PVDF in Agricultural Equipment: Raising Efficiency Levels

PVDF in Agriculture: Evolution and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a revolutionary material in agricultural equipment, marking a significant evolution in the industry's pursuit of efficiency and sustainability. The journey of PVDF in agriculture began in the late 20th century when researchers recognized its potential for enhancing crop protection and irrigation systems. Initially, PVDF was primarily used in specialized applications due to its high cost and limited availability.

As manufacturing processes improved and costs decreased, PVDF found its way into more mainstream agricultural equipment. The material's exceptional chemical resistance, durability, and weather resistance made it an ideal choice for components exposed to harsh environmental conditions and aggressive chemicals commonly used in farming. This led to the development of PVDF-based sprayer nozzles, irrigation pipes, and greenhouse coverings, which significantly outperformed traditional materials in terms of longevity and efficiency.

The early 2000s saw a surge in research focused on optimizing PVDF for agricultural applications. Scientists and engineers worked on enhancing the material's properties to better suit specific farming needs. This period witnessed the introduction of PVDF-based sensors for soil moisture monitoring and precision agriculture, revolutionizing data-driven farming practices.

In recent years, the focus has shifted towards leveraging PVDF's piezoelectric properties in smart farming technologies. This has opened up new possibilities for energy harvesting in remote agricultural settings and the development of self-powered sensors for crop monitoring. The integration of PVDF into Internet of Things (IoT) devices for agriculture has become a key area of innovation, promising to transform farm management and decision-making processes.

The current objectives for PVDF in agriculture are multifaceted and ambitious. Researchers are striving to further improve the material's performance in extreme weather conditions, enhancing its resistance to UV radiation and temperature fluctuations. There is also a push to develop more eco-friendly PVDF formulations, aligning with the growing demand for sustainable agricultural practices.

Another critical goal is to expand PVDF's application in precision agriculture. This includes the development of advanced PVDF-based sensors capable of detecting plant stress, nutrient levels, and pest infestations at an early stage. The aim is to create a comprehensive network of PVDF-enabled devices that can provide real-time, actionable data to farmers, ultimately leading to more efficient resource utilization and higher crop yields.

Looking ahead, the agricultural sector is set to witness the integration of PVDF into more sophisticated autonomous farming equipment. The material's unique properties make it an excellent candidate for developing durable and weather-resistant components for robotic harvesters, drones, and other automated farm machinery. As these technologies evolve, PVDF is expected to play a crucial role in enhancing their reliability and performance, further driving the efficiency levels in modern agriculture.

Market Demand Analysis for PVDF-Enhanced Equipment

The market demand for PVDF-enhanced agricultural equipment has been steadily growing, driven by the increasing need for more efficient and durable farming tools. PVDF, or polyvinylidene fluoride, offers unique properties that make it particularly suitable for agricultural applications, including excellent chemical resistance, weatherability, and mechanical strength.

In the agricultural sector, there is a rising demand for equipment that can withstand harsh environmental conditions and prolonged exposure to chemicals such as fertilizers and pesticides. PVDF-enhanced equipment addresses these needs by providing superior corrosion resistance and longevity compared to traditional materials. This translates to reduced maintenance costs and increased uptime for farmers, which is crucial in an industry where time and efficiency are paramount.

The global agricultural equipment market is projected to expand significantly in the coming years, with a substantial portion of this growth attributed to the adoption of advanced materials like PVDF. Farmers are increasingly recognizing the long-term cost benefits of investing in more durable and efficient equipment, despite the potentially higher initial costs.

One of the key drivers of market demand for PVDF-enhanced agricultural equipment is the growing trend towards precision agriculture. This approach requires sophisticated machinery capable of withstanding various environmental factors while maintaining high performance. PVDF components in sensors, irrigation systems, and spraying equipment contribute to the accuracy and reliability needed in precision farming practices.

Additionally, the push for sustainable agriculture has created a niche market for PVDF-enhanced equipment. The material's recyclability and long lifespan align well with sustainability goals, appealing to environmentally conscious farmers and agricultural businesses. This trend is particularly strong in developed markets where environmental regulations are more stringent.

In emerging markets, the demand for PVDF-enhanced agricultural equipment is driven by the need to modernize farming practices and increase crop yields. As these regions invest in agricultural infrastructure, there is a growing preference for equipment that offers long-term reliability and efficiency gains.

The market for PVDF in agricultural applications extends beyond just field equipment. There is increasing demand in greenhouse and hydroponics systems, where the material's resistance to moisture and chemicals is particularly valuable. This diversification of applications further expands the potential market for PVDF-enhanced agricultural products.

