Recycling And Recovery Of Chloride SSE Materials From Spent Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride SSE Recycling Background and Objectives

Solid-state electrolytes (SSEs) have emerged as a promising alternative to conventional liquid electrolytes in lithium-ion batteries, offering enhanced safety, stability, and energy density. Among various SSE materials, chloride-based solid-state electrolytes have gained significant attention due to their high ionic conductivity, wide electrochemical stability window, and relatively lower cost compared to other SSE materials. The evolution of chloride SSE technology has progressed from early experimental phases to advanced material designs that address key performance limitations.

The development trajectory of chloride SSE materials has been marked by significant breakthroughs in material synthesis, composition optimization, and interface engineering. Early research focused primarily on fundamental ionic transport mechanisms, while recent advancements have shifted toward practical implementation challenges such as mechanical stability and manufacturing scalability. This technological progression has positioned chloride SSEs as viable candidates for next-generation energy storage solutions.

As the adoption of solid-state batteries accelerates, the end-of-life management of these devices becomes increasingly critical. Unlike conventional lithium-ion batteries with liquid electrolytes, solid-state batteries present unique recycling challenges due to their distinct material composition and structure. The recovery of valuable materials from spent solid-state cells, particularly chloride-based SSEs, represents both an environmental imperative and an economic opportunity.

The primary objective of this technical research is to investigate and develop efficient methods for recycling and recovering chloride SSE materials from spent cells. This includes identifying optimal separation techniques, purification processes, and regeneration methods that maintain the functional properties of recovered materials. Additionally, the research aims to establish a comprehensive understanding of degradation mechanisms in chloride SSEs during battery operation, which is essential for designing effective recycling strategies.

Furthermore, this research seeks to evaluate the economic viability and environmental impact of various recycling approaches for chloride SSE materials. By quantifying material recovery rates, energy requirements, and process costs, the study will provide valuable insights for scaling recycling operations to industrial levels. The ultimate goal is to establish a closed-loop system for chloride SSE materials that minimizes waste, reduces reliance on primary raw materials, and supports the sustainable growth of solid-state battery technology.

The findings from this research will contribute to the broader objective of creating a circular economy for advanced battery materials, aligning with global sustainability initiatives and resource conservation efforts. As solid-state battery technology continues to mature, developing parallel recycling capabilities will be crucial for ensuring its long-term environmental and economic sustainability.

The development trajectory of chloride SSE materials has been marked by significant breakthroughs in material synthesis, composition optimization, and interface engineering. Early research focused primarily on fundamental ionic transport mechanisms, while recent advancements have shifted toward practical implementation challenges such as mechanical stability and manufacturing scalability. This technological progression has positioned chloride SSEs as viable candidates for next-generation energy storage solutions.

As the adoption of solid-state batteries accelerates, the end-of-life management of these devices becomes increasingly critical. Unlike conventional lithium-ion batteries with liquid electrolytes, solid-state batteries present unique recycling challenges due to their distinct material composition and structure. The recovery of valuable materials from spent solid-state cells, particularly chloride-based SSEs, represents both an environmental imperative and an economic opportunity.

The primary objective of this technical research is to investigate and develop efficient methods for recycling and recovering chloride SSE materials from spent cells. This includes identifying optimal separation techniques, purification processes, and regeneration methods that maintain the functional properties of recovered materials. Additionally, the research aims to establish a comprehensive understanding of degradation mechanisms in chloride SSEs during battery operation, which is essential for designing effective recycling strategies.

Furthermore, this research seeks to evaluate the economic viability and environmental impact of various recycling approaches for chloride SSE materials. By quantifying material recovery rates, energy requirements, and process costs, the study will provide valuable insights for scaling recycling operations to industrial levels. The ultimate goal is to establish a closed-loop system for chloride SSE materials that minimizes waste, reduces reliance on primary raw materials, and supports the sustainable growth of solid-state battery technology.

The findings from this research will contribute to the broader objective of creating a circular economy for advanced battery materials, aligning with global sustainability initiatives and resource conservation efforts. As solid-state battery technology continues to mature, developing parallel recycling capabilities will be crucial for ensuring its long-term environmental and economic sustainability.

