How to Utilize PVDF in Advanced Liquid Crystal Displays?

PVDF in LCD: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the field of advanced liquid crystal displays (LCDs), marking a significant milestone in display technology evolution. The journey of PVDF in LCDs began with the recognition of its unique properties, particularly its piezoelectric and ferroelectric characteristics, which offer potential enhancements to LCD performance and functionality.

The development of PVDF for LCD applications is rooted in the broader context of polymer science and electronic materials research. As display technologies have progressed, there has been a constant push for materials that can improve image quality, energy efficiency, and overall device performance. PVDF, with its versatile properties, has attracted attention as a potential solution to several challenges faced by conventional LCD technologies.

One of the primary objectives in utilizing PVDF in advanced LCDs is to enhance the electro-optical properties of the display. Researchers aim to leverage PVDF's piezoelectric nature to create more responsive and energy-efficient pixel switching mechanisms. This could lead to displays with faster refresh rates, improved contrast ratios, and reduced power consumption – all critical factors in the competitive display market.

Another key goal is to explore PVDF's potential in flexible and bendable displays. The polymer's mechanical properties make it an attractive candidate for next-generation flexible LCDs, which could revolutionize the form factor of electronic devices. This aligns with the industry trend towards more versatile and adaptable display technologies.

The integration of PVDF into LCDs also aims to address some of the longstanding issues in display technology, such as viewing angle limitations and color accuracy. By incorporating PVDF into various components of the LCD structure, researchers hope to achieve more uniform light distribution and better color reproduction across different viewing angles.

Furthermore, the use of PVDF in LCDs is part of a broader trend towards more sustainable and environmentally friendly display technologies. As a polymer, PVDF offers potential advantages in terms of recyclability and reduced environmental impact compared to some traditional LCD materials.

The technical evolution in this field is closely tied to advancements in material science and nanotechnology. Researchers are exploring various forms of PVDF, including nanocomposites and thin films, to optimize its properties for LCD applications. This involves a multidisciplinary approach, combining expertise from polymer chemistry, physics, and electrical engineering.

As we delve deeper into the potential of PVDF in advanced LCDs, it's crucial to consider both the technological possibilities and the practical challenges of implementation. The ultimate goal is to develop LCD technologies that not only push the boundaries of display performance but also meet the evolving needs of consumers and industries in an increasingly digital world.

Market Analysis for PVDF-Enhanced LCDs

The market for PVDF-enhanced LCDs is experiencing significant growth, driven by the increasing demand for high-performance display technologies across various industries. PVDF (Polyvinylidene Fluoride) has emerged as a promising material for enhancing the performance and durability of liquid crystal displays, offering improved optical properties, thermal stability, and chemical resistance.

In the consumer electronics sector, PVDF-enhanced LCDs are gaining traction in smartphones, tablets, and laptops. The material's ability to enhance display brightness, contrast, and viewing angles addresses the growing consumer demand for superior visual experiences. Additionally, PVDF's resistance to environmental factors such as humidity and temperature fluctuations makes it particularly attractive for outdoor and automotive display applications.

The automotive industry represents a key growth area for PVDF-enhanced LCDs. As vehicles become more technologically advanced, the demand for high-quality, durable displays for infotainment systems, instrument clusters, and heads-up displays is increasing. PVDF's ability to withstand harsh automotive environments while maintaining optical clarity positions it as a preferred material for these applications.

In the industrial and medical sectors, PVDF-enhanced LCDs are finding applications in equipment displays, control panels, and diagnostic devices. The material's chemical resistance and durability make it suitable for use in environments where displays may be exposed to harsh chemicals or frequent cleaning, such as in healthcare facilities or manufacturing plants.

The market for PVDF-enhanced LCDs is also benefiting from the growing trend towards flexible and foldable displays. PVDF's unique properties allow for the development of more flexible and robust display components, potentially opening up new form factors and applications in wearable technology and next-generation mobile devices.

Geographically, Asia-Pacific is expected to dominate the PVDF-enhanced LCD market, driven by the presence of major display manufacturers and the region's strong consumer electronics industry. North America and Europe are also significant markets, particularly in automotive and industrial applications.

However, the market faces challenges, including the higher cost of PVDF compared to traditional materials and the need for specialized manufacturing processes. These factors may limit adoption in price-sensitive segments of the market. Additionally, the ongoing development of alternative display technologies, such as OLED and MicroLED, presents competitive pressure on the LCD market as a whole.

