PVDF: Key Trends in Flexible Electronics Manufacturing

PVDF in Flexible Electronics: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a key material in the rapidly evolving field of flexible electronics manufacturing. This versatile polymer has garnered significant attention due to its unique combination of properties, including piezoelectricity, ferroelectricity, and high dielectric constant. The development of PVDF and its applications in flexible electronics can be traced back to the 1960s when its piezoelectric properties were first discovered.

Over the past few decades, the electronics industry has witnessed a paradigm shift towards flexible, wearable, and stretchable devices. This trend has been driven by the increasing demand for lightweight, conformable, and durable electronic products across various sectors, including consumer electronics, healthcare, and aerospace. PVDF has played a crucial role in enabling this transition, owing to its excellent mechanical flexibility, chemical stability, and electrical properties.

The evolution of PVDF in flexible electronics has been marked by continuous improvements in material synthesis, processing techniques, and device fabrication methods. Researchers and industry professionals have focused on enhancing the piezoelectric and ferroelectric properties of PVDF through various strategies, such as controlling the crystalline phase, incorporating nanofillers, and developing copolymers and terpolymers.

One of the primary objectives in the field of PVDF for flexible electronics is to optimize the material's performance for specific applications. This includes improving the piezoelectric response for energy harvesting and sensing devices, enhancing the ferroelectric properties for non-volatile memory applications, and developing high-k dielectric formulations for capacitive components in flexible circuits.

Another critical goal is to address the challenges associated with large-scale manufacturing of PVDF-based flexible electronic devices. This involves developing scalable production techniques, improving the compatibility of PVDF with other materials used in flexible electronics, and ensuring long-term stability and reliability of PVDF-based components under various environmental conditions.

As the field of flexible electronics continues to advance, researchers are exploring novel applications of PVDF, such as in biomedical sensors, soft robotics, and smart textiles. The ongoing research aims to push the boundaries of PVDF's capabilities, exploring new formulations, nanocomposites, and hybrid materials that can further enhance its performance and expand its applicability in next-generation flexible electronic devices.

Market Analysis for PVDF-based Flexible Electronics

The market for PVDF-based flexible electronics is experiencing significant growth, driven by the increasing demand for lightweight, durable, and flexible electronic devices across various industries. PVDF (Polyvinylidene fluoride) has emerged as a key material in this sector due to its unique properties, including high flexibility, excellent chemical resistance, and piezoelectric characteristics.

The global flexible electronics market is projected to expand rapidly in the coming years, with PVDF playing a crucial role in this growth. The automotive industry is a major driver, as manufacturers seek to incorporate flexible displays and sensors into vehicle interiors. Consumer electronics, particularly wearable devices and foldable smartphones, represent another significant market segment for PVDF-based flexible electronics.

In the healthcare sector, PVDF is gaining traction for its use in flexible biosensors and medical devices. The material's biocompatibility and ability to be sterilized make it ideal for applications such as wearable health monitors and implantable devices. The aerospace industry is also exploring PVDF-based flexible electronics for lightweight, conformal sensors and antennas.

The energy sector presents a promising market for PVDF in flexible solar cells and energy harvesting devices. As renewable energy adoption increases, the demand for flexible, efficient solar panels is expected to drive further growth in this segment. Additionally, the Internet of Things (IoT) and smart home technologies are creating new opportunities for PVDF-based flexible electronics in sensors and actuators.

Geographically, Asia-Pacific is the largest market for PVDF-based flexible electronics, with China and South Korea leading in production and innovation. North America and Europe follow closely, with significant investments in research and development. Emerging economies in South America and Africa are expected to contribute to market growth as they adopt advanced technologies.

Key market challenges include the high cost of PVDF compared to traditional materials and the need for specialized manufacturing processes. However, ongoing research and development efforts are focused on improving production efficiency and reducing costs, which is likely to drive wider adoption in the coming years.

In terms of market dynamics, collaborations between material suppliers, device manufacturers, and end-users are becoming increasingly common. These partnerships aim to accelerate innovation and bring new PVDF-based flexible electronic products to market more quickly. As the technology matures, standardization efforts are also underway to ensure compatibility and interoperability across different platforms and applications.

Current Challenges in PVDF Flexible Electronics Manufacturing

Despite the promising potential of PVDF in flexible electronics manufacturing, several significant challenges persist in its widespread adoption and optimal utilization. One of the primary obstacles is the complex processing requirements of PVDF. The material's high melting point and strong intermolecular forces necessitate specialized equipment and precise control over processing parameters, which can be both costly and technically demanding for manufacturers.

