PVDF for Underwater Sensors: Expanding Detection Range

PVDF Sensor Evolution

The evolution of PVDF (Polyvinylidene Fluoride) sensors for underwater applications has been marked by significant advancements in material science and sensor technology. Initially developed in the 1960s, PVDF's piezoelectric properties were first recognized for their potential in sensing applications. The early stages of PVDF sensor development focused primarily on basic acoustic detection in air and water environments.

In the 1970s and 1980s, researchers began to explore PVDF's unique characteristics for underwater sensing. The material's flexibility, low density, and broad frequency response made it particularly suitable for hydrophone applications. During this period, the focus was on improving the sensitivity and signal-to-noise ratio of PVDF sensors, leading to the development of multi-layer PVDF structures and enhanced electrode designs.

The 1990s saw a shift towards miniaturization and integration of PVDF sensors. This era marked the beginning of array-based PVDF sensor systems, allowing for improved directional sensing and spatial resolution. Concurrently, advancements in signal processing techniques enabled better discrimination between target signals and ambient noise, significantly enhancing the detection capabilities of PVDF-based underwater sensors.

The turn of the millennium brought about a renewed interest in expanding the detection range of PVDF sensors. Researchers began exploring novel fabrication techniques, such as nanocomposite PVDF materials and 3D-printed sensor structures. These innovations aimed to enhance the piezoelectric response and overall performance of PVDF sensors in challenging underwater environments.

In recent years, the focus has shifted towards developing smart PVDF sensor systems. Integration with advanced microelectronics and artificial intelligence has led to self-calibrating and adaptive PVDF sensors capable of operating in diverse underwater conditions. Moreover, the incorporation of machine learning algorithms has significantly improved signal interpretation and target identification capabilities.

The latest frontier in PVDF sensor evolution involves the development of distributed sensor networks and long-range detection systems. By combining multiple PVDF sensor arrays and leveraging advanced signal processing techniques, researchers are pushing the boundaries of detection range and accuracy. Additionally, efforts are being made to enhance the durability and longevity of PVDF sensors in harsh underwater environments, addressing challenges such as pressure resistance and biofouling.

As we look to the future, the evolution of PVDF sensors for underwater applications continues to be driven by the demand for increased range, sensitivity, and reliability. Emerging technologies such as quantum sensing and metamaterials are being explored to further enhance PVDF sensor performance. The ongoing research in this field promises to unlock new possibilities for underwater detection and monitoring, with potential applications ranging from marine research and environmental monitoring to defense and offshore energy industries.

Underwater Detection Demand

The demand for underwater detection technologies has been steadily increasing across various sectors, driven by the growing need for maritime security, environmental monitoring, and resource exploration. In the realm of maritime security, naval forces worldwide are seeking advanced underwater sensor systems to detect and track submarines, mines, and other potential threats. This has led to a surge in research and development efforts focused on expanding the detection range and accuracy of underwater sensors.

Environmental monitoring represents another significant area of demand for underwater detection technologies. With rising concerns about climate change and marine ecosystem health, there is a pressing need for sophisticated sensor networks capable of monitoring water quality, marine life populations, and oceanic conditions over vast areas. These sensors play a crucial role in understanding the impacts of human activities on marine environments and informing conservation efforts.

The offshore energy sector, particularly oil and gas exploration, continues to be a major driver of underwater detection technology advancements. As exploration moves into deeper waters and more challenging environments, the industry requires more sensitive and reliable sensor systems for seabed mapping, pipeline inspection, and leak detection. The emerging field of underwater renewable energy, such as tidal and wave power, also contributes to the demand for specialized underwater sensing capabilities.

Scientific research in oceanography and marine biology has been pushing the boundaries of underwater detection technologies. Researchers require advanced sensors to study deep-sea ecosystems, underwater geological formations, and ocean currents. The ability to collect high-resolution data over extended periods and across large areas is crucial for advancing our understanding of marine systems and their role in global climate dynamics.

The aquaculture industry, which has been expanding rapidly to meet global food demand, is another sector driving innovation in underwater detection. Fish farmers need reliable monitoring systems to track water quality, fish health, and feeding patterns in large-scale underwater farming operations. This has led to the development of specialized acoustic and optical sensors tailored for aquaculture applications.

