How To Repaint A PVDF Finish?

PVDF Repainting Background and Objectives

Polyvinylidene fluoride (PVDF) coatings have been widely used in architectural and industrial applications for decades due to their exceptional durability, weather resistance, and color retention properties. As these coatings age, the need for repainting becomes increasingly important to maintain the aesthetic appeal and protective qualities of structures. The objective of this technical research report is to explore the challenges and solutions associated with repainting PVDF finishes, addressing the growing demand for effective renovation techniques in the construction and maintenance industries.

The evolution of PVDF coatings can be traced back to the 1960s when they were first introduced as a high-performance alternative to traditional paint systems. Over the years, advancements in polymer chemistry and application technologies have led to significant improvements in PVDF coating formulations, enhancing their resistance to UV radiation, chemical exposure, and physical wear. However, as these coatings approach the end of their service life, typically 20-30 years, the need for repainting becomes evident.

The primary goal of PVDF repainting is to restore the protective and aesthetic properties of the original coating while ensuring long-term adhesion and performance. This process presents unique challenges due to the inherent chemical stability and low surface energy of PVDF, which can hinder the adhesion of new paint layers. Consequently, developing effective surface preparation techniques and compatible paint systems has become a focal point for research and development in the coatings industry.

Recent technological trends in PVDF repainting have focused on innovative surface treatment methods, such as chemical etching and plasma activation, to improve the adhesion of new coatings. Additionally, the development of specialized primer systems and topcoats designed specifically for PVDF repainting has gained momentum, aiming to achieve optimal compatibility and long-term performance.

Market demand for PVDF repainting solutions has been driven by the aging infrastructure in developed countries and the increasing emphasis on sustainable building practices. Building owners and facility managers are seeking cost-effective alternatives to complete facade replacement, creating opportunities for advanced repainting technologies. This trend is further supported by stringent environmental regulations that favor renovation over replacement, aligning with broader sustainability goals in the construction sector.

As the field of PVDF repainting continues to evolve, research efforts are being directed towards understanding the long-term performance of repainted surfaces, optimizing application techniques, and developing environmentally friendly coating systems. The integration of nanotechnology and smart materials in PVDF repainting formulations represents an emerging area of interest, potentially offering enhanced durability and self-cleaning properties for repainted surfaces.

Market Analysis for PVDF Repainting Services

The market for PVDF repainting services has shown significant growth potential in recent years, driven by the increasing demand for durable and weather-resistant coatings in various industries. PVDF (Polyvinylidene Fluoride) finishes are known for their exceptional resistance to UV radiation, chemicals, and weathering, making them popular in architectural, automotive, and industrial applications. However, over time, even these high-performance coatings may require repainting due to wear, damage, or aesthetic reasons.

The global market for PVDF repainting services is closely tied to the broader architectural coatings industry, which was valued at approximately $75 billion in 2020 and is expected to grow at a CAGR of 4.5% through 2027. Within this market, the demand for PVDF repainting services is particularly strong in regions with harsh climates or high levels of industrial pollution, where the protective properties of PVDF coatings are most valuable.

Key drivers of market growth include the aging infrastructure in developed countries, increasing awareness of the benefits of PVDF coatings in emerging economies, and the growing emphasis on sustainable building practices. The construction industry's recovery post-COVID-19 pandemic is also expected to boost demand for PVDF repainting services, as property owners seek to maintain and upgrade their assets.

The market is segmented by application, with architectural applications representing the largest share, followed by automotive and industrial uses. Geographically, North America and Europe are the leading markets for PVDF repainting services, owing to their large installed base of PVDF-coated structures and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid urbanization and industrialization in countries like China and India.

Competition in the PVDF repainting services market is moderately fragmented, with a mix of large multinational coating companies and specialized local service providers. Key players are focusing on developing advanced repainting techniques that can extend the life of PVDF coatings while minimizing environmental impact. Innovation in this space includes the development of water-based PVDF formulations and improved application methods that reduce volatile organic compound (VOC) emissions.

Customer demand is increasingly shifting towards service providers that can offer comprehensive solutions, including surface preparation, coating application, and long-term maintenance plans. This trend is driving consolidation in the market, as larger companies acquire specialized service providers to expand their capabilities and geographic reach.

