PVDF in Heat Exchangers: Increasing Thermal Transfer Efficiency

PVDF Heat Exchanger Evolution and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a revolutionary material in heat exchanger technology, offering unique properties that address longstanding challenges in thermal transfer efficiency. The evolution of PVDF in heat exchangers can be traced back to the 1960s when its exceptional chemical resistance and thermal stability were first recognized. Initially, PVDF found limited applications due to its higher cost compared to traditional materials like stainless steel or copper.

As environmental regulations tightened and industries sought more durable and efficient solutions, PVDF gained traction in the 1980s and 1990s. Its resistance to corrosion and fouling made it particularly attractive for use in aggressive chemical environments and applications where maintaining cleanliness was crucial. The material's low thermal conductivity, once seen as a limitation, became an advantage in certain scenarios where heat loss prevention was essential.

The turn of the millennium marked a significant shift in PVDF heat exchanger development. Advances in polymer science and manufacturing techniques allowed for the creation of thinner PVDF films and more complex geometries. This breakthrough enabled the design of heat exchangers with larger surface areas and improved flow dynamics, directly addressing the thermal transfer efficiency challenge.

In recent years, the focus has shifted towards enhancing PVDF's inherent properties. Research efforts have concentrated on developing composite PVDF materials, incorporating nanoparticles or other additives to boost thermal conductivity without compromising the polymer's beneficial characteristics. These innovations have opened new possibilities for PVDF in high-performance heat exchange applications.

The primary objective in the ongoing evolution of PVDF heat exchangers is to significantly increase thermal transfer efficiency while maintaining the material's core advantages. This goal encompasses several key areas: optimizing surface area-to-volume ratios, improving heat transfer coefficients through advanced designs, and enhancing the material's thermal conductivity. Additionally, there is a strong emphasis on developing PVDF heat exchangers that are more compact, lighter, and easier to manufacture, thereby reducing overall system costs and expanding their applicability across various industries.

Another critical objective is to extend the operational range of PVDF heat exchangers, particularly in terms of temperature and pressure tolerances. This expansion would allow PVDF to compete more effectively with metallic heat exchangers in a broader range of applications, including those in more demanding industrial processes.

As environmental concerns continue to grow, there is also a focus on improving the recyclability and overall lifecycle sustainability of PVDF heat exchangers. This aligns with global trends towards circular economy principles and reduced environmental impact in industrial processes.

Market Analysis for High-Efficiency Heat Exchangers

The market for high-efficiency heat exchangers has been experiencing significant growth in recent years, driven by increasing demand for energy-efficient solutions across various industries. The global heat exchanger market is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 6% during the forecast period. This growth is primarily attributed to the rising focus on energy conservation, stringent environmental regulations, and the need for cost-effective thermal management solutions.

Several key factors are influencing the market dynamics for high-efficiency heat exchangers. The industrial sector, including chemical processing, oil and gas, and power generation, remains the largest consumer of heat exchangers. However, the HVAC and refrigeration sectors are rapidly emerging as significant contributors to market growth, driven by urbanization and the increasing adoption of smart building technologies.

The automotive industry is also playing a crucial role in shaping the heat exchanger market. With the shift towards electric vehicles and the need for more efficient thermal management systems, demand for compact and lightweight heat exchangers is on the rise. This trend is expected to continue as automotive manufacturers strive to improve vehicle performance and energy efficiency.

Geographically, Asia-Pacific is leading the market growth, with China and India being the major contributors. The rapid industrialization, infrastructure development, and increasing investments in renewable energy projects in these countries are driving the demand for high-efficiency heat exchangers. North America and Europe follow closely, with a strong focus on energy-efficient technologies and stringent environmental regulations propelling market growth.

The market is witnessing a shift towards more advanced materials and designs to enhance thermal transfer efficiency. Polyvinylidene fluoride (PVDF) is gaining traction as a material of choice for heat exchangers due to its excellent chemical resistance, thermal stability, and low thermal conductivity. The integration of PVDF in heat exchangers is expected to open new opportunities for market players, particularly in corrosive and high-temperature applications.

Competition in the high-efficiency heat exchanger market is intense, with several global and regional players vying for market share. Key market players are focusing on research and development activities to introduce innovative products and gain a competitive edge. Strategic partnerships, mergers, and acquisitions are also common strategies employed by companies to expand their product portfolios and geographical presence.