As underwater communication networks become more prevalent, there is a growing demand for sensors that can facilitate data transmission and reception in challenging underwater environments. These sensors are essential for enabling underwater Internet of Things (IoT) applications, autonomous underwater vehicle (AUV) operations, and underwater drone swarms.

The expansion of underwater tourism and recreational diving has also created a niche market for personal underwater detection devices. These range from simple depth and pressure sensors to more advanced sonar systems for navigation and obstacle avoidance, catering to both safety and exploration needs of recreational divers.

PVDF Limitations

Despite its widespread use in underwater sensor applications, Polyvinylidene Fluoride (PVDF) faces several limitations that constrain its performance and applicability in expanding detection range. One of the primary challenges is its relatively low piezoelectric coefficient compared to other piezoelectric materials. This inherent property limits PVDF's sensitivity to acoustic signals, particularly at greater depths or in environments with high background noise.

The frequency response of PVDF sensors is another area of concern. While PVDF exhibits a broad frequency range, its sensitivity tends to decrease at lower frequencies. This characteristic can be problematic for detecting long-range, low-frequency signals that are often crucial in underwater applications such as submarine detection or seismic monitoring.

Temperature sensitivity poses another significant limitation for PVDF sensors. The material's piezoelectric properties can vary with temperature changes, affecting the accuracy and reliability of measurements in environments with fluctuating temperatures. This is particularly challenging in deep-sea applications where temperature gradients can be substantial.

The mechanical properties of PVDF also present limitations in certain underwater scenarios. Although PVDF is flexible and can conform to various shapes, it may not possess the necessary robustness for high-pressure deep-sea environments. The material can experience creep or deformation under prolonged stress, potentially compromising the sensor's long-term performance and accuracy.

Electrical limitations further constrain PVDF's capabilities in underwater sensing. The material has a relatively high dielectric constant, which can lead to increased electrical noise and reduced signal-to-noise ratio. This characteristic becomes more pronounced when attempting to detect weak signals over long distances, limiting the effective range of PVDF-based sensors.

The manufacturing process of PVDF sensors also introduces limitations. Achieving consistent piezoelectric properties across large areas or in complex geometries can be challenging, leading to potential variations in sensor performance. This inconsistency can affect the reliability and reproducibility of measurements, particularly in applications requiring high precision or large-scale sensor arrays.

Lastly, the long-term stability of PVDF in underwater environments remains a concern. Prolonged exposure to water, especially in marine environments with high salinity, can lead to degradation of the material's properties over time. This degradation may manifest as reduced sensitivity, altered frequency response, or even physical deterioration of the sensor, limiting its lifespan and reliability in long-term underwater monitoring applications.

Current PVDF Solutions

01 PVDF-based sensors for detection range

PVDF-based sensors are utilized for various detection applications due to their piezoelectric properties. These sensors can be designed to detect a wide range of physical phenomena, including pressure, vibration, and temperature changes. The detection range can be optimized by modifying the PVDF film thickness, electrode configuration, and signal processing techniques.- PVDF-based sensors for wide detection range: PVDF-based sensors are developed to detect a wide range of substances and parameters. These sensors utilize the piezoelectric properties of PVDF to convert mechanical stress into electrical signals, allowing for the detection of various physical and chemical changes. The sensors can be designed to operate across different frequency ranges and environmental conditions, making them versatile for multiple applications.

- PVDF membranes for filtration and separation: PVDF membranes are used in filtration and separation processes with a broad detection range for various particles and molecules. These membranes can be tailored to have specific pore sizes and surface properties, allowing for the selective filtration of substances across different size ranges. The membranes can be applied in water treatment, pharmaceutical processing, and other industries requiring precise separation capabilities.

- PVDF-based acoustic and ultrasonic devices: PVDF is utilized in acoustic and ultrasonic devices for detecting a wide range of frequencies. These devices leverage the material's piezoelectric properties to convert sound waves into electrical signals and vice versa. The detection range can span from infrasonic to ultrasonic frequencies, making PVDF-based devices suitable for various applications in medical imaging, non-destructive testing, and underwater acoustics.

- PVDF composites for enhanced detection capabilities: PVDF composites are developed by incorporating other materials to enhance detection capabilities and expand the detection range. These composites can combine the properties of PVDF with those of conductive fillers, nanoparticles, or other polymers. The resulting materials often exhibit improved sensitivity, selectivity, or responsiveness to specific stimuli, broadening the range of detectable substances or parameters.

