PVDF in Biometric Monitoring Devices: Improving Accuracy

PVDF in BMD: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the field of biometric monitoring devices (BMDs), offering potential improvements in accuracy and reliability. The evolution of PVDF in this context can be traced back to its discovery in 1948 by Kawai. Initially utilized in industrial applications, PVDF's unique piezoelectric properties have gradually found their way into the realm of biomedical sensing and monitoring.

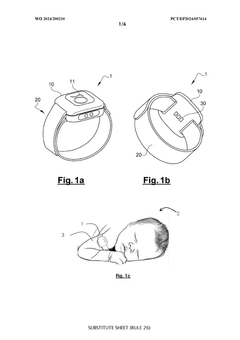

The development of PVDF for biometric applications has been driven by the increasing demand for wearable and non-invasive health monitoring solutions. As the global population ages and chronic diseases become more prevalent, there is a growing need for accurate, continuous, and user-friendly health monitoring devices. PVDF's flexibility, biocompatibility, and sensitivity to mechanical stress make it an ideal candidate for integration into such devices.

Recent advancements in PVDF technology have focused on enhancing its piezoelectric properties and developing novel fabrication techniques. These efforts aim to improve the material's sensitivity and reliability in detecting subtle physiological signals, such as heart rate, respiratory rate, and blood pressure. The integration of PVDF into BMDs represents a convergence of materials science, bioengineering, and electronics, highlighting the interdisciplinary nature of this field.

The primary objective of incorporating PVDF into BMDs is to significantly improve the accuracy of physiological measurements. Traditional sensing technologies often suffer from motion artifacts and environmental interference, leading to unreliable data. PVDF's unique properties offer the potential to overcome these limitations by providing more stable and precise measurements, even in dynamic environments.

Another key goal is to expand the range of biometric parameters that can be monitored using PVDF-based sensors. Researchers are exploring the material's capability to detect not only mechanical signals but also biochemical markers through functionalization of the PVDF surface. This could lead to the development of multifunctional BMDs capable of providing a more comprehensive picture of an individual's health status.

The technological trajectory of PVDF in BMDs is expected to focus on miniaturization, energy efficiency, and integration with data analytics platforms. As the Internet of Things (IoT) and artificial intelligence continue to advance, PVDF-based sensors are likely to play a crucial role in the development of smart healthcare ecosystems, enabling real-time health monitoring and predictive analytics.

In conclusion, the background and objectives of PVDF in biometric monitoring devices reflect a broader trend towards personalized, preventive healthcare. By improving the accuracy and expanding the capabilities of BMDs, PVDF technology has the potential to revolutionize health monitoring, empowering individuals to take a more proactive approach to their well-being and enabling healthcare providers to deliver more targeted and effective interventions.

Market Analysis for PVDF-based Biometric Devices

The market for PVDF-based biometric devices is experiencing significant growth, driven by increasing demand for accurate and reliable health monitoring solutions. The global biometric monitoring device market, which includes PVDF-based sensors, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages.

PVDF (Polyvinylidene Fluoride) sensors are gaining traction in the biometric monitoring space due to their unique properties, including high sensitivity, flexibility, and durability. These characteristics make PVDF an ideal material for wearable devices and continuous health monitoring applications. The market demand for PVDF-based biometric devices is particularly strong in sectors such as healthcare, fitness, and sports performance monitoring.

In the healthcare sector, there is a growing need for non-invasive, continuous monitoring of vital signs, especially for patients with chronic conditions. PVDF-based devices offer the potential for improved accuracy in measuring parameters such as heart rate, respiratory rate, and blood pressure. This aligns with the broader trend of remote patient monitoring and telemedicine, which has seen accelerated adoption in recent years.

The fitness and wellness industry represents another significant market segment for PVDF-based biometric devices. Consumers are increasingly interested in tracking their health metrics and physical performance, driving demand for more sophisticated wearable devices. PVDF sensors can provide enhanced accuracy in measuring motion, stress, and physiological parameters, offering a competitive edge in the crowded wearables market.

Sports performance monitoring is an emerging application area where PVDF-based biometric devices show promise. Professional athletes and sports teams are seeking advanced tools to optimize training and prevent injuries. The high sensitivity and flexibility of PVDF sensors make them suitable for capturing subtle movements and physiological changes during athletic activities.

