PVDF in Sports Equipment Design: Improving Athletic Performance

PVDF in Sports: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a revolutionary material in sports equipment design, offering unique properties that can significantly enhance athletic performance. The journey of PVDF in sports began in the late 20th century when researchers discovered its piezoelectric and ferroelectric characteristics. These properties allow PVDF to convert mechanical stress into electrical energy and vice versa, opening up a wide range of applications in sports technology.

The evolution of PVDF in sports equipment has been driven by the increasing demand for high-performance gear that can provide athletes with a competitive edge. As sports have become more technologically advanced, the integration of smart materials like PVDF has become crucial in developing equipment that can adapt to an athlete's needs and provide real-time feedback.

One of the primary objectives of incorporating PVDF into sports equipment is to improve energy transfer and absorption. In activities such as running or jumping, PVDF can be used to create shoes that store and release energy more efficiently, potentially increasing an athlete's speed and endurance. Similarly, in racquet sports, PVDF can be integrated into the strings or frame to enhance power and control.

Another key goal is to utilize PVDF's sensing capabilities to provide athletes and coaches with valuable data. By incorporating PVDF sensors into equipment like golf clubs, tennis racquets, or even clothing, it becomes possible to measure and analyze various aspects of an athlete's performance, such as swing speed, impact force, or body movements. This data can be used to refine techniques, prevent injuries, and optimize training regimens.

The development of PVDF in sports also aims to create more durable and lightweight equipment. The material's high strength-to-weight ratio and resistance to wear and tear make it an ideal component in the construction of various sporting goods, from protective gear to high-performance textiles.

As we look to the future, the objectives for PVDF in sports equipment design continue to expand. Researchers and manufacturers are exploring ways to combine PVDF with other advanced materials and technologies, such as carbon fiber composites or Internet of Things (IoT) devices, to create even more sophisticated and responsive sports equipment. The ultimate goal is to push the boundaries of athletic performance while also enhancing safety and comfort for athletes at all levels of competition.

Market Analysis for PVDF-Enhanced Sports Gear

The market for PVDF-enhanced sports gear has shown significant growth potential in recent years, driven by increasing demand for high-performance athletic equipment. PVDF (Polyvinylidene Fluoride) has emerged as a key material in sports equipment design due to its unique properties, including excellent durability, flexibility, and resistance to environmental factors.

The global sports equipment market, valued at approximately $126 billion in 2021, is projected to reach $165 billion by 2027, with a compound annual growth rate (CAGR) of 4.8%. Within this broader market, the segment for advanced materials in sports gear, including PVDF-based products, is experiencing even faster growth, estimated at a CAGR of 6.5% from 2022 to 2028.

PVDF's application in sports equipment spans various categories, including footwear, apparel, protective gear, and sporting goods. In the footwear sector, PVDF is increasingly used in high-performance athletic shoes, particularly in midsoles and outsoles, enhancing durability and energy return. The global athletic footwear market, valued at $127.3 billion in 2021, is expected to reach $196.6 billion by 2030, presenting a substantial opportunity for PVDF-enhanced products.

In sports apparel, PVDF is utilized in moisture-wicking fabrics and waterproof outerwear, catering to the growing demand for functional sportswear. The global sports apparel market, worth $167.7 billion in 2021, is forecasted to reach $248.1 billion by 2026, with technologically advanced materials playing a crucial role in this growth.

The protective gear segment, including helmets, pads, and guards, is another area where PVDF is gaining traction due to its impact resistance and lightweight properties. This market segment is expected to grow at a CAGR of 4.2% from 2021 to 2026, driven by increasing awareness of sports safety and regulations mandating the use of protective equipment.

Geographically, North America and Europe currently dominate the market for PVDF-enhanced sports gear, accounting for over 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with countries like China, Japan, and India showing increased adoption of advanced sports equipment.

Key market drivers include the rising popularity of sports and fitness activities, growing consumer awareness of the benefits of high-performance gear, and technological advancements in material science. The COVID-19 pandemic has also accelerated the trend towards personal fitness and outdoor activities, further boosting demand for premium sports equipment.