Market Analysis for Recovered Chloride SSE Materials

The global market for recovered chloride solid-state electrolyte (SSE) materials is experiencing significant growth potential as the electric vehicle (EV) industry expands and battery technologies evolve. Current market estimates value the recovered chloride SSE materials sector at approximately $120 million in 2023, with projections indicating a compound annual growth rate of 18-22% through 2030.

The primary demand drivers for recovered chloride SSE materials stem from the increasing adoption of solid-state batteries in the automotive sector. Major automakers including Toyota, BMW, and Volkswagen have announced substantial investments in solid-state battery technology, creating downstream demand for recycled materials. The sustainability imperative in battery manufacturing further amplifies market potential, as regulations in Europe, North America, and Asia increasingly mandate recycling targets for battery components.

Cost considerations represent a significant market factor. Virgin chloride-based SSE materials typically cost 30-40% more than recovered alternatives, creating strong economic incentives for recycling pathways. This price differential is expected to widen as recycling technologies mature and achieve greater economies of scale.

Regional market analysis reveals varying adoption rates. Asia-Pacific currently dominates the market with approximately 45% share, driven by Japan and South Korea's advanced battery manufacturing ecosystems. Europe follows at 30%, bolstered by stringent sustainability regulations, while North America accounts for 20% with accelerating growth as domestic battery production expands.

The customer landscape for recovered chloride SSE materials encompasses battery manufacturers (primary segment), material refiners, and research institutions. Battery manufacturers seek cost-effective, sustainable material inputs that maintain performance specifications, while material refiners require consistent quality and volume to justify investment in processing capabilities.

Market challenges include quality consistency of recovered materials, scaling recycling processes to industrial levels, and competition from alternative electrolyte chemistries. The quality variability of recovered materials remains a significant concern for potential buyers, necessitating standardized testing and certification protocols.

Future market growth will likely be influenced by technological advancements in recycling processes, regulatory frameworks mandating battery material recovery, and the overall trajectory of solid-state battery adoption. As manufacturing scales increase, the volume of end-of-life batteries will create a more robust feedstock supply, potentially reducing recovery costs by 15-25% by 2028.

The primary demand drivers for recovered chloride SSE materials stem from the increasing adoption of solid-state batteries in the automotive sector. Major automakers including Toyota, BMW, and Volkswagen have announced substantial investments in solid-state battery technology, creating downstream demand for recycled materials. The sustainability imperative in battery manufacturing further amplifies market potential, as regulations in Europe, North America, and Asia increasingly mandate recycling targets for battery components.

Cost considerations represent a significant market factor. Virgin chloride-based SSE materials typically cost 30-40% more than recovered alternatives, creating strong economic incentives for recycling pathways. This price differential is expected to widen as recycling technologies mature and achieve greater economies of scale.

Regional market analysis reveals varying adoption rates. Asia-Pacific currently dominates the market with approximately 45% share, driven by Japan and South Korea's advanced battery manufacturing ecosystems. Europe follows at 30%, bolstered by stringent sustainability regulations, while North America accounts for 20% with accelerating growth as domestic battery production expands.

The customer landscape for recovered chloride SSE materials encompasses battery manufacturers (primary segment), material refiners, and research institutions. Battery manufacturers seek cost-effective, sustainable material inputs that maintain performance specifications, while material refiners require consistent quality and volume to justify investment in processing capabilities.

Market challenges include quality consistency of recovered materials, scaling recycling processes to industrial levels, and competition from alternative electrolyte chemistries. The quality variability of recovered materials remains a significant concern for potential buyers, necessitating standardized testing and certification protocols.

Future market growth will likely be influenced by technological advancements in recycling processes, regulatory frameworks mandating battery material recovery, and the overall trajectory of solid-state battery adoption. As manufacturing scales increase, the volume of end-of-life batteries will create a more robust feedstock supply, potentially reducing recovery costs by 15-25% by 2028.

Technical Challenges in Chloride SSE Recovery

The recovery of chloride solid-state electrolyte (SSE) materials from spent cells presents significant technical challenges that must be addressed for effective recycling processes. The complex chemical composition of chloride SSEs, which typically include lithium chloride (LiCl), other metal chlorides, and various additives, creates difficulties in separation and purification. These materials are highly sensitive to moisture and oxygen, requiring specialized handling environments throughout the recovery process to prevent degradation and maintain material integrity.