Another challenge lies in achieving consistent and uniform thin film formation with PVDF. The polymer's tendency to crystallize rapidly can lead to inhomogeneous structures and surface defects, potentially compromising the performance and reliability of flexible electronic devices. This issue is particularly pronounced when attempting to produce ultra-thin films required for certain applications.

The piezoelectric properties of PVDF, while advantageous in many scenarios, also present challenges in terms of controlling and optimizing these characteristics for specific device requirements. The degree of piezoelectricity can vary depending on the processing conditions and the polymer's microstructure, making it difficult to achieve reproducible results across different batches or manufacturing lines.

Adhesion and interface issues between PVDF and other materials used in flexible electronics pose another significant challenge. Ensuring strong and stable bonding between PVDF layers and conductive elements or substrates is crucial for device longevity and performance. However, PVDF's inherent chemical inertness can make it resistant to conventional bonding techniques, necessitating the development of specialized surface treatments or adhesion promoters.

The long-term stability and reliability of PVDF in flexible electronic applications remain areas of concern. While PVDF exhibits good chemical resistance and thermal stability, its performance under prolonged mechanical stress, repeated flexing, and exposure to various environmental conditions needs further investigation and improvement to meet the demanding requirements of wearable and flexible electronics.

Scalability and cost-effectiveness in PVDF-based flexible electronics manufacturing also present ongoing challenges. As the industry moves towards larger-scale production, maintaining consistent quality and performance while reducing manufacturing costs becomes increasingly important. This requires innovations in processing techniques, equipment design, and material formulations to enhance productivity without compromising the unique properties of PVDF.

Lastly, the environmental impact and recyclability of PVDF-based flexible electronics are emerging concerns. As sustainability becomes a key focus in the electronics industry, developing eco-friendly processing methods and end-of-life solutions for PVDF-containing devices is crucial. This includes addressing issues related to the disposal or recycling of fluoropolymer materials and exploring more sustainable alternatives or modifications to PVDF.

Current PVDF Manufacturing Techniques for Flexible Electronics

01 Copolymerization with other monomers

PVDF flexibility can be enhanced by copolymerizing it with other monomers. This approach allows for the modification of the polymer's properties, including its flexibility. By carefully selecting and incorporating appropriate comonomers, the rigidity of PVDF can be reduced, resulting in a more flexible material suitable for various applications.- Copolymerization with other monomers: PVDF flexibility can be enhanced by copolymerizing it with other monomers. This approach allows for the modification of the polymer's properties, including its flexibility. By incorporating specific comonomers, the rigidity of PVDF can be reduced, resulting in a more flexible material suitable for various applications.

- Addition of plasticizers: The flexibility of PVDF can be improved by incorporating plasticizers into the polymer matrix. Plasticizers work by increasing the free volume between polymer chains, reducing intermolecular forces, and enhancing chain mobility. This results in a more flexible and pliable PVDF material, suitable for applications requiring improved flexibility.

- Blending with other polymers: PVDF flexibility can be enhanced by blending it with other more flexible polymers. This approach creates a polymer blend that combines the desirable properties of PVDF with the flexibility of the added polymer. The resulting material exhibits improved flexibility while maintaining other beneficial characteristics of PVDF.

- Nanocomposite formation: The incorporation of nanoparticles or nanofillers into PVDF can lead to improved flexibility. These nanocomposites can modify the polymer structure at the nanoscale, resulting in enhanced flexibility and other mechanical properties. The type and concentration of nanofillers can be optimized to achieve the desired level of flexibility.

- Processing techniques: Various processing techniques can be employed to enhance the flexibility of PVDF. These may include specific heat treatments, stretching processes, or the application of external fields during polymer processing. Such techniques can modify the polymer's crystalline structure or orientation, leading to improved flexibility in the final product.

02 Addition of plasticizers

Incorporating plasticizers into PVDF formulations is an effective method to increase flexibility. Plasticizers work by reducing the intermolecular forces between polymer chains, allowing for greater mobility and flexibility. The type and amount of plasticizer can be optimized to achieve the desired level of flexibility while maintaining other important properties of PVDF.Expand Specific Solutions03 Blending with other polymers

Blending PVDF with other flexible polymers can significantly improve its flexibility. This approach allows for the combination of PVDF's desirable properties with the flexibility of other polymers. The selection of compatible polymers and the optimization of blend ratios are crucial for achieving the desired balance of properties, including enhanced flexibility.Expand Specific Solutions04 Nanocomposite formation