Challenges in the market include the higher cost of PVDF-enhanced products compared to traditional materials, which may limit adoption in price-sensitive segments. Additionally, increasing environmental concerns and regulations regarding synthetic materials pose potential hurdles for market growth, necessitating the development of more sustainable PVDF formulations or alternative eco-friendly materials.

Current PVDF Applications and Challenges

Polyvinylidene fluoride (PVDF) has gained significant traction in sports equipment design due to its unique properties that can enhance athletic performance. Currently, PVDF is being applied in various sports equipment, including footwear, protective gear, and high-performance textiles. In footwear, PVDF is utilized in midsoles and insoles to provide superior cushioning and energy return, improving comfort and reducing fatigue for athletes during prolonged activities.

In protective gear, such as helmets and body armor, PVDF's impact resistance and lightweight nature make it an ideal material for absorbing and dissipating energy from collisions. This application has shown promising results in reducing the risk of injuries in contact sports. Additionally, PVDF's piezoelectric properties are being explored in smart sports equipment, enabling real-time performance monitoring and data collection.

Despite these advancements, several challenges persist in the widespread adoption of PVDF in sports equipment. One significant hurdle is the cost of production and processing PVDF, which can be higher compared to traditional materials used in sports gear. This cost factor often limits its use to high-end or professional-grade equipment, making it less accessible to amateur athletes and recreational users.

Another challenge lies in the complexity of integrating PVDF into existing manufacturing processes. Many sports equipment manufacturers need to modify their production lines and techniques to accommodate PVDF, which can be a significant investment. Furthermore, ensuring consistent quality and performance across different batches of PVDF-enhanced products remains a technical challenge, particularly in large-scale production.

The durability of PVDF in sports applications is also an area of ongoing research and development. While PVDF exhibits excellent resistance to chemicals and UV radiation, its long-term performance under repeated high-stress conditions typical in sports activities is still being evaluated. Manufacturers are working on improving the material's resistance to wear and tear, especially in high-friction areas of sports equipment.

Environmental concerns present another challenge in PVDF applications. As sustainability becomes increasingly important in product design, the recyclability and end-of-life disposal of PVDF-containing sports equipment need to be addressed. Current recycling technologies for PVDF are limited, and the material's persistence in the environment raises questions about its long-term ecological impact.

Lastly, regulatory compliance and safety standards for PVDF in sports equipment are still evolving. As a relatively new material in this field, comprehensive long-term studies on its safety and performance are ongoing. This uncertainty can lead to hesitation among manufacturers and consumers in fully embracing PVDF technology in sports equipment.

Existing PVDF Integration Methods

01 PVDF-based athletic wear

PVDF is used in the development of high-performance athletic wear due to its excellent moisture-wicking properties, durability, and flexibility. These garments can enhance athlete comfort and performance by regulating body temperature and moisture levels during physical activities.- PVDF in athletic apparel: PVDF is used in athletic apparel for its moisture-wicking and breathable properties. It can be incorporated into fabrics to enhance performance by regulating body temperature and improving comfort during physical activities. The material's durability and resistance to wear make it suitable for high-intensity sports.

- PVDF in sports equipment: PVDF is utilized in the manufacturing of sports equipment due to its lightweight and high-strength characteristics. It can be found in items such as rackets, protective gear, and footwear, contributing to improved performance and reduced fatigue for athletes. The material's flexibility and impact resistance make it ideal for various sporting applications.

- PVDF coatings for athletic surfaces: PVDF-based coatings are applied to athletic surfaces to enhance durability and performance. These coatings provide weather resistance, UV protection, and improved traction for outdoor sports facilities. The material's chemical resistance also helps maintain the integrity of the surface under various environmental conditions.

- PVDF in wearable sports technology: PVDF is incorporated into wearable sports technology due to its piezoelectric properties. It can be used in sensors to measure athletic performance metrics such as speed, force, and motion. These sensors can be integrated into clothing or equipment to provide real-time feedback and data analysis for athletes and coaches.

- PVDF in sports injury prevention and rehabilitation: PVDF-based materials are used in sports injury prevention and rehabilitation products. The material's flexibility and ability to conform to body contours make it suitable for supportive braces, compression garments, and therapeutic devices. Its durability and moisture-wicking properties contribute to improved comfort and effectiveness in injury recovery and prevention.