Despite these challenges, the overall outlook for PVDF-enhanced LCDs remains positive. The material's unique combination of optical and physical properties addresses key performance requirements in multiple industries, positioning it for continued growth in the evolving display technology landscape.

PVDF Integration Challenges in LCDs

The integration of Polyvinylidene Fluoride (PVDF) into advanced Liquid Crystal Displays (LCDs) presents several significant challenges that require innovative solutions. One of the primary obstacles is achieving uniform dispersion of PVDF within the LCD structure. PVDF's inherent hydrophobicity can lead to agglomeration, potentially causing optical distortions and reducing display quality. Overcoming this requires advanced mixing techniques and potentially the use of compatibilizers to ensure even distribution throughout the LCD matrix.

Another critical challenge lies in maintaining the optical clarity of the display while incorporating PVDF. The polymer's semi-crystalline nature can introduce haze or light scattering effects, which are detrimental to the display's performance. Researchers are exploring methods to control PVDF's crystallization process or developing amorphous PVDF variants to mitigate these optical issues.

The thermal stability of PVDF in LCD applications poses an additional hurdle. LCDs often operate under varying temperature conditions, and PVDF's thermal expansion characteristics must be carefully managed to prevent delamination or distortion of the display structure. This necessitates the development of PVDF formulations with enhanced thermal stability and coefficients of thermal expansion that are compatible with other LCD components.

Electrical properties present another set of challenges. While PVDF's piezoelectric and ferroelectric properties can be advantageous for certain applications, they may interfere with the precise voltage control required in LCD operation. Engineers must design circuits and electrode structures that can accommodate or neutralize these effects to ensure stable display performance.

The manufacturing process for PVDF-integrated LCDs also requires significant adaptation. Traditional LCD production methods may not be directly compatible with PVDF incorporation, necessitating the development of new deposition techniques, curing processes, and quality control measures. This may involve modifications to existing production lines or the creation of entirely new manufacturing protocols.

Durability and long-term stability of PVDF in LCD environments are additional concerns. The polymer must withstand exposure to UV light, humidity, and various chemicals used in LCD assembly without degrading or altering its properties over the lifespan of the display. This requires extensive testing and potentially the development of protective coatings or additives to enhance PVDF's resistance to environmental factors.

Lastly, the cost-effectiveness of PVDF integration must be addressed. While PVDF offers unique properties, its incorporation must not significantly increase the overall cost of LCD production. This economic challenge drives research into more efficient synthesis methods for PVDF and exploration of hybrid materials that combine PVDF's benefits with more cost-effective components.

Current PVDF Implementation in LCDs

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties, such as improved hydrophilicity, fouling resistance, and separation performance. These methods may include blending with other polymers, surface modification, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes are explored, including blending with other polymers, surface treatments, and incorporation of nanoparticles. These modifications aim to enhance properties such as hydrophilicity, fouling resistance, and mechanical strength for applications in water treatment and filtration.

- PVDF-based piezoelectric and energy harvesting devices: PVDF's piezoelectric properties are utilized in the development of sensors, actuators, and energy harvesting devices. Research focuses on improving the piezoelectric performance through various methods, including nanocomposite formation and specialized fabrication techniques.

- PVDF in battery and supercapacitor applications: PVDF is investigated as a binder material and separator in lithium-ion batteries and supercapacitors. Research aims to enhance the electrochemical performance, stability, and safety of energy storage devices through PVDF-based components and composites.

- PVDF-based coatings and films: Development of PVDF-based coatings and films for various applications, including corrosion protection, self-cleaning surfaces, and electromagnetic shielding. Research focuses on improving durability, adhesion, and functional properties through polymer blending and surface modifications.

- PVDF in composite materials: Incorporation of PVDF into composite materials for enhanced mechanical, thermal, and electrical properties. Research explores various filler materials, including carbon nanotubes, graphene, and ceramic particles, to create high-performance composites for aerospace, automotive, and electronics applications.