However, the market demand is not without challenges. The higher cost of PVDF compared to traditional materials can be a barrier to adoption, especially in price-sensitive markets. Education and demonstration of the long-term benefits of PVDF-enhanced equipment are crucial in overcoming this hurdle and driving market growth.

Current PVDF Applications and Challenges in Agriculture

Polyvinylidene fluoride (PVDF) has emerged as a versatile material in agricultural equipment, offering unique properties that enhance efficiency and durability. In recent years, PVDF applications in agriculture have expanded significantly, addressing various challenges faced by the industry. One of the primary uses of PVDF in agricultural equipment is in irrigation systems, where it serves as an excellent material for pipes and fittings due to its resistance to chemicals, UV radiation, and microbial growth. This application has greatly improved water distribution efficiency and reduced maintenance costs for farmers.

Another notable application of PVDF in agriculture is in greenhouse coverings and films. The material's transparency, weather resistance, and self-cleaning properties make it an ideal choice for creating controlled environments that optimize crop growth. PVDF films allow for better light transmission while protecting crops from harsh weather conditions, ultimately leading to increased yields and improved crop quality.

In the realm of precision agriculture, PVDF sensors are being utilized for soil moisture monitoring and crop health assessment. These sensors offer high sensitivity and reliability, enabling farmers to make data-driven decisions regarding irrigation and fertilization. The implementation of PVDF-based sensing technologies has contributed to more efficient resource management and improved crop productivity.

Despite the numerous advantages, the adoption of PVDF in agricultural equipment faces several challenges. One of the primary obstacles is the relatively high cost of PVDF compared to traditional materials like polyethylene or PVC. This cost factor can be a significant barrier for small-scale farmers or those operating in developing regions with limited financial resources.

Another challenge lies in the complexity of processing PVDF for specific agricultural applications. The material requires specialized manufacturing techniques and equipment, which can limit its availability and customization options for agricultural equipment manufacturers. This complexity also extends to the repair and maintenance of PVDF-based equipment, potentially increasing downtime and operational costs for farmers.

Furthermore, while PVDF exhibits excellent chemical resistance, it may not be suitable for all agricultural environments. In some cases, exposure to certain agrochemicals or extreme pH conditions can affect the material's performance over time. This limitation necessitates careful consideration and testing when implementing PVDF solutions in diverse agricultural settings.

Lastly, the environmental impact of PVDF in agriculture remains a concern. Although the material is durable and long-lasting, its end-of-life disposal and potential for microplastic generation pose challenges to sustainability efforts in the agricultural sector. Addressing these environmental concerns through improved recycling methods and the development of bio-based alternatives is crucial for the long-term viability of PVDF in agricultural applications.

Existing PVDF Integration Methods in Farm Equipment

01 PVDF membrane efficiency in water treatment

PVDF membranes are widely used in water treatment applications due to their high efficiency in removing contaminants. The efficiency levels of PVDF membranes can be improved through various modifications and treatments, such as surface modification or blending with other materials. These enhancements can lead to better filtration performance, increased fouling resistance, and longer membrane lifespan.- PVDF membrane efficiency in water treatment: PVDF membranes are widely used in water treatment applications due to their high efficiency in removing contaminants. The efficiency levels of PVDF membranes can be improved through various modifications, such as surface treatments or the incorporation of nanoparticles, enhancing their filtration performance and fouling resistance.

- PVDF in energy storage applications: PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. The efficiency of PVDF-based separators and electrodes can be enhanced by optimizing the polymer structure, blending with other materials, or incorporating functional additives to improve ionic conductivity and mechanical properties.

- PVDF efficiency in piezoelectric applications: PVDF exhibits piezoelectric properties, making it suitable for energy harvesting and sensing applications. The efficiency of PVDF-based piezoelectric devices can be improved by controlling the crystalline structure, enhancing the β-phase content, or developing composite materials with other piezoelectric elements.

- PVDF in coating and film applications: PVDF is used in high-performance coatings and films due to its excellent chemical resistance and weatherability. The efficiency of PVDF coatings can be enhanced by optimizing the formulation, incorporating functional additives, or developing hybrid materials to improve adhesion, durability, and self-cleaning properties.

- PVDF efficiency in gas separation membranes: PVDF membranes are employed in gas separation processes, particularly for CO2 capture and natural gas purification. The efficiency of PVDF-based gas separation membranes can be improved through surface modifications, the development of mixed-matrix membranes, or the incorporation of facilitated transport agents to enhance selectivity and permeability.

