PVDF's Role in Performance Metrics of Cutting-Edge Equipment

PVDF Technology Evolution

Polyvinylidene fluoride (PVDF) has undergone significant technological evolution since its discovery in 1948. Initially developed as a high-performance thermoplastic, PVDF's unique properties have led to its widespread adoption in various industries, particularly in cutting-edge equipment manufacturing.

The early stages of PVDF technology focused primarily on its chemical resistance and thermal stability. These properties made it an ideal material for use in chemical processing equipment and high-temperature applications. As research progressed, scientists discovered PVDF's piezoelectric and pyroelectric properties, opening up new avenues for its application in sensors and actuators.

In the 1960s and 1970s, advancements in polymer science led to the development of different crystalline forms of PVDF, each with distinct properties. The alpha, beta, and gamma phases of PVDF were identified, with the beta phase exhibiting the strongest piezoelectric response. This discovery paved the way for PVDF's use in acoustic and ultrasonic transducers, as well as in energy harvesting devices.

The 1980s and 1990s saw a surge in PVDF membrane technology. Researchers developed techniques to create porous PVDF membranes with controlled pore sizes, making them ideal for filtration and separation processes. This innovation revolutionized water treatment and biomedical applications, enabling more efficient and cost-effective purification methods.

As nanotechnology emerged in the early 2000s, PVDF nanocomposites became a focal point of research. By incorporating nanoparticles into PVDF matrices, scientists were able to enhance its mechanical, electrical, and thermal properties. These nanocomposites found applications in advanced sensors, actuators, and energy storage devices, pushing the boundaries of PVDF's capabilities in cutting-edge equipment.

Recent years have witnessed the integration of PVDF into flexible and wearable electronics. Its flexibility, coupled with its piezoelectric properties, has made it an excellent candidate for developing self-powered sensors and energy harvesters in smart textiles and wearable devices. This has opened up new possibilities in health monitoring, sports performance tracking, and human-machine interfaces.

The ongoing evolution of PVDF technology continues to focus on improving its performance metrics in cutting-edge equipment. Current research aims to enhance its piezoelectric response, increase its thermal stability, and improve its compatibility with other materials. Additionally, efforts are being made to develop more sustainable production methods and explore biodegradable variants of PVDF to address environmental concerns.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) in cutting-edge equipment has been experiencing significant growth in recent years. This surge is primarily driven by the material's unique properties, which make it ideal for various high-performance applications across multiple industries.

In the electronics sector, PVDF plays a crucial role in the production of advanced sensors, actuators, and transducers. The increasing demand for smart devices, wearable technology, and Internet of Things (IoT) applications has led to a substantial rise in the need for PVDF-based components. These components offer excellent piezoelectric and pyroelectric properties, enabling the development of more sensitive and reliable sensors for consumer electronics, automotive systems, and industrial equipment.

The aerospace and defense industries have also shown a growing interest in PVDF-based materials. The material's high chemical resistance, thermal stability, and mechanical strength make it suitable for use in aircraft components, satellite systems, and military equipment. As these sectors continue to push the boundaries of performance and reliability, the demand for PVDF in specialized coatings, insulation materials, and structural components is expected to increase.

In the renewable energy sector, PVDF has found applications in photovoltaic modules and wind turbine components. The material's weather resistance and durability contribute to extended lifespans of solar panels and wind turbine blades, driving its adoption in the rapidly expanding clean energy market. As governments worldwide push for greater renewable energy adoption, the demand for PVDF in this sector is projected to grow substantially.

The healthcare industry represents another significant market for PVDF-based products. The material's biocompatibility and resistance to chemicals and sterilization processes make it valuable in medical devices, implants, and drug delivery systems. With the aging global population and increasing focus on advanced medical treatments, the demand for PVDF in healthcare applications is expected to rise steadily.

