PVDF in Electrical Insulation: Technical Efficiency Improvements

PVDF Insulation Evolution

The evolution of PVDF insulation in electrical applications has been marked by significant advancements in material science and engineering. Initially developed in the 1960s, Polyvinylidene Fluoride (PVDF) quickly gained attention for its unique combination of properties, including high dielectric strength, excellent chemical resistance, and thermal stability.

In the early stages of its development, PVDF was primarily used in specialized applications where its superior properties justified the higher cost compared to traditional insulation materials. The 1970s and 1980s saw increased research into PVDF's molecular structure and its relationship to electrical properties, leading to the development of various grades optimized for specific electrical applications.

A major breakthrough came in the 1990s with the introduction of PVDF copolymers and terpolymers. These modified versions of PVDF offered enhanced flexibility and processability while maintaining the core electrical insulation properties. This innovation expanded PVDF's use in wire and cable insulation, particularly in high-temperature and chemically aggressive environments.

The turn of the millennium brought about a focus on nanocomposite PVDF materials. By incorporating nanoparticles such as silica, alumina, or carbon nanotubes, researchers were able to further enhance the dielectric properties and thermal conductivity of PVDF insulation. This development was particularly significant for high-voltage applications and in the emerging field of power electronics.

In recent years, the evolution of PVDF insulation has been driven by the demands of miniaturization and increased energy efficiency in electrical systems. Advanced manufacturing techniques, such as electrospinning and 3D printing, have enabled the production of PVDF insulation with precisely controlled microstructures, leading to improved performance in compact designs.

The latest frontier in PVDF insulation evolution is the development of smart and responsive materials. By incorporating piezoelectric properties or phase-change capabilities, PVDF insulation can now adapt to changing electrical and thermal conditions, offering dynamic protection and potentially self-healing properties in electrical systems.

Throughout its evolution, PVDF insulation has consistently pushed the boundaries of electrical efficiency. From its initial introduction as a high-performance alternative to traditional materials, through the development of tailored copolymers and nanocomposites, to the current exploration of smart functionalities, PVDF has demonstrated a remarkable capacity for innovation and adaptation to meet the ever-increasing demands of modern electrical systems.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) in electrical insulation applications has been experiencing significant growth, driven by the increasing need for high-performance materials in various industries. The global PVDF market size was valued at over $1 billion in 2020, with a compound annual growth rate (CAGR) projected to exceed 6% from 2021 to 2028.

The electrical and electronics sector represents a substantial portion of this market, with PVDF being widely used for its excellent dielectric properties, thermal stability, and chemical resistance. The growing emphasis on energy efficiency and the rapid expansion of renewable energy sources have further boosted the demand for PVDF in electrical insulation applications.

In the power generation and distribution sector, PVDF is increasingly being utilized in high-voltage cables, transformers, and switchgear. The material's ability to withstand extreme temperatures and harsh environmental conditions makes it particularly suitable for outdoor electrical equipment. As countries worldwide invest in upgrading their power infrastructure and expanding renewable energy capacity, the demand for PVDF-based insulation materials is expected to rise significantly.

The automotive industry is another key driver of PVDF demand in electrical insulation. With the growing adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), there is an increased need for high-performance insulation materials in battery systems, power electronics, and electric motors. PVDF's excellent electrical properties and resistance to automotive fluids make it an ideal choice for these applications.

In the telecommunications sector, the ongoing rollout of 5G networks and the expansion of fiber-optic infrastructure are creating new opportunities for PVDF in cable insulation and protective coatings. The material's durability and resistance to UV radiation make it well-suited for outdoor telecommunications equipment.

The industrial sector is also contributing to the growing demand for PVDF in electrical insulation. As manufacturing processes become increasingly automated and reliant on sophisticated electronic systems, there is a greater need for reliable insulation materials that can withstand harsh industrial environments.

Looking ahead, the market for PVDF in electrical insulation is expected to continue its upward trajectory. Technological advancements aimed at improving the material's performance characteristics, such as enhanced dielectric strength and thermal conductivity, are likely to open up new application areas and drive further market growth. Additionally, the increasing focus on sustainability and recyclability in the electrical and electronics industry may lead to the development of more environmentally friendly PVDF formulations, potentially expanding its market reach.