02 PVDF in energy storage applications

PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors, due to its high dielectric constant and electrochemical stability. The efficiency of PVDF-based separators and electrodes can be enhanced through various techniques, such as nanocomposite formation or surface treatments. These improvements lead to better energy storage capacity, faster charging rates, and increased cycle life of the devices.Expand Specific Solutions03 PVDF in piezoelectric applications

PVDF exhibits piezoelectric properties, making it suitable for various sensing and energy harvesting applications. The efficiency of PVDF-based piezoelectric devices can be improved through techniques such as stretching, poling, or incorporation of nanofillers. These enhancements lead to higher piezoelectric coefficients, improved sensitivity, and better energy conversion efficiency in applications like sensors, actuators, and energy harvesters.Expand Specific Solutions04 PVDF in membrane distillation

PVDF membranes are used in membrane distillation processes for water purification and desalination. The efficiency of PVDF membranes in these applications can be improved through surface modifications, such as hydrophobic treatments or incorporation of nanoparticles. These enhancements lead to better flux rates, higher salt rejection, and improved resistance to fouling and wetting, resulting in more efficient and sustainable water treatment processes.Expand Specific Solutions05 PVDF in gas separation membranes

PVDF-based membranes are employed in gas separation applications, such as CO2 capture or natural gas purification. The efficiency of PVDF membranes for gas separation can be enhanced through various methods, including blending with other polymers, incorporation of inorganic fillers, or surface modifications. These improvements lead to higher gas permeability, better selectivity, and increased membrane stability, resulting in more efficient gas separation processes.Expand Specific Solutions

Key Players in PVDF Agricultural Solutions

The application of PVDF in agricultural equipment to raise efficiency levels is in a growth phase, with increasing market size and technological advancements. The market is driven by the need for more efficient and sustainable farming practices. Companies like AGCO Corp. and BASF Plant Science LLC are at the forefront of this technology, developing innovative solutions. The technological maturity varies, with established players like Dow Global Technologies LLC and Arkema, Inc. contributing to material advancements. Research institutions such as Purdue Research Foundation and Tianjin University are also actively involved, indicating ongoing development and potential for further innovation in this field.

The Institute of Genetics & Developmental Biology

AGCO Corp.

Innovative PVDF Formulations for Agricultural Use

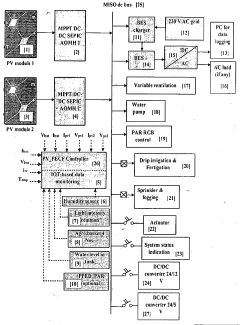

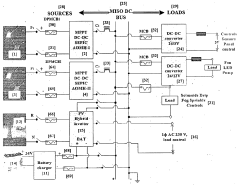

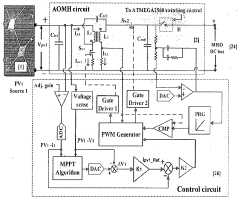

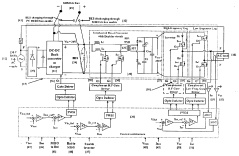

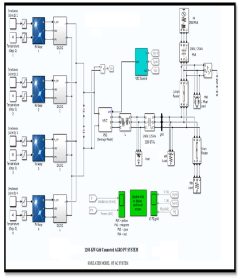

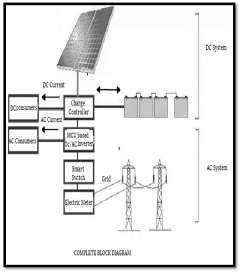

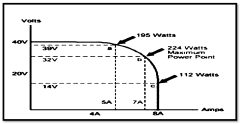

- A PV-based protected environment controlled farming (PV_PECF) system utilizing poly-crystalline photovoltaic panels, modular hardware modules, and IoT-based automation for climate control, MPPT operation, and agro baskets with independent soil substrates for efficient energy management and crop growth, incorporating LED-based PAR enhancement and remote data logging.

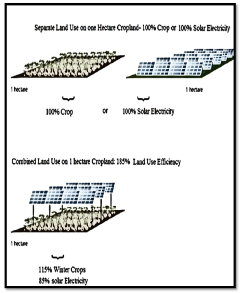

- The development of agro photovoltaic systems that allow for dual use of arable land by integrating solar electricity generation with agricultural production, utilizing semi-transparent photovoltaic modules that enhance crop yields and solar energy production, and incorporating a Smart Switching System to manage excess energy without the need for storage.

Environmental Impact of PVDF in Agriculture

The environmental impact of PVDF (Polyvinylidene Fluoride) in agriculture is a critical consideration as its use in agricultural equipment becomes more widespread. PVDF's unique properties, including chemical resistance and durability, contribute to increased efficiency in farming operations. However, these benefits must be weighed against potential environmental consequences.