Incorporating nanofillers into PVDF can enhance its flexibility while maintaining or improving other properties. Nanocomposites can be created by dispersing nanomaterials such as carbon nanotubes, graphene, or nanocellulose within the PVDF matrix. These nanofillers can modify the polymer structure and interactions, leading to improved flexibility and other desirable characteristics.Expand Specific Solutions05 Processing techniques

Various processing techniques can be employed to enhance the flexibility of PVDF. These may include specific extrusion or molding processes, heat treatments, or stretching methods. By optimizing processing parameters such as temperature, pressure, and cooling rates, the molecular orientation and crystallinity of PVDF can be controlled, resulting in improved flexibility without compromising other essential properties.Expand Specific Solutions

Key Players in PVDF and Flexible Electronics Industry

The PVDF market for flexible electronics manufacturing is in a growth phase, driven by increasing demand for lightweight, durable, and flexible electronic devices. The global market size is expanding rapidly, with key players like Arkema, 3M, and Wanhua Chemical Group leading innovation. Technological maturity varies, with established companies like LG Display and BOE Technology Group advancing commercial applications, while research institutions such as MIT, Nanyang Technological University, and the University of Electronic Science & Technology of China are pushing boundaries in material science and fabrication techniques. Emerging trends include improved piezoelectric properties, enhanced thermal stability, and novel processing methods for better integration with flexible substrates.

Wanhua Chemical Group Co., Ltd.

Arkema, Inc.

