PVDF in Renewable Energy Systems: Leading Next-Gen Solutions

PVDF Technology Evolution

Polyvinylidene fluoride (PVDF) has undergone significant technological evolution in the context of renewable energy systems, marking a transformative journey from its initial discovery to its current status as a leading material in next-generation solutions. The progression of PVDF technology can be traced through several key developmental stages, each characterized by breakthroughs that have expanded its applicability and efficiency in renewable energy applications.

In the early stages of PVDF development, the focus was primarily on understanding and refining its unique piezoelectric properties. This phase laid the groundwork for its eventual use in energy harvesting applications. As research advanced, scientists began to explore PVDF's potential in thin-film form, which opened up new possibilities for flexible and lightweight energy solutions.

The next significant milestone in PVDF technology evolution came with the development of PVDF nanofibers and nanocomposites. This advancement dramatically increased the material's surface area and reactivity, enhancing its performance in energy storage and conversion applications. The incorporation of nanoparticles and carbon-based materials into PVDF matrices further improved its electrical and mechanical properties, paving the way for more efficient solar cells and energy storage devices.

A crucial turning point in PVDF's evolution was the refinement of its ferroelectric properties. This led to the creation of PVDF-based ferroelectric polymers with enhanced energy density and improved temperature stability. These advancements made PVDF an attractive option for capacitors and energy storage systems in renewable energy applications, particularly in wind and solar power installations.

Recent years have seen a focus on optimizing PVDF's performance in specific renewable energy applications. For instance, in solar energy, researchers have developed PVDF-based backsheets that offer superior weather resistance and durability, extending the lifespan of photovoltaic panels. In wind energy, PVDF composites are being used to create more efficient and lightweight turbine blades, improving overall energy capture.

The latest frontier in PVDF technology evolution is the development of smart PVDF materials. These advanced formulations incorporate self-healing properties and responsive behaviors, allowing for adaptive energy harvesting and storage solutions. This innovation promises to enhance the reliability and efficiency of renewable energy systems, particularly in challenging environmental conditions.

Looking ahead, the trajectory of PVDF technology in renewable energy systems points towards even more sophisticated applications. Ongoing research is exploring the potential of PVDF in hybrid energy systems, where it could play a crucial role in integrating multiple renewable sources. Additionally, advancements in PVDF processing techniques, such as 3D printing and electrospinning, are opening up new possibilities for customized and highly efficient energy solutions.

Renewable Energy Market Trends

The renewable energy market has experienced unprecedented growth in recent years, driven by increasing environmental concerns, government policies, and technological advancements. This trend is expected to continue, with the global renewable energy market projected to reach $1.1 trillion by 2027, growing at a CAGR of 8.4% from 2020 to 2027.

Solar and wind energy have been at the forefront of this growth, with solar PV installations reaching a record 139 GW in 2020 despite the COVID-19 pandemic. Wind energy has also seen significant expansion, with global capacity increasing by 53% in 2020 compared to the previous year. Hydropower remains the largest source of renewable electricity generation, accounting for 16% of global electricity production.

Emerging technologies such as energy storage systems, green hydrogen, and advanced materials are playing an increasingly important role in the renewable energy landscape. Energy storage, in particular, is crucial for addressing the intermittency issues associated with solar and wind power. The global energy storage market is expected to grow at a CAGR of 24% from 2020 to 2030.

Government policies and incentives continue to be major drivers of renewable energy adoption. Many countries have set ambitious targets for renewable energy deployment as part of their commitments to reduce greenhouse gas emissions. For instance, the European Union aims to increase its share of renewable energy to 32% by 2030, while China plans to achieve carbon neutrality by 2060.

Corporate investments in renewable energy have also surged, with many large companies committing to 100% renewable energy targets. This trend is expected to continue as businesses seek to reduce their carbon footprint and meet sustainability goals.