02 PVDF in sports equipment

PVDF is incorporated into various sports equipment, such as rackets, skis, and protective gear, to improve their performance characteristics. Its lightweight nature, impact resistance, and ability to dampen vibrations make it an ideal material for enhancing athletic equipment.Expand Specific Solutions03 PVDF-based sensors for athletic performance monitoring

PVDF's piezoelectric properties are utilized in the development of sensors for monitoring athletic performance. These sensors can be integrated into wearable devices or sports equipment to measure various parameters such as speed, force, and movement, providing valuable data for athletes and coaches.Expand Specific Solutions04 PVDF coatings for sports surfaces

PVDF-based coatings are applied to sports surfaces, such as running tracks and court floors, to enhance their durability, weather resistance, and performance characteristics. These coatings can improve traction, reduce maintenance requirements, and extend the lifespan of athletic facilities.Expand Specific Solutions05 PVDF membranes in athletic footwear

PVDF membranes are incorporated into athletic footwear to improve breathability, water resistance, and overall comfort. These membranes allow sweat to evaporate while preventing water from entering, resulting in better foot climate control and enhanced athletic performance.Expand Specific Solutions

Key Players in PVDF Sports Equipment

The PVDF market in sports equipment design is in a growth phase, driven by increasing demand for high-performance athletic gear. The market size is expanding as more manufacturers recognize PVDF's potential to enhance athletic performance. Technologically, PVDF applications are advancing rapidly, with companies like Arkema, Inc., Solvay Specialty Polymers, and Toray Industries leading innovation. These firms are developing specialized PVDF formulations for sports applications, focusing on properties such as flexibility, durability, and moisture-wicking capabilities. Emerging players like ASICS Corp. and NIKE Innovate CV are integrating PVDF into cutting-edge sports equipment designs, indicating a trend towards mainstream adoption in the athletic industry.

Arkema, Inc.

Toray Industries, Inc.

Innovative PVDF Properties for Sports

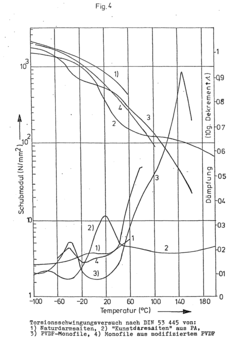

- A string made from a monofilament of polyvinylidene fluoride (PVDF) with added acrylates, such as polymethyl methacrylate, to enhance damping and elasticity, combined with a specific manufacturing process involving warm and cold stretching to achieve properties similar to natural gut strings.

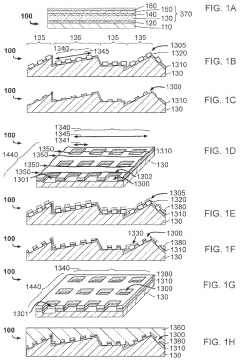

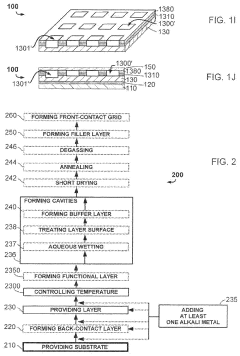

- The method involves adding alkali metals like Cs and Rb to the absorber layer, controlling temperature for self-assembly, and selectively dissolving alkali crystals to form nanopatterns, which enhances doping, reduces carrier recombination, and optimizes buffer layer thickness, thereby improving photovoltaic conversion efficiency and reducing environmental impact.

Environmental Impact of PVDF in Sports

The environmental impact of PVDF (Polyvinylidene Fluoride) in sports equipment is a crucial consideration as the material gains popularity in athletic gear design. PVDF's unique properties, including its durability, flexibility, and resistance to chemicals and UV radiation, make it an attractive choice for sports equipment manufacturers. However, these same characteristics also raise concerns about its long-term environmental effects.

One of the primary environmental challenges associated with PVDF in sports equipment is its end-of-life disposal. As a synthetic polymer, PVDF is not biodegradable and can persist in the environment for extended periods. When sports equipment containing PVDF reaches the end of its useful life, it often ends up in landfills or incinerators, contributing to plastic pollution and potentially releasing harmful chemicals into the ecosystem.

The production process of PVDF also has environmental implications. The synthesis of PVDF involves the use of fluorine-containing compounds, which can have significant environmental impacts if not properly managed. Emissions from PVDF manufacturing facilities may contribute to air and water pollution, potentially affecting local ecosystems and human health.

On the other hand, the durability of PVDF can be seen as an environmental advantage in some respects. Sports equipment made with PVDF tends to have a longer lifespan compared to products made from less durable materials. This longevity can reduce the frequency of replacement and, consequently, the overall consumption of resources and energy associated with manufacturing new equipment.

Water resistance is another property of PVDF that has both positive and negative environmental implications. While it enhances the performance and durability of sports equipment in wet conditions, it also makes the material less susceptible to natural degradation processes, further contributing to its persistence in the environment.

Efforts to mitigate the environmental impact of PVDF in sports equipment are ongoing. Some manufacturers are exploring recycling technologies specifically designed for PVDF-containing products. These initiatives aim to create closed-loop systems where used equipment can be processed and the PVDF material recovered for reuse in new products.

Additionally, research is being conducted on developing more environmentally friendly alternatives that can match PVDF's performance characteristics. Biobased polymers and composite materials are being investigated as potential substitutes that could offer similar benefits with reduced environmental impact.

As the sports industry continues to prioritize sustainability, the use of PVDF in equipment design is likely to face increased scrutiny. Balancing the material's performance benefits with its environmental consequences will be crucial for manufacturers and athletes alike. Future developments in material science and recycling technologies may provide solutions that allow for the continued use of PVDF while minimizing its ecological footprint.

Biomechanical Benefits of PVDF Equipment

Polyvinylidene fluoride (PVDF) has emerged as a revolutionary material in sports equipment design, offering significant biomechanical benefits that enhance athletic performance. The incorporation of PVDF in sports gear has led to improvements in energy transfer, impact absorption, and overall equipment responsiveness.

One of the primary biomechanical advantages of PVDF-enhanced equipment is its piezoelectric properties. When subjected to mechanical stress, PVDF generates an electrical charge, which can be harnessed to provide real-time feedback on an athlete's movements and performance. This feature allows for more precise analysis of biomechanics, enabling athletes and coaches to optimize training regimens and technique.

PVDF's high strength-to-weight ratio contributes to the development of lighter yet more durable sports equipment. This reduction in weight translates to decreased energy expenditure for athletes, potentially improving endurance and reducing fatigue during prolonged physical activities. The material's flexibility also allows for better conformity to body contours, enhancing comfort and reducing the risk of injury.

In impact-intensive sports, PVDF's excellent shock-absorbing properties play a crucial role in minimizing the transfer of harmful forces to the athlete's body. This characteristic is particularly beneficial in protective gear, such as helmets and padding, where it can significantly reduce the risk of concussions and other impact-related injuries.

The material's ability to dampen vibrations is another key biomechanical benefit. In racquet sports, for example, PVDF-infused equipment can reduce the transmission of vibrations to the player's arm, potentially decreasing the incidence of conditions like tennis elbow and improving overall comfort during play.

PVDF's thermal stability and resistance to environmental factors ensure consistent performance across various weather conditions. This stability translates to more reliable equipment behavior, allowing athletes to maintain their biomechanical efficiency regardless of external temperature fluctuations or humidity levels.

The integration of PVDF in sports equipment also facilitates the development of smart gear. By leveraging its piezoelectric properties, manufacturers can create equipment that actively adapts to an athlete's movements, providing dynamic support and optimizing energy return. This adaptability can lead to improved biomechanical efficiency and potentially enhance overall athletic performance.

In conclusion, the biomechanical benefits of PVDF in sports equipment design are multifaceted and significant. From improved energy transfer and impact absorption to enhanced feedback mechanisms and adaptability, PVDF is revolutionizing the way athletes interact with their gear, ultimately contributing to better performance and reduced injury risk across various sporting disciplines.