PVDF in High-Performance Insulators: Technical Advancements

PVDF Insulation Evolution

The evolution of PVDF insulation in high-performance insulators represents a significant technological advancement in the field of electrical engineering and materials science. This progression can be traced through several key stages, each marked by notable improvements in performance and functionality.

In the early stages of PVDF insulation development, the focus was primarily on exploiting the material's inherent properties, such as its high dielectric strength and chemical resistance. These initial applications were relatively basic, with PVDF being used as a straightforward replacement for traditional insulating materials in various electrical components.

As research and development efforts intensified, the next phase saw the introduction of modified PVDF formulations. Scientists and engineers began experimenting with various additives and processing techniques to enhance the material's insulating properties. This period was characterized by the emergence of PVDF copolymers and blends, which offered improved thermal stability and mechanical strength.

A significant milestone in PVDF insulation evolution came with the development of nanocomposite PVDF materials. By incorporating nanoparticles such as silica, titanium dioxide, or carbon nanotubes into the PVDF matrix, researchers were able to dramatically improve the material's dielectric properties and breakdown strength. This breakthrough opened up new possibilities for high-voltage and high-temperature applications.

The advent of piezoelectric PVDF variants marked another crucial stage in the material's evolution. These specialized forms of PVDF exhibited the ability to convert mechanical stress into electrical energy and vice versa, leading to novel applications in sensors, actuators, and energy harvesting devices within insulation systems.

Recent years have seen a shift towards smart and responsive PVDF insulation materials. These advanced formulations incorporate features such as self-healing capabilities, allowing the insulation to repair minor damage autonomously. Additionally, researchers have developed PVDF-based materials with tunable properties, enabling real-time adjustment of insulation characteristics in response to changing environmental conditions.

The latest frontier in PVDF insulation evolution involves the integration of nanotechnology and advanced manufacturing techniques. 3D printing of PVDF-based insulators, for instance, allows for the creation of complex geometries and tailored insulation profiles that were previously impossible to achieve. This has led to more efficient and compact insulation designs in high-performance electrical systems.

Throughout this evolutionary journey, PVDF insulation has consistently demonstrated its versatility and adaptability to meet the ever-increasing demands of modern electrical and electronic applications. From simple insulating layers to multifunctional smart materials, PVDF has proven to be a cornerstone in the advancement of high-performance insulation technology.

Market Demand Analysis

The market demand for high-performance insulators incorporating PVDF (Polyvinylidene Fluoride) has been steadily increasing across various industries. This growth is primarily driven by the expanding energy sector, particularly in renewable energy generation and transmission. The global shift towards clean energy sources has intensified the need for advanced insulation materials that can withstand harsh environmental conditions and provide superior electrical insulation properties.

In the power transmission and distribution sector, the demand for PVDF-based insulators is particularly strong. As power grids modernize and expand to accommodate renewable energy sources, there is a growing requirement for insulators that can operate efficiently under high voltage conditions while maintaining long-term reliability. PVDF's excellent dielectric properties, coupled with its resistance to UV radiation and chemical corrosion, make it an ideal material for these applications.

The automotive industry represents another significant market for PVDF-based insulators. With the rapid growth of electric vehicles (EVs), there is an increasing need for high-performance insulation materials in battery systems and power electronics. PVDF's thermal stability and chemical resistance make it well-suited for these demanding applications, contributing to improved safety and longevity of EV components.

In the aerospace and defense sectors, the demand for lightweight, high-performance insulators is also driving the adoption of PVDF-based solutions. These industries require materials that can withstand extreme temperatures and maintain their electrical properties under challenging conditions. PVDF's unique combination of low weight and high performance makes it an attractive option for various aerospace and defense applications.

The electronics industry is another key driver of market demand for PVDF in high-performance insulators. As electronic devices become more compact and powerful, the need for efficient thermal management and electrical insulation increases. PVDF's excellent dielectric properties and thermal stability make it a preferred choice for insulation in miniaturized electronic components and high-frequency applications.

