Mechanical Properties And Densification Behavior Of Chloride SSE Pellets

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride SSE Pellets: Background and Development Goals

Chloride-based solid-state electrolytes (SSEs) have emerged as promising candidates for next-generation energy storage systems, particularly in the development of all-solid-state batteries (ASSBs). The evolution of these materials can be traced back to the early 2000s when researchers began exploring alternatives to conventional liquid electrolytes due to their inherent safety concerns and performance limitations. Chloride SSEs represent a significant advancement in this field, offering superior ionic conductivity, enhanced thermal stability, and improved electrochemical performance compared to their oxide and sulfide counterparts.

The development of chloride SSE pellets has been driven by the increasing demand for safer, more efficient, and higher energy density batteries for applications ranging from portable electronics to electric vehicles and grid-scale energy storage. Traditional lithium-ion batteries with liquid electrolytes pose safety risks due to their flammability and potential for thermal runaway, creating a compelling need for solid-state alternatives that maintain or exceed current performance standards.

Historically, the densification behavior and mechanical properties of chloride SSE pellets have presented significant challenges. Early iterations suffered from high porosity, poor interfacial contact, and mechanical fragility, limiting their practical application. The mechanical integrity of these pellets is crucial for maintaining stable electrochemical performance over extended cycling periods and preventing the formation of lithium dendrites that can cause short circuits.

Recent technological breakthroughs have focused on optimizing sintering processes, incorporating novel dopants, and developing composite structures to enhance the mechanical robustness and densification characteristics of chloride SSE pellets. These advancements aim to achieve near-theoretical density while maintaining high ionic conductivity, a balance that has proven elusive in previous research efforts.

The primary technical goals for chloride SSE pellet development include achieving room-temperature ionic conductivity exceeding 10^-3 S/cm, Young's modulus values above 10 GPa to effectively suppress lithium dendrite growth, and relative densities greater than 95% to minimize porosity and enhance mechanical strength. Additionally, researchers aim to develop scalable manufacturing processes that can transition these materials from laboratory curiosities to commercially viable products.

International research collaborations have accelerated progress in this field, with significant contributions from academic institutions and industrial research centers in Asia, North America, and Europe. The competitive landscape has intensified as major battery manufacturers recognize the potential of chloride-based solid electrolytes to revolutionize energy storage technology and address the limitations of current battery systems.

The development of chloride SSE pellets has been driven by the increasing demand for safer, more efficient, and higher energy density batteries for applications ranging from portable electronics to electric vehicles and grid-scale energy storage. Traditional lithium-ion batteries with liquid electrolytes pose safety risks due to their flammability and potential for thermal runaway, creating a compelling need for solid-state alternatives that maintain or exceed current performance standards.

Historically, the densification behavior and mechanical properties of chloride SSE pellets have presented significant challenges. Early iterations suffered from high porosity, poor interfacial contact, and mechanical fragility, limiting their practical application. The mechanical integrity of these pellets is crucial for maintaining stable electrochemical performance over extended cycling periods and preventing the formation of lithium dendrites that can cause short circuits.

Recent technological breakthroughs have focused on optimizing sintering processes, incorporating novel dopants, and developing composite structures to enhance the mechanical robustness and densification characteristics of chloride SSE pellets. These advancements aim to achieve near-theoretical density while maintaining high ionic conductivity, a balance that has proven elusive in previous research efforts.

The primary technical goals for chloride SSE pellet development include achieving room-temperature ionic conductivity exceeding 10^-3 S/cm, Young's modulus values above 10 GPa to effectively suppress lithium dendrite growth, and relative densities greater than 95% to minimize porosity and enhance mechanical strength. Additionally, researchers aim to develop scalable manufacturing processes that can transition these materials from laboratory curiosities to commercially viable products.

International research collaborations have accelerated progress in this field, with significant contributions from academic institutions and industrial research centers in Asia, North America, and Europe. The competitive landscape has intensified as major battery manufacturers recognize the potential of chloride-based solid electrolytes to revolutionize energy storage technology and address the limitations of current battery systems.

Market Analysis for Solid-State Battery Components

The solid-state battery components market is experiencing unprecedented growth, driven by the increasing demand for safer, higher energy density batteries across multiple industries. Current market valuations place the global solid-state battery market at approximately $500 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 34-36% through 2030, potentially reaching $8-10 billion by the end of the decade.