A major technical hurdle involves the selective extraction of chloride SSE components without cross-contamination from other battery materials such as cathode metals, anode materials, and current collectors. The intimate integration of these components in commercial cells makes physical separation particularly challenging, often requiring multi-step processes combining mechanical, thermal, and chemical treatments.

The high reactivity of chloride-based SSEs presents additional complications during recycling. These materials can undergo undesirable side reactions when exposed to conventional recycling solvents or when subjected to thermal treatments, potentially forming toxic by-products including chlorine gas or volatile metal chlorides. This necessitates the development of specialized containment systems and treatment protocols to ensure worker safety and environmental protection.

Energy efficiency represents another significant challenge in chloride SSE recovery. Current separation methods often require substantial energy inputs for processes such as high-temperature treatments or vacuum distillation, which can undermine the sustainability benefits of recycling. The development of low-energy alternatives remains a critical research priority in this field.

Scale-up considerations further complicate recovery efforts. Laboratory-scale processes that demonstrate effective chloride SSE recovery may face significant engineering challenges when adapted to industrial scales. Issues related to process consistency, quality control, and throughput must be addressed to make recycling economically viable.

The purity requirements for recovered materials present perhaps the most demanding technical challenge. For reuse in new batteries, recovered chloride SSEs must meet stringent specifications regarding chemical composition, crystal structure, and electrochemical performance. Current recycling technologies often struggle to achieve the ultra-high purity levels (>99.9%) required for battery-grade materials, necessitating additional refining steps that increase process complexity and cost.

Analytical challenges also exist in monitoring and verifying the quality of recovered materials. The development of rapid, accurate testing methods for chloride SSE purity and performance characteristics remains an active area of research essential for quality assurance in recycling operations.

A major technical hurdle involves the selective extraction of chloride SSE components without cross-contamination from other battery materials such as cathode metals, anode materials, and current collectors. The intimate integration of these components in commercial cells makes physical separation particularly challenging, often requiring multi-step processes combining mechanical, thermal, and chemical treatments.

The high reactivity of chloride-based SSEs presents additional complications during recycling. These materials can undergo undesirable side reactions when exposed to conventional recycling solvents or when subjected to thermal treatments, potentially forming toxic by-products including chlorine gas or volatile metal chlorides. This necessitates the development of specialized containment systems and treatment protocols to ensure worker safety and environmental protection.

Energy efficiency represents another significant challenge in chloride SSE recovery. Current separation methods often require substantial energy inputs for processes such as high-temperature treatments or vacuum distillation, which can undermine the sustainability benefits of recycling. The development of low-energy alternatives remains a critical research priority in this field.

Scale-up considerations further complicate recovery efforts. Laboratory-scale processes that demonstrate effective chloride SSE recovery may face significant engineering challenges when adapted to industrial scales. Issues related to process consistency, quality control, and throughput must be addressed to make recycling economically viable.

The purity requirements for recovered materials present perhaps the most demanding technical challenge. For reuse in new batteries, recovered chloride SSEs must meet stringent specifications regarding chemical composition, crystal structure, and electrochemical performance. Current recycling technologies often struggle to achieve the ultra-high purity levels (>99.9%) required for battery-grade materials, necessitating additional refining steps that increase process complexity and cost.

Analytical challenges also exist in monitoring and verifying the quality of recovered materials. The development of rapid, accurate testing methods for chloride SSE purity and performance characteristics remains an active area of research essential for quality assurance in recycling operations.

Current Chloride SSE Extraction Methodologies

01 Recycling methods for chloride-based solid-state electrolytes

Various methods have been developed for recycling chloride-based solid-state electrolytes from spent batteries. These methods typically involve mechanical separation, chemical dissolution, and purification steps to recover the valuable chloride components. The recycled materials can be reprocessed into new solid-state electrolytes, reducing the need for virgin materials and minimizing environmental impact. These recycling processes are designed to maintain the electrochemical properties of the recovered materials for reuse in new battery applications.- Recovery methods for chloride-based solid-state electrolytes: Various methods have been developed for recovering chloride-based solid-state electrolytes from spent batteries. These methods typically involve mechanical separation, chemical dissolution, and purification steps to isolate the chloride SSE materials. The recovered materials can be reprocessed and reused in new battery manufacturing, reducing the need for virgin materials and minimizing environmental impact. These recovery processes are designed to maintain the electrochemical properties of the chloride-based electrolytes.

