PVDF in High-Transparency Films: Innovations in Clarity

PVDF Film Evolution

The evolution of PVDF films in high-transparency applications represents a significant technological advancement in the field of polymer science and materials engineering. This journey began in the mid-20th century when polyvinylidene fluoride (PVDF) was first synthesized and its unique properties were discovered. Initially, PVDF was primarily used for its excellent chemical resistance and thermal stability in industrial applications.

The pursuit of transparency in PVDF films emerged as a critical research focus in the 1980s and 1990s. During this period, researchers and engineers recognized the potential of PVDF in optical applications, particularly in display technologies and protective coatings. However, the inherent semi-crystalline nature of PVDF posed significant challenges to achieving high transparency.

A major breakthrough came in the early 2000s with the development of nano-scale PVDF particles. This innovation allowed for the creation of PVDF films with significantly reduced light scattering, marking a pivotal moment in the quest for transparency. Concurrently, advancements in polymer blending techniques enabled the incorporation of PVDF with other transparent polymers, further enhancing clarity while maintaining PVDF's desirable properties.

The mid-2000s saw the introduction of controlled crystallization techniques, which allowed for the manipulation of PVDF's crystal structure at the molecular level. This approach led to the production of PVDF films with greatly improved optical properties, approaching the transparency levels of traditional clear polymers like polyethylene terephthalate (PET).

In the 2010s, the focus shifted towards enhancing the durability and longevity of transparent PVDF films. Researchers developed novel surface treatment methods and coating technologies to improve scratch resistance and UV stability, critical factors for outdoor and high-wear applications. This period also saw the integration of PVDF films into flexible electronics and solar cell technologies, driving further innovations in film thinness and optical clarity.

Recent years have witnessed a surge in eco-friendly approaches to PVDF film production. Efforts to reduce the environmental impact of fluoropolymers have led to the development of bio-based additives and more sustainable manufacturing processes. These advancements not only improve the ecological footprint of PVDF films but also contribute to their overall performance and market appeal.

Looking ahead, the evolution of PVDF in high-transparency films continues to push boundaries. Current research is focused on achieving ultra-high transparency while maintaining PVDF's exceptional chemical and thermal properties. Emerging technologies such as 3D printing and nanocomposite integration are opening new avenues for customized, high-performance PVDF films with unprecedented clarity and functionality.

Market Demand Analysis

The market demand for high-transparency PVDF films has been steadily increasing across various industries, driven by the growing need for advanced materials with superior optical and mechanical properties. The automotive sector, in particular, has shown significant interest in these films for applications in heads-up displays (HUDs) and smart windshields. As vehicle manufacturers strive to enhance driver safety and user experience, the demand for clearer, more durable films has surged.

In the electronics industry, PVDF films with improved clarity are gaining traction for use in flexible displays, touchscreens, and protective covers for smartphones and tablets. The consumer electronics market's continuous evolution towards thinner, more resilient devices has created a substantial demand for high-performance transparent films that can withstand daily wear and tear while maintaining optical clarity.

The construction sector has also emerged as a key market for high-transparency PVDF films. These materials are increasingly used in architectural applications, such as building facades and skylights, where long-term weatherability and optical clarity are crucial. The growing trend towards energy-efficient buildings has further boosted the demand for these films, as they can contribute to improved thermal insulation without compromising natural light transmission.

In the renewable energy sector, particularly in solar panel manufacturing, there is a rising interest in high-transparency PVDF films. These films can serve as protective layers for photovoltaic cells, offering excellent UV resistance and optical clarity, which are essential for maintaining the efficiency of solar panels over extended periods.

The packaging industry represents another significant market for high-transparency PVDF films. With increasing consumer demand for product visibility and shelf appeal, food and beverage companies are seeking packaging materials that offer both clarity and barrier properties. PVDF films with enhanced transparency can meet these requirements while also providing chemical resistance and durability.

The medical and pharmaceutical sectors have also shown growing demand for high-clarity PVDF films. These materials are being explored for use in medical device packaging, diagnostic equipment, and drug delivery systems, where optical clarity and chemical inertness are paramount.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the market is increasingly favoring materials that offer sustainability alongside performance. This trend is likely to drive further innovations in PVDF film technology, focusing on improving recyclability and reducing environmental impact without compromising on transparency and other key properties.