- PVDF-based flexible and wearable sensors: Flexible and wearable sensors based on PVDF are developed for detecting a range of physiological and environmental parameters. These sensors can be integrated into clothing or attached directly to the skin, allowing for continuous monitoring of various biomarkers, movements, or external stimuli. The flexibility of PVDF enables these sensors to conform to different shapes and maintain functionality under various conditions.

02 PVDF membranes for filtration and separation

PVDF membranes are employed in filtration and separation processes, with their detection range influenced by pore size and surface modifications. These membranes can be tailored to detect and separate particles, molecules, or ions of specific sizes, making them suitable for applications in water treatment, pharmaceutical processing, and chemical analysis.Expand Specific Solutions03 PVDF in energy harvesting and sensing devices

PVDF is used in energy harvesting and sensing devices, where its detection range is related to its ability to convert mechanical energy into electrical signals. These devices can detect and measure various forms of mechanical energy, including human motion, vibrations from machinery, and acoustic waves, with applications in wearable technology and structural health monitoring.Expand Specific Solutions04 PVDF nanocomposites for enhanced detection capabilities

PVDF nanocomposites, formed by incorporating nanoparticles or nanostructures into the PVDF matrix, can extend the detection range of sensors. These nanocomposites can enhance sensitivity, selectivity, and responsiveness to various stimuli, including gases, biomolecules, and electromagnetic radiation, broadening the potential applications in environmental monitoring and biosensing.Expand Specific Solutions05 PVDF in acoustic and ultrasonic detection

PVDF films and transducers are used in acoustic and ultrasonic detection systems, with their detection range covering a wide frequency spectrum. These materials can be optimized for specific frequency ranges, enabling applications in medical imaging, non-destructive testing, and underwater acoustics. The detection range can be further extended by using multi-layer structures or frequency-tuning techniques.Expand Specific Solutions

Underwater Sensor Players

The development of PVDF for underwater sensors to expand detection range is in a growth phase, with increasing market size and technological advancements. The market is driven by rising demand for improved underwater sensing capabilities across various industries. Technologically, the field is progressing rapidly, with universities and research institutions like Southeast University, Hohai University, and Ocean University of China leading academic research. Companies such as Qingdao Oushen Ayers Marine Information Equipment Co., Ltd. and Nanjing Junyuan Kebao Engineering Technology Co., Ltd. are actively developing commercial applications. International players like BP Corporation North America, Inc. and Arkema France SA are also contributing to the field's maturation, indicating a globally competitive landscape with diverse stakeholders working towards enhancing PVDF-based underwater sensor technology.

Nanjing Institute of Geography & Limnology of CAS

Ocean University of China

PVDF Innovations

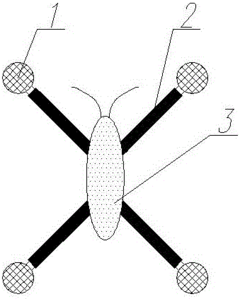

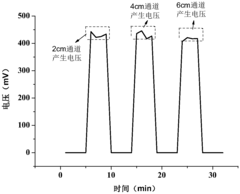

- A water surface wave sensor measurement device is used, which includes a floating ball and four PVDF piezoelectric fibers, which are evenly and symmetrically distributed on the base, and the surface is coated with symmetrical electrodes. The voltage signal generated by the water surface wave on the PVDF piezoelectric fibers is used to detect the water surface. The location of the target.

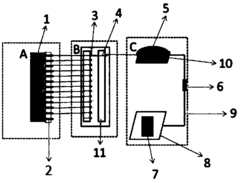

- A sensor is designed that uses the electrochemical reaction principle of sediment microorganisms, including a signal collector, a height adjustment component and a sediment microbial fuel cell component. It generates electrical signals through the oxidation of microorganisms in the sediment, and combines the floating plate and sliding rod structures for real-time monitoring. Changes in water depth.

Environmental Impact

The environmental impact of PVDF (Polyvinylidene Fluoride) in underwater sensors for expanding detection range is a critical consideration in the development and deployment of these technologies. PVDF, as a piezoelectric polymer, offers unique advantages in underwater sensing applications, but its use also raises important environmental concerns.