Market analysts project a compound annual growth rate (CAGR) for the PVDF market in the high-performance insulator segment to exceed the overall polymer insulator market growth. This trend is expected to continue as industries increasingly prioritize energy efficiency, reliability, and sustainability in their operations.

The Asia-Pacific region is anticipated to be the fastest-growing market for PVDF-based insulators, driven by rapid industrialization, infrastructure development, and increasing investments in renewable energy projects. North America and Europe are also expected to maintain strong demand, primarily due to ongoing grid modernization efforts and the transition to electric vehicles.

Technical Challenges

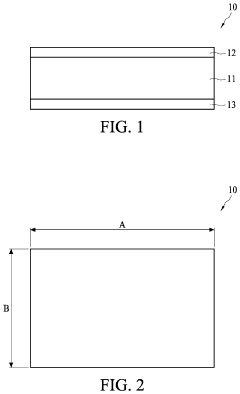

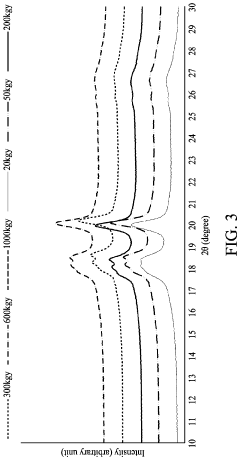

The development of PVDF (Polyvinylidene Fluoride) for high-performance insulators faces several significant technical challenges. One of the primary obstacles is achieving optimal crystallinity and morphology control. The electrical and mechanical properties of PVDF are heavily dependent on its crystalline structure, particularly the β-phase, which exhibits the highest piezoelectric and ferroelectric properties. However, controlling the formation of this phase during processing remains difficult, often requiring specific conditions and additives.

Another major challenge lies in enhancing the thermal stability of PVDF-based insulators. While PVDF offers excellent chemical resistance and electrical properties, its relatively low melting point (around 177°C) limits its application in high-temperature environments. Researchers are working on developing PVDF copolymers and composites to improve thermal resistance without compromising other desirable properties.

Dielectric strength improvement is also a critical area of focus. Although PVDF has good dielectric properties, there is a constant push to increase its breakdown strength to meet the demands of advanced electrical systems. This involves addressing issues such as space charge accumulation and electrical treeing, which can lead to premature failure of the insulator.

The long-term reliability and aging characteristics of PVDF insulators present another significant challenge. Understanding and mitigating the effects of environmental factors, electrical stress, and mechanical strain on the material's performance over extended periods is crucial for ensuring the longevity of insulation systems.

Processability and scalability of PVDF for large-scale insulator production also pose technical hurdles. Developing efficient manufacturing techniques that can maintain consistent material properties while allowing for complex shapes and sizes is essential for widespread industrial adoption.

Lastly, there is an ongoing challenge in balancing the various property requirements of high-performance insulators. Enhancing one property, such as dielectric strength, often comes at the expense of others, like flexibility or thermal stability. Finding the optimal balance that meets the diverse needs of different applications remains a complex task for researchers and engineers in the field.

Current PVDF Solutions

01 PVDF insulation in electrical applications

PVDF is widely used as an insulation material in electrical applications due to its excellent dielectric properties. It provides high electrical resistance and breakdown strength, making it suitable for use in cables, wires, and other electrical components. The material's insulation performance can be further enhanced through various processing techniques and additives.- Thermal insulation properties of PVDF: PVDF exhibits excellent thermal insulation properties, making it suitable for applications requiring temperature control. Its low thermal conductivity helps maintain stable temperatures in various environments, contributing to energy efficiency in insulation systems.

- Electrical insulation characteristics of PVDF: PVDF demonstrates superior electrical insulation properties, making it an ideal material for electrical and electronic applications. Its high dielectric strength and low dielectric loss contribute to its effectiveness as an electrical insulator in various devices and components.