Chloride-based solid-state electrolytes (SSEs) represent a significant segment within this market, particularly valued for their high ionic conductivity and compatibility with high-voltage cathode materials. Market research indicates that chloride SSEs could capture 25-30% of the total solid electrolyte market by 2028, primarily due to their superior performance characteristics compared to oxide and sulfide alternatives.

The demand for optimized chloride SSE pellets is being driven by several key market factors. Electric vehicle manufacturers are the primary demand generators, with major automotive OEMs investing heavily in solid-state battery technology to achieve the 400+ Wh/kg energy density threshold needed for next-generation EVs. This segment alone is expected to consume approximately 65% of all advanced SSE materials produced in the coming years.

Consumer electronics represents the second largest market segment, accounting for roughly 20% of demand. Manufacturers are seeking batteries with improved safety profiles and higher energy densities to enable slimmer device designs and longer operating times between charges. The remaining 15% of market demand comes from grid storage applications and specialized industrial uses.

Regional analysis reveals Asia-Pacific as the dominant market for chloride SSE components, with Japan, South Korea, and China collectively representing 58% of global demand. North America follows at 24%, with Europe at 16%. This regional distribution closely mirrors the geographical concentration of battery manufacturing facilities and related supply chains.

Market barriers for chloride SSE pellets include high production costs, currently estimated at 3-4 times that of conventional liquid electrolyte systems, and scalability challenges related to maintaining consistent mechanical properties during mass production. Industry analysts predict that achieving cost parity with conventional lithium-ion batteries will require significant manufacturing innovations and economies of scale, potentially achievable by 2027-2028.

Customer requirements are increasingly focused on mechanical stability and densification consistency, with battery manufacturers specifying minimum pellet density thresholds of >95% theoretical density and fracture toughness values exceeding 0.8 MPa·m^(1/2) to ensure long-term cycling stability and safety under various operating conditions.

Chloride-based solid-state electrolytes (SSEs) represent a significant segment within this market, particularly valued for their high ionic conductivity and compatibility with high-voltage cathode materials. Market research indicates that chloride SSEs could capture 25-30% of the total solid electrolyte market by 2028, primarily due to their superior performance characteristics compared to oxide and sulfide alternatives.

The demand for optimized chloride SSE pellets is being driven by several key market factors. Electric vehicle manufacturers are the primary demand generators, with major automotive OEMs investing heavily in solid-state battery technology to achieve the 400+ Wh/kg energy density threshold needed for next-generation EVs. This segment alone is expected to consume approximately 65% of all advanced SSE materials produced in the coming years.

Consumer electronics represents the second largest market segment, accounting for roughly 20% of demand. Manufacturers are seeking batteries with improved safety profiles and higher energy densities to enable slimmer device designs and longer operating times between charges. The remaining 15% of market demand comes from grid storage applications and specialized industrial uses.

Regional analysis reveals Asia-Pacific as the dominant market for chloride SSE components, with Japan, South Korea, and China collectively representing 58% of global demand. North America follows at 24%, with Europe at 16%. This regional distribution closely mirrors the geographical concentration of battery manufacturing facilities and related supply chains.

Market barriers for chloride SSE pellets include high production costs, currently estimated at 3-4 times that of conventional liquid electrolyte systems, and scalability challenges related to maintaining consistent mechanical properties during mass production. Industry analysts predict that achieving cost parity with conventional lithium-ion batteries will require significant manufacturing innovations and economies of scale, potentially achievable by 2027-2028.

Customer requirements are increasingly focused on mechanical stability and densification consistency, with battery manufacturers specifying minimum pellet density thresholds of >95% theoretical density and fracture toughness values exceeding 0.8 MPa·m^(1/2) to ensure long-term cycling stability and safety under various operating conditions.

Current Challenges in Chloride SSE Pellet Fabrication

The fabrication of chloride solid-state electrolyte (SSE) pellets faces significant challenges that impede their widespread application in next-generation batteries. One primary obstacle is the high sensitivity of chloride SSEs to moisture, which necessitates stringent handling conditions throughout the entire manufacturing process. Even trace amounts of moisture can trigger hydrolysis reactions, leading to the formation of hydroxides and oxides that severely compromise ionic conductivity and mechanical integrity.