PVDF Thermal Transfer Challenges

Polyvinylidene fluoride (PVDF) has gained significant attention in heat exchanger applications due to its unique properties. However, its use in enhancing thermal transfer efficiency faces several challenges that require careful consideration and innovative solutions.

One of the primary challenges is PVDF's inherently low thermal conductivity compared to traditional metal-based heat exchanger materials. This characteristic limits its ability to efficiently transfer heat, potentially reducing the overall performance of heat exchange systems. Engineers and researchers are actively exploring methods to overcome this limitation, such as incorporating conductive fillers or developing composite materials that maintain PVDF's desirable properties while improving thermal conductivity.

Another significant challenge lies in the temperature limitations of PVDF. While it exhibits excellent chemical resistance and durability, its relatively low melting point restricts its use in high-temperature applications. This constraint narrows the range of industrial processes where PVDF-based heat exchangers can be effectively employed, necessitating the development of heat-resistant PVDF grades or alternative polymer blends that can withstand higher operating temperatures without compromising performance.

The surface properties of PVDF also present challenges in heat transfer applications. Its hydrophobic nature can lead to reduced wetting and increased fouling, which negatively impacts heat transfer efficiency over time. Addressing this issue requires innovative surface modification techniques or the development of specialized coatings that can enhance wettability and reduce fouling while maintaining PVDF's core benefits.

Mechanical strength and long-term durability under thermal cycling conditions are additional concerns when using PVDF in heat exchangers. The material must withstand repeated temperature fluctuations and potential thermal shocks without degradation or loss of structural integrity. This necessitates careful design considerations and potentially the use of reinforcing materials or specialized manufacturing techniques to enhance the mechanical properties of PVDF-based heat exchanger components.

Furthermore, the processing and fabrication of PVDF for heat exchanger applications present their own set of challenges. Achieving consistent wall thickness, optimal surface finish, and precise geometries required for efficient heat transfer can be more complex with PVDF compared to traditional metallic materials. This calls for advancements in manufacturing processes and quality control measures specific to PVDF-based heat exchanger production.

Lastly, the integration of PVDF components into existing heat exchanger designs and systems poses compatibility challenges. Differences in thermal expansion coefficients between PVDF and other materials used in heat exchanger assemblies can lead to stress and potential failure points. Overcoming these integration challenges requires innovative design approaches and potentially the development of new joining techniques or interface materials to ensure seamless operation and longevity of PVDF-based heat exchange systems.

Current PVDF Heat Transfer Enhancement Techniques

01 PVDF composite materials for improved thermal transfer

Composite materials incorporating PVDF and other components are developed to enhance thermal transfer efficiency. These composites may include conductive fillers, nanoparticles, or other polymers to create a synergistic effect that improves heat transfer properties while maintaining the desirable characteristics of PVDF.- PVDF composite materials for improved thermal transfer: Incorporating various materials into PVDF to create composite structures can enhance thermal transfer efficiency. These composites may include carbon nanotubes, graphene, or other conductive fillers, which can significantly improve the thermal conductivity of the resulting material while maintaining PVDF's desirable properties.

- Surface modification of PVDF for enhanced thermal properties: Modifying the surface of PVDF through various treatments or coatings can improve its thermal transfer efficiency. This may involve plasma treatment, chemical etching, or the application of specialized coatings that enhance the material's ability to transfer heat while retaining its other beneficial characteristics.

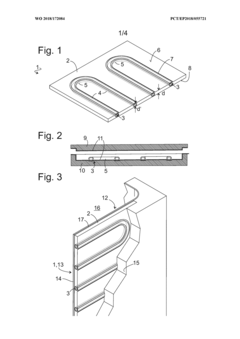

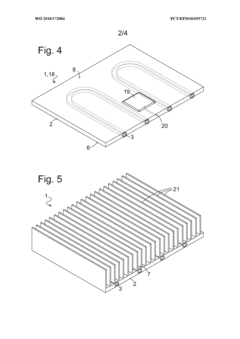

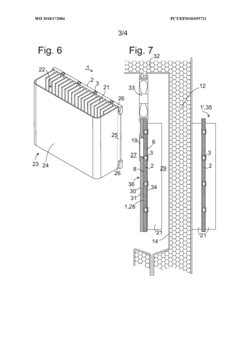

- PVDF-based heat exchange systems: Designing heat exchange systems that utilize PVDF's unique properties can lead to improved thermal transfer efficiency. These systems may incorporate specialized geometries, flow patterns, or multi-layer structures that maximize heat transfer while taking advantage of PVDF's chemical resistance and durability.