02 PVDF in energy storage applications

Utilization of PVDF in energy storage devices, particularly in lithium-ion batteries and supercapacitors. PVDF serves as a binder material for electrodes, separator membranes, or as a component in solid electrolytes, contributing to improved battery performance and safety.Expand Specific Solutions03 PVDF-based piezoelectric materials

Development of PVDF and its copolymers as piezoelectric materials for various applications, including sensors, actuators, and energy harvesters. Methods to enhance the piezoelectric properties through processing techniques or incorporation of fillers are explored.Expand Specific Solutions04 PVDF in coating and film applications

Use of PVDF in protective coatings and films for various industries, including construction, automotive, and electronics. These applications leverage PVDF's excellent weather resistance, chemical inertness, and durability properties.Expand Specific Solutions05 PVDF in water treatment and filtration

Application of PVDF membranes in water treatment and filtration processes, including ultrafiltration and microfiltration. Research focuses on improving membrane performance, antifouling properties, and durability for various water purification applications.Expand Specific Solutions

Key Players in PVDF-LCD Industry

The utilization of PVDF in advanced liquid crystal displays is an emerging technology in a rapidly evolving industry. The market is in a growth phase, with increasing demand for high-performance displays driving innovation. Major players like Samsung Display, LG Display, and BOE Technology Group are investing heavily in research and development to integrate PVDF into their products. The market size is expanding, fueled by applications in consumer electronics and automotive sectors. Technologically, the use of PVDF in LCDs is still maturing, with companies like Sharp, Innolux, and TCL China Star Optoelectronics Technology working on improving its implementation. The competitive landscape is intense, with both established manufacturers and emerging players like HKC Corp and Chongqing HKC Optoelectronics Technology vying for market share.

LG Electronics, Inc.

LG Display Co., Ltd.