Water treatment and filtration systems are also driving the demand for PVDF membranes. The material's excellent filtration properties, combined with its chemical resistance, make it ideal for use in water purification processes, wastewater treatment, and industrial separations. As water scarcity becomes a global concern and environmental regulations become stricter, the market for PVDF-based filtration solutions is anticipated to expand significantly.

The automotive industry is another key driver of PVDF demand, particularly in the electric vehicle (EV) segment. PVDF is used in battery components, fuel cell membranes, and various sensors throughout modern vehicles. As the automotive sector transitions towards electrification and autonomous driving technologies, the demand for PVDF-based components is expected to grow exponentially.

Current Challenges

PVDF (Polyvinylidene fluoride) has emerged as a critical material in cutting-edge equipment, yet its implementation faces several significant challenges. One of the primary obstacles is the complex processing requirements for PVDF. The material's high melting point and strong intermolecular forces necessitate specialized manufacturing techniques, which can be both costly and time-consuming. This complexity often leads to increased production expenses and longer lead times, potentially hindering widespread adoption in certain industries.

Another challenge lies in the material's inherent properties. While PVDF boasts excellent chemical resistance and thermal stability, it can be prone to degradation under certain conditions, particularly when exposed to high pH environments or specific organic solvents. This limitation can restrict its application in some cutting-edge equipment where exposure to harsh chemicals is unavoidable, necessitating additional protective measures or alternative material choices.

The piezoelectric properties of PVDF, while beneficial in many applications, also present challenges. The material's sensitivity to mechanical stress can lead to unintended electrical signals in certain high-precision equipment, potentially compromising accuracy and reliability. Engineers must carefully consider this characteristic when designing systems, often requiring additional shielding or compensation mechanisms.

Compatibility issues with other materials used in cutting-edge equipment pose another significant challenge. PVDF's low surface energy can result in poor adhesion to other materials, complicating the integration process in complex systems. This can lead to difficulties in creating effective seals or bonds, potentially compromising the overall performance and longevity of the equipment.

The environmental impact of PVDF production and disposal is an increasing concern. While the material itself is relatively inert, the manufacturing process can involve the use of harmful chemicals and generate significant amounts of waste. Additionally, the long-term environmental effects of PVDF microparticles are not yet fully understood, raising questions about its sustainability in certain applications.

Lastly, the variability in PVDF's performance metrics across different grades and processing conditions presents a challenge for standardization. This variability can make it difficult for engineers to predict and consistently achieve desired performance characteristics, potentially leading to quality control issues and increased development cycles for new equipment.

Existing PVDF Solutions

01 Mechanical properties of PVDF

PVDF exhibits excellent mechanical properties, including high tensile strength, flexibility, and impact resistance. These characteristics make it suitable for various applications in industries such as automotive, aerospace, and construction. The polymer's mechanical performance can be further enhanced through the addition of reinforcing agents or by adjusting processing conditions.- Mechanical properties of PVDF: PVDF exhibits excellent mechanical properties, including high tensile strength, flexibility, and impact resistance. These characteristics make it suitable for various applications in industries such as automotive, aerospace, and construction. The polymer's mechanical performance can be further enhanced through the addition of reinforcing agents or by optimizing processing conditions.

- Thermal and chemical resistance of PVDF: PVDF demonstrates exceptional thermal stability and chemical resistance. It can withstand high temperatures and maintain its properties in harsh chemical environments. This makes it ideal for use in applications involving corrosive substances or extreme temperature conditions, such as in chemical processing equipment and heat exchangers.

- Electrical properties of PVDF: PVDF possesses unique electrical properties, including high dielectric strength and piezoelectric behavior. These characteristics make it valuable in electronic and sensor applications. The polymer can be used in the production of capacitors, transducers, and other electronic components where its electrical performance is advantageous.

- Barrier properties and permeability of PVDF: PVDF exhibits excellent barrier properties against gases, moisture, and chemicals. Its low permeability makes it suitable for packaging applications, protective coatings, and membrane technologies. The polymer's barrier performance can be further improved through the incorporation of nanofillers or by creating multi-layer structures.