- Nanostructured PVDF for enhanced thermal properties: Creating nanostructured forms of PVDF, such as nanofibers or nanoparticles, can significantly increase the surface area available for heat transfer. This approach can lead to improved thermal transfer efficiency in applications ranging from textiles to electronic cooling systems.

- PVDF blends and copolymers for optimized thermal performance: Developing blends or copolymers of PVDF with other materials can result in improved thermal transfer efficiency. These formulations may combine the desirable properties of PVDF with those of other polymers or additives to create materials with enhanced thermal conductivity and heat transfer characteristics.

02 Surface modification of PVDF for enhanced thermal conductivity

Various surface modification techniques are applied to PVDF to improve its thermal transfer efficiency. These methods may include plasma treatment, chemical grafting, or the application of specialized coatings that alter the surface properties of PVDF, resulting in better heat transfer characteristics.Expand Specific Solutions03 PVDF-based heat exchange systems

Innovative heat exchange systems utilizing PVDF as a key component are designed to maximize thermal transfer efficiency. These systems may incorporate unique geometries, flow patterns, or multi-layer structures that optimize heat transfer while taking advantage of PVDF's chemical resistance and durability.Expand Specific Solutions04 Nanostructured PVDF for improved thermal properties

Nanostructured forms of PVDF, such as nanofibers, nanoparticles, or nanocomposites, are developed to enhance thermal transfer efficiency. These nanostructures provide increased surface area and unique properties that contribute to improved heat transfer capabilities compared to bulk PVDF materials.Expand Specific Solutions05 PVDF blends and copolymers for thermal applications

Specialized PVDF blends and copolymers are formulated to optimize thermal transfer efficiency while maintaining other desirable properties. These materials may combine PVDF with other polymers or incorporate specific chemical modifications to achieve an ideal balance of thermal conductivity, mechanical strength, and chemical resistance.Expand Specific Solutions

Key Players in PVDF Heat Exchanger Industry

The application of PVDF in heat exchangers for increasing thermal transfer efficiency is in a growth phase, with a rapidly expanding market driven by the demand for more efficient and durable heat exchange solutions. The global market size for PVDF in heat exchangers is projected to grow significantly in the coming years. Technologically, the field is advancing rapidly, with companies like Siemens Corp., LG Electronics, Inc., and Daikin Industries Ltd. leading innovation. These firms, along with others such as Alfa Laval Corporate AB and Mitsubishi Electric Corp., are investing heavily in R&D to improve PVDF-based heat exchanger performance. The technology's maturity is progressing, with ongoing research at institutions like Xi'an Jiaotong University and Fraunhofer-Gesellschaft eV contributing to advancements in material properties and design optimization.

Hangzhou Sanhua Micro Channel Heat Exchanger Co., Ltd.

Arkema France SA

Innovative PVDF Surface Modification Methods

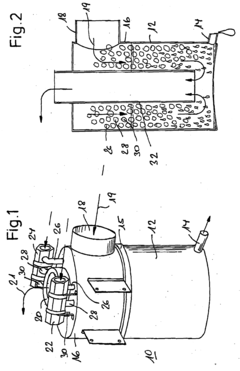

- A heat exchanger device with a condensate-resistant plastic container, preferably made of PVDF, and stainless steel components, where the plastic is crosslinked for enhanced temperature resistance, and fluid lines are coated with plastic and equipped with gas diffusion barriers to prevent corrosion and optimize heat transfer, allowing for easy handling, cleaning, and retrofitting.

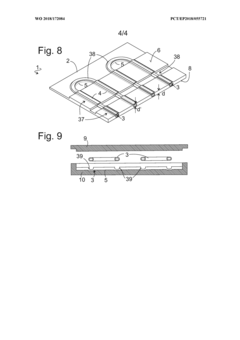

- A heat exchanger with a plastic base plate and embedded heat transfer tube, where the tube is cast into the base plate to ensure direct contact over a large circumference, enhanced with thermally conductive additives like graphite or metal powder for improved conductivity, and designed with varying wall thickness and protrusions to promote even surface temperature and airflow.

