PVDF in High-Performance Seals: Raising Standards

PVDF Seal Evolution

The evolution of PVDF seals represents a significant advancement in high-performance sealing technology. Initially developed in the 1960s, polyvinylidene fluoride (PVDF) quickly gained recognition for its exceptional chemical resistance and thermal stability. The early applications of PVDF in seals were primarily focused on chemical processing industries where corrosion resistance was paramount.

As the demand for more robust sealing solutions grew, PVDF seal technology underwent several iterations. In the 1980s, manufacturers began to explore ways to enhance the mechanical properties of PVDF seals. This led to the development of composite PVDF materials, incorporating fillers such as carbon fiber or glass fiber to improve strength and dimensional stability.

The 1990s saw a shift towards optimizing the molecular structure of PVDF for sealing applications. Researchers focused on controlling the crystallinity and molecular weight distribution of PVDF, resulting in seals with improved flexibility and resilience. This period also marked the introduction of cross-linked PVDF seals, offering superior resistance to creep and stress relaxation.

Entering the 2000s, the evolution of PVDF seals was characterized by a focus on customization for specific industrial applications. Manufacturers developed specialized PVDF blends tailored for extreme temperature ranges, high-pressure environments, and aggressive chemical exposures. This era also saw the integration of nanotechnology, with nano-additives being incorporated to further enhance the performance characteristics of PVDF seals.

Recent advancements in PVDF seal technology have centered on sustainability and extended service life. Innovations in manufacturing processes have led to PVDF seals with reduced material waste and improved recyclability. Additionally, the development of self-lubricating PVDF compounds has significantly extended the operational lifespan of seals in high-wear applications.

The latest frontier in PVDF seal evolution involves smart sealing solutions. Researchers are exploring ways to incorporate sensors and monitoring capabilities directly into PVDF seals, allowing for real-time performance tracking and predictive maintenance. This integration of digital technology with traditional sealing materials represents a paradigm shift in how seals are designed, implemented, and maintained in industrial settings.

Throughout its evolution, PVDF seal technology has consistently pushed the boundaries of what is possible in sealing applications. From its humble beginnings as a corrosion-resistant alternative to traditional materials, PVDF has transformed into a versatile, high-performance sealing solution capable of meeting the most demanding industrial challenges. The ongoing research and development in this field continue to open new possibilities for PVDF seals, promising even greater advancements in the future.

Market Demand Analysis

The market demand for high-performance seals incorporating PVDF (Polyvinylidene Fluoride) has been steadily increasing across various industries. This growth is primarily driven by the material's exceptional chemical resistance, thermal stability, and mechanical properties, which make it ideal for demanding sealing applications.

In the oil and gas sector, there is a significant demand for PVDF-based seals due to their ability to withstand harsh environments, including exposure to corrosive chemicals and high temperatures. As offshore drilling operations expand and unconventional extraction methods become more prevalent, the need for reliable sealing solutions has intensified. PVDF seals offer superior performance in these challenging conditions, contributing to increased safety and operational efficiency.

The automotive industry has also shown growing interest in PVDF seals, particularly in fuel system components and engine applications. With stricter emissions regulations and the push for more fuel-efficient vehicles, manufacturers are seeking materials that can withstand aggressive fuels and high temperatures while maintaining their sealing properties. PVDF meets these requirements, making it an attractive option for automotive sealing applications.

In the aerospace sector, the demand for lightweight, high-performance materials has led to increased adoption of PVDF seals. These seals offer excellent resistance to hydraulic fluids and jet fuels, while also providing weight savings compared to traditional sealing materials. As the aerospace industry continues to focus on fuel efficiency and reliability, the market for PVDF seals is expected to expand further.

The chemical processing industry represents another significant market for PVDF seals. The material's resistance to a wide range of chemicals, including acids, bases, and solvents, makes it ideal for use in pumps, valves, and other equipment exposed to aggressive media. As chemical manufacturers seek to improve process efficiency and reduce maintenance costs, the demand for PVDF seals in this sector is projected to grow.

The pharmaceutical and biotechnology industries are also driving demand for PVDF seals. The material's purity, biocompatibility, and resistance to cleaning agents make it suitable for use in critical applications such as drug manufacturing and laboratory equipment. As these industries continue to expand and face stricter regulatory requirements, the need for high-performance sealing solutions is expected to increase.