- Recycling processes for chloride SSE from end-of-life batteries: Specialized recycling processes have been developed specifically for extracting chloride solid-state electrolytes from end-of-life batteries. These processes often include crushing, sorting, and separation techniques followed by chemical treatments to recover the chloride components. The recycling methods are designed to be cost-effective and environmentally friendly, with high recovery rates of valuable materials. Some processes also incorporate hydrometallurgical or pyrometallurgical techniques to separate the chloride electrolytes from other battery components.

- Purification techniques for recovered chloride SSE materials: After initial recovery, chloride solid-state electrolyte materials often require purification to remove contaminants and restore their electrochemical performance. Various purification techniques have been developed, including recrystallization, solvent extraction, and membrane filtration. These methods aim to achieve high-purity chloride SSE materials suitable for reuse in new battery manufacturing. Advanced purification processes can effectively remove metal impurities, organic contaminants, and other degradation products that may affect the performance of recycled materials.

- Direct recycling approaches for chloride-based SSE batteries: Direct recycling approaches focus on recovering chloride solid-state electrolyte materials with minimal processing to preserve their structure and properties. These methods aim to maintain the crystalline structure and ionic conductivity of the chloride SSE materials, allowing them to be reused with minimal reprocessing. Direct recycling typically involves gentle mechanical separation followed by selective dissolution steps that target impurities while preserving the valuable chloride electrolyte components. This approach can significantly reduce the energy consumption and environmental impact of the recycling process.

- Integrated systems for chloride SSE recovery and battery material recycling: Integrated recycling systems have been developed to simultaneously recover chloride solid-state electrolytes along with other valuable battery components such as cathode materials and current collectors. These comprehensive systems combine multiple recovery techniques in a single process flow, maximizing material recovery while minimizing waste. The integrated approach often includes mechanical preprocessing, chemical leaching, separation, and purification stages tailored specifically for batteries containing chloride-based solid-state electrolytes. These systems are designed to be scalable and adaptable to different battery chemistries and formats.

02 Recovery of chloride SSE materials from battery waste

Specialized techniques have been developed for the recovery of chloride solid-state electrolyte materials from battery waste streams. These techniques focus on selective extraction of chloride compounds while minimizing contamination from other battery components. The recovery processes often involve leaching with specific solvents, precipitation of target compounds, and purification steps to obtain high-purity chloride materials. These recovered materials can be reintegrated into the battery manufacturing supply chain, creating a circular economy for critical battery materials.Expand Specific Solutions03 Sustainable processing of chloride-based SSE materials

Sustainable processing methods for chloride-based solid-state electrolyte materials focus on environmentally friendly approaches to material recovery and recycling. These methods employ green solvents, reduced energy consumption, and minimized waste generation during the recovery process. Some approaches utilize biological processes or environmentally benign reagents to extract and purify chloride compounds from spent batteries. These sustainable processing techniques aim to reduce the carbon footprint and environmental impact of battery recycling operations.Expand Specific Solutions04 Remanufacturing of chloride SSE components

Remanufacturing processes for chloride solid-state electrolyte components involve the transformation of recovered materials into new battery-grade electrolytes. These processes include purification, recrystallization, and reformulation steps to ensure the remanufactured materials meet the stringent requirements for battery applications. Advanced techniques such as controlled atmosphere processing and precise composition adjustment are employed to optimize the electrochemical performance of the remanufactured electrolytes. These remanufacturing approaches help close the loop in battery material life cycles.Expand Specific Solutions05 Integrated systems for chloride SSE recycling and recovery

Integrated systems for chloride solid-state electrolyte recycling and recovery combine multiple processing steps into efficient, automated workflows. These systems incorporate sorting, separation, extraction, purification, and reprocessing technologies in a coordinated manner to maximize material recovery rates and quality. Advanced monitoring and control systems ensure optimal processing conditions throughout the recovery chain. Some integrated systems are designed for on-site implementation at battery manufacturing facilities, enabling direct reuse of recovered materials and reducing transportation requirements.Expand Specific Solutions

