PVDF in Plasma Technology: Enhancing Surface Treatments

PVDF Plasma Tech Background

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in plasma technology, particularly in enhancing surface treatments. The integration of PVDF with plasma processes represents a significant advancement in materials science and surface engineering. This technology has evolved over several decades, with its roots tracing back to the mid-20th century when researchers began exploring the potential of fluoropolymers in various applications.

The development of PVDF plasma technology has been driven by the increasing demand for advanced surface modification techniques in industries such as electronics, aerospace, and biomedical engineering. As traditional surface treatment methods reached their limitations, plasma technology offered a promising alternative, providing more precise control over surface properties and enabling the creation of unique surface characteristics.

PVDF's unique properties, including its excellent chemical resistance, thermal stability, and piezoelectric behavior, have made it an ideal candidate for plasma-based surface treatments. The combination of PVDF with plasma technology has opened up new possibilities for creating surfaces with tailored properties, such as improved adhesion, hydrophobicity, or biocompatibility.

The evolution of PVDF plasma technology has been marked by several key milestones. Initially, research focused on understanding the fundamental interactions between PVDF and plasma, leading to the development of basic surface modification techniques. As the field progressed, more sophisticated methods emerged, including plasma-induced grafting, plasma polymerization, and plasma-assisted deposition of PVDF thin films.

Recent advancements in PVDF plasma technology have been driven by the need for more sustainable and environmentally friendly surface treatment processes. Researchers have been exploring low-temperature plasma treatments and atmospheric pressure plasma techniques, which offer reduced energy consumption and eliminate the need for vacuum systems.

The current technological landscape of PVDF in plasma technology is characterized by a diverse range of applications across multiple industries. In the electronics sector, PVDF plasma treatments are used to enhance the performance of flexible displays and printed circuit boards. In biomedical engineering, plasma-modified PVDF surfaces are being developed for improved cell adhesion and tissue engineering scaffolds.

Looking ahead, the field of PVDF plasma technology is poised for further growth and innovation. Emerging trends include the development of smart surfaces with switchable properties, the integration of PVDF plasma treatments with other advanced manufacturing techniques such as 3D printing, and the exploration of novel plasma sources for more efficient and precise surface modifications.

Market Demand Analysis

The market demand for PVDF in plasma technology for surface treatments has been steadily increasing due to its unique properties and versatile applications across various industries. The global market for plasma-treated PVDF is projected to grow significantly in the coming years, driven by the rising need for advanced surface modification techniques in sectors such as aerospace, automotive, electronics, and medical devices.

In the aerospace industry, PVDF treated with plasma technology is gaining traction for its ability to enhance the durability and performance of aircraft components. The material's improved adhesion properties and resistance to harsh environmental conditions make it ideal for use in aircraft interiors, exterior coatings, and fuel systems. As the aerospace sector continues to expand, particularly in emerging markets, the demand for plasma-treated PVDF is expected to surge.

The automotive sector represents another substantial market for PVDF in plasma technology. With the increasing focus on lightweight materials and fuel efficiency, automakers are turning to plasma-treated PVDF for applications such as paint protection films, interior trim components, and under-the-hood applications. The material's resistance to chemicals, UV radiation, and extreme temperatures makes it an attractive choice for enhancing vehicle durability and aesthetics.

In the electronics industry, the demand for plasma-treated PVDF is driven by the need for advanced insulation materials and protective coatings. As electronic devices become smaller and more complex, the importance of reliable surface treatments grows. PVDF treated with plasma technology offers excellent dielectric properties and chemical resistance, making it suitable for use in printed circuit boards, connectors, and other electronic components.

The medical device sector is another key driver of market demand for plasma-treated PVDF. The material's biocompatibility and ability to be sterilized make it valuable for applications such as implantable devices, surgical instruments, and drug delivery systems. As the global population ages and healthcare expenditures increase, the demand for advanced medical devices incorporating plasma-treated PVDF is expected to rise.

Environmental concerns and stringent regulations are also contributing to the growing market for PVDF in plasma technology. The material's resistance to weathering, UV radiation, and chemical degradation makes it an environmentally friendly choice for outdoor applications, such as architectural coatings and solar panel components. As sustainability becomes increasingly important across industries, the demand for durable and long-lasting materials like plasma-treated PVDF is likely to expand.

Overall, the market demand for PVDF in plasma technology for surface treatments is poised for substantial growth across multiple sectors. The material's unique combination of properties, coupled with the advantages offered by plasma treatment, positions it as a key player in addressing the evolving needs of various industries for advanced surface modification solutions.

Current Challenges

The application of PVDF in plasma technology for surface treatments faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the complexity of controlling plasma parameters to achieve consistent and uniform surface modifications. The interaction between plasma and PVDF surfaces is highly sensitive to factors such as gas composition, pressure, power input, and treatment duration. Achieving reproducible results across different batches or production scales remains a persistent challenge for researchers and industry practitioners.

Another critical issue is the degradation of PVDF properties during plasma treatment. While plasma modification can enhance certain surface characteristics, it may simultaneously lead to undesirable changes in the bulk properties of the material. This includes potential alterations in mechanical strength, thermal stability, or chemical resistance, which are often crucial for the intended applications of PVDF. Balancing the benefits of surface modification with the preservation of bulk properties requires careful optimization and presents a significant technical hurdle.