One of the primary environmental concerns associated with PVDF in agriculture is its persistence in the environment. As a synthetic polymer, PVDF does not readily biodegrade, potentially leading to long-term accumulation in soil and water systems. This persistence raises questions about its impact on soil health and the potential for microplastic pollution in agricultural landscapes.

The production process of PVDF also carries environmental implications. The manufacturing of PVDF involves energy-intensive processes and the use of fluorine-based chemicals, which can contribute to greenhouse gas emissions and potential chemical pollution if not properly managed. However, the extended lifespan of PVDF-based agricultural equipment may offset some of these production-related environmental costs over time.

PVDF's resistance to chemical degradation offers both advantages and challenges from an environmental perspective. While this property extends the life of agricultural equipment, reducing waste and the need for frequent replacements, it also means that when PVDF products do reach the end of their life cycle, they pose significant challenges for disposal or recycling.

The use of PVDF in irrigation systems and water management equipment in agriculture presents a complex environmental scenario. On one hand, PVDF's durability and resistance to corrosion can lead to more efficient water use and reduced leakage, contributing to water conservation efforts. On the other hand, the potential leaching of microplastics or chemical additives from PVDF components into water systems raises concerns about water quality and ecosystem health.

In terms of soil impact, the interaction between PVDF and soil microorganisms is an area of ongoing research. While PVDF is generally considered inert, the long-term effects of its presence on soil microbial communities and overall soil health are not yet fully understood. This uncertainty underscores the need for continued monitoring and research into the ecological impacts of PVDF in agricultural settings.

The recyclability of PVDF presents both challenges and opportunities. While PVDF can be recycled, the process is complex and not widely implemented in many regions. Improving recycling technologies and infrastructure for PVDF could significantly mitigate its environmental impact, creating a more circular economy approach to its use in agriculture.

As the agricultural sector continues to adopt PVDF-based technologies, balancing efficiency gains with environmental stewardship remains crucial. Future research and development efforts should focus on enhancing the biodegradability of PVDF or developing equally efficient but more environmentally friendly alternatives. Additionally, implementing comprehensive life cycle assessments for PVDF products in agriculture will be essential in fully understanding and mitigating their environmental impact.

Cost-Benefit Analysis of PVDF Agricultural Applications

The implementation of PVDF (Polyvinylidene Fluoride) in agricultural equipment presents a compelling case for enhancing efficiency levels in the sector. To fully understand the economic implications, a comprehensive cost-benefit analysis is essential.

Initial investment in PVDF-based agricultural equipment typically involves higher upfront costs compared to traditional materials. This includes expenses for research and development, manufacturing processes, and potential retooling of production lines. However, these costs are often offset by the long-term benefits and improved performance characteristics of PVDF.

One of the primary advantages of PVDF in agricultural applications is its exceptional durability and resistance to chemical corrosion. This translates to reduced maintenance costs and extended equipment lifespan. Farmers can expect fewer replacements and repairs, leading to significant savings over time. Additionally, the lightweight nature of PVDF contributes to fuel efficiency in mobile agricultural machinery, further reducing operational costs.

The improved efficiency of PVDF-equipped agricultural tools and machinery is a key factor in the cost-benefit equation. Enhanced performance in tasks such as irrigation, pesticide application, and harvesting can lead to increased crop yields and quality. This productivity boost directly impacts the farmer's bottom line, potentially offsetting the initial investment within a few growing seasons.

Environmental benefits associated with PVDF use also carry economic implications. The material's resistance to bacterial growth and ease of cleaning reduce the need for harsh chemical treatments, potentially lowering environmental compliance costs and improving worker safety. Furthermore, the recyclability of PVDF aligns with sustainable farming practices, which can open doors to eco-friendly certifications and premium market positioning.

When considering the total cost of ownership, PVDF-based equipment often proves more economical in the long run. While the initial purchase price may be higher, the extended service life, reduced downtime, and lower maintenance requirements contribute to a favorable return on investment. This is particularly true in intensive farming operations where equipment reliability is crucial.

However, it's important to note that the cost-benefit ratio can vary depending on the specific application, scale of operation, and local agricultural conditions. Smaller farms with limited capital may find the initial investment challenging, while larger operations are better positioned to leverage the long-term advantages of PVDF technology.

In conclusion, while the upfront costs of implementing PVDF in agricultural equipment are considerable, the long-term economic benefits are substantial. Improved efficiency, durability, and environmental performance contribute to a strong value proposition for farmers looking to optimize their operations and stay competitive in an evolving agricultural landscape.