- Processing and fabrication of PVDF: PVDF can be processed using various techniques such as extrusion, injection molding, and film casting. The polymer's processing characteristics, including melt flow index and crystallization behavior, affect its final performance. Optimizing processing parameters and exploring new fabrication methods can lead to improved PVDF products with enhanced performance metrics.

02 Thermal and chemical resistance of PVDF

PVDF demonstrates exceptional thermal stability and chemical resistance. It can withstand high temperatures and maintain its properties in harsh chemical environments. This makes it ideal for use in industrial applications, such as chemical processing equipment, pipes, and coatings. The polymer's resistance to UV radiation also contributes to its long-term durability in outdoor applications.Expand Specific Solutions03 Electrical and piezoelectric properties of PVDF

PVDF exhibits unique electrical and piezoelectric properties, making it valuable in sensor and actuator applications. Its high dielectric strength and low dielectric loss make it suitable for use in capacitors and electrical insulation. The polymer's piezoelectric behavior allows it to convert mechanical stress into electrical signals, enabling its use in various sensing and energy harvesting devices.Expand Specific Solutions04 PVDF membrane performance in filtration applications

PVDF membranes are widely used in filtration applications due to their excellent performance characteristics. These membranes offer high flux rates, good fouling resistance, and chemical stability. They are particularly effective in water and wastewater treatment, as well as in the separation of gases and liquids in industrial processes. The pore size and surface properties of PVDF membranes can be tailored to meet specific filtration requirements.Expand Specific Solutions05 PVDF performance in coating and film applications

PVDF-based coatings and films demonstrate superior weatherability, chemical resistance, and durability. These properties make them ideal for architectural coatings, protective films, and high-performance packaging materials. PVDF coatings provide excellent color retention and resistance to chalking, making them suitable for long-lasting exterior applications. The polymer's low surface energy also contributes to its non-stick and self-cleaning properties in various coating applications.Expand Specific Solutions

Key Industry Players

The PVDF market for cutting-edge equipment performance metrics is in a growth phase, driven by increasing demand in various high-tech industries. The market size is expanding rapidly, with a projected CAGR of over 7% in the coming years. Technologically, PVDF applications are advancing, with companies like Arkema, Solvay, and Honeywell International leading innovation. These firms are developing enhanced PVDF formulations for improved equipment performance. Other players such as Applied Materials and Lam Research are integrating PVDF into semiconductor manufacturing equipment, while companies like Tokyo Electron and IBM are exploring its potential in next-generation electronics. The technology's maturity varies across applications, with established uses in some sectors and emerging opportunities in others, indicating a dynamic competitive landscape.

Arkema France SA

International Business Machines Corp.

PVDF Innovations

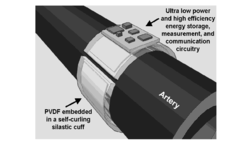

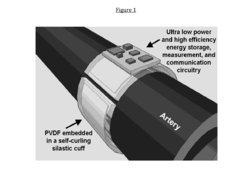

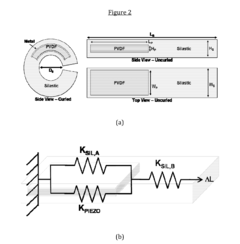

- The development of energy harvesting devices that convert mechanical and thermal energy from biological sources, such as blood pressure variations, into electrical energy using piezoelectric thin films embedded in biocompatible insulators, allowing for self-powered, autonomous implantable microsystems with reduced surgical needs and external interface requirements.

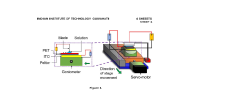

- Dynamic contact line lithography (DCLL) coupled with an electrostatic field (EF) is used to fabricate PVDF microthreads, employing a movable motorized stage with a thermos-electric Peltier heater and a conductive blade to generate PVDF microthreads with enhanced β-phase crystallinity at lower voltages, avoiding the need for sophisticated equipment.