Overall, the market for PVDF in high-performance seals is poised for continued growth across multiple industries. The material's unique combination of properties addresses key challenges in sealing applications, including chemical resistance, temperature stability, and longevity. As industries continue to push the boundaries of performance and reliability, PVDF seals are well-positioned to meet these evolving demands, driving further market expansion and technological innovation in the field of high-performance sealing solutions.

PVDF Seal Challenges

PVDF (polyvinylidene fluoride) has emerged as a promising material for high-performance seals due to its exceptional chemical resistance, thermal stability, and mechanical properties. However, the application of PVDF in sealing technology faces several significant challenges that need to be addressed to fully harness its potential.

One of the primary challenges is the material's inherent stiffness, which can compromise its sealing effectiveness in certain applications. PVDF's high crystallinity contributes to its excellent mechanical strength but also results in reduced flexibility compared to some elastomeric materials traditionally used in seals. This characteristic can lead to inadequate conformity to mating surfaces, potentially causing leakage in dynamic sealing scenarios or under varying pressure conditions.

Another critical challenge lies in PVDF's thermal expansion behavior. While the material exhibits good thermal stability, its coefficient of thermal expansion is relatively high compared to metals commonly used in sealing applications. This mismatch can lead to dimensional instability and potential seal failure in environments with significant temperature fluctuations, necessitating careful design considerations and material selection for the entire sealing system.

The processing and fabrication of PVDF seals present additional hurdles. The material's high melting point and melt viscosity can make it challenging to process using conventional molding techniques. This limitation often requires specialized equipment and expertise, potentially increasing manufacturing costs and limiting widespread adoption in certain industries.

PVDF's susceptibility to creep under sustained load is another concern for long-term sealing applications. While the material exhibits excellent resistance to many chemicals and solvents, prolonged exposure to stress can result in dimensional changes over time, potentially compromising the seal's integrity and performance.

Furthermore, the compatibility of PVDF with other materials in complex sealing systems poses challenges. In multi-component assemblies, the interaction between PVDF and other materials, such as lubricants, adhesives, or adjacent components, must be carefully evaluated to prevent degradation or loss of sealing properties.

Lastly, the cost factor remains a significant challenge in the widespread adoption of PVDF for high-performance seals. While the material offers superior performance in many aspects, its higher cost compared to traditional sealing materials can be a barrier, particularly in price-sensitive applications or industries.

Addressing these challenges requires a multifaceted approach, combining materials science, engineering design, and manufacturing innovation. Ongoing research efforts are focused on developing PVDF blends and composites to enhance flexibility and reduce creep, as well as improving processing techniques to optimize seal geometry and performance. Additionally, the development of predictive models and advanced testing methodologies is crucial for understanding and mitigating the long-term behavior of PVDF seals under various operating conditions.

Current PVDF Solutions

01 Enhanced electrical properties of PVDF

PVDF can be modified to improve its electrical properties, such as piezoelectric and ferroelectric characteristics. This enhancement can be achieved through various methods, including the addition of specific additives or by controlling the crystallization process. The improved electrical properties make PVDF suitable for applications in sensors, actuators, and energy harvesting devices.- Improved mechanical properties of PVDF: PVDF can be modified to enhance its mechanical properties such as tensile strength, impact resistance, and flexibility. This can be achieved through various methods including blending with other polymers, adding reinforcing fillers, or optimizing the crystalline structure. These improvements make PVDF suitable for a wide range of applications requiring durability and strength.

- Enhanced thermal stability and flame retardancy: PVDF can be formulated to exhibit improved thermal stability and flame retardant properties. This is often achieved by incorporating specific additives or modifying the polymer structure. These enhancements make PVDF suitable for high-temperature applications and in environments where fire safety is crucial.

- Improved chemical resistance and barrier properties: PVDF can be engineered to have excellent chemical resistance and barrier properties against various substances. This makes it ideal for use in corrosive environments and in applications requiring protection against gas or liquid permeation. The polymer's structure can be modified to enhance these properties further.