Market trends indicate a shift towards more integrated and multifunctional biometric devices. PVDF sensors have the potential to be incorporated into a wide range of form factors, from traditional wristbands to smart textiles and patches. This versatility opens up new market opportunities and applications across various industries.

While the market potential for PVDF-based biometric devices is substantial, challenges such as data privacy concerns, regulatory compliance, and integration with existing healthcare systems need to be addressed. Companies that can effectively navigate these challenges while delivering accurate and user-friendly solutions are likely to capture significant market share in this growing industry.

Current PVDF Technology in Biometric Monitoring

Polyvinylidene fluoride (PVDF) has emerged as a key material in the development of advanced biometric monitoring devices. Its unique piezoelectric properties make it particularly suitable for detecting subtle physiological signals, such as heart rate, respiration, and blood pressure. In current applications, PVDF is primarily utilized in the form of thin films or sensors integrated into wearable devices and medical equipment.

The technology behind PVDF-based biometric monitoring relies on the material's ability to generate an electrical charge in response to mechanical stress. This characteristic allows for the precise measurement of minute movements and vibrations associated with various bodily functions. In recent years, significant advancements have been made in the fabrication and integration of PVDF sensors, leading to improved sensitivity and reliability in biometric data collection.

One of the primary advantages of PVDF technology in biometric monitoring is its flexibility and conformability to the human body. This feature enables the creation of comfortable, unobtrusive wearable devices that can continuously monitor vital signs without interfering with the user's daily activities. Additionally, PVDF sensors are known for their high sensitivity and wide frequency response, making them capable of detecting a broad range of physiological signals with high accuracy.

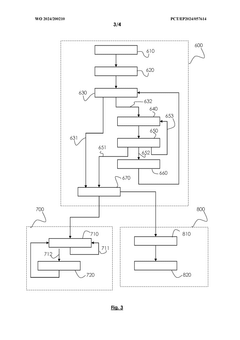

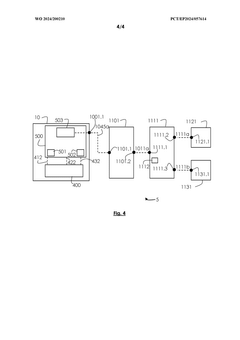

Current PVDF-based biometric monitoring systems often incorporate advanced signal processing algorithms and machine learning techniques to enhance the accuracy of measurements and reduce noise. These computational methods help in filtering out artifacts and isolating the desired physiological signals from background interference. Furthermore, the integration of PVDF sensors with other sensing technologies, such as optical sensors or accelerometers, has led to the development of multi-modal biometric monitoring devices that offer more comprehensive health insights.

Recent research has focused on improving the performance of PVDF sensors through various methods, including nanostructuring and surface modification. These techniques aim to enhance the piezoelectric response of the material and increase its sensitivity to even smaller mechanical deformations. Additionally, efforts are being made to develop more efficient manufacturing processes for PVDF sensors, with the goal of reducing costs and enabling large-scale production for widespread adoption in consumer and medical devices.

Despite the advancements, challenges remain in the current PVDF technology for biometric monitoring. These include optimizing the signal-to-noise ratio in real-world environments, ensuring long-term stability and durability of the sensors, and developing standardized calibration methods for consistent performance across different devices and users. Ongoing research is addressing these issues to further improve the reliability and accuracy of PVDF-based biometric monitoring systems.

Existing PVDF Solutions for Biometric Accuracy

01 PVDF membrane fabrication techniques

Various techniques are employed to fabricate PVDF membranes with improved accuracy. These methods include phase inversion, electrospinning, and solution casting. The choice of fabrication technique significantly influences the membrane's structure, porosity, and overall performance, thereby affecting its accuracy in filtration and separation processes.- PVDF membrane fabrication techniques: Various techniques are employed to fabricate PVDF membranes with improved accuracy and performance. These methods include phase inversion, electrospinning, and surface modification processes. The focus is on optimizing membrane morphology, pore size distribution, and surface properties to enhance filtration efficiency and selectivity.

- PVDF-based sensors and transducers: PVDF's piezoelectric properties are utilized in developing high-accuracy sensors and transducers. These devices are designed for various applications, including pressure sensing, vibration monitoring, and acoustic measurements. The emphasis is on improving sensitivity, response time, and signal-to-noise ratio to achieve higher accuracy in measurements.