- Chemical resistance and durability of PVDF insulation: PVDF insulation exhibits exceptional chemical resistance and durability, allowing it to withstand harsh environments and maintain its insulation properties over extended periods. This characteristic makes it suitable for use in corrosive and chemically aggressive settings.

- PVDF composites for enhanced insulation performance: Composite materials incorporating PVDF have been developed to further improve insulation performance. These composites combine the inherent properties of PVDF with other materials to achieve superior thermal, electrical, or acoustic insulation characteristics for specific applications.

- Application of PVDF insulation in various industries: PVDF insulation finds widespread use across multiple industries due to its versatile properties. It is employed in construction, automotive, aerospace, electronics, and energy sectors for thermal management, electrical insulation, and protection against environmental factors.

02 Thermal insulation properties of PVDF

PVDF exhibits good thermal insulation characteristics, making it suitable for applications requiring temperature control. Its low thermal conductivity helps maintain stable temperatures in various environments. The material can be used in thermal insulation systems for buildings, industrial equipment, and aerospace applications.Expand Specific Solutions03 PVDF composites for enhanced insulation

Combining PVDF with other materials to create composites can significantly improve its insulation performance. These composites may incorporate nanoparticles, fibers, or other polymers to enhance thermal, electrical, or acoustic insulation properties. Such composites find applications in advanced insulation systems for various industries.Expand Specific Solutions04 PVDF foam for improved insulation

PVDF foam structures offer enhanced insulation performance compared to solid PVDF. The foam's cellular structure traps air or gas, reducing thermal conductivity and improving overall insulation efficiency. This makes PVDF foam suitable for applications in construction, automotive, and aerospace industries where lightweight insulation is required.Expand Specific Solutions05 PVDF in acoustic insulation applications

PVDF demonstrates good acoustic insulation properties, making it suitable for noise reduction applications. Its ability to absorb and dampen sound waves makes it useful in automotive, construction, and industrial settings where noise control is important. The material can be processed into various forms, such as films or foams, to optimize its acoustic insulation performance.Expand Specific Solutions

Key Industry Players

The PVDF high-performance insulator market is in a growth phase, driven by increasing demand for advanced materials in various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, PVDF insulators are reaching maturity, with ongoing advancements in performance and applications. Key players like Arkema, Solvay, and DuPont are leading innovation, while companies such as Kyulux and Polytronics are focusing on niche applications. Chinese firms like Shanghai Huayi 3F and Jiangsu Tongguang are rapidly gaining market share, particularly in the Asia-Pacific region. The competitive landscape is characterized by a mix of established global chemical companies and emerging specialized manufacturers, with a focus on R&D to maintain technological edge.

Arkema, Inc.

DuPont de Nemours, Inc.

PVDF Innovations

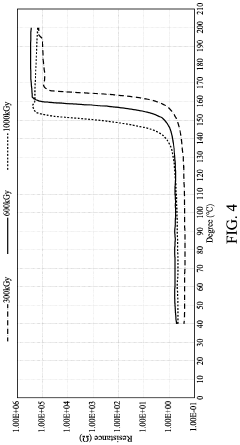

- The device employs a PVDF matrix with adjusted proportions of α-PVDF, β-PVDF, and γ-PVDF crystalline phases, combined with a metal-ceramic conductive filler and a fluoropolymer, to achieve low electrical resistivity and improved voltage endurance without additional additives, allowing for repeated resistance recovery after tripping.

- The device employs a heat-sensitive layer with a specific proportion of PVDF crystalline phases (α-PVDF, β-PVDF, and γ-PVDF) and carbon black as a conductive filler, optimized to improve voltage endurance and thermal stability without additional additives, with a structure comprising metal layers and a fluoropolymer matrix for enhanced electrical characteristics.

Environmental Impact

The environmental impact of PVDF (Polyvinylidene Fluoride) in high-performance insulators is a critical aspect to consider as the material gains prominence in various applications. PVDF's unique properties, including its chemical resistance and thermal stability, contribute to its longevity and durability in insulation systems. This extended lifespan reduces the frequency of replacement, potentially lowering the overall environmental footprint associated with insulator production and disposal.