Technical Challenges

The development of PVDF (Polyvinylidene Fluoride) for electrical insulation applications faces several technical challenges that hinder its widespread adoption and efficiency improvements. One of the primary obstacles is the material's inherent limitations in thermal stability at high temperatures. While PVDF exhibits excellent dielectric properties, its performance can degrade significantly when exposed to temperatures above 150°C for extended periods, limiting its use in high-temperature environments.

Another significant challenge lies in the processing and manufacturing of PVDF for electrical insulation purposes. The material's high melt viscosity and tendency to degrade during processing make it difficult to produce thin, uniform films or coatings required for many insulation applications. This challenge often results in increased production costs and potential quality inconsistencies in the final product.

The crystallinity of PVDF poses a dual challenge. On one hand, higher crystallinity improves mechanical strength and chemical resistance, which are desirable for insulation materials. On the other hand, it can lead to reduced flexibility and impact resistance, potentially compromising the material's performance in dynamic or high-stress environments. Balancing these properties to achieve optimal performance across various applications remains a significant technical hurdle.

Moisture absorption is another critical issue facing PVDF in electrical insulation applications. Although PVDF is generally considered hydrophobic, it can still absorb small amounts of moisture over time, particularly in high-humidity environments. This moisture absorption can lead to a decrease in insulation resistance and potentially compromise the material's long-term performance and reliability.

The development of PVDF composites and blends to enhance its properties presents its own set of challenges. While incorporating additives or blending with other polymers can improve certain characteristics, it often comes at the cost of compromising other desirable properties. Achieving the right balance of additives or blend ratios to enhance electrical insulation properties without significantly affecting other critical attributes remains a complex task for researchers and engineers.

Lastly, the environmental impact and end-of-life considerations for PVDF insulation materials pose growing challenges. As global focus shifts towards sustainability, developing eco-friendly processing methods, reducing the carbon footprint of PVDF production, and improving recyclability or biodegradability of PVDF insulation products have become increasingly important technical challenges that need to be addressed to ensure the material's long-term viability in electrical insulation applications.

Current PVDF Solutions

01 Improved PVDF membrane fabrication techniques

Advanced methods for fabricating PVDF membranes with enhanced properties, such as improved porosity, mechanical strength, and chemical resistance. These techniques may involve novel casting processes, additives, or post-treatment methods to optimize the membrane structure and performance.- PVDF membrane fabrication techniques: Various techniques are employed to fabricate PVDF membranes with improved technical efficiency. These methods include phase inversion, electrospinning, and blending with other polymers. The fabrication process can be optimized to enhance the membrane's porosity, mechanical strength, and overall performance in applications such as water treatment and energy storage.

- PVDF-based composite materials: Combining PVDF with other materials to create composite structures can significantly improve its technical efficiency. These composites often incorporate nanoparticles, carbon-based materials, or other polymers to enhance properties such as electrical conductivity, thermal stability, and mechanical strength. The resulting materials find applications in sensors, actuators, and energy harvesting devices.

- Surface modification of PVDF: Surface modification techniques are applied to PVDF to improve its hydrophilicity, biocompatibility, and fouling resistance. Methods such as plasma treatment, grafting, and chemical modification can alter the surface properties of PVDF, enhancing its performance in applications like membrane filtration and biomedical devices.

- PVDF in energy storage applications: PVDF's piezoelectric and ferroelectric properties make it valuable for energy storage applications. Research focuses on optimizing PVDF-based materials for use in capacitors, batteries, and energy harvesting devices. Techniques to enhance its dielectric constant, energy density, and charge-discharge efficiency are explored to improve overall energy storage performance.

- PVDF processing for improved efficiency: Advanced processing techniques are developed to enhance the technical efficiency of PVDF. These include optimizing crystallization conditions, controlling molecular weight distribution, and developing novel extrusion or molding processes. The goal is to improve the material's mechanical properties, thermal stability, and processability for various industrial applications.