- Enhanced electrical and piezoelectric properties: PVDF can be processed to exhibit improved electrical insulation and piezoelectric properties. This is often achieved through specific crystallization techniques or by incorporating certain additives. These enhancements make PVDF suitable for various electronic and sensor applications.

- Improved processing and fabrication techniques: Advanced processing and fabrication techniques have been developed to enhance PVDF performance. These include methods for creating specific morphologies, improving melt processability, and developing new coating or film-forming techniques. These advancements allow for the production of PVDF materials with tailored properties for specific applications.

02 Improved mechanical strength and durability

PVDF can be formulated to enhance its mechanical properties, including tensile strength, impact resistance, and abrasion resistance. This can be achieved through the incorporation of reinforcing agents, such as nanoparticles or fibers, or by optimizing the polymer structure. The improved mechanical performance makes PVDF suitable for use in demanding applications, such as protective coatings and high-stress environments.Expand Specific Solutions03 Enhanced thermal stability and flame retardancy

PVDF can be modified to improve its thermal stability and flame retardant properties. This can be achieved through the incorporation of specific additives or by altering the polymer structure. The enhanced thermal performance makes PVDF suitable for use in high-temperature applications and environments where fire resistance is crucial.Expand Specific Solutions04 Improved chemical resistance and barrier properties

PVDF can be formulated to enhance its resistance to various chemicals and improve its barrier properties against gases and liquids. This can be achieved through the optimization of the polymer structure or the incorporation of specific additives. The improved chemical resistance and barrier properties make PVDF suitable for use in corrosive environments and packaging applications.Expand Specific Solutions05 Enhanced processability and compatibility

PVDF can be modified to improve its processability and compatibility with other materials. This can be achieved through the use of specific additives or by altering the polymer structure. The enhanced processability and compatibility make PVDF suitable for use in various manufacturing processes and enable its integration with other materials in composite structures.Expand Specific Solutions

Key PVDF Seal Players

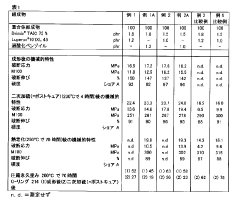

The PVDF high-performance seals market is in a growth phase, driven by increasing demand for advanced sealing solutions in various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, PVDF seals are reaching maturity, with ongoing innovations focused on enhancing performance and durability. Key players like Saint-Gobain Performance Plastics Corp., Solvay Specialty Polymers Italy SpA, and 3M Innovative Properties Co. are at the forefront, investing heavily in R&D to develop cutting-edge PVDF seal technologies. These companies, along with others such as Arkema, Inc. and Hitachi Ltd., are competing to raise industry standards through improved chemical resistance, temperature tolerance, and overall seal reliability.

Saint-Gobain Performance Plastics Corp.

Solvay Specialty Polymers Italy SpA

PVDF Seal Innovations

- Incorporating semi-crystalline thermoplastic fluoropolymers, such as VDF homopolymers and copolymers, in a specific weight percentage range, and subjecting the composition to thermal post-treatment above the melting point of the polymer to create a vulcanized (per)fluoroelastomer sealing article.

- A seal comprising plastically deformable ceramic green tape reinforced with ceramic fibers and high ceramic powder loading, which is not sintered after installation, providing flexibility and resistance to thermal cycling, and using a binder for strength, with specific fiber and particle combinations for optimal sealing performance.

PVDF Material Science

Polyvinylidene fluoride (PVDF) is a high-performance thermoplastic fluoropolymer that has gained significant attention in various industrial applications, particularly in high-performance seals. The material science behind PVDF is crucial to understanding its exceptional properties and potential for raising standards in sealing technologies.

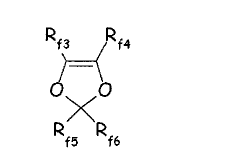

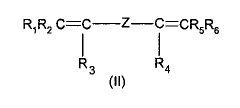

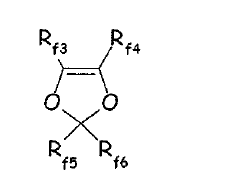

PVDF's unique molecular structure consists of alternating CH2 and CF2 units, resulting in a semi-crystalline polymer with a balance of properties from both fluoropolymers and hydrocarbon polymers. This structure contributes to PVDF's excellent chemical resistance, thermal stability, and mechanical strength. The material exhibits a high degree of crystallinity, typically ranging from 50% to 70%, which enhances its mechanical properties and resistance to creep.