Cold sintering processes, while promising for their energy efficiency, struggle to achieve optimal densification of chloride SSE pellets. The relatively low temperatures employed in cold sintering often result in incomplete particle coalescence, leaving residual porosity that creates pathways for dendrite growth and reduces overall ionic conductivity. This trade-off between energy efficiency and performance remains unresolved.

Conventional high-temperature sintering methods present their own set of challenges. The volatile nature of chloride components leads to compositional changes during sintering, as certain elements preferentially evaporate at elevated temperatures. This compositional drift alters the stoichiometry of the final product, resulting in unpredictable electrochemical performance and mechanical properties.

Interface engineering between particles represents another critical challenge. The formation of high-resistance grain boundaries significantly impedes ion transport across the pellet, reducing overall conductivity. Current sintering approaches struggle to promote effective grain boundary engineering that maintains high ionic conductivity while ensuring mechanical robustness.

The mechanical fragility of chloride SSE pellets poses serious limitations for battery assembly processes. These pellets often exhibit brittle behavior with low fracture toughness, making them susceptible to cracking during cell assembly and cycling. The development of chloride SSEs with enhanced mechanical properties without sacrificing ionic conductivity remains elusive.

Scale-up challenges further complicate industrial adoption. Laboratory-scale fabrication methods that produce high-quality pellets often fail to translate effectively to industrial scales. Issues such as non-uniform densification, thermal gradients during sintering, and batch-to-batch variability become increasingly problematic at larger scales, hampering commercialization efforts.

Additionally, the high cost and limited availability of ultra-high purity precursors required for chloride SSE synthesis present economic barriers. Impurities can significantly degrade performance, yet achieving the necessary purity levels substantially increases production costs, creating a challenging cost-performance balance for commercial viability.

Cold sintering processes, while promising for their energy efficiency, struggle to achieve optimal densification of chloride SSE pellets. The relatively low temperatures employed in cold sintering often result in incomplete particle coalescence, leaving residual porosity that creates pathways for dendrite growth and reduces overall ionic conductivity. This trade-off between energy efficiency and performance remains unresolved.

Conventional high-temperature sintering methods present their own set of challenges. The volatile nature of chloride components leads to compositional changes during sintering, as certain elements preferentially evaporate at elevated temperatures. This compositional drift alters the stoichiometry of the final product, resulting in unpredictable electrochemical performance and mechanical properties.

Interface engineering between particles represents another critical challenge. The formation of high-resistance grain boundaries significantly impedes ion transport across the pellet, reducing overall conductivity. Current sintering approaches struggle to promote effective grain boundary engineering that maintains high ionic conductivity while ensuring mechanical robustness.

The mechanical fragility of chloride SSE pellets poses serious limitations for battery assembly processes. These pellets often exhibit brittle behavior with low fracture toughness, making them susceptible to cracking during cell assembly and cycling. The development of chloride SSEs with enhanced mechanical properties without sacrificing ionic conductivity remains elusive.

Scale-up challenges further complicate industrial adoption. Laboratory-scale fabrication methods that produce high-quality pellets often fail to translate effectively to industrial scales. Issues such as non-uniform densification, thermal gradients during sintering, and batch-to-batch variability become increasingly problematic at larger scales, hampering commercialization efforts.

Additionally, the high cost and limited availability of ultra-high purity precursors required for chloride SSE synthesis present economic barriers. Impurities can significantly degrade performance, yet achieving the necessary purity levels substantially increases production costs, creating a challenging cost-performance balance for commercial viability.

Current Methods for Enhancing Mechanical Properties of Chloride SSEs

01 Densification methods for chloride SSE pellets

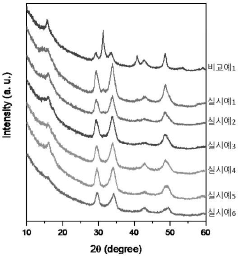

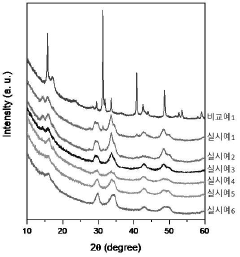

Various densification methods can be employed to improve the mechanical properties of chloride solid-state electrolyte pellets. These include cold pressing, hot pressing, and sintering techniques that help achieve higher density and better mechanical integrity. The densification process typically involves applying pressure and/or heat to the SSE powder to reduce porosity and increase the contact area between particles, resulting in improved ionic conductivity and mechanical strength.- Densification techniques for chloride SSE pellets: Various densification techniques can be applied to chloride solid-state electrolyte pellets to improve their mechanical properties. These include cold pressing followed by sintering, hot pressing, and spark plasma sintering. The densification process parameters such as temperature, pressure, and duration significantly affect the final density and mechanical strength of the pellets. Higher densification leads to improved ionic conductivity and reduced porosity, which enhances the overall performance of the solid-state batteries.

- Composition engineering for enhanced mechanical properties: The mechanical properties of chloride solid-state electrolyte pellets can be enhanced through composition engineering. This involves incorporating dopants, additives, or creating composite structures with polymers or ceramics. For example, adding small amounts of lithium-containing compounds or other halides can improve the plasticity and reduce brittleness of the pellets. The composition also affects grain boundary properties, which are critical for both mechanical integrity and ion transport across the electrolyte.

- Grain size control and boundary engineering: Controlling grain size and engineering grain boundaries are crucial for optimizing the mechanical properties of chloride SSE pellets. Smaller grain sizes typically lead to higher mechanical strength but may affect ionic conductivity. Techniques such as controlled cooling rates during sintering, addition of grain growth inhibitors, and post-processing treatments can be employed to achieve desired grain structures. The nature of grain boundaries significantly influences crack propagation resistance and overall pellet toughness.

- Pressure-temperature relationship in pellet formation: The relationship between pressure and temperature during pellet formation plays a critical role in determining the final mechanical properties and densification behavior of chloride solid-state electrolytes. Higher pressures during compaction can lead to improved density but may introduce internal stresses. Similarly, the sintering temperature profile affects phase stability, grain growth, and potential decomposition of the electrolyte material. Optimizing these parameters is essential for achieving pellets with high density while maintaining desired mechanical properties.

- Interface stability and environmental sensitivity: Chloride solid-state electrolyte pellets are often sensitive to environmental conditions, particularly moisture, which can affect their mechanical stability and densification behavior. Protective coatings or encapsulation methods can be employed to enhance the environmental stability of these pellets. Additionally, the interfaces between the electrolyte and electrodes play a crucial role in the mechanical integrity of the entire battery system. Engineering stable interfaces that can accommodate volume changes during cycling while maintaining good contact is essential for long-term mechanical stability.

02 Composition engineering for enhanced mechanical properties

The mechanical properties of chloride solid-state electrolyte pellets can be significantly improved through composition engineering. This involves adding dopants, stabilizers, or secondary phases to the chloride-based electrolytes to enhance their mechanical strength, flexibility, and resistance to fracture. Optimizing the ratio of different chloride components and incorporating reinforcing materials can lead to SSE pellets with superior mechanical performance while maintaining high ionic conductivity.Expand Specific Solutions03 Pressure-temperature processing relationships

The relationship between pressure and temperature during processing plays a crucial role in determining the final mechanical properties and densification behavior of chloride SSE pellets. Controlled application of pressure at specific temperature ranges can optimize grain growth, reduce porosity, and enhance interfacial contact between particles. Understanding these processing parameters helps in developing SSE pellets with tailored mechanical properties suitable for various battery applications.Expand Specific Solutions04 Microstructure control and grain boundary engineering

Controlling the microstructure and engineering grain boundaries are essential approaches for improving the mechanical properties of chloride SSE pellets. Techniques such as grain size refinement, grain boundary modification, and creation of specific microstructural features can enhance the fracture toughness and flexibility of the electrolyte. The grain boundary composition and structure significantly influence both the mechanical integrity and ionic transport properties of the SSE pellets.Expand Specific Solutions05 Interface engineering for improved mechanical stability

Interface engineering focuses on enhancing the mechanical stability of chloride SSE pellets by addressing the interfaces between different components. This includes developing strategies to improve adhesion between the electrolyte and electrodes, reducing interfacial resistance, and preventing mechanical degradation during cycling. Coating technologies, buffer layers, and gradient compositions are employed to create robust interfaces that can withstand volume changes and mechanical stresses during battery operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SSE Development

The solid-state electrolyte (SSE) market for chloride-based pellets is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global SSE market is projected to reach $2-3 billion by 2025, with chloride-based systems representing a growing segment due to their promising mechanical properties and ionic conductivity. Technical maturity varies significantly among key players, with LG Chem, QingTao Energy, and SES Holdings demonstrating advanced capabilities in chloride SSE pellet densification and mechanical optimization. Research institutions like Karlsruher Institut für Technologie and Northeastern University are contributing fundamental breakthroughs, while established materials companies such as Dow Global Technologies and Bostik SA are leveraging their expertise to address manufacturing challenges. Apple's involvement signals potential mainstream applications, accelerating the technology's commercialization timeline.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced chloride solid-state electrolyte (SSE) pellets with enhanced mechanical properties through a proprietary cold sintering process. Their technology utilizes a combination of pressure-assisted sintering at relatively low temperatures (150-300°C) and controlled moisture content to achieve densification levels exceeding 95% of theoretical density. The company's approach incorporates nano-sized Li3YCl6 and Li3InCl6 particles with optimized particle size distribution to enhance grain boundary contact during sintering. LG Chem's chloride SSE pellets feature a unique composite structure where they integrate small amounts (3-5 wt%) of polymer binders like PVDF to improve mechanical flexibility while maintaining high ionic conductivity (>1 mS/cm at room temperature). Their manufacturing process includes precise control of sintering parameters and atmosphere to minimize moisture contamination, which is critical for chloride-based SSEs.

Strengths: Achieves high densification without requiring extreme temperatures, preserving ionic conductivity. The composite approach with polymer binders enhances mechanical flexibility and reduces brittleness typical of ceramic electrolytes. Weaknesses: The cold sintering process requires precise moisture control which adds complexity to manufacturing. The addition of polymer binders, while improving mechanical properties, may slightly reduce overall ionic conductivity compared to pure ceramic systems.

Karlsruher Institut für Technologie

Technical Solution: Karlsruher Institut für Technologie (KIT) has developed an innovative "Pressure-Modulated Atmospheric Sintering" (PMAS) technique for chloride solid-state electrolyte pellets. Their research focuses on Li3MCl6 systems (where M = Y, Er, In) with carefully controlled stoichiometry and halide ratios. KIT's approach utilizes a specialized sintering chamber with dynamic pressure control (50-300 MPa) and precise atmosphere management to maintain ultra-low moisture levels (<1 ppm H2O). The institute has pioneered the use of nanoscale ceramic additives (0.5-2 wt% Al2O3 or ZrO2) as mechanical reinforcement agents that preferentially distribute at grain boundaries. Their process includes a unique pre-conditioning step where chloride SSE powders undergo controlled exposure to specific organic solvents (primarily anhydrous acetonitrile) to modify surface chemistry before compaction. This treatment enhances particle-particle interaction during sintering, leading to densification levels of 94-97% at relatively moderate temperatures (280-320°C). KIT's pellets exhibit exceptional mechanical stability under cycling conditions, with flexural strength values of 30-35 MPa and fracture toughness approximately 60% higher than conventional cold-pressed chloride SSEs.

Strengths: The PMAS technique achieves excellent densification at moderate temperatures while maintaining the chemical stability of chloride SSEs. The nanoscale ceramic reinforcement strategy significantly enhances mechanical properties without substantially compromising ionic conductivity. Weaknesses: The specialized atmosphere control requirements add complexity to the manufacturing process. The pre-conditioning step with organic solvents requires additional processing time and careful solvent removal to avoid contamination.

Critical Patents and Research on Chloride SSE Densification

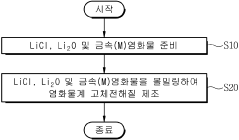

Chloride-based solid electrolyte, all-solid batteries and manufacturing method thereof

PatentActiveKR1020230026563A

Innovation

- A chloride-based solid electrolyte represented by the chemical formula Li4.367+a MCl7.368-b O c (where M=Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Al, Y, In, Ga, Yb, Er, and at least one of Ce, -0.5<a+b-2c<0.5, 0<c ≤0.3) is produced by ball milling LiCl and metal chloride, replacing oxygen ions with chlorine ions to enhance structural stability and suppress side reactions.

