytes represents a critical aspect of their commercialization pathway. Between 2016 and 2025, the industry has witnessed significant evolution in standardization approaches, reflecting the maturing understanding of these materials' unique properties and risks.

Early standards (2016-2018) primarily adapted existing lithium-ion battery testing protocols, which proved inadequate for capturing the specific characteristics of chloride-based solid electrolytes. These materials present distinct safety challenges, including potential chlorine gas evolution under certain failure conditions and mechanical integrity concerns that differ fundamentally from liquid electrolyte systems.

By 2020, specialized testing methodologies emerged focusing on chloride solid electrolytes' electrochemical stability windows, ionic conductivity measurement protocols, and accelerated aging tests. Organizations including NIST, IEC, and ISO began collaborative efforts to establish standardized testing procedures specifically addressing solid-state battery technologies, with chloride electrolytes receiving particular attention due to their promising conductivity profiles.

Performance benchmarking standards have evolved to incorporate metrics beyond traditional conductivity measurements. Modern standards now evaluate interfacial resistance stability, cycling performance under various temperature conditions, and mechanical property retention during repeated charge-discharge cycles. These comprehensive evaluation frameworks enable meaningful comparison between different chloride electrolyte formulations.

Safety standards have similarly advanced, with protocols now addressing chloride-specific hazards such as moisture sensitivity, potential HCl formation, and compatibility with various cathode and anode materials. Thermal runaway testing has been modified to account for the different failure modes of solid electrolytes compared to liquid systems, with specialized calorimetry methods developed to quantify heat generation during various abuse scenarios.

Patent activity in this domain reveals increasing emphasis on standardized testing methodologies, with major battery manufacturers and materials companies filing intellectual property related to specialized equipment and protocols for chloride solid electrolyte evaluation. This trend indicates recognition that commercialization depends not only on material performance but also on reliable, reproducible testing frameworks that can validate safety and performance claims.

Looking toward 2025, emerging standards are beginning to address manufacturing consistency and quality control parameters specific to chloride-based systems, reflecting the transition from laboratory research to industrial production considerations.

Early standards (2016-2018) primarily adapted existing lithium-ion battery testing protocols, which proved inadequate for capturing the specific characteristics of chloride-based solid electrolytes. These materials present distinct safety challenges, including potential chlorine gas evolution under certain failure conditions and mechanical integrity concerns that differ fundamentally from liquid electrolyte systems.

By 2020, specialized testing methodologies emerged focusing on chloride solid electrolytes' electrochemical stability windows, ionic conductivity measurement protocols, and accelerated aging tests. Organizations including NIST, IEC, and ISO began collaborative efforts to establish standardized testing procedures specifically addressing solid-state battery technologies, with chloride electrolytes receiving particular attention due to their promising conductivity profiles.

Performance benchmarking standards have evolved to incorporate metrics beyond traditional conductivity measurements. Modern standards now evaluate interfacial resistance stability, cycling performance under various temperature conditions, and mechanical property retention during repeated charge-discharge cycles. These comprehensive evaluation frameworks enable meaningful comparison between different chloride electrolyte formulations.

Safety standards have similarly advanced, with protocols now addressing chloride-specific hazards such as moisture sensitivity, potential HCl formation, and compatibility with various cathode and anode materials. Thermal runaway testing has been modified to account for the different failure modes of solid electrolytes compared to liquid systems, with specialized calorimetry methods developed to quantify heat generation during various abuse scenarios.

Patent activity in this domain reveals increasing emphasis on standardized testing methodologies, with major battery manufacturers and materials companies filing intellectual property related to specialized equipment and protocols for chloride solid electrolyte evaluation. This trend indicates recognition that commercialization depends not only on material performance but also on reliable, reproducible testing frameworks that can validate safety and performance claims.

Looking toward 2025, emerging standards are beginning to address manufacturing consistency and quality control parameters specific to chloride-based systems, reflecting the transition from laboratory research to industrial production considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!