Transparency Challenges

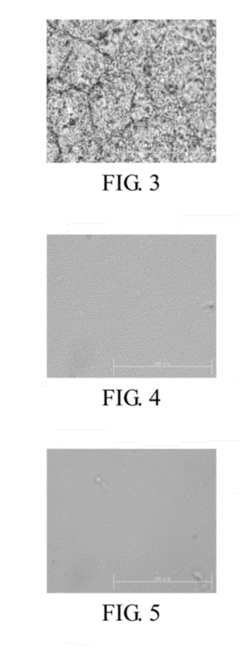

Achieving high transparency in PVDF films presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is the inherent crystalline structure of PVDF, which tends to scatter light and reduce overall transparency. The semi-crystalline nature of PVDF results in a hazy appearance, limiting its application in optical and display technologies where clarity is paramount.

Another major challenge lies in maintaining the desirable properties of PVDF while enhancing its transparency. PVDF is valued for its excellent chemical resistance, thermal stability, and mechanical strength. However, traditional methods to improve transparency, such as reducing crystallinity, often compromise these beneficial characteristics. Striking a balance between transparency and performance is a complex task that requires innovative approaches.

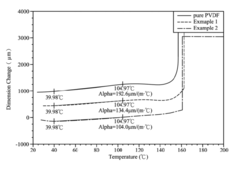

The processing conditions of PVDF films also play a crucial role in determining their transparency. Factors such as cooling rate, stretching ratio, and annealing temperature significantly impact the film's microstructure and, consequently, its optical properties. Optimizing these parameters to achieve high transparency while maintaining processability and scalability for industrial production remains a considerable challenge.

Furthermore, the thickness of PVDF films presents a dilemma. Thinner films generally exhibit better transparency but may sacrifice mechanical strength and barrier properties. Conversely, thicker films provide enhanced performance but at the cost of reduced clarity. Developing techniques to produce ultra-thin, highly transparent PVDF films without compromising their functional properties is an ongoing area of research.

Surface roughness and impurities in PVDF films also contribute to reduced transparency. Even minor surface irregularities can cause light scattering, diminishing the film's clarity. Achieving and maintaining a smooth surface finish during production and subsequent handling is essential for high-transparency applications.

Additionally, the compatibility of PVDF with other materials in multilayer film structures poses challenges. When combined with other polymers or additives to enhance specific properties, maintaining transparency across the entire film structure becomes more complex. Ensuring good interfacial adhesion and minimizing refractive index mismatches between layers are critical considerations.

Lastly, the long-term stability of transparent PVDF films under various environmental conditions remains a concern. Exposure to UV radiation, temperature fluctuations, and chemical agents can potentially degrade the film's transparency over time. Developing strategies to enhance the durability of transparent PVDF films without compromising their initial optical properties is crucial for their widespread adoption in demanding applications.

Current Clarity Solutions

01 Improving PVDF transparency through composition modification

Enhancing the transparency of PVDF can be achieved by modifying its composition. This may involve blending PVDF with other polymers or incorporating additives that improve light transmission. The modified composition can result in PVDF films or sheets with increased clarity while maintaining other desirable properties.- Improving PVDF transparency through composition modification: Enhancing the transparency of PVDF can be achieved by modifying its composition. This may involve blending PVDF with other polymers or incorporating specific additives that improve light transmission. The modified composition aims to reduce light scattering within the material, resulting in increased transparency without compromising other desirable properties of PVDF.

- Processing techniques for transparent PVDF films: Various processing techniques can be employed to produce transparent PVDF films. These may include optimized extrusion parameters, controlled cooling rates, and specific stretching methods. The processing conditions are crucial in determining the crystalline structure and orientation of the PVDF molecules, which directly impact the material's transparency.

- Surface treatment methods for enhancing PVDF transparency: Surface treatments can be applied to PVDF to improve its transparency. These treatments may include plasma treatment, chemical etching, or the application of specific coatings. By modifying the surface properties, these methods can reduce surface reflections and increase light transmission through the PVDF material.