Innovative PVDF Formulations for Enhanced Flexibility

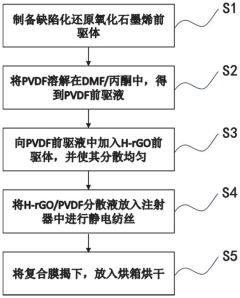

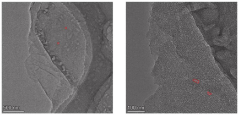

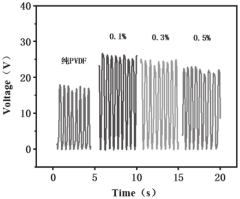

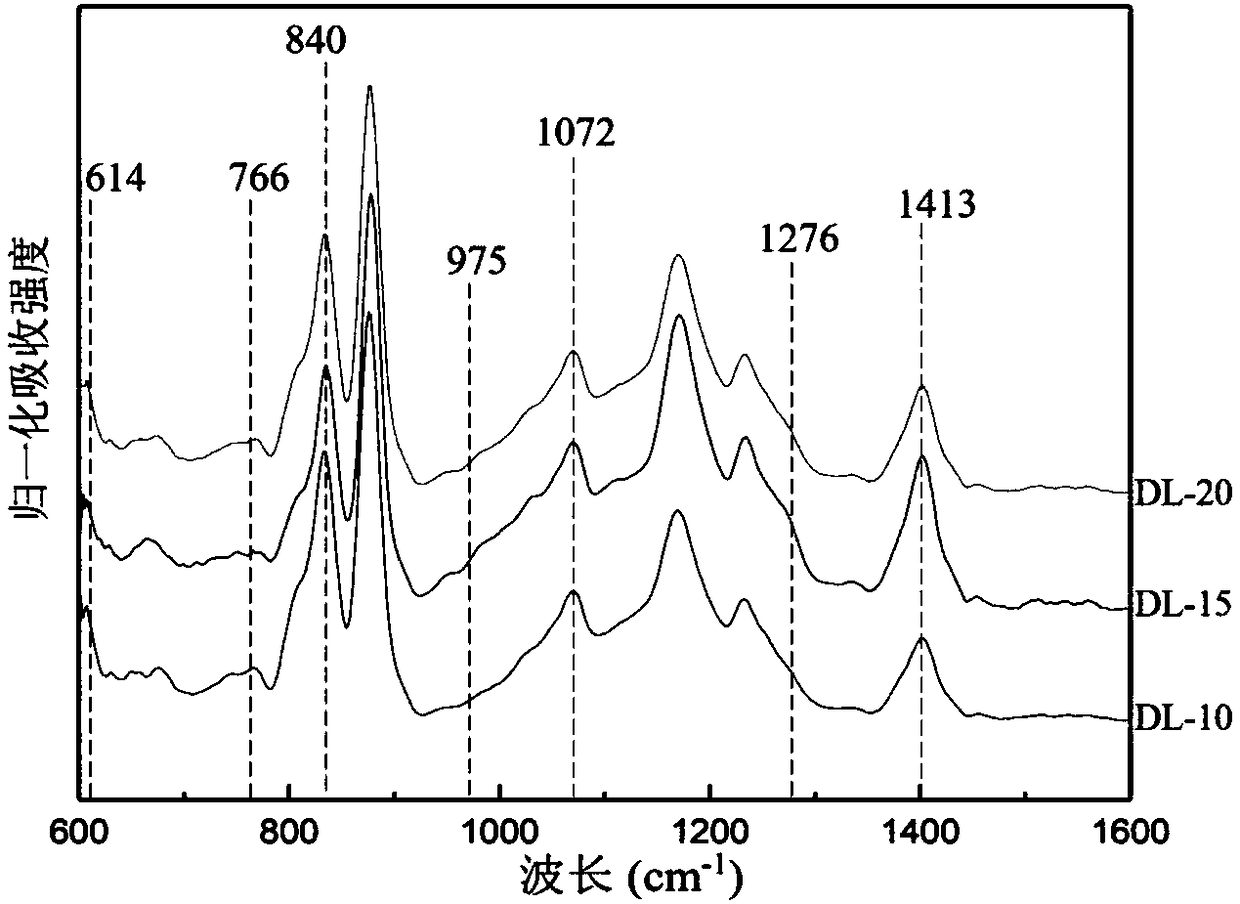

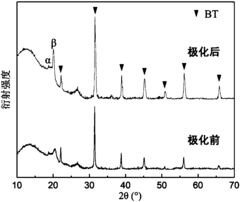

- By reducing and defective treatment of graphene oxide, defective reduced graphene oxide (H-rGO) was prepared. After evenly mixing with the PVDF solution, the H-rGO/PVDF piezoelectric composite film was prepared using electrospinning technology. -rGO induces the conversion of PVDF into more β phases and orients the molecular chains through electric field polarization, thereby improving the piezoelectric output.

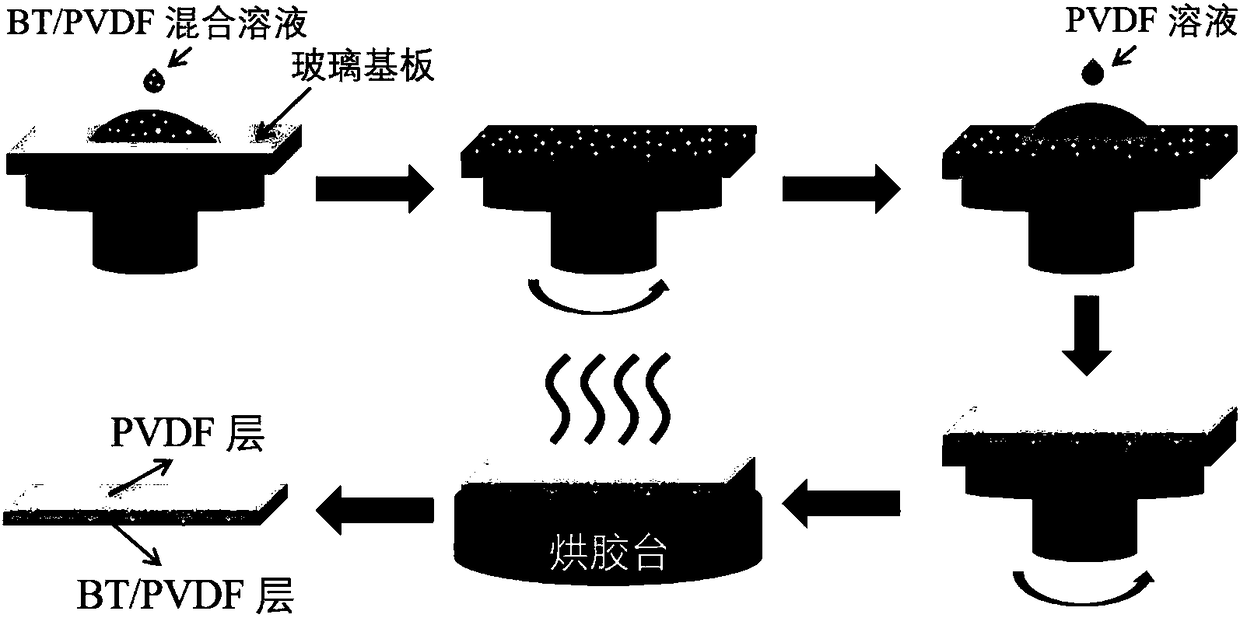

- A two-layer structure nanocomposite film is prepared using a solution spin coating process. One layer is filled with a higher content of inorganic nanofillers to improve the electromechanical conversion efficiency, and the other layer is filled with a lower content of inorganic nanofillers to maintain flexibility. properties, optimizing interfaces and stress distribution.