The long-term stability of plasma-treated PVDF surfaces is also a matter of concern. Many surface modifications achieved through plasma treatment tend to degrade over time, a phenomenon known as hydrophobic recovery. This aging effect can compromise the enhanced properties, reducing the effectiveness of the treatment in long-term applications. Developing strategies to maintain the stability of modified surfaces without compromising the material's inherent properties is an ongoing challenge in the field.

Furthermore, the scalability of plasma treatment processes for PVDF remains a significant obstacle for industrial applications. While laboratory-scale experiments often yield promising results, translating these outcomes to large-scale production environments presents numerous technical and economic challenges. Issues such as maintaining uniform plasma distribution over large surface areas, ensuring consistent treatment quality, and managing energy consumption and process efficiency at scale are critical hurdles that need to be addressed.

Lastly, the environmental impact and safety considerations of plasma treatments for PVDF are becoming increasingly important. The use of certain process gases and the generation of by-products during plasma treatment raise concerns about worker safety and environmental sustainability. Developing eco-friendly plasma processes that minimize harmful emissions and reduce energy consumption while maintaining treatment effectiveness is a pressing challenge for the industry.

Existing PVDF Solutions

01 Plasma treatment of PVDF surfaces

Plasma treatment is used to modify the surface properties of PVDF. This process can improve adhesion, wettability, and other surface characteristics by introducing functional groups or altering the surface structure. The treatment can be optimized by adjusting parameters such as gas composition, power, and exposure time.- Plasma treatment of PVDF surfaces: Plasma treatment is used to modify the surface properties of PVDF. This process can improve adhesion, wettability, and other surface characteristics by introducing functional groups or altering the surface structure. The treatment can be optimized by adjusting parameters such as gas composition, power, and exposure time.

- Chemical modification of PVDF surfaces: Chemical treatments are applied to PVDF surfaces to introduce specific functional groups or to alter surface properties. This can include processes such as grafting, oxidation, or the use of coupling agents. These modifications can enhance compatibility with other materials, improve adhesion, or introduce desired functionalities.

- PVDF surface treatment for membrane applications: Surface treatments are applied to PVDF membranes to enhance their performance in filtration and separation processes. These treatments can improve hydrophilicity, reduce fouling, or introduce specific selectivity. Methods may include coating, grafting, or blending with other polymers.

- Thermal and mechanical surface treatments of PVDF: Thermal and mechanical treatments are used to modify PVDF surfaces. These can include processes such as annealing, stretching, or embossing. Such treatments can alter the crystallinity, orientation, or surface topography of PVDF, influencing its properties and performance in various applications.

- PVDF surface treatment for composite materials: Surface treatments are applied to PVDF for use in composite materials. These treatments aim to improve interfacial adhesion between PVDF and other components, such as fibers or matrices. Methods may include sizing treatments, coupling agents, or surface activation techniques to enhance compatibility and overall composite performance.

02 Chemical modification of PVDF surfaces

Chemical treatments are applied to PVDF surfaces to introduce specific functional groups or to alter surface properties. This can include methods such as grafting, oxidation, or the use of coupling agents. These treatments can enhance the material's compatibility with other substances or improve its performance in specific applications.Expand Specific Solutions03 PVDF surface treatment for membrane applications

Surface treatments are employed to modify PVDF membranes for various applications, including water treatment and separation processes. These treatments can enhance properties such as fouling resistance, hydrophilicity, or selectivity. Methods may include coating, blending with other polymers, or incorporating nanoparticles.Expand Specific Solutions04 PVDF surface modification for improved adhesion

Various surface treatments are used to enhance the adhesion properties of PVDF. These can include physical methods like roughening, or chemical treatments that introduce reactive groups on the surface. The improved adhesion is beneficial for applications such as coating, painting, or bonding PVDF to other materials.Expand Specific Solutions05 Nanostructured PVDF surface treatments

Advanced techniques are used to create nanostructured surfaces on PVDF materials. These treatments can involve the creation of nanopatterns, incorporation of nanoparticles, or growth of nanostructures on the PVDF surface. The resulting nanostructured surfaces can exhibit unique properties such as superhydrophobicity, improved mechanical characteristics, or enhanced electrical properties.Expand Specific Solutions

Key Industry Players

The PVDF in Plasma Technology market for enhancing surface treatments is in a growth phase, with increasing adoption across various industries. The market size is expanding due to the technology's versatility and effectiveness in improving surface properties. Technologically, the field is advancing rapidly, with companies like Applied Materials, Inc., AIXTRON SE, and Evatec AG leading in equipment development. Materials suppliers such as Arkema France SA and Dow Global Technologies LLC are contributing to PVDF innovations. Research institutions like Xi'an Jiaotong University and the University of Washington are pushing the boundaries of plasma-PVDF applications. The technology's maturity varies across sectors, with electronics and medical industries showing more advanced implementations, while emerging applications in energy storage and aerospace are still evolving.

Applied Materials, Inc.