The synthesis of PVDF involves the polymerization of vinylidene fluoride (VDF) monomers, typically through free-radical polymerization techniques. The polymerization process can be tailored to produce different grades of PVDF with varying molecular weights and crystallinity levels, allowing for customization of material properties to suit specific sealing applications.

One of the key attributes of PVDF that makes it suitable for high-performance seals is its exceptional chemical resistance. The material is inert to a wide range of chemicals, including acids, bases, and organic solvents. This resistance is attributed to the strong carbon-fluorine bonds in the polymer backbone, which provide a protective barrier against chemical attack.

Thermal stability is another critical aspect of PVDF's material science. The polymer maintains its properties over a wide temperature range, typically from -40°C to 150°C, with some grades capable of withstanding even higher temperatures. This thermal stability is crucial for seals that operate in extreme temperature environments.

PVDF also exhibits excellent mechanical properties, including high tensile strength, flexibility, and abrasion resistance. These properties are essential for maintaining seal integrity under various operating conditions. The material's low coefficient of friction further enhances its performance in dynamic sealing applications.

The piezoelectric and ferroelectric properties of PVDF add another dimension to its material science. These properties arise from the polar nature of the CF2 groups and can be enhanced through specific processing techniques. While not directly related to sealing applications, these characteristics open up possibilities for smart sealing solutions that could incorporate sensing or actuation capabilities.

Recent advancements in PVDF material science have focused on enhancing its properties through various modification techniques. These include the development of PVDF copolymers, such as PVDF-HFP (hexafluoropropylene), which offer improved flexibility and lower crystallinity. Additionally, the incorporation of nanofillers and the creation of PVDF nanocomposites have shown promise in further enhancing the material's mechanical and barrier properties.

Environmental Impact

The environmental impact of PVDF in high-performance seals is a critical consideration as industries strive for sustainability alongside performance. PVDF, or polyvinylidene fluoride, offers excellent chemical resistance and durability, making it a preferred material for seals in demanding applications. However, its environmental footprint requires careful examination.

PVDF production involves energy-intensive processes and the use of fluorine-based compounds, which can contribute to greenhouse gas emissions. The manufacturing of PVDF monomers and subsequent polymerization require significant energy inputs, potentially increasing the carbon footprint of seal production. Additionally, the use of fluorinated precursors raises concerns about potential environmental contamination if not properly managed.

Despite these challenges, PVDF seals offer environmental benefits through their longevity and performance. The extended lifespan of PVDF seals reduces the frequency of replacements, minimizing waste generation and resource consumption associated with seal production and disposal. This durability factor is particularly significant in industries where frequent maintenance shutdowns can lead to increased energy consumption and emissions.

The chemical inertness of PVDF contributes to its environmental profile in application. Its resistance to a wide range of chemicals prevents leakage and contamination in industrial processes, safeguarding against potential environmental hazards. This property is especially valuable in sectors handling hazardous materials, where seal failure could lead to significant environmental damage.

End-of-life considerations for PVDF seals present both challenges and opportunities. While PVDF is not biodegradable, advancements in recycling technologies offer potential for material recovery. Mechanical recycling methods can process PVDF into reusable grades, though the quality may degrade with each cycle. Emerging chemical recycling techniques show promise for breaking down PVDF into its constituent monomers, enabling a more circular approach to material use.

The environmental impact of PVDF seals extends to their role in energy efficiency. In applications such as pumps and compressors, high-performance PVDF seals contribute to improved system efficiency, indirectly reducing energy consumption and associated emissions. This efficiency gain must be weighed against the initial environmental cost of PVDF production when assessing overall environmental impact.

As industries push for higher standards in seal performance, the environmental considerations of PVDF usage become increasingly complex. Balancing the material's exceptional properties with its environmental footprint requires a holistic approach, considering the entire lifecycle from production to disposal. Ongoing research into more sustainable production methods and improved recycling technologies will be crucial in optimizing the environmental profile of PVDF in high-performance seals.