PVDF sensors, when deployed in aquatic environments, have minimal direct impact on water quality due to their chemical stability. The material is resistant to degradation in water, which prevents the release of harmful substances. However, this durability also means that PVDF sensors, if not properly managed, can contribute to long-term plastic pollution in marine ecosystems.

The manufacturing process of PVDF involves the use of fluorine-based compounds, which can have significant environmental implications if not properly controlled. Emissions from production facilities may contribute to air and water pollution if stringent environmental regulations are not in place. Additionally, the energy-intensive nature of PVDF production contributes to carbon emissions, impacting climate change.

On the positive side, the expanded detection range offered by PVDF sensors can lead to more efficient and targeted underwater operations. This improved efficiency can reduce the need for extensive physical exploration, potentially minimizing disturbances to marine habitats. Furthermore, the enhanced monitoring capabilities provided by these sensors can contribute to better understanding and protection of aquatic ecosystems.

The disposal of PVDF sensors at the end of their lifecycle presents another environmental challenge. While the material is recyclable, the specialized nature of these sensors often makes recycling processes complex and energy-intensive. Improper disposal can lead to the accumulation of non-biodegradable materials in marine environments, potentially harming wildlife through ingestion or entanglement.

Efforts to mitigate the environmental impact of PVDF in underwater sensors include developing more eco-friendly manufacturing processes, improving the recyclability of sensor components, and implementing strict protocols for sensor deployment and retrieval. Research into biodegradable alternatives or hybrid materials that maintain PVDF's sensing capabilities while reducing environmental persistence is also ongoing.

In conclusion, while PVDF offers significant benefits for underwater sensing and detection range expansion, its environmental impact must be carefully managed. Balancing the technological advantages with ecological considerations is crucial for the sustainable development and application of these advanced underwater sensing technologies.

Acoustic Signal Processing

Acoustic signal processing plays a crucial role in expanding the detection range of PVDF-based underwater sensors. This technology involves the manipulation and analysis of acoustic waves to extract meaningful information from underwater environments. In the context of PVDF sensors, acoustic signal processing techniques are employed to enhance the sensitivity and range of detection, ultimately improving the overall performance of underwater sensing systems.

One of the primary challenges in underwater acoustic signal processing is dealing with the complex propagation characteristics of sound in water. Factors such as temperature, salinity, and pressure variations can significantly affect the transmission of acoustic signals. Advanced signal processing algorithms are developed to compensate for these environmental factors, ensuring accurate and reliable detection over extended ranges.

Beamforming is a key technique used in acoustic signal processing for PVDF underwater sensors. This method involves combining signals from multiple sensor elements to focus on specific directions or locations, effectively increasing the signal-to-noise ratio and extending the detection range. Adaptive beamforming algorithms can dynamically adjust to changing underwater conditions, further enhancing the sensor's performance.

Time-frequency analysis is another important aspect of acoustic signal processing for underwater sensors. This technique allows for the examination of signal characteristics in both time and frequency domains simultaneously. By employing methods such as short-time Fourier transform (STFT) or wavelet analysis, researchers can extract valuable information from complex underwater acoustic signals, enabling better detection and classification of targets at greater distances.

Signal denoising and filtering techniques are essential for improving the quality of acoustic signals received by PVDF sensors. Advanced filtering algorithms, such as Kalman filters or particle filters, can effectively remove unwanted noise and interference, thereby increasing the effective detection range of the sensors. These techniques are particularly important in challenging underwater environments with high levels of ambient noise or multiple acoustic sources.

Machine learning and artificial intelligence are increasingly being applied to acoustic signal processing for underwater sensors. These technologies enable the development of sophisticated algorithms capable of learning from vast amounts of acoustic data and adapting to diverse underwater conditions. Neural networks and deep learning models can be trained to recognize complex patterns in acoustic signals, potentially extending the detection range and capabilities of PVDF-based underwater sensors beyond traditional signal processing methods.

The integration of acoustic signal processing with other sensor technologies, such as sonar and imaging systems, can further enhance the detection range and accuracy of underwater sensing systems. By fusing data from multiple sensor modalities, more comprehensive and reliable information about the underwater environment can be obtained, leading to improved detection and classification capabilities at extended ranges.