PVDF Applications in Food Industry: Preserving Quality Standards

PVDF in Food Industry: Evolution and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in the food industry, with its applications evolving significantly over the past few decades. The journey of PVDF in food-related applications began in the 1960s when its unique properties were first recognized for potential use in food processing and packaging. Initially, PVDF was primarily utilized in specialized filtration systems due to its excellent chemical resistance and mechanical strength.

As food safety standards became more stringent in the 1980s and 1990s, PVDF's role in the industry expanded. Its non-reactive nature and ability to withstand high temperatures made it an ideal material for food-contact surfaces in processing equipment. This period saw the development of PVDF-based membranes for ultrafiltration and microfiltration processes, revolutionizing dairy product manufacturing and beverage clarification techniques.

The early 2000s marked a significant shift in PVDF applications, focusing on food preservation and quality maintenance. Researchers and industry professionals recognized PVDF's potential in creating advanced packaging materials that could extend shelf life and maintain food freshness. This led to the development of PVDF-based films and coatings with enhanced barrier properties against moisture, gases, and contaminants.

In recent years, the objectives of PVDF applications in the food industry have become more sophisticated and multifaceted. The primary goal is to leverage PVDF's unique properties to address the growing demands for food safety, quality, and sustainability. Current research aims to develop PVDF-based smart packaging solutions that can monitor food freshness and alert consumers to potential spoilage.

Another key objective is to enhance PVDF's functionality in food processing equipment. This includes improving its non-stick properties to reduce food waste and developing PVDF composites that offer antimicrobial properties, thereby reducing the risk of foodborne illnesses. Additionally, there is a growing focus on making PVDF more environmentally friendly, with efforts to improve its recyclability and explore bio-based alternatives.

The evolution of PVDF in the food industry reflects a broader trend towards advanced materials that can meet the complex challenges of modern food production and distribution. As we look to the future, the objectives for PVDF applications continue to expand, with a particular emphasis on integrating nanotechnology and smart materials to create innovative solutions for food preservation and quality control.

Market Demand Analysis for PVDF in Food Packaging

The market demand for PVDF in food packaging has been steadily increasing due to its unique properties and the growing emphasis on food safety and quality preservation. PVDF, or polyvinylidene fluoride, offers excellent chemical resistance, thermal stability, and barrier properties, making it an ideal material for various food packaging applications.

In recent years, the global food packaging industry has witnessed a significant shift towards more advanced and sustainable packaging solutions. This trend has been driven by consumer demand for safer, longer-lasting food products and stricter regulations on food safety and packaging materials. PVDF has emerged as a key player in this evolving market, particularly in high-performance packaging applications.

The food and beverage sector represents a substantial portion of the PVDF market, with packaging being one of the primary applications. The market size for PVDF in food packaging is expected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is attributed to the material's ability to maintain food quality, extend shelf life, and prevent contamination.

One of the key drivers of PVDF demand in food packaging is its excellent barrier properties against moisture, gases, and chemicals. This characteristic is crucial for preserving food quality and preventing spoilage, especially for products with long shelf lives or those requiring stringent preservation conditions. Additionally, PVDF's resistance to high temperatures makes it suitable for packaging applications that involve hot-filling or sterilization processes.

The increasing focus on food safety regulations worldwide has also contributed to the rising demand for PVDF in packaging. As regulatory bodies impose stricter standards on food contact materials, PVDF's compliance with various food safety regulations, including FDA and EU standards, has positioned it as a preferred choice for manufacturers.

Moreover, the growing trend towards sustainable packaging solutions has opened up new opportunities for PVDF in the food industry. While PVDF is not biodegradable, its durability and recyclability align with the circular economy principles, making it an attractive option for companies looking to reduce their environmental footprint without compromising on packaging performance.

The market demand for PVDF in food packaging varies across different food segments. The processed food sector, including ready-to-eat meals and snacks, represents a significant portion of the demand due to the need for extended shelf life and protection against external factors. The beverage industry, particularly for bottled water and soft drinks, is another key market segment where PVDF films and coatings are increasingly being used to enhance barrier properties and product safety.