The integration of digital technologies, such as artificial intelligence and the Internet of Things, is enhancing the efficiency and reliability of renewable energy systems. These technologies are enabling better forecasting, grid management, and optimization of energy production and consumption.

As the renewable energy market matures, there is an increasing focus on sustainability and circular economy principles. This includes the development of recyclable materials for solar panels and wind turbines, as well as strategies for managing end-of-life equipment.

The role of developing countries in the renewable energy market is becoming more prominent, with significant investments being made in countries like India, Brazil, and several African nations. This trend is expected to continue as renewable energy becomes increasingly cost-competitive with traditional fossil fuels.

PVDF Challenges in Energy Systems

Polyvinylidene fluoride (PVDF) has emerged as a promising material in renewable energy systems, particularly in solar panels, wind turbines, and energy storage devices. However, its integration into these systems presents several significant challenges that need to be addressed for optimal performance and widespread adoption.

One of the primary challenges is the thermal stability of PVDF in high-temperature environments. While PVDF exhibits excellent thermal properties compared to many other polymers, prolonged exposure to elevated temperatures in solar panels or energy storage systems can lead to degradation of its mechanical and electrical properties. This degradation can result in reduced efficiency and shortened lifespan of the energy systems, necessitating the development of more thermally stable PVDF formulations or protective coatings.

Another critical challenge is the piezoelectric performance of PVDF in energy harvesting applications, particularly in wind turbines. Although PVDF demonstrates piezoelectric properties, its efficiency in converting mechanical stress into electrical energy is still lower than some ceramic alternatives. Enhancing the piezoelectric response of PVDF through various methods, such as incorporating nanofillers or optimizing the polymer chain orientation, remains an active area of research.

The processability of PVDF for large-scale manufacturing of renewable energy components also poses challenges. While PVDF can be processed using conventional polymer processing techniques, achieving consistent quality and desired properties across large surface areas or complex geometries can be difficult. This is particularly relevant for the production of solar panel encapsulants or wind turbine blade coatings, where uniformity and defect-free surfaces are crucial for optimal performance.

Compatibility issues between PVDF and other materials used in renewable energy systems present another set of challenges. For instance, in solar panels, ensuring strong adhesion between PVDF-based backsheets and other layers without compromising the overall performance of the panel is essential. Similarly, in energy storage devices, the interaction between PVDF-based separators or binders and electrolytes must be carefully managed to prevent degradation or unwanted side reactions.

Lastly, the environmental impact and recyclability of PVDF in renewable energy applications need to be addressed. While PVDF offers excellent durability and chemical resistance, these properties also make it challenging to recycle or dispose of at the end of its life cycle. Developing eco-friendly recycling methods or biodegradable alternatives that maintain PVDF's desirable properties is crucial for the long-term sustainability of renewable energy systems.

Current PVDF Energy Solutions

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.

- PVDF-based piezoelectric and energy harvesting devices: Development of piezoelectric devices and energy harvesters using PVDF and its copolymers. These materials are utilized for their excellent piezoelectric properties to convert mechanical energy into electrical energy, with applications in sensors, actuators, and small-scale power generation systems.

- PVDF in battery and supercapacitor applications: Utilization of PVDF as a binder material in lithium-ion batteries and supercapacitors. PVDF's chemical stability and adhesive properties make it suitable for electrode fabrication, improving the overall performance and longevity of energy storage devices.

- PVDF-based coatings and surface treatments: Development of PVDF-based coatings and surface treatments for various substrates to impart properties such as chemical resistance, weatherability, and self-cleaning capabilities. These coatings find applications in architectural finishes, industrial equipment protection, and anti-corrosion treatments.

- PVDF in composite materials and blends: Incorporation of PVDF into composite materials and polymer blends to create materials with enhanced properties. This includes the development of PVDF-based nanocomposites, fiber-reinforced composites, and polymer alloys for applications in aerospace, automotive, and industrial sectors.