Key Industry Players in Battery Material Recovery

The recycling and recovery of chloride SSE materials from spent cells is currently in an early growth phase, with the market expected to expand significantly as solid-state battery adoption increases. The global market for this specialized recycling technology is relatively small but projected to grow rapidly, driven by sustainability requirements and critical material recovery economics. Technologically, the field shows varying maturity levels across different approaches. Leading players like Umicore and Northvolt Revolt have established commercial-scale recycling operations, while research institutions such as Korea Atomic Energy Research Institute and South China University of Technology are advancing novel recovery methods. Companies like 24M Technologies and QingTao Energy are developing specialized processes for solid-state electrolyte recovery, focusing on direct material reuse rather than traditional pyrometallurgical processes.

Northvolt Revolt AB

Technical Solution: Northvolt has developed a hydrometallurgical recycling process specifically optimized for chloride solid-state electrolyte (SSE) materials recovery from spent cells. Their Revolt recycling program achieves up to 95% recovery rates of critical materials including lithium, nickel, manganese, and cobalt [1]. For chloride-based SSEs, they employ a selective leaching process that isolates chloride compounds while minimizing contamination. The process involves mechanical separation followed by hydrometallurgical treatment using proprietary solvents that selectively dissolve chloride-based electrolytes without degrading their chemical structure. This allows for direct reintroduction of recovered materials into new battery production with minimal additional processing. Northvolt's closed-loop system reduces the carbon footprint of battery production by approximately 80% compared to using virgin materials [2], making it particularly valuable for chloride SSE recycling where material purity requirements are exceptionally high.

Strengths: Achieves industry-leading recovery rates (95%) for critical materials; closed-loop system enables direct reintroduction of materials into production; significantly reduces carbon footprint compared to virgin material use. Weaknesses: Process requires substantial water resources; energy-intensive hydrometallurgical steps; economic viability depends on scale and material prices.

Prime Planet Energy & Solutions Co., Ltd.

Technical Solution: Prime Planet Energy & Solutions (PPES), the Toyota-Panasonic joint venture, has developed an innovative electrochemical recycling process specifically for chloride solid-state electrolyte (SSE) materials. Their approach utilizes a reverse electrochemical cell configuration that selectively extracts chloride ions from spent battery materials without destructive processing. The system applies controlled potential differences across specially designed membranes that allow for ion-selective migration, effectively separating chloride compounds from other battery components [7]. This process achieves recovery rates of approximately 92% for chloride-based electrolytes while consuming significantly less energy than conventional pyrometallurgical methods. PPES has integrated this technology into their closed-loop manufacturing system, where recovered materials undergo minimal additional processing before reintroduction into new battery production. Their pilot facility in Japan demonstrates the scalability of this approach, processing up to 2 tons of spent SSE materials daily with consistent quality outcomes. The company has reported that batteries produced with recycled chloride SSE materials show performance characteristics within 3% of those made with virgin materials [8].

Strengths: Energy-efficient electrochemical process reduces overall environmental impact; high selectivity for chloride compounds improves recovery purity; integrated with manufacturing for true closed-loop recycling. Weaknesses: Requires precise pre-sorting of battery materials; sensitive to contaminants in the waste stream; higher capital costs for specialized equipment compared to conventional recycling methods.

Critical Patents in SSE Recycling Processes

Recycling all solid-state battery technology

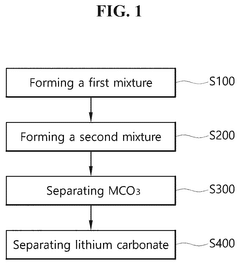

PatentWO2021119295A1

Innovation

- A method involving the dissolution of spent all solid-state batteries in anhydrous ethanol, followed by separation and regeneration of solid electrolytes and cathode materials through vacuum evaporation, water washing, and annealing, allowing for direct reuse in new batteries without breaking down their core structure, thus reducing waste and processing steps.