- PVDF composite materials for enhanced performance: Composite materials incorporating PVDF are developed to improve mechanical, thermal, and electrical properties. These composites often combine PVDF with nanoparticles, carbon-based materials, or other polymers to enhance specific characteristics such as conductivity, strength, or thermal stability, leading to more accurate and reliable performance in various applications.

- PVDF in energy storage and conversion devices: PVDF is utilized in the development of high-performance energy storage and conversion devices, such as batteries, supercapacitors, and fuel cells. The focus is on improving the accuracy of energy storage capacity, charge-discharge efficiency, and overall device performance through optimized PVDF-based components and structures.

- PVDF surface modification for improved accuracy: Various surface modification techniques are applied to PVDF materials to enhance their accuracy in specific applications. These methods include plasma treatment, chemical grafting, and coating processes. The aim is to tailor surface properties such as hydrophobicity, chemical resistance, and biocompatibility, leading to more precise and reliable performance in areas like filtration, sensing, and biomedical applications.

02 PVDF composite materials for enhanced accuracy

Incorporating other materials into PVDF to create composite membranes can enhance accuracy in various applications. Common additives include inorganic nanoparticles, other polymers, and functional groups. These composites often exhibit improved mechanical strength, thermal stability, and selectivity, leading to more accurate performance in filtration, sensing, and energy storage applications.Expand Specific Solutions03 Surface modification of PVDF for improved accuracy

Surface modification techniques are applied to PVDF membranes to enhance their accuracy in specific applications. Methods such as plasma treatment, grafting, and chemical functionalization can alter the surface properties of PVDF, improving its hydrophilicity, fouling resistance, and selectivity. These modifications result in more accurate and efficient performance in various separation and sensing processes.Expand Specific Solutions04 PVDF-based sensors for accurate measurements

PVDF and its copolymers are utilized in the development of highly accurate sensors. The piezoelectric and pyroelectric properties of PVDF make it suitable for pressure, temperature, and vibration sensing applications. By optimizing the polymer structure and incorporating it into appropriate sensor designs, researchers have achieved high levels of accuracy in various measurement scenarios.Expand Specific Solutions05 Characterization techniques for PVDF accuracy assessment

Various characterization techniques are employed to assess and improve the accuracy of PVDF-based materials and devices. These methods include spectroscopic analysis, microscopy, mechanical testing, and electrical characterization. By utilizing these techniques, researchers can optimize PVDF properties and processing conditions to achieve higher accuracy in specific applications.Expand Specific Solutions

Key Players in PVDF Biometric Technology

The PVDF technology in biometric monitoring devices is in a growth phase, with increasing market size and evolving applications. The global market for these devices is expanding rapidly, driven by growing health consciousness and demand for personalized healthcare. Technologically, PVDF sensors are advancing, with companies like Samsung Electronics, Sony Group, and Qualcomm leading innovation. These firms are improving sensor accuracy and integrating PVDF into diverse wearable devices. While the technology is maturing, there's still room for significant advancements in sensitivity and reliability. Emerging players like Valencell and Shenzhen Goodix Technology are also contributing to the competitive landscape, focusing on specialized applications and novel sensor designs.

Samsung Electronics Co., Ltd.

Shenzhen Goodix Technology Co., Ltd.

Core PVDF Innovations for Biometric Monitoring

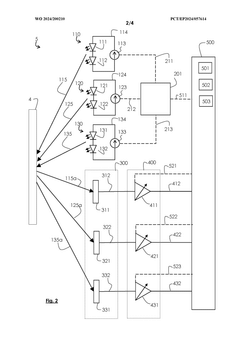

- A system comprising multiple LED sources emitting radiation at various wavelengths, an intensifier system for controlling intensity, and an amplifier system for adjusting gain values, with a control unit to individually manage intensity and gain for each wavelength to optimize PPG signal quality and accuracy.

- The electronic device employs an optical sensor system that irradiates light of different wavelengths to the user's body, compares the similarity between optical signals received, and identifies sections with venous blood waveform signals to prevent data acquisition, ensuring accurate biometric information is obtained only from sections with predominantly arterial blood signals.