02 PVDF-based piezoelectric and ferroelectric materials

Development of PVDF and its copolymers as piezoelectric and ferroelectric materials for sensors, actuators, and energy harvesting devices. This includes methods for enhancing the piezoelectric properties through various processing techniques, such as stretching, poling, and addition of fillers or nanoparticles.Expand Specific Solutions03 PVDF in energy storage applications

Utilization of PVDF as a binder material or separator in lithium-ion batteries and other energy storage devices. This includes methods for improving the electrochemical performance, thermal stability, and mechanical properties of PVDF-based components in battery systems.Expand Specific Solutions04 PVDF-based coatings and films

Development of PVDF-based coatings and films for various applications, including corrosion protection, weather resistance, and self-cleaning surfaces. This includes methods for improving adhesion, durability, and functional properties of PVDF coatings through formulation adjustments and surface treatments.Expand Specific Solutions05 PVDF in composite materials

Incorporation of PVDF into composite materials to enhance their properties, such as mechanical strength, thermal stability, and chemical resistance. This includes methods for improving the compatibility and interfacial adhesion between PVDF and other materials in composite systems.Expand Specific Solutions

Key PVDF Industry Players

The PVDF market in renewable energy systems is experiencing rapid growth, driven by increasing demand for sustainable energy solutions. The industry is in an expansion phase, with a projected market size reaching billions of dollars by 2030. Technological maturity varies across applications, with established players like Arkema, Inc. and 3M Innovative Properties Co. leading in material development. Emerging companies such as Sunlight Aerospace, Inc. and Alta Devices, Inc. are pushing innovations in specific renewable energy sectors. Academic institutions like Nanjing University of Posts & Telecommunications and Xi'an Jiaotong University are contributing to R&D efforts, while major energy corporations like State Grid Corp. of China and Duke Energy Corp. are integrating PVDF technologies into large-scale renewable energy systems, indicating a maturing market with diverse players across the value chain.

Arkema, Inc.

3M Innovative Properties Co.

PVDF Material Advancements

- The use of polyvinylidene fluoride (PVDF) as the outermost backsheet layer in photovoltaic modules, which can be coextruded, laminated, or applied as a solvent or aqueous coating, providing improved adhesion and eliminating the need for adhesive layers or surface treatments, and can be functionalized for enhanced performance.

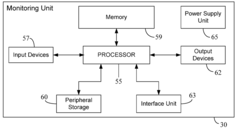

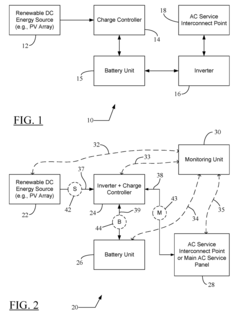

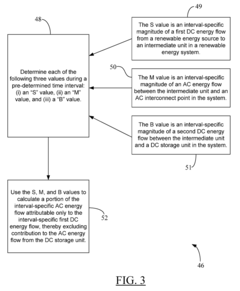

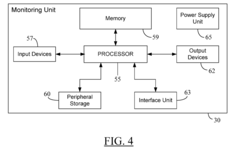

- A monitoring unit calculates the portion of AC energy flow attributable only to the DC energy flow from the renewable energy source by determining specific energy flow values during predetermined intervals and using these values to separate the contribution of the storage unit, enabling storage-independent measurement and efficiency quantification.

Environmental Impact of PVDF

The environmental impact of PVDF (Polyvinylidene Fluoride) in renewable energy systems is a critical consideration as the material gains prominence in next-generation solutions. PVDF's unique properties, including its chemical resistance, thermal stability, and piezoelectric characteristics, make it an attractive option for various applications in renewable energy technologies.

One of the primary environmental benefits of PVDF in renewable energy systems is its contribution to increased efficiency and longevity of components. In solar panels, PVDF-based backsheets enhance durability and weather resistance, potentially extending the lifespan of photovoltaic modules. This longevity reduces the frequency of panel replacements, thereby minimizing waste generation and resource consumption associated with manufacturing new panels.