Solid electrolyte composition and manufacturing method therefor

PatentWO2025079993A1

Innovation

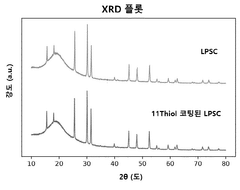

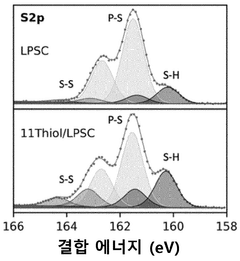

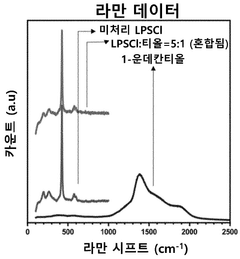

- A high-density solid electrolyte composition is developed by modifying sulfide-containing solid electrolyte materials with an organic coating, such as a long chain thiol, to enhance ion conductivity, mechanical strength, and interfacial stability, thereby improving the safety and performance of solid batteries.

Safety and Stability Considerations for Chloride-Based Electrolytes

Safety considerations for chloride-based solid-state electrolytes (SSEs) are paramount when evaluating their implementation in next-generation battery technologies. These materials, while promising for their high ionic conductivity, present several critical safety challenges that must be addressed. The hygroscopic nature of chloride-based SSEs makes them particularly susceptible to moisture absorption, which can lead to degradation of mechanical properties and compromise the structural integrity of the pellets. When exposed to ambient conditions, these materials rapidly absorb atmospheric moisture, resulting in chemical decomposition and the formation of hydroxides that significantly alter their electrochemical performance.

The chemical stability of chloride SSE pellets represents another major concern, particularly at the interfaces with electrode materials. Under operational conditions, chloride electrolytes may undergo redox reactions with both cathode and anode materials, forming interphases that increase interfacial resistance and potentially lead to mechanical failure. This reactivity is exacerbated at elevated temperatures, which are often encountered during battery operation or manufacturing processes such as hot-pressing for densification.

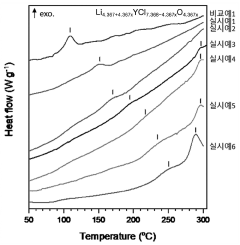

Thermal stability issues also present significant challenges for chloride-based systems. Many chloride SSEs exhibit phase transitions at temperatures within the operational range of batteries, leading to volume changes that can induce mechanical stress and cracking in the pellets. Furthermore, some chloride compounds may release chlorine gas when subjected to high temperatures or in the presence of strong reducing agents, posing both safety and environmental hazards.

The mechanical fragility of densified chloride SSE pellets introduces additional safety concerns. Despite densification processes improving ionic conductivity, these pellets often remain brittle and susceptible to fracture under mechanical stress. Such fractures can create pathways for dendrite growth, potentially leading to internal short circuits and catastrophic battery failure. The correlation between densification parameters and mechanical robustness therefore requires careful optimization to ensure both performance and safety.

Long-term cycling stability represents perhaps the most significant challenge for practical implementation. Repeated volume changes during lithium insertion/extraction cycles can gradually deteriorate the mechanical integrity of chloride SSE pellets, leading to increased interfacial resistance and eventual failure. This degradation pathway is particularly concerning for applications requiring extended service life, such as electric vehicles or grid storage systems.

The chemical stability of chloride SSE pellets represents another major concern, particularly at the interfaces with electrode materials. Under operational conditions, chloride electrolytes may undergo redox reactions with both cathode and anode materials, forming interphases that increase interfacial resistance and potentially lead to mechanical failure. This reactivity is exacerbated at elevated temperatures, which are often encountered during battery operation or manufacturing processes such as hot-pressing for densification.

Thermal stability issues also present significant challenges for chloride-based systems. Many chloride SSEs exhibit phase transitions at temperatures within the operational range of batteries, leading to volume changes that can induce mechanical stress and cracking in the pellets. Furthermore, some chloride compounds may release chlorine gas when subjected to high temperatures or in the presence of strong reducing agents, posing both safety and environmental hazards.

The mechanical fragility of densified chloride SSE pellets introduces additional safety concerns. Despite densification processes improving ionic conductivity, these pellets often remain brittle and susceptible to fracture under mechanical stress. Such fractures can create pathways for dendrite growth, potentially leading to internal short circuits and catastrophic battery failure. The correlation between densification parameters and mechanical robustness therefore requires careful optimization to ensure both performance and safety.