Regulatory Framework for PVDF in Medical Devices

The regulatory framework for PVDF (Polyvinylidene Fluoride) in medical devices, particularly in biometric monitoring devices, is a complex and evolving landscape. As these devices increasingly incorporate PVDF for improved accuracy in biometric measurements, regulatory bodies have had to adapt their guidelines to ensure safety and efficacy.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating medical devices. PVDF-based biometric monitoring devices typically fall under Class II medical devices, requiring a 510(k) premarket notification. This process involves demonstrating that the device is substantially equivalent to a legally marketed predicate device in terms of safety and effectiveness.

The FDA has established specific guidelines for the use of PVDF in medical devices, focusing on biocompatibility, electrical safety, and performance standards. Manufacturers must provide comprehensive data on the material's properties, including its piezoelectric characteristics and potential long-term effects on human tissue.

In the European Union, the Medical Device Regulation (MDR) governs the use of PVDF in biometric monitoring devices. The MDR requires manufacturers to obtain CE marking, which involves a conformity assessment procedure and clinical evaluation. The European Medicines Agency (EMA) also provides guidance on the use of novel materials like PVDF in medical devices.

International standards, such as ISO 10993 for biocompatibility evaluation and IEC 60601 for electrical safety, play a significant role in the regulatory framework. These standards provide a harmonized approach to assessing the safety and performance of PVDF-based devices across different jurisdictions.

Regulatory bodies in other major markets, such as Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA), have also developed specific requirements for PVDF-containing medical devices. These often include extensive testing for material stability, degradation, and potential leaching of chemicals.

As the technology advances, regulatory frameworks are continuously updated to address emerging concerns. Recent focus areas include the long-term durability of PVDF in implantable devices, potential electromagnetic interference in wearable monitors, and data privacy considerations for devices that collect and transmit biometric information.

Manufacturers developing PVDF-based biometric monitoring devices must navigate this complex regulatory landscape, ensuring compliance with regional and international standards. This often requires a multidisciplinary approach, involving materials scientists, biomedical engineers, and regulatory affairs specialists to address the unique challenges posed by PVDF in medical applications.

Biocompatibility and Safety of PVDF in BMDs

The biocompatibility and safety of Polyvinylidene Fluoride (PVDF) in Biometric Monitoring Devices (BMDs) are crucial factors in its application for improving accuracy in biometric measurements. PVDF has demonstrated excellent biocompatibility in various medical applications, making it a promising material for use in BMDs that come into direct contact with the skin or other biological tissues.

PVDF's biocompatibility is attributed to its chemical stability and resistance to degradation in biological environments. The polymer's inert nature minimizes the risk of adverse reactions when in contact with human tissue. Studies have shown that PVDF does not elicit significant inflammatory responses or cytotoxicity, which are essential considerations for materials used in long-term wearable devices.

In terms of safety, PVDF has been extensively tested and approved for use in medical implants and other biomedical applications. Its non-toxic nature and resistance to bacterial growth contribute to its safety profile. Additionally, PVDF's low thrombogenicity reduces the risk of blood clot formation, which is particularly important for devices that may come into contact with blood vessels or be used in invasive monitoring applications.

The use of PVDF in BMDs also presents advantages in terms of mechanical properties. Its flexibility and durability allow for comfortable, long-term wear without compromising device integrity. This is particularly important for continuous monitoring applications where user comfort and device longevity are critical factors.

However, it is essential to consider potential limitations and safety concerns. While PVDF itself is biocompatible, the manufacturing process and any additives used in the final product must be carefully controlled to maintain safety standards. Rigorous testing and quality control measures are necessary to ensure that PVDF-based components in BMDs meet regulatory requirements for biomedical devices.

Furthermore, the long-term effects of PVDF exposure through BMDs should be continuously monitored and studied. As these devices are often worn for extended periods, understanding any potential cumulative effects is crucial for ensuring user safety.

In conclusion, the biocompatibility and safety profile of PVDF make it a suitable material for improving accuracy in BMDs. Its chemical stability, low reactivity with biological tissues, and proven track record in medical applications provide a solid foundation for its use in wearable biometric devices. However, ongoing research and vigilant safety monitoring remain essential to fully leverage PVDF's potential while maintaining the highest standards of user safety in BMD applications.