However, the production of PVDF involves fluorine-based chemicals, which can have significant environmental implications. The manufacturing process may release greenhouse gases and other pollutants if not properly managed. Additionally, the use of fluoropolymers has raised concerns about potential long-term environmental persistence and bioaccumulation of fluorinated compounds.

On the positive side, PVDF's excellent electrical properties enable more efficient energy transmission and distribution systems. This efficiency can lead to reduced energy losses and, consequently, lower greenhouse gas emissions from power generation. Furthermore, PVDF's resistance to degradation under harsh environmental conditions means less leaching of potentially harmful substances into the surrounding ecosystem over time.

The recyclability of PVDF is an area of ongoing research and development. While the material itself is theoretically recyclable, the current infrastructure and processes for recycling fluoropolymers are limited. Improving end-of-life management for PVDF-based insulators is crucial for minimizing their environmental impact and promoting a circular economy approach in the electrical industry.

In terms of toxicity, PVDF is generally considered to have low environmental toxicity compared to some other insulating materials. However, the potential release of fluoride ions during degradation or incineration at the end of its life cycle requires careful consideration and appropriate disposal methods.

The use of PVDF in high-performance insulators also intersects with broader sustainability goals. By enhancing the reliability and efficiency of electrical systems, PVDF contributes to the development of smart grids and renewable energy infrastructure. This indirect environmental benefit should be weighed against the material's production and end-of-life impacts when assessing its overall environmental footprint.

As regulations around fluorinated compounds become more stringent, manufacturers are exploring ways to reduce the environmental impact of PVDF production and use. This includes developing more eco-friendly synthesis methods, improving production efficiency to reduce waste, and investigating alternative materials that can match PVDF's performance with a lower environmental burden.

Regulatory Compliance

The regulatory landscape for PVDF in high-performance insulators is complex and evolving, with various standards and guidelines in place to ensure safety, reliability, and environmental compliance. In the United States, the National Electrical Manufacturers Association (NEMA) and the American National Standards Institute (ANSI) play crucial roles in setting standards for insulation materials, including PVDF-based products. These organizations work closely with industry stakeholders to develop and update specifications that address the unique properties and applications of PVDF in high-voltage environments.

Internationally, the International Electrotechnical Commission (IEC) provides a framework for global standardization of electrical, electronic, and related technologies. IEC 60243 and IEC 62631 are particularly relevant for PVDF insulators, covering dielectric and insulating properties of solid materials. Manufacturers must ensure their PVDF-based products meet or exceed these standards to maintain market access and customer confidence.

Environmental regulations also significantly impact the use of PVDF in insulators. The European Union's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation and the Restriction of Hazardous Substances (RoHS) directive have implications for PVDF production and application. While PVDF itself is generally considered environmentally friendly, manufacturers must carefully manage the entire supply chain to ensure compliance with these stringent regulations.

In recent years, there has been an increased focus on the end-of-life management of insulation materials. Regulatory bodies are pushing for more sustainable practices, including recyclability and reduced environmental impact. This has led to the development of new standards and guidelines for the disposal and recycling of PVDF-based insulators, challenging manufacturers to innovate in both material composition and product design.

The automotive and aerospace industries, which are increasingly adopting PVDF-based insulation materials, face additional regulatory hurdles. These sectors must comply with industry-specific standards such as those set by the Federal Aviation Administration (FAA) in the United States or the European Aviation Safety Agency (EASA) in Europe. These regulations often require extensive testing and certification processes to ensure the reliability and safety of PVDF insulators in critical applications.

As the technology advances, regulatory bodies are working to keep pace with new developments in PVDF insulation. This includes addressing emerging concerns such as the long-term performance of PVDF under extreme conditions, its interaction with other materials in complex systems, and potential health and safety implications of nanocomposite PVDF formulations. Manufacturers and researchers must maintain open dialogues with regulatory agencies to ensure that standards evolve alongside technological progress, fostering innovation while safeguarding public and environmental interests.