In conclusion, the market demand for PVDF in food packaging is driven by its superior performance characteristics, compliance with food safety regulations, and ability to meet the evolving needs of the food industry. As consumers continue to prioritize food quality and safety, and as regulations become more stringent, the demand for PVDF in food packaging applications is expected to maintain its upward trajectory in the foreseeable future.

Current PVDF Applications and Challenges in Food Preservation

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in the food industry, particularly in preserving quality standards. Its unique properties, including chemical resistance, thermal stability, and mechanical strength, make it ideal for various applications in food preservation and packaging.

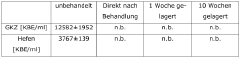

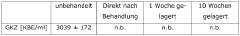

In the realm of food packaging, PVDF is widely used as a protective barrier against moisture, gases, and contaminants. Its low permeability to oxygen and water vapor helps extend the shelf life of packaged foods, maintaining their freshness and quality for longer periods. PVDF films and coatings are applied to packaging materials to create high-performance food containers and wraps that effectively preserve the organoleptic properties of food products.

PVDF membranes play a significant role in food processing, particularly in filtration and separation processes. These membranes are employed in the dairy industry for milk concentration and whey processing, allowing for efficient removal of bacteria and other impurities while retaining valuable proteins and nutrients. In beverage production, PVDF membranes are used for clarification and sterilization, ensuring product consistency and safety.

The material's resistance to chemicals and high temperatures makes it suitable for food processing equipment. PVDF-coated surfaces in tanks, pipes, and conveyor systems prevent food contamination and facilitate easy cleaning and sanitization. This application is particularly valuable in maintaining hygiene standards in food production facilities.

Despite its widespread use, PVDF faces several challenges in food preservation applications. One primary concern is the potential for chemical leaching. While PVDF is generally considered safe, there are ongoing studies to ensure that no harmful substances migrate from PVDF materials into food products over extended periods or under various environmental conditions.

Another challenge lies in the cost-effectiveness of PVDF solutions. While the material offers superior performance, its higher cost compared to traditional alternatives can be a barrier to adoption, especially for smaller food producers. Balancing the long-term benefits of improved food preservation against initial investment costs remains a consideration for many in the industry.

The recyclability and environmental impact of PVDF in food packaging are also areas of concern. As sustainability becomes increasingly important in the food industry, there is a growing need to develop effective recycling methods for PVDF materials and explore more eco-friendly alternatives that maintain the same level of food preservation efficacy.

Lastly, the regulatory landscape surrounding PVDF use in food contact materials varies globally, presenting challenges for international food producers and packagers. Ensuring compliance with diverse regulatory standards while maintaining consistent product quality across different markets requires careful navigation and ongoing adaptation to evolving guidelines.

Existing PVDF-based Food Preservation Techniques

01 Purity and composition standards

PVDF quality standards often focus on the purity and composition of the material. This includes specifications for the content of vinylidene fluoride monomers, allowable levels of impurities, and the overall molecular weight distribution. These factors significantly influence the material's properties and performance in various applications.- Purity and composition standards: PVDF quality standards often focus on the purity and composition of the material. This includes specifications for the content of vinylidene fluoride monomers, allowable levels of impurities, and the overall molecular weight distribution. These factors significantly influence the material's performance and properties in various applications.

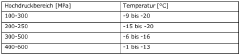

- Mechanical and physical property requirements: Quality standards for PVDF typically include specifications for mechanical and physical properties. These may encompass tensile strength, elongation at break, flexural modulus, and impact resistance. Additionally, standards often cover thermal properties such as melting point, glass transition temperature, and thermal stability.

- Chemical resistance and stability criteria: PVDF quality standards often include requirements for chemical resistance and stability. This involves testing the material's resistance to various solvents, acids, bases, and other chemicals. Long-term stability under different environmental conditions, including UV exposure and weathering resistance, may also be part of the quality criteria.