Environmental Impact of PVDF in Flexible Electronics

The environmental impact of PVDF (polyvinylidene fluoride) in flexible electronics manufacturing is a critical consideration as this material gains prominence in the industry. PVDF's unique properties, including its flexibility, chemical resistance, and piezoelectric characteristics, make it an attractive option for various electronic applications. However, its production and use raise several environmental concerns that warrant careful examination.

The manufacturing process of PVDF involves the use of fluorine-containing compounds, which can contribute to greenhouse gas emissions if not properly managed. The production of PVDF monomers and polymers requires energy-intensive processes, potentially increasing the carbon footprint of flexible electronics that incorporate this material. Additionally, the use of solvents and other chemicals in PVDF processing may lead to air and water pollution if appropriate containment and treatment measures are not implemented.

One of the primary environmental challenges associated with PVDF in flexible electronics is its end-of-life management. PVDF is not biodegradable and can persist in the environment for extended periods. As flexible electronics become more prevalent, the disposal of PVDF-containing devices may contribute to electronic waste accumulation. Recycling PVDF from flexible electronics presents technical difficulties due to its integration with other materials and components, potentially leading to increased landfill waste.

However, it is important to note that PVDF's durability and long lifespan in electronic applications can offset some of its environmental impacts. The material's resistance to degradation means that PVDF-based flexible electronics may have longer operational lives, reducing the frequency of device replacement and associated electronic waste generation. Furthermore, ongoing research into PVDF recycling and upcycling techniques shows promise for mitigating its end-of-life environmental impact.

The use of PVDF in flexible electronics also presents opportunities for environmental benefits. Its piezoelectric properties enable the development of energy harvesting devices, which can convert mechanical energy into electrical energy. This capability supports the creation of self-powered electronic systems, potentially reducing reliance on batteries and their associated environmental burdens.

As the flexible electronics industry continues to evolve, there is a growing focus on developing more environmentally friendly alternatives to PVDF or improving its eco-profile. Research into bio-based and biodegradable polymers with similar properties to PVDF is ongoing, aiming to address the material's environmental persistence. Additionally, advancements in green chemistry approaches to PVDF synthesis and processing are being explored to reduce the environmental impact of its production.

In conclusion, while PVDF offers significant advantages in flexible electronics manufacturing, its environmental impact remains a complex issue. Balancing the material's performance benefits with ecological considerations will be crucial for the sustainable development of the flexible electronics industry. Future innovations in material science and manufacturing processes will play a vital role in mitigating the environmental challenges associated with PVDF use in this rapidly growing sector.

Standardization Efforts for PVDF in Flexible Electronics

Standardization efforts for PVDF in flexible electronics manufacturing are gaining momentum as the industry recognizes the need for consistent quality and performance across applications. These initiatives aim to establish uniform guidelines for material properties, processing techniques, and testing methods, ensuring reliability and interoperability of PVDF-based flexible electronic components.

Several international organizations are spearheading the development of standards for PVDF in flexible electronics. The International Electrotechnical Commission (IEC) has formed a working group dedicated to piezoelectric and ferroelectric polymers, with a focus on PVDF and its copolymers. This group is working on standardizing terminology, measurement techniques, and characterization methods specific to PVDF in flexible electronic applications.

The American Society for Testing and Materials (ASTM) has also initiated efforts to create standards for PVDF films used in flexible electronics. These standards address key aspects such as thickness uniformity, surface roughness, and electrical properties. The goal is to provide manufacturers and end-users with reliable benchmarks for evaluating PVDF materials and ensuring consistency across different suppliers.

In addition to material properties, standardization efforts are also focusing on processing techniques for PVDF in flexible electronics. The Institute of Electrical and Electronics Engineers (IEEE) is developing guidelines for the integration of PVDF films into flexible electronic devices, including best practices for electrode deposition, poling procedures, and encapsulation methods. These standards aim to improve manufacturing yield and device performance across the industry.

Collaboration between academia and industry is playing a crucial role in these standardization efforts. Research institutions are contributing their expertise in PVDF characterization and device fabrication, while industry partners provide insights into practical manufacturing challenges and market requirements. This collaborative approach ensures that the resulting standards are both scientifically rigorous and commercially relevant.

As the standardization process progresses, it is expected to drive innovation and accelerate the adoption of PVDF in flexible electronics. Established standards will facilitate easier comparison between different PVDF formulations and processing techniques, enabling manufacturers to make informed decisions about material selection and production methods. Furthermore, standardization will likely lead to improved quality control measures and more reliable performance of PVDF-based flexible electronic devices.