Long-term cycling stability represents perhaps the most significant challenge for practical implementation. Repeated volume changes during lithium insertion/extraction cycles can gradually deteriorate the mechanical integrity of chloride SSE pellets, leading to increased interfacial resistance and eventual failure. This degradation pathway is particularly concerning for applications requiring extended service life, such as electric vehicles or grid storage systems.

Scale-up Challenges for Commercial Production of SSE Pellets

The transition from laboratory-scale production to commercial manufacturing of chloride solid-state electrolyte (SSE) pellets presents significant challenges that must be addressed for viable market deployment. Current laboratory processes typically produce small batches of pellets with carefully controlled conditions, but scaling these processes to industrial volumes introduces numerous complications. The primary challenge lies in maintaining consistent mechanical properties and densification behavior across large production batches while simultaneously reducing manufacturing costs.

Equipment scaling represents a critical hurdle, as the specialized high-pressure presses and controlled-atmosphere sintering furnaces used in laboratory settings must be redesigned for continuous or semi-continuous operation. Industrial-scale cold isostatic pressing (CIP) or hot isostatic pressing (HIP) systems require substantial capital investment and process optimization to achieve the necessary densification without compromising structural integrity.

Material homogeneity becomes increasingly difficult to maintain at larger scales. Chloride-based SSEs are particularly sensitive to moisture and impurities, requiring stringent environmental controls throughout the manufacturing process. Achieving uniform particle size distribution, consistent mixing, and homogeneous compaction across larger pellet dimensions or multiple pellets simultaneously demands advanced process control systems and potentially new equipment designs.

The densification kinetics observed in laboratory samples may not translate directly to larger pellets due to thermal gradients, pressure distribution variations, and differing mass transport phenomena. These factors can lead to inconsistent mechanical properties, including fracture toughness, elastic modulus, and hardness, which are critical for battery performance and safety. Developing predictive models that account for scale-dependent behavior is essential for process optimization.

Energy consumption and processing time present additional challenges for commercial viability. Laboratory-scale sintering processes often employ extended high-temperature treatments that would be prohibitively expensive at industrial scales. Alternative rapid sintering techniques such as spark plasma sintering or microwave-assisted sintering may offer solutions but require significant process development to maintain desired mechanical properties.

Quality control methodologies must evolve to accommodate high-volume production. Non-destructive testing techniques capable of rapidly assessing densification levels and mechanical integrity are needed to replace time-consuming laboratory characterization methods. In-line monitoring systems that can detect defects, cracks, or density variations in real-time would significantly improve production efficiency and product reliability.

Equipment scaling represents a critical hurdle, as the specialized high-pressure presses and controlled-atmosphere sintering furnaces used in laboratory settings must be redesigned for continuous or semi-continuous operation. Industrial-scale cold isostatic pressing (CIP) or hot isostatic pressing (HIP) systems require substantial capital investment and process optimization to achieve the necessary densification without compromising structural integrity.

Material homogeneity becomes increasingly difficult to maintain at larger scales. Chloride-based SSEs are particularly sensitive to moisture and impurities, requiring stringent environmental controls throughout the manufacturing process. Achieving uniform particle size distribution, consistent mixing, and homogeneous compaction across larger pellet dimensions or multiple pellets simultaneously demands advanced process control systems and potentially new equipment designs.

The densification kinetics observed in laboratory samples may not translate directly to larger pellets due to thermal gradients, pressure distribution variations, and differing mass transport phenomena. These factors can lead to inconsistent mechanical properties, including fracture toughness, elastic modulus, and hardness, which are critical for battery performance and safety. Developing predictive models that account for scale-dependent behavior is essential for process optimization.

Energy consumption and processing time present additional challenges for commercial viability. Laboratory-scale sintering processes often employ extended high-temperature treatments that would be prohibitively expensive at industrial scales. Alternative rapid sintering techniques such as spark plasma sintering or microwave-assisted sintering may offer solutions but require significant process development to maintain desired mechanical properties.

Quality control methodologies must evolve to accommodate high-volume production. Non-destructive testing techniques capable of rapidly assessing densification levels and mechanical integrity are needed to replace time-consuming laboratory characterization methods. In-line monitoring systems that can detect defects, cracks, or density variations in real-time would significantly improve production efficiency and product reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!