Environmental Impact

The environmental impact of PVDF (Polyvinylidene Fluoride) in cutting-edge equipment is a critical consideration as industries strive for sustainability alongside technological advancement. PVDF's unique properties, including its chemical resistance and durability, contribute to the longevity of equipment, potentially reducing the frequency of replacements and associated waste generation.

However, the production of PVDF involves fluorine-based chemicals, which can have significant environmental implications. The manufacturing process may release greenhouse gases and other pollutants, contributing to climate change and air quality issues. Additionally, the use of fluoropolymers like PVDF has raised concerns about the persistence of these materials in the environment, as they do not readily biodegrade.

On the positive side, PVDF's role in enhancing equipment performance can lead to improved energy efficiency in various applications. For instance, in membrane filtration systems, PVDF membranes can operate at higher flux rates with lower energy consumption compared to traditional materials. This energy savings translates to reduced carbon emissions over the lifecycle of the equipment.

The recyclability of PVDF is another important aspect of its environmental profile. While challenging, PVDF can be recycled through specialized processes, which could help mitigate its end-of-life environmental impact. However, the current recycling infrastructure for fluoropolymers is limited, and more research and development are needed to make recycling economically viable on a large scale.

In the context of water treatment and purification equipment, PVDF's resistance to fouling and chemical degradation can lead to more efficient and longer-lasting systems. This efficiency can result in reduced water and chemical consumption, indirectly benefiting the environment through resource conservation.

As regulations around environmental protection become more stringent, the use of PVDF in cutting-edge equipment may face increased scrutiny. Manufacturers are likely to invest in research to develop more environmentally friendly alternatives or improve the sustainability of PVDF production and use. This could include exploring bio-based precursors for PVDF synthesis or developing more efficient recycling technologies.

The environmental impact of PVDF extends beyond its production and use phases to its potential release into ecosystems. While PVDF itself is considered relatively inert, there are concerns about the potential for microplastic formation as PVDF-containing products degrade over time. This aspect requires further study to fully understand the long-term environmental consequences of widespread PVDF use in high-performance equipment.

Regulatory Compliance

The regulatory landscape surrounding PVDF's use in cutting-edge equipment is complex and multifaceted, reflecting the material's widespread applications across various industries. As PVDF continues to play a crucial role in enhancing performance metrics, regulatory bodies have implemented stringent guidelines to ensure safety, quality, and environmental compliance.

In the medical device sector, PVDF components must adhere to FDA regulations in the United States and the Medical Device Regulation (MDR) in the European Union. These regulations focus on biocompatibility, sterilization processes, and long-term stability of PVDF-based materials in medical applications. Manufacturers must provide extensive documentation and undergo rigorous testing to demonstrate compliance with these standards.

For aerospace and automotive applications, PVDF materials are subject to industry-specific regulations such as the Federal Aviation Administration (FAA) requirements and automotive safety standards. These regulations emphasize the material's ability to withstand extreme conditions, resist chemical degradation, and maintain structural integrity over extended periods.

Environmental regulations also play a significant role in PVDF's regulatory compliance. The material's production and disposal are governed by regulations such as the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. These regulations aim to minimize the environmental impact of PVDF throughout its lifecycle, from manufacturing to end-of-life disposal.

In the electronics industry, PVDF's use in high-performance components must comply with international standards such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) specifications. These standards focus on electrical properties, thermal stability, and reliability of PVDF-based materials in electronic applications.

Regulatory compliance also extends to the manufacturing processes of PVDF. Good Manufacturing Practices (GMP) and ISO standards are often required to ensure consistent quality and traceability of PVDF products. These standards encompass aspects such as raw material sourcing, production processes, quality control, and documentation.

As PVDF finds new applications in emerging technologies, regulatory bodies are continuously updating their guidelines to address potential risks and ensure public safety. This dynamic regulatory environment requires manufacturers and researchers to stay informed about the latest compliance requirements and adapt their processes accordingly.