PVDF-LCD Core Patents and Literature

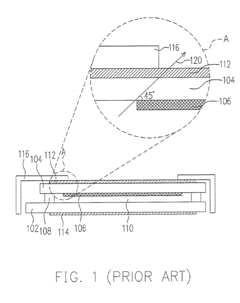

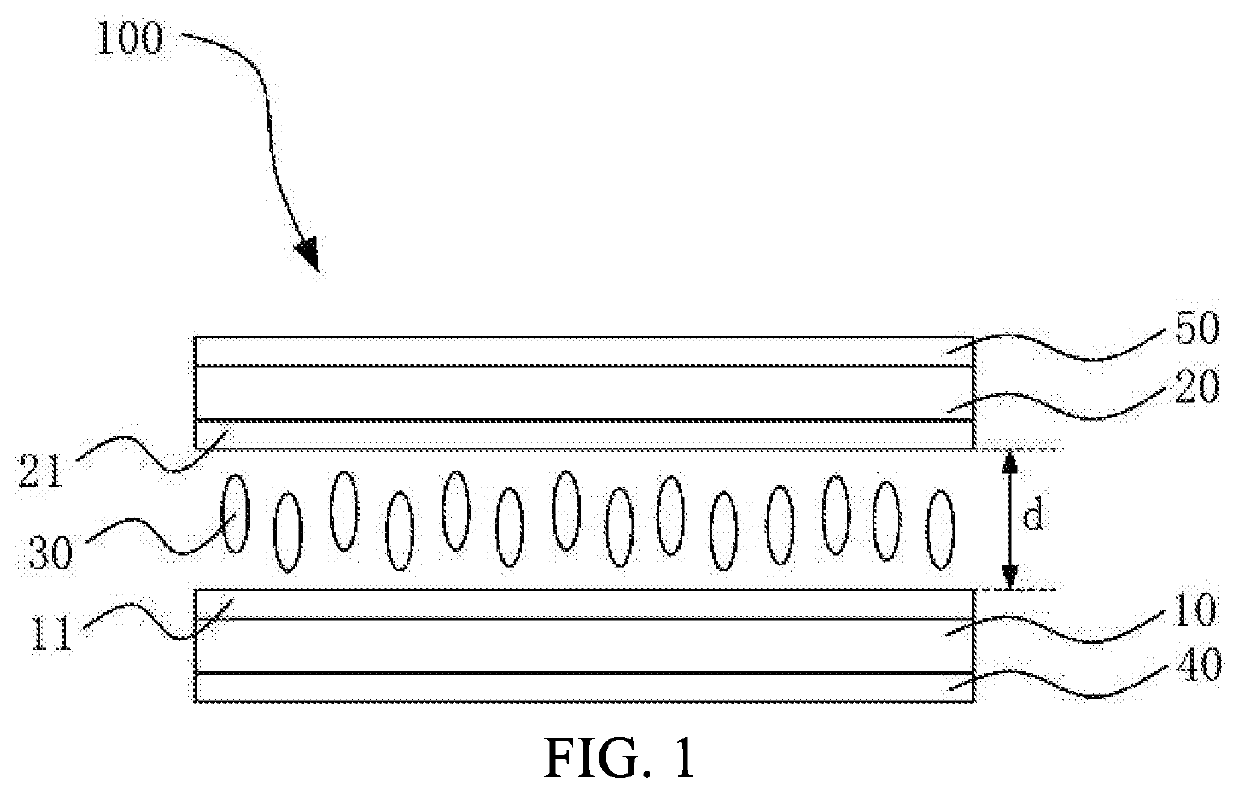

- A light-shielding layer is applied on the outer surfaces of the substrates, with an optical density of 2.0 or higher, positioned outside the display area to prevent light leakage, while maintaining the ODF process compatibility with the SPWG specification.