02 PVDF-based composite materials

Development of PVDF-based composite materials by incorporating various fillers, nanoparticles, or other polymers to enhance specific properties such as electrical conductivity, thermal stability, or mechanical strength. These composites can offer improved performance in applications like energy storage, sensors, and filtration systems.Expand Specific Solutions03 PVDF in energy harvesting and storage

Utilization of PVDF's piezoelectric properties for energy harvesting applications, as well as its use in energy storage devices such as lithium-ion batteries and supercapacitors. This includes the development of PVDF-based electrodes, separators, and electrolytes with improved efficiency and durability.Expand Specific Solutions04 Surface modification of PVDF materials

Techniques for modifying the surface properties of PVDF materials to enhance their performance in specific applications. This may include plasma treatment, chemical grafting, or coating processes to improve hydrophilicity, biocompatibility, or fouling resistance in membrane applications.Expand Specific Solutions05 PVDF in advanced sensing and actuator systems

Development of PVDF-based sensors and actuators with improved sensitivity, response time, and durability. This includes applications in pressure sensors, acoustic transducers, and tactile sensors, leveraging PVDF's piezoelectric and pyroelectric properties for enhanced performance in various industries.Expand Specific Solutions

Key Industry Players

The PVDF electrical insulation market is in a growth phase, driven by increasing demand for high-performance insulation materials in various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, PVDF insulation is maturing, with companies like Arkema, Inc. and Arkema France SA leading in material development. State Grid Corp. of China and Tianjin Electric Power Corp. are advancing applications in power infrastructure. Polytronics Technology Corp. and Samsung Display Co., Ltd. are innovating in consumer electronics insulation. Research institutions such as Xi'an Jiaotong University and Tsinghua University are contributing to technological advancements, while companies like Sansan Intelligent Technology (Rizhao) Co., Ltd. are focusing on smart insulation solutions.

Arkema, Inc.

State Grid Corp. of China

Core PVDF Innovations

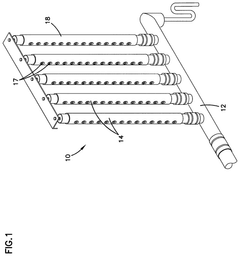

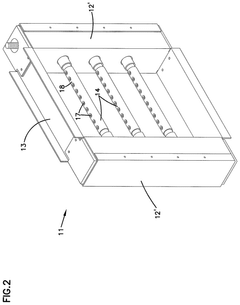

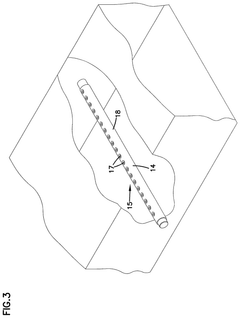

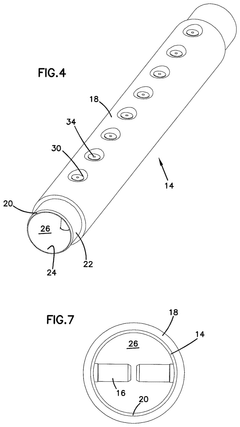

- A foamed polyvinylidene fluoride tubular structure is created by adding a foaming agent to the PVDF resin, reducing density and maintaining flame and smoke resistance while being lighter and more flexible, with optional additives like flame retardants and fillers to meet specific performance standards.

- The use of a polyvinylidene fluoride (PVDF) fluoropolymer insulation covering on steam dispersion tubes and other system parts, which reduces condensate and heat gain, and a method for attaching this insulation using various forms and methods such as strips, tubular forms, or sprays, ensuring secure and efficient coverage.

Environmental Impact

The environmental impact of PVDF (Polyvinylidene Fluoride) in electrical insulation applications is a critical consideration as the industry strives for technical efficiency improvements. PVDF's unique properties contribute to both positive and negative environmental effects throughout its lifecycle.