However, the production of PVDF itself raises environmental concerns. The synthesis of PVDF involves the use of fluorine-containing compounds, which can have significant environmental implications if not properly managed. The production process may result in the emission of greenhouse gases and other pollutants, contributing to air and water pollution if adequate control measures are not implemented.

End-of-life considerations for PVDF-containing renewable energy components present both challenges and opportunities. While PVDF is recyclable, the complex nature of composite materials used in renewable energy systems can make separation and recycling processes difficult. Developing efficient recycling technologies for PVDF-based components is crucial to minimize the environmental impact of these materials at the end of their useful life.

In the context of energy storage systems, PVDF's role in improving battery performance and safety can indirectly contribute to environmental benefits. Enhanced battery efficiency and lifespan can lead to reduced resource consumption and waste generation in the long term. However, the increased use of PVDF in energy storage applications necessitates careful consideration of its lifecycle environmental impact.

The water footprint of PVDF production and its potential for microplastic generation are additional environmental factors to consider. While PVDF is generally considered stable, the long-term effects of potential microplastic shedding from PVDF-based components in renewable energy systems require further study and monitoring.

As the renewable energy sector continues to grow, the demand for PVDF is expected to increase. This trend underscores the importance of developing more sustainable production methods for PVDF and improving the recyclability of PVDF-containing components. Innovations in green chemistry and circular economy principles could play a crucial role in mitigating the environmental impact of PVDF while harnessing its benefits for renewable energy technologies.

PVDF Manufacturing Processes

The manufacturing processes for Polyvinylidene Fluoride (PVDF) play a crucial role in its application within renewable energy systems. The primary methods for PVDF production include suspension polymerization, emulsion polymerization, and solution polymerization. Each process offers distinct advantages and influences the final properties of the PVDF material.

Suspension polymerization is widely used for large-scale PVDF production. In this process, vinyl fluoride monomers are dispersed in water and polymerized using free-radical initiators. The resulting PVDF particles are typically spherical and range from 20 to 500 micrometers in diameter. This method allows for good control over particle size distribution and molecular weight, which are essential factors in determining the material's performance in renewable energy applications.

Emulsion polymerization is another significant manufacturing technique for PVDF. This process involves the dispersion of vinyl fluoride monomers in an aqueous medium containing surfactants. The polymerization occurs within micelles, resulting in smaller PVDF particles compared to suspension polymerization. The emulsion method produces PVDF with a high degree of crystallinity and excellent thermal stability, making it particularly suitable for use in solar panel components and energy storage systems.

Solution polymerization is employed when specific PVDF grades with unique properties are required. This process involves dissolving the vinyl fluoride monomers in an organic solvent before polymerization. The resulting PVDF can be easily modified during the manufacturing process, allowing for the incorporation of additives or the creation of copolymers with enhanced characteristics for renewable energy applications.

Post-polymerization processing techniques are essential in tailoring PVDF for specific renewable energy applications. These include melt processing, solution casting, and electrospinning. Melt processing involves heating the PVDF above its melting point and shaping it into films, fibers, or other forms. Solution casting allows for the production of thin, uniform PVDF films with controlled porosity, which is crucial for membrane applications in fuel cells and energy storage devices.

Electrospinning is an advanced manufacturing technique that has gained significant attention in recent years. This process involves applying a high voltage to a PVDF solution, creating ultra-fine fibers with diameters in the nanometer range. These nanofibers exhibit exceptional piezoelectric properties, making them ideal for energy harvesting applications in renewable energy systems.

Continuous improvement in PVDF manufacturing processes focuses on enhancing energy efficiency, reducing environmental impact, and optimizing material properties. Recent advancements include the development of green solvents for solution polymerization, the implementation of microwave-assisted polymerization techniques, and the use of supercritical CO2 as a reaction medium. These innovations aim to reduce the carbon footprint of PVDF production while improving the material's performance in renewable energy applications.