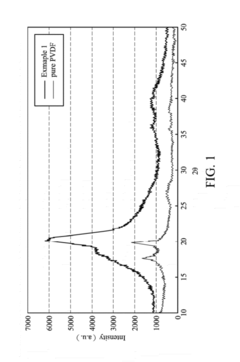

- Nanocomposite approach for transparent PVDF: Incorporating nanoparticles or nanostructures into PVDF can enhance its transparency. This approach involves carefully selecting and dispersing nanofillers that have refractive indices close to that of PVDF. The nanocomposite structure can reduce light scattering and improve overall transparency while potentially enhancing other properties such as mechanical strength or thermal stability.

- Optical property control in PVDF-based multilayer films: Developing multilayer films with PVDF as one of the components can offer enhanced control over optical properties, including transparency. By carefully designing the layer structure, thickness, and composition, it is possible to create PVDF-containing films with improved transparency and other desirable optical characteristics. This approach may involve combining PVDF with other transparent polymers in a layered structure.

02 Processing techniques for transparent PVDF

Various processing techniques can be employed to improve the transparency of PVDF. These may include optimizing extrusion parameters, using specific cooling methods, or applying post-processing treatments. Such techniques can help reduce crystallinity or control the microstructure of PVDF, leading to enhanced optical properties.Expand Specific Solutions03 PVDF copolymers for improved transparency

Developing PVDF copolymers by incorporating other monomers can lead to improved transparency. These copolymers may have a different crystal structure or reduced crystallinity compared to homopolymer PVDF, resulting in better light transmission. The choice of comonomers and their ratios can be optimized to achieve the desired balance of transparency and other properties.Expand Specific Solutions04 Nanocomposites for enhancing PVDF transparency

Incorporating nanoparticles or nanofillers into PVDF can improve its transparency. These nanocomposites may alter the polymer's optical properties by reducing light scattering or modifying its refractive index. The type, size, and distribution of nanofillers can be optimized to achieve the desired level of transparency while maintaining or enhancing other properties of PVDF.Expand Specific Solutions05 Surface treatments for improving PVDF transparency

Applying various surface treatments to PVDF films or products can enhance their transparency. These treatments may include plasma treatment, chemical etching, or the application of transparent coatings. Such methods can modify the surface properties of PVDF, reducing light scattering and improving overall transparency without significantly altering the bulk properties of the material.Expand Specific Solutions

Key Industry Players

The market for PVDF in high-transparency films is experiencing rapid growth, driven by increasing demand for advanced materials in various industries. The technology is in a mature stage, with ongoing innovations focused on enhancing clarity and performance. Key players like Arkema, DAIKIN INDUSTRIES, and Kaneka Corp. are leading the market with their advanced PVDF formulations. The competitive landscape is characterized by intense R&D activities, with companies such as Asahi Kasei, Toray Advanced Materials, and 3M Innovative Properties contributing significant advancements. The market size is expanding, fueled by applications in electronics, solar panels, and architectural coatings. As the technology continues to evolve, collaborations between industry leaders and research institutions like the University of Minho and Industrial Technology Research Institute are driving further innovations in PVDF-based high-transparency films.

Arkema, Inc.

DAIKIN INDUSTRIES Ltd.

Breakthrough Patents

- A coextrudable composition comprising 30-50 parts PVDF, 70-50 parts of a copolymer with 90-50% methyl methacrylate and 10-50% alkyl (meth)acrylate, and 1-4 parts of a UV absorber, which forms a flexible, transparent film that maintains mechanical integrity and UV protection without whitening when deformed.

- An organic/inorganic composite film is developed with poly(vinylidene fluoride) (PVDF) and inorganic nano-platelets dispersed at a weight ratio between 97:3 and 20:80, using an organic dispersion of H-form inorganic nano-platelets with uniform particle size between 20 and 80 nm, maintaining high transparency and PVDF's β crystalline phase without additional polymers like PMMA.