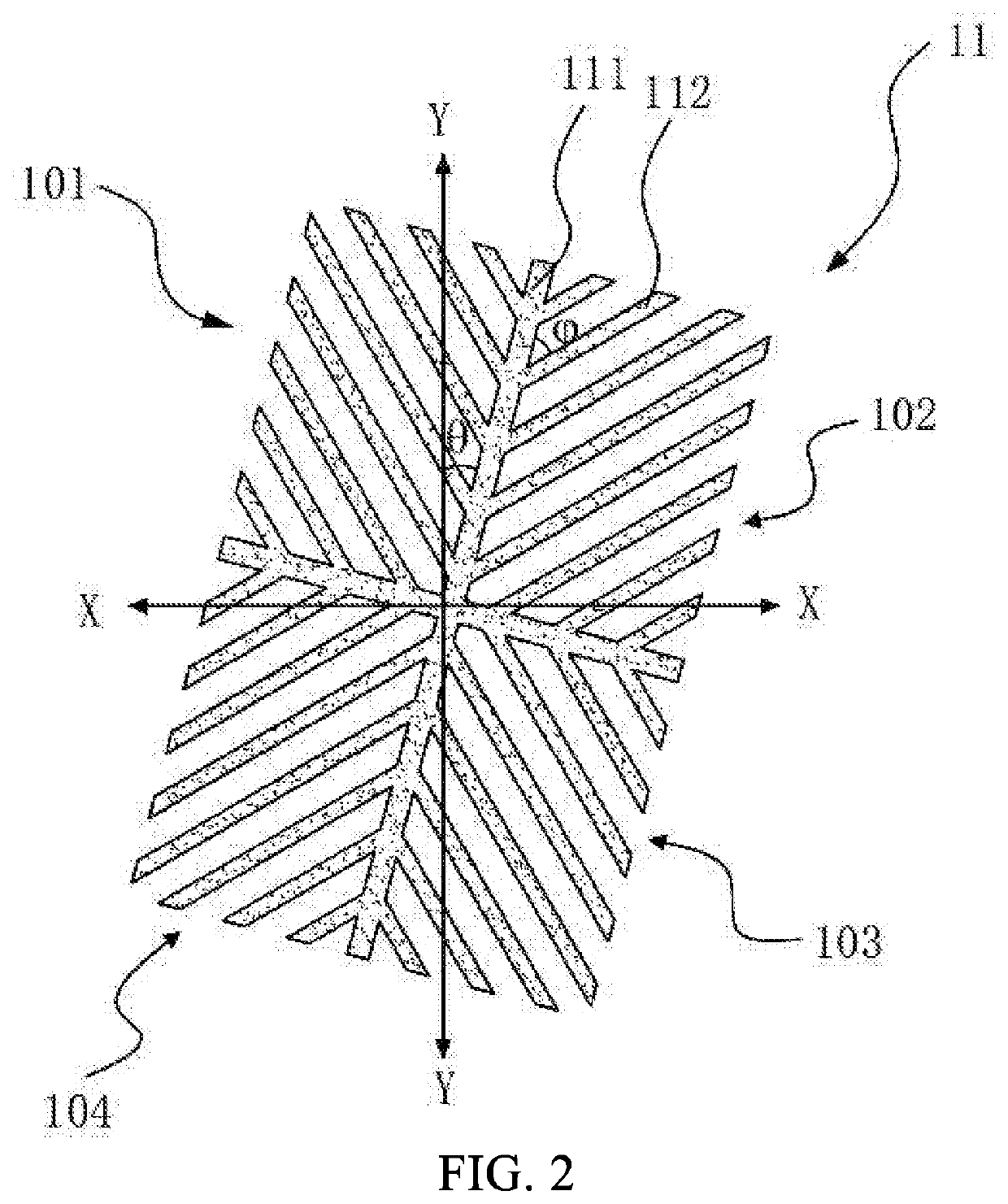

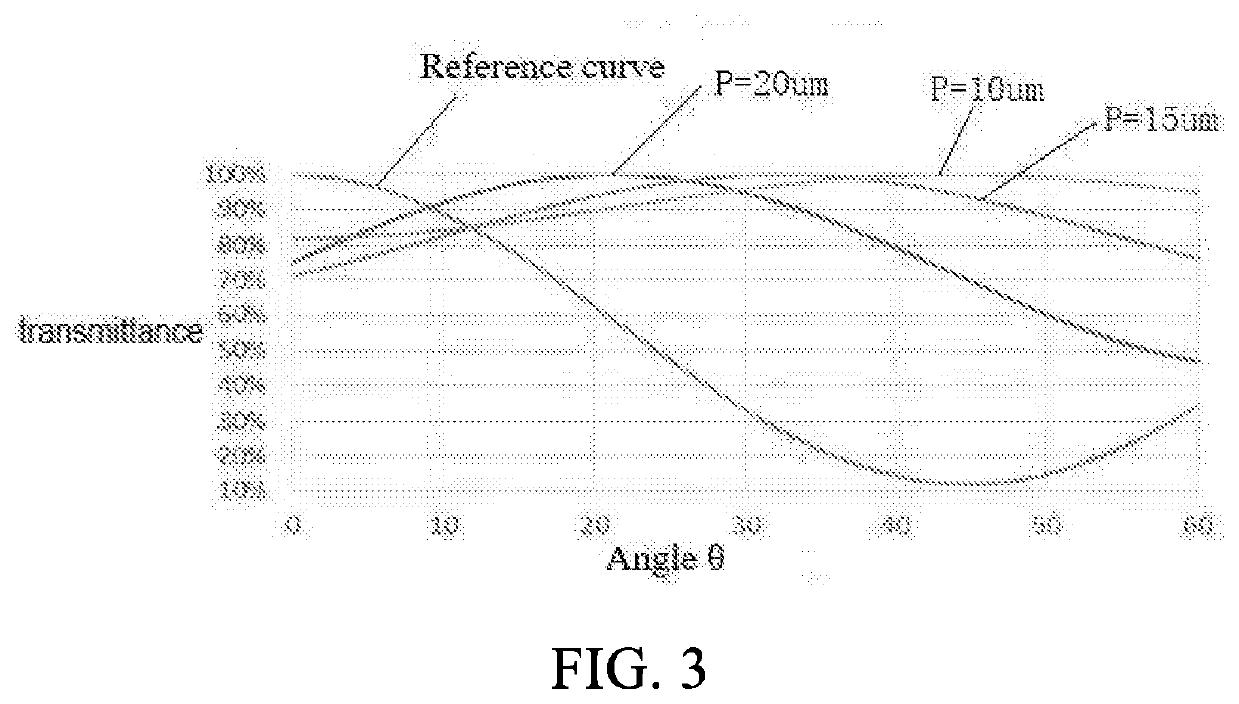

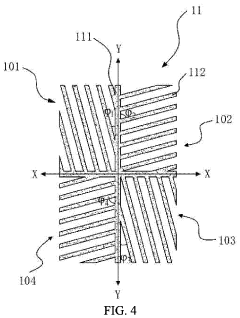

- Incorporating a chiral agent into the liquid crystal layer to generate a helical twisting force that rotates liquid crystal molecules, combined with a specific electrode structure and polarizer angle configuration to maximize transmittance, including a first and second polarizer arrangement with stem and branch electrodes, and adjusting the angles between these electrodes and the polarizer axis to optimize the pitch and thickness of the liquid crystal layer.

Environmental Impact of PVDF-LCDs

The integration of Polyvinylidene Fluoride (PVDF) in advanced Liquid Crystal Displays (LCDs) presents both opportunities and challenges from an environmental perspective. PVDF, a fluoropolymer known for its excellent chemical resistance and durability, offers potential benefits in terms of display longevity and performance. However, its production and end-of-life disposal raise significant environmental concerns.

The manufacturing process of PVDF involves the use of fluorine-based compounds, which can contribute to greenhouse gas emissions if not properly managed. The production of PVDF requires energy-intensive processes, potentially increasing the carbon footprint of LCD manufacturing. However, the extended lifespan of PVDF-enhanced LCDs may offset some of these initial environmental costs by reducing the frequency of device replacement.