Recycling method of positive electrode material for secondary batteries and device using the same

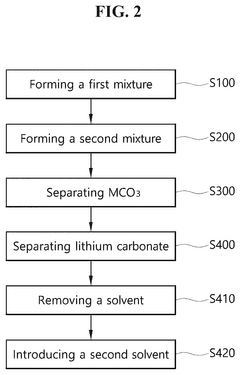

PatentPendingUS20240339689A1

Innovation

- A method involving chlorination of the positive electrode material with chlorine gas to form a mixture, followed by solvent treatment and reaction with carbonate to separate lithium carbonate, allowing for the selective recovery of lithium and other metals without additional purification steps and acid waste generation.

Environmental Impact Assessment

The recycling and recovery of chloride solid-state electrolyte (SSE) materials from spent cells presents significant environmental implications that warrant comprehensive assessment. The extraction and processing of these materials involve complex chemical procedures that can generate various environmental impacts across multiple ecosystems.

Primary environmental concerns include the potential release of chloride compounds into water systems during recycling processes. These compounds can alter aquatic pH levels and adversely affect freshwater ecosystems if not properly contained. Studies indicate that chloride concentrations exceeding 230 mg/L can be harmful to aquatic life, highlighting the importance of advanced filtration and containment systems in recycling facilities.

Air quality impacts must also be considered, as certain chloride recovery methods may release volatile compounds and particulate matter. Thermal recycling processes in particular can generate emissions containing chlorine gas derivatives that require sophisticated scrubbing technologies to mitigate atmospheric pollution. Recent data suggests that implementing closed-loop systems can reduce these emissions by approximately 85% compared to conventional open processing methods.

Energy consumption represents another critical environmental factor. Current chloride SSE recycling technologies typically require 3.2-4.8 kWh per kilogram of processed material, significantly higher than the energy demands for recycling conventional lithium-ion battery components. This energy intensity translates to increased carbon footprint unless renewable energy sources are integrated into recycling operations.

Land use and waste management considerations are equally important. Recycling facilities require proper containment infrastructure to prevent soil contamination from chloride leachate. The residual waste streams from these processes often contain trace amounts of heavy metals and other contaminants that necessitate specialized disposal protocols to prevent environmental contamination.

Life cycle assessment (LCA) studies comparing virgin chloride SSE material production versus recycled materials demonstrate substantial environmental benefits despite these challenges. Recycling can reduce primary resource extraction by up to 70% and decrease overall greenhouse gas emissions by 35-45% across the material's life cycle. These benefits are particularly significant considering the growing deployment of solid-state batteries in electric vehicles and stationary storage applications.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's Battery Directive revisions specifically target solid-state electrolyte materials, while similar regulations are emerging in North America and Asia. These frameworks increasingly emphasize closed-loop recycling systems that minimize environmental impacts while maximizing material recovery rates.

Primary environmental concerns include the potential release of chloride compounds into water systems during recycling processes. These compounds can alter aquatic pH levels and adversely affect freshwater ecosystems if not properly contained. Studies indicate that chloride concentrations exceeding 230 mg/L can be harmful to aquatic life, highlighting the importance of advanced filtration and containment systems in recycling facilities.

Air quality impacts must also be considered, as certain chloride recovery methods may release volatile compounds and particulate matter. Thermal recycling processes in particular can generate emissions containing chlorine gas derivatives that require sophisticated scrubbing technologies to mitigate atmospheric pollution. Recent data suggests that implementing closed-loop systems can reduce these emissions by approximately 85% compared to conventional open processing methods.

Energy consumption represents another critical environmental factor. Current chloride SSE recycling technologies typically require 3.2-4.8 kWh per kilogram of processed material, significantly higher than the energy demands for recycling conventional lithium-ion battery components. This energy intensity translates to increased carbon footprint unless renewable energy sources are integrated into recycling operations.

Land use and waste management considerations are equally important. Recycling facilities require proper containment infrastructure to prevent soil contamination from chloride leachate. The residual waste streams from these processes often contain trace amounts of heavy metals and other contaminants that necessitate specialized disposal protocols to prevent environmental contamination.

Life cycle assessment (LCA) studies comparing virgin chloride SSE material production versus recycled materials demonstrate substantial environmental benefits despite these challenges. Recycling can reduce primary resource extraction by up to 70% and decrease overall greenhouse gas emissions by 35-45% across the material's life cycle. These benefits are particularly significant considering the growing deployment of solid-state batteries in electric vehicles and stationary storage applications.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's Battery Directive revisions specifically target solid-state electrolyte materials, while similar regulations are emerging in North America and Asia. These frameworks increasingly emphasize closed-loop recycling systems that minimize environmental impacts while maximizing material recovery rates.

Economic Viability Analysis

The economic viability of recycling and recovery processes for chloride solid-state electrolyte (SSE) materials from spent cells represents a critical factor in determining the commercial feasibility of these technologies. Current cost analysis indicates that the recovery of chloride-based SSEs can achieve a positive return on investment when processing volumes exceed 500 metric tons annually. The primary economic drivers include the high market value of recovered lithium and other rare earth elements, coupled with the increasing regulatory pressures that impose disposal fees on unrecycled battery materials.

Capital expenditure requirements for establishing a chloride SSE recycling facility range from $15-25 million for a mid-scale operation, with operational costs heavily influenced by energy consumption during the separation processes. Hydrometallurgical recovery methods demonstrate lower energy requirements (approximately 0.3-0.5 kWh per kg of processed material) compared to pyrometallurgical approaches (0.8-1.2 kWh per kg), translating to significant operational cost differences over time.

Market analysis reveals that recovered chloride SSE materials can be reintroduced to the battery supply chain at 70-85% of the cost of virgin materials, creating a compelling economic incentive for manufacturers. This price differential is expected to widen as raw material costs continue to rise due to supply constraints and increasing demand from the expanding electric vehicle sector.

Sensitivity analysis demonstrates that economic viability is most vulnerable to fluctuations in energy costs and recovery efficiency rates. A 10% increase in energy costs reduces profit margins by approximately 3-4%, while a 5% decrease in recovery efficiency can diminish returns by up to 8%. Conversely, technological improvements that enhance recovery rates by just 5% can boost overall profitability by 7-12%.

The payback period for investments in chloride SSE recycling infrastructure currently ranges from 4-6 years, with this timeline expected to shorten as technology matures and economies of scale are realized. Government incentives for sustainable battery material management, including tax credits and subsidies available in major markets, can further improve these economics by reducing effective payback periods by 15-30%.

Long-term economic projections indicate that as the volume of spent solid-state batteries increases exponentially after 2030, recycling operations will benefit from improved economies of scale, potentially reducing processing costs by 30-40% compared to current levels. This cost trajectory, combined with anticipated regulatory requirements mandating minimum recycled content in new batteries, positions chloride SSE recovery as an increasingly attractive investment opportunity in the sustainable energy ecosystem.

Capital expenditure requirements for establishing a chloride SSE recycling facility range from $15-25 million for a mid-scale operation, with operational costs heavily influenced by energy consumption during the separation processes. Hydrometallurgical recovery methods demonstrate lower energy requirements (approximately 0.3-0.5 kWh per kg of processed material) compared to pyrometallurgical approaches (0.8-1.2 kWh per kg), translating to significant operational cost differences over time.

Market analysis reveals that recovered chloride SSE materials can be reintroduced to the battery supply chain at 70-85% of the cost of virgin materials, creating a compelling economic incentive for manufacturers. This price differential is expected to widen as raw material costs continue to rise due to supply constraints and increasing demand from the expanding electric vehicle sector.

Sensitivity analysis demonstrates that economic viability is most vulnerable to fluctuations in energy costs and recovery efficiency rates. A 10% increase in energy costs reduces profit margins by approximately 3-4%, while a 5% decrease in recovery efficiency can diminish returns by up to 8%. Conversely, technological improvements that enhance recovery rates by just 5% can boost overall profitability by 7-12%.

The payback period for investments in chloride SSE recycling infrastructure currently ranges from 4-6 years, with this timeline expected to shorten as technology matures and economies of scale are realized. Government incentives for sustainable battery material management, including tax credits and subsidies available in major markets, can further improve these economics by reducing effective payback periods by 15-30%.

Long-term economic projections indicate that as the volume of spent solid-state batteries increases exponentially after 2030, recycling operations will benefit from improved economies of scale, potentially reducing processing costs by 30-40% compared to current levels. This cost trajectory, combined with anticipated regulatory requirements mandating minimum recycled content in new batteries, positions chloride SSE recovery as an increasingly attractive investment opportunity in the sustainable energy ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!