- Electrical and dielectric property specifications: For applications in electronics and electrical industries, PVDF quality standards may include specifications for electrical and dielectric properties. These can include dielectric constant, dissipation factor, volume resistivity, and breakdown voltage. The consistency and reliability of these properties are crucial for many high-performance applications.

- Processing and fabrication quality standards: Quality standards for PVDF often address aspects related to processing and fabrication. This may include melt flow index, thermal stability during processing, and consistency in pellet size and shape. Standards may also cover the material's suitability for specific manufacturing processes such as injection molding, extrusion, or film formation.

02 Mechanical and physical properties

Quality standards for PVDF typically include specifications for mechanical and physical properties. These may encompass tensile strength, elongation at break, flexural modulus, and impact resistance. Additionally, standards often cover thermal properties such as melting point, glass transition temperature, and thermal stability.Expand Specific Solutions03 Chemical resistance and stability

PVDF quality standards often address the material's chemical resistance and stability. This includes resistance to various solvents, acids, and bases, as well as long-term stability under different environmental conditions. UV resistance and weatherability are also important factors considered in these standards.Expand Specific Solutions04 Electrical and dielectric properties

For applications in electronics and electrical industries, PVDF quality standards may specify requirements for electrical and dielectric properties. These can include dielectric constant, dissipation factor, volume resistivity, and breakdown voltage. The piezoelectric properties of certain PVDF grades may also be subject to specific quality standards.Expand Specific Solutions05 Processing characteristics and additives

Quality standards for PVDF often include specifications related to its processing characteristics. This may cover melt flow rate, thermal stability during processing, and compatibility with various additives. Standards may also address the use and quality of specific additives, such as plasticizers, stabilizers, or fillers, which can affect the final properties of PVDF products.Expand Specific Solutions

Key Players in PVDF Food Packaging Solutions

The application of PVDF in the food industry is in a growth phase, with increasing market size due to its excellent properties for preserving food quality. The global PVDF market is expected to expand significantly, driven by demand in various sectors, including food packaging. Technologically, PVDF applications are maturing, with companies like Arkema France SA, BASF Corp., and Wanhua Chemical Group Co., Ltd. leading innovation. These firms are developing advanced PVDF formulations tailored for food contact materials, focusing on enhancing barrier properties and chemical resistance. Research institutions such as Kunming University of Science & Technology and Nanyang Technological University are contributing to technological advancements, exploring new applications and improving PVDF performance in food preservation.

Arkema France SA

BASF Corp.

Innovative PVDF Formulations for Food Contact Materials

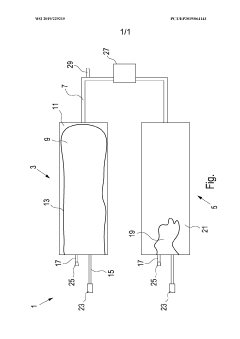

- A continuous high-pressure process involving steps like providing a product, applying high pressure, cooling below its freezing point, reducing pressure, and dispensing, which can include stages of pressure increase and gas addition, to maintain product quality and extend shelf life without significant thermal stress.

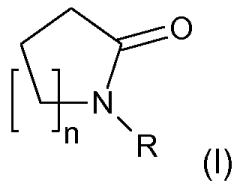

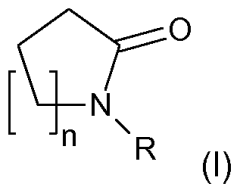

- A mixture of PVDF, N-alkyllactam, and organic carbonate with a molar ratio of 0.2:1 to 20:1, where PVDF content is 1 to 95% by weight, is developed, allowing for improved color stability and solvency, eliminating the need for elaborate cleaning procedures.

Regulatory Framework for PVDF in Food Contact Materials

The regulatory framework for PVDF in food contact materials is a critical aspect of ensuring food safety and quality standards in the industry. The use of PVDF in food packaging and processing equipment is subject to stringent regulations and guidelines set forth by various international and national regulatory bodies.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating the use of PVDF in food contact materials. The FDA has established specific requirements for PVDF under the Code of Federal Regulations (CFR) Title 21, particularly in sections 177.1615 and 177.2510. These regulations outline the acceptable composition, manufacturing processes, and intended uses of PVDF in food contact applications.