Environmental Impact of PVDF Heat Exchangers

The environmental impact of PVDF heat exchangers is a crucial consideration in their application and development. PVDF (polyvinylidene fluoride) has gained popularity in heat exchanger design due to its excellent chemical resistance, thermal stability, and mechanical properties. However, its environmental footprint must be carefully evaluated throughout its lifecycle.

During the production phase, the manufacturing of PVDF involves energy-intensive processes and the use of fluorine-based chemicals. These processes can contribute to greenhouse gas emissions and potential environmental contamination if not properly managed. However, compared to traditional metal-based heat exchangers, PVDF production generally requires less energy and produces fewer emissions, particularly when considering the entire lifecycle of the product.

In the operational phase, PVDF heat exchangers offer several environmental benefits. Their corrosion resistance and durability lead to longer service lives, reducing the frequency of replacements and associated resource consumption. The smooth surface of PVDF also resists fouling, which maintains thermal efficiency over time and reduces the need for chemical cleaning agents, thereby minimizing the release of harmful substances into the environment.

Energy efficiency is another critical factor in assessing environmental impact. PVDF heat exchangers, when properly designed and optimized, can achieve high thermal transfer efficiency. This increased efficiency translates to lower energy consumption in various industrial processes, contributing to overall energy savings and reduced carbon emissions.

At the end of their lifecycle, PVDF heat exchangers present both challenges and opportunities from an environmental perspective. While PVDF is not biodegradable, it is recyclable. Advanced recycling technologies can recover and repurpose PVDF materials, reducing waste and conserving resources. However, the recycling infrastructure for PVDF is not as well-established as for some other materials, which may limit its recyclability in practice.

The use of PVDF in heat exchangers also has indirect environmental benefits. In applications such as wastewater treatment or chemical processing, PVDF's chemical resistance allows for the handling of corrosive fluids without leakage or contamination, preventing potential environmental hazards. Additionally, in renewable energy applications like geothermal power plants, PVDF heat exchangers can withstand harsh conditions, supporting the expansion of clean energy sources.

Cost-Benefit Analysis of PVDF Heat Exchangers

The implementation of PVDF (polyvinylidene fluoride) in heat exchangers presents a compelling case for cost-benefit analysis. Initial investment in PVDF heat exchangers is typically higher compared to traditional materials like stainless steel or titanium. However, the long-term benefits often outweigh the upfront costs, making PVDF an economically viable option for many applications.

PVDF's exceptional chemical resistance significantly reduces maintenance and replacement costs over the lifetime of the heat exchanger. In corrosive environments, where traditional materials may degrade rapidly, PVDF maintains its integrity, leading to extended operational lifespans. This durability translates to fewer production interruptions and lower overall maintenance expenses, contributing positively to the cost-benefit equation.

Energy efficiency is another crucial factor in the economic analysis of PVDF heat exchangers. The material's low thermal conductivity, while seemingly a disadvantage, can be leveraged to create more efficient designs. By optimizing wall thickness and surface area, PVDF heat exchangers can achieve comparable or even superior heat transfer rates to metal alternatives. This efficiency can lead to reduced energy consumption and associated costs in the long run.

The lightweight nature of PVDF offers additional cost benefits in terms of transportation, installation, and structural support requirements. These factors can significantly reduce project costs, especially in large-scale industrial applications or in situations where weight is a critical consideration.

From an operational perspective, PVDF's non-stick properties minimize fouling and scaling, which are common issues in heat exchanger systems. This characteristic reduces the frequency and intensity of cleaning procedures, lowering labor costs and minimizing the use of potentially harmful cleaning chemicals. The resulting increase in operational uptime further enhances the economic benefits of PVDF heat exchangers.

Environmental considerations also play a role in the cost-benefit analysis. PVDF's resistance to bacterial growth and its ability to operate without additional anti-fouling treatments contribute to reduced environmental impact and associated costs. Furthermore, the material's recyclability at the end of its lifecycle adds to its overall sustainability profile, potentially offering cost savings or even revenue through recycling programs.

When evaluating the total cost of ownership, it's essential to consider the specific application requirements. In industries where corrosion resistance is paramount, such as chemical processing or wastewater treatment, the benefits of PVDF often far outweigh the initial investment. However, in less demanding environments, the cost-benefit ratio may be less favorable, necessitating a careful analysis of operational conditions and long-term economic impacts.