Environmental Impact

The environmental impact of PVDF in high-transparency films is a critical consideration in the development and application of this innovative material. As the demand for clearer and more durable films grows across various industries, it is essential to assess the ecological footprint of PVDF-based solutions.

PVDF, or polyvinylidene fluoride, is known for its excellent chemical resistance and durability. However, its production process involves the use of fluorine-containing compounds, which can have significant environmental implications. The synthesis of PVDF typically requires energy-intensive processes and potentially harmful chemicals, raising concerns about greenhouse gas emissions and the release of fluorinated compounds into the environment.

Despite these challenges, recent innovations in PVDF production have focused on reducing its environmental impact. Manufacturers are exploring greener synthesis methods, such as using supercritical CO2 as a solvent, which can significantly reduce the use of traditional organic solvents. This approach not only minimizes waste but also decreases the overall carbon footprint of PVDF production.

In terms of product lifecycle, PVDF-based high-transparency films offer several environmental benefits. Their exceptional durability and resistance to degradation mean they have a longer lifespan compared to alternative materials. This longevity reduces the need for frequent replacements, ultimately lowering resource consumption and waste generation over time.

Furthermore, the high clarity of PVDF films can contribute to energy efficiency in certain applications. For instance, when used in solar panel encapsulation, these films can enhance light transmission, potentially improving the overall efficiency of photovoltaic systems. This indirect environmental benefit should be considered when evaluating the material's ecological impact.

End-of-life considerations for PVDF films present both challenges and opportunities. While PVDF is not biodegradable, it is recyclable. Advanced recycling technologies are being developed to recover and reprocess PVDF, reducing the amount of material that ends up in landfills. However, the widespread implementation of these recycling processes remains a challenge that requires further investment and infrastructure development.

As the industry moves towards more sustainable practices, there is ongoing research into bio-based alternatives that could potentially replace or complement PVDF in high-transparency film applications. These efforts aim to reduce reliance on petroleum-based raw materials and minimize the environmental footprint of film production.

Optical Applications

PVDF (polyvinylidene fluoride) has emerged as a promising material for high-transparency films, offering innovative solutions in various optical applications. These films have gained significant traction in industries requiring exceptional clarity and durability, such as display technologies, photovoltaics, and optical coatings.

In display technologies, PVDF-based transparent films have revolutionized the production of flexible and foldable screens. Their high transparency and excellent mechanical properties allow for the creation of ultra-thin, lightweight displays with enhanced durability. This has led to the development of next-generation smartphones, tablets, and wearable devices with improved visual quality and form factor flexibility.

The photovoltaic industry has also benefited from PVDF's optical properties. High-transparency PVDF films are being utilized as protective layers for solar panels, offering superior UV resistance and weatherability. These films maintain their clarity over extended periods, ensuring optimal light transmission to the photovoltaic cells and maximizing energy conversion efficiency.

Optical coatings represent another significant application area for PVDF-based transparent films. Their exceptional chemical resistance and low refractive index make them ideal for anti-reflective coatings on lenses, windows, and other optical components. This has led to improved performance in cameras, telescopes, and other optical instruments, reducing glare and enhancing image quality.

In the automotive sector, PVDF transparent films are being employed in heads-up displays (HUDs) and smart windshields. The films' high clarity and resistance to environmental factors contribute to clearer, more durable displays that can withstand harsh automotive conditions while providing drivers with crucial information without obstructing their view.

The aerospace industry has also adopted PVDF-based transparent films for aircraft windows and cockpit displays. These films offer superior optical clarity while providing protection against UV radiation and maintaining structural integrity at high altitudes.

Furthermore, PVDF's unique properties have opened up possibilities in advanced optical applications such as augmented reality (AR) and virtual reality (VR) devices. The films' ability to maintain clarity while being flexible and durable makes them suitable for creating lightweight, high-performance optical components in these immersive technologies.

As research in PVDF-based transparent films continues to advance, we can expect to see further innovations in optical applications. These may include smart windows with tunable transparency, advanced holographic displays, and ultra-thin, flexible optical sensors. The ongoing development of PVDF films with enhanced clarity and functionality will likely drive progress in various optical technologies, shaping the future of visual interfaces and optical systems across multiple industries.