Arkema France SA

Core PVDF Innovations

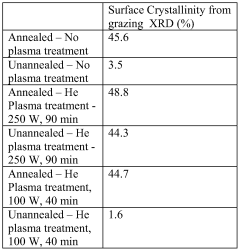

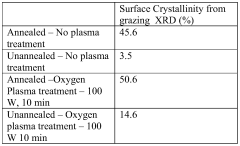

- A method involving RF plasma treatment in an inert gas atmosphere is applied to semi-crystalline biodegradable polymer substrates to increase surface crystallinity and roughness, enhancing cell attachment and growth without affecting the bulk properties, using specific power and time parameters to achieve desired surface characteristics.

- A method involving RF plasma treatment in an inert gas atmosphere to increase surface crystallinity and roughness of biocompatible, biodegradable polymer substrates, specifically semi-crystalline polymers, without affecting the bulk properties, thereby enhancing cell attachment and growth.

Environmental Impact

The environmental impact of PVDF in plasma technology for surface treatments is a crucial aspect to consider in the broader context of sustainable industrial practices. Plasma-enhanced surface treatments using PVDF offer significant advantages in terms of efficiency and effectiveness, but their environmental implications must be carefully evaluated.

One of the primary environmental benefits of PVDF plasma treatments is the reduction in chemical usage compared to traditional surface modification methods. This leads to a decrease in hazardous waste generation and minimizes the release of potentially harmful substances into the environment. The plasma process itself is typically a dry method, further reducing water consumption and the associated wastewater treatment requirements.

However, the production of PVDF and its use in plasma treatments does have some environmental considerations. The synthesis of PVDF involves fluorine-containing compounds, which can have a high global warming potential if released into the atmosphere. Proper handling and disposal protocols are essential to mitigate these risks.

Energy consumption is another factor to consider. While plasma treatments are generally more energy-efficient than conventional chemical processes, they still require significant power input. The environmental impact of this energy use depends largely on the source of electricity. Facilities utilizing renewable energy sources can substantially reduce the carbon footprint of PVDF plasma treatments.

In terms of product lifecycle, PVDF-treated surfaces often exhibit enhanced durability and resistance to degradation. This can lead to extended product lifespans, potentially reducing waste and the need for frequent replacements. However, the improved durability of PVDF-treated materials may also present challenges for recycling and end-of-life disposal.

The plasma treatment process itself produces minimal direct emissions, as the reactions occur in controlled, closed systems. However, the production of process gases and the disposal of any byproducts must be managed responsibly to prevent environmental contamination.

Advancements in plasma technology are continually improving the environmental profile of PVDF surface treatments. Research into low-temperature plasma processes and the use of environmentally benign process gases is promising for further reducing the ecological footprint of these treatments.

Overall, while PVDF plasma treatments offer several environmental advantages over traditional surface modification techniques, ongoing efforts are needed to optimize their sustainability. This includes improving energy efficiency, minimizing waste generation, and developing more environmentally friendly PVDF formulations and plasma processes.

Regulatory Compliance

The regulatory landscape surrounding the use of PVDF in plasma technology for surface treatments is complex and multifaceted. Compliance with various regulations is crucial for manufacturers and end-users to ensure the safety, efficacy, and environmental sustainability of their processes and products.

In the United States, the Environmental Protection Agency (EPA) regulates the use of PVDF under the Toxic Substances Control Act (TSCA). Manufacturers must adhere to specific reporting and record-keeping requirements, particularly when introducing new applications or modifications to existing processes involving PVDF. The Occupational Safety and Health Administration (OSHA) also plays a role in regulating workplace safety aspects related to PVDF handling and plasma treatment processes.

European regulations are generally more stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation being the primary framework governing PVDF use. Companies operating in the EU must register PVDF with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the RoHS (Restriction of Hazardous Substances) directive may impact certain applications of PVDF in electronic and electrical equipment.

In the context of surface treatments, regulatory bodies often focus on the potential release of fluorinated compounds during plasma processing. The Stockholm Convention on Persistent Organic Pollutants (POPs) has implications for PVDF use, particularly concerning the potential formation of perfluorooctanoic acid (PFOA) as a byproduct. Manufacturers must demonstrate that their plasma treatment processes do not generate harmful levels of such compounds.

Industry-specific regulations also come into play. For instance, in the medical device sector, the use of PVDF in plasma-treated surfaces must comply with FDA regulations in the US and the Medical Device Regulation (MDR) in the EU. These regulations emphasize biocompatibility and the need for thorough documentation of materials and processes.

Environmental regulations are becoming increasingly important. Many jurisdictions are implementing stricter controls on fluoropolymers, including PVDF, due to concerns about their persistence in the environment. Companies must stay abreast of evolving regulations and potentially invest in technologies to minimize environmental impact, such as closed-loop systems for plasma treatment processes.

Compliance with these regulations often requires significant investment in testing, documentation, and potentially process modifications. Companies must conduct thorough risk assessments, implement robust quality management systems, and maintain detailed records of their PVDF usage and plasma treatment processes. Regular audits and updates to compliance strategies are necessary to keep pace with evolving regulatory requirements.