In terms of device performance, PVDF's incorporation into LCDs can lead to improved energy efficiency. The material's unique properties allow for better light management and potentially lower power consumption in display operation. This energy-saving aspect could contribute to reduced environmental impact over the lifecycle of PVDF-LCDs compared to conventional displays.

End-of-life considerations for PVDF-LCDs present significant challenges. The durability that makes PVDF attractive for use in displays also makes it resistant to natural degradation. Proper recycling of PVDF-containing components requires specialized processes to separate and recover the material effectively. Without appropriate recycling infrastructure, there is a risk of PVDF contributing to electronic waste accumulation.

Water pollution is another environmental concern associated with PVDF-LCDs. During the manufacturing process and potential leaching from improperly disposed devices, fluoropolymer particles could enter water systems. These microplastics pose risks to aquatic ecosystems and may enter the food chain.

Despite these challenges, ongoing research into green chemistry approaches for PVDF production and recycling shows promise. Innovations in eco-friendly synthesis methods and the development of more efficient recycling technologies could mitigate some of the environmental impacts associated with PVDF-LCDs.

Balancing the environmental trade-offs of PVDF use in LCDs requires a comprehensive lifecycle assessment. While the material offers potential benefits in terms of device longevity and performance, addressing the environmental concerns throughout its lifecycle is crucial for sustainable implementation in advanced display technologies.

PVDF-LCD Manufacturing Processes

The integration of Polyvinylidene Fluoride (PVDF) in advanced Liquid Crystal Display (LCD) manufacturing processes represents a significant technological advancement in the field of display technology. PVDF, a highly non-reactive thermoplastic fluoropolymer, offers unique properties that enhance the performance and durability of LCD panels.

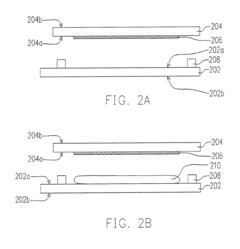

In the initial stages of LCD manufacturing, PVDF is utilized in the creation of thin, uniform films that serve as crucial components in the display structure. These films are produced through a sophisticated extrusion process, where PVDF pellets are melted and pressed into sheets of precise thickness. The extrusion parameters, including temperature, pressure, and cooling rate, are meticulously controlled to achieve optimal film properties.

Following extrusion, the PVDF films undergo a stretching process to enhance their piezoelectric and pyroelectric properties. This step involves carefully applying tension to the film in one or two directions, aligning the polymer chains and creating a more ordered structure. The stretching process is critical in determining the final electrical and mechanical characteristics of the PVDF layer in the LCD.

The next phase involves the application of conductive coatings to the PVDF films. This is typically achieved through vacuum deposition techniques such as sputtering or thermal evaporation. The conductive layers, often composed of materials like indium tin oxide (ITO), enable the PVDF film to function as an active element in the LCD, responding to electrical signals to modulate light transmission.

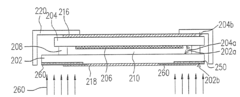

Integration of the PVDF layer into the LCD stack is a precision-driven process. The film is carefully aligned and bonded with other layers, including the liquid crystal layer, color filters, and polarizers. Advanced bonding techniques, such as optical bonding or pressure-sensitive adhesives, are employed to ensure seamless integration without compromising the optical properties of the display.

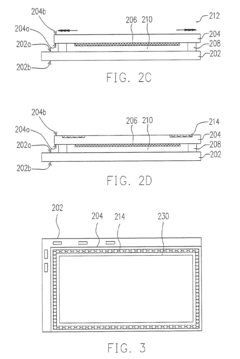

Quality control measures are implemented throughout the manufacturing process to ensure the consistency and reliability of PVDF-enhanced LCDs. These include optical inspections, electrical testing, and environmental stress tests to verify the performance and durability of the displays under various conditions.

The final stages of manufacturing involve the assembly of the LCD module, including the attachment of driver circuits and backlighting systems. The unique properties of PVDF contribute to improved backlight efficiency and more uniform light distribution across the display surface.

By incorporating PVDF into LCD manufacturing, manufacturers can produce displays with enhanced touch sensitivity, improved durability, and potentially thinner form factors. The piezoelectric properties of PVDF also open up possibilities for integrating haptic feedback directly into the display, creating more interactive and responsive user interfaces.