PVDF's durability and resistance to chemical degradation result in a longer lifespan for electrical insulation components, reducing the frequency of replacements and associated waste generation. This longevity contributes to resource conservation and minimizes the environmental burden of manufacturing and disposal processes.

However, the production of PVDF involves energy-intensive processes and the use of fluorine-based compounds, which can have significant environmental implications. The synthesis of PVDF typically requires high temperatures and pressures, leading to increased energy consumption and greenhouse gas emissions. Additionally, the use of fluorinated precursors raises concerns about potential releases of harmful substances during manufacturing.

In terms of end-of-life management, PVDF presents challenges for recycling due to its chemical stability. While this stability is advantageous for its performance in electrical insulation, it makes the material resistant to conventional recycling methods. Consequently, PVDF waste often ends up in landfills or incineration facilities, contributing to environmental pollution and resource depletion.

On the positive side, the superior insulation properties of PVDF can lead to improved energy efficiency in electrical systems. By reducing energy losses and enhancing the performance of electrical equipment, PVDF indirectly contributes to lower energy consumption and reduced carbon emissions during the operational phase of insulated components.

Recent advancements in PVDF technology have focused on enhancing its environmental profile. Researchers are exploring bio-based alternatives and developing more sustainable production methods to reduce the carbon footprint of PVDF manufacturing. Additionally, efforts are underway to improve the recyclability of PVDF through the development of novel chemical recycling techniques and the integration of additives that facilitate easier material recovery.

The electrical insulation industry is also investigating the potential of PVDF composites that incorporate recycled materials or renewable fillers. These innovations aim to reduce the reliance on virgin raw materials and minimize the overall environmental impact of PVDF-based insulation products.

As environmental regulations become more stringent, manufacturers are increasingly adopting life cycle assessment (LCA) approaches to evaluate and mitigate the environmental impacts of PVDF in electrical insulation applications. This holistic perspective enables the identification of hotspots in the product lifecycle and informs strategies for continuous improvement in environmental performance.

Regulatory Compliance

The regulatory landscape for PVDF in electrical insulation applications is complex and evolving, with various standards and guidelines in place to ensure safety, reliability, and environmental protection. In the United States, the National Electrical Code (NEC) sets the foundation for electrical wiring and equipment standards, including insulation materials. The Occupational Safety and Health Administration (OSHA) also plays a crucial role in enforcing safety regulations in electrical installations.

For PVDF specifically, compliance with UL (Underwriters Laboratories) standards is essential. UL 746A and UL 746B are particularly relevant, as they cover the evaluation of polymeric materials used in electrical equipment. These standards assess properties such as dielectric strength, flame resistance, and long-term thermal stability, which are critical for PVDF's performance as an electrical insulator.

In Europe, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of PVDF in electrical insulation. Manufacturers must ensure that PVDF and any additives used in their formulations comply with REACH requirements. Additionally, the RoHS (Restriction of Hazardous Substances) Directive restricts the use of certain hazardous substances in electrical and electronic equipment, which may affect the composition of PVDF-based insulation materials.

The International Electrotechnical Commission (IEC) provides global standards for electrical, electronic, and related technologies. IEC 60243 is particularly relevant for PVDF insulation, as it specifies test methods for electric strength of insulating materials. Compliance with these standards is crucial for international market access and ensuring the reliability of PVDF-based insulation products.

As energy efficiency becomes increasingly important, regulations such as the EU's Ecodesign Directive are driving the development of more efficient electrical systems. This indirectly affects PVDF insulation, as manufacturers seek materials that can contribute to overall system efficiency while meeting regulatory requirements.

Environmental regulations also play a significant role in the use of PVDF for electrical insulation. The material's resistance to chemical degradation and its potential for recycling align well with sustainability goals. However, end-of-life considerations and proper disposal methods must be addressed to comply with waste management regulations in various jurisdictions.

To ensure ongoing compliance and technical efficiency improvements, manufacturers working with PVDF in electrical insulation applications must maintain vigilant monitoring of regulatory changes across different regions. This includes staying informed about updates to existing standards and the introduction of new regulations that may impact material selection, manufacturing processes, or product performance requirements.