The European Union has implemented comprehensive legislation through the European Food Safety Authority (EFSA) and the European Commission. Regulation (EC) No 1935/2004 serves as the overarching framework for all food contact materials, including PVDF. Additionally, Commission Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, providing detailed requirements for PVDF usage.

In Japan, the Ministry of Health, Labour and Welfare (MHLW) regulates food contact materials through the Food Sanitation Act. PVDF must comply with the positive list system for synthetic resins used in food contact materials, ensuring its safety for intended applications.

China's regulatory framework for food contact materials, including PVDF, is governed by the National Health Commission (NHC) and the State Administration for Market Regulation (SAMR). The national food safety standard GB 4806.1-2016 provides general safety requirements for food contact materials, while GB 4806.6-2016 specifically addresses plastic resins used in food contact applications.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international standards and guidelines for food safety, including recommendations for food contact materials like PVDF.

These regulatory frameworks typically require manufacturers to demonstrate the safety of PVDF in food contact applications through extensive testing and documentation. This includes migration studies to assess potential transfer of substances from PVDF to food, as well as toxicological evaluations to ensure the material's safety for human consumption.

Compliance with these regulations often involves obtaining certifications or approvals from relevant authorities. For instance, in the EU, manufacturers may need to provide a Declaration of Compliance (DoC) for PVDF materials used in food contact applications, detailing their conformity with applicable regulations.

As the food industry continues to evolve, regulatory bodies regularly review and update their guidelines to address emerging concerns and new scientific findings. This dynamic regulatory landscape necessitates ongoing vigilance and adaptation from manufacturers and users of PVDF in food contact applications to ensure continued compliance and safety.

Environmental Impact of PVDF in Food Packaging

The environmental impact of PVDF in food packaging is a critical consideration as the material gains prominence in the food industry. PVDF, or polyvinylidene fluoride, offers excellent barrier properties and chemical resistance, making it an attractive option for food packaging. However, its widespread use raises concerns about its ecological footprint throughout its lifecycle.

PVDF production involves energy-intensive processes and the use of fluorine-based chemicals, which can contribute to greenhouse gas emissions and potential environmental contamination if not properly managed. The manufacturing process requires careful monitoring and control to minimize the release of harmful byproducts and ensure worker safety.

In terms of waste management, PVDF presents both challenges and opportunities. While the material is highly durable and resistant to degradation, this characteristic also means that PVDF packaging can persist in the environment for extended periods if not properly disposed of. However, PVDF's recyclability offers a potential solution to mitigate its environmental impact. Advanced recycling technologies can recover and repurpose PVDF, reducing the need for virgin material production and minimizing waste.

The use of PVDF in food packaging may also have indirect environmental benefits. Its superior barrier properties can extend the shelf life of food products, potentially reducing food waste and the associated environmental burdens of food production and distribution. Additionally, the material's resistance to chemicals and contaminants can help prevent food spoilage and reduce the need for additional preservatives or packaging layers.

However, concerns persist regarding the potential leaching of fluorinated compounds from PVDF packaging into food and the environment. While PVDF is generally considered stable, long-term exposure to various conditions may lead to the release of trace amounts of these compounds. Research is ongoing to fully understand the implications of such leaching on ecosystems and human health.

As regulations around plastic use and disposal become more stringent, the food industry must carefully consider the lifecycle impact of PVDF packaging. This includes assessing the material's carbon footprint, evaluating its potential for contamination, and developing effective recycling and disposal strategies. Innovations in PVDF formulation and processing techniques may help address some of these environmental concerns, potentially leading to more sustainable food packaging solutions.

In conclusion, while PVDF offers significant benefits for food packaging, its environmental impact requires careful consideration and management. Balancing the material's performance advantages with ecological responsibility will be crucial for its continued use in the food industry. Future developments in PVDF technology and recycling infrastructure will play a key role in determining its long-term sustainability in food packaging applications.