The future outlook for the PVDF repainting services market remains positive, with opportunities for growth in both established and emerging markets. However, challenges such as the high cost of PVDF materials and the technical expertise required for proper application may limit market penetration in some segments. Successful players in this market will need to balance technical innovation with cost-effective service delivery to capture a growing share of this specialized repainting market.

Current Challenges in PVDF Repainting

Repainting a PVDF (Polyvinylidene Fluoride) finish presents several significant challenges due to the unique properties of this material. PVDF coatings are known for their exceptional durability, weather resistance, and color retention, which paradoxically make them difficult to repaint when necessary.

One of the primary challenges is adhesion. PVDF finishes are designed to resist chemical bonding, which is beneficial for their longevity but problematic when attempting to apply a new coating. The smooth, non-porous surface of PVDF makes it difficult for new paint to adhere properly, often resulting in peeling or flaking of the new coating over time.

Surface preparation is another critical challenge. Traditional methods of sanding or abrading the surface to promote adhesion can be ineffective with PVDF coatings. Excessive abrasion may damage the underlying PVDF layer, compromising its protective properties, while insufficient preparation can lead to poor paint adhesion.

The chemical resistance of PVDF also poses difficulties in the repainting process. Many conventional paint strippers and solvents are ineffective against PVDF, making it challenging to remove any existing contamination or degraded coating without damaging the underlying substrate.

Environmental factors further complicate the repainting process. PVDF coatings are often used in exterior applications exposed to harsh weather conditions. Ensuring that the new paint system can match the performance of the original PVDF coating in terms of UV resistance, color stability, and weathering is a significant challenge.

Compatibility between the new coating system and the existing PVDF finish is another hurdle. The new paint must not only adhere well but also expand and contract at a similar rate to the PVDF coating to prevent cracking or delamination over time.

The limited range of suitable paint options for PVDF repainting is an additional challenge. Not all paint systems are compatible with PVDF substrates, and those that are may not offer the same level of performance as the original coating, potentially compromising the long-term durability of the finished surface.

Achieving color matching and uniformity can be particularly difficult when repainting PVDF finishes. The high color retention of PVDF means that any new coating must precisely match the original color, which may have undergone minimal fading compared to other coating types.

Existing PVDF Repainting Techniques

01 PVDF coating composition and application

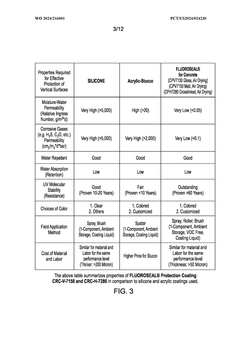

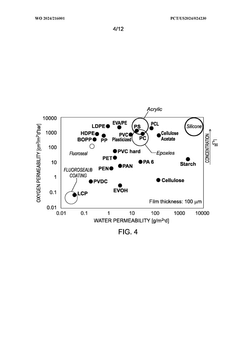

PVDF (polyvinylidene fluoride) coatings are widely used for their durability and weather resistance. These coatings typically consist of PVDF resin, acrylic resin, and various additives. The composition can be applied to different substrates, such as metal panels or building materials, to provide a protective and decorative finish.- PVDF coating composition and application: PVDF (polyvinylidene fluoride) coatings are used for various applications due to their excellent weather resistance and durability. These coatings typically consist of PVDF resin, acrylic resin, and other additives. The composition can be applied to surfaces using spray coating, dip coating, or other methods to achieve a protective and decorative finish.

- PVDF finish for architectural applications: PVDF finishes are widely used in architectural applications, particularly for exterior building panels and facades. These finishes provide long-lasting color retention, resistance to UV radiation, and protection against environmental pollutants. The coating system often includes a primer, PVDF topcoat, and sometimes a clear coat for enhanced performance.

- PVDF membrane technology: PVDF membranes are utilized in various filtration and separation processes. These membranes offer excellent chemical resistance, thermal stability, and mechanical strength. They are commonly used in water treatment, pharmaceutical manufacturing, and other industrial applications where high-performance filtration is required.

- PVDF-based composite materials: Composite materials incorporating PVDF are developed for specialized applications. These composites may combine PVDF with other polymers, nanoparticles, or reinforcing materials to enhance specific properties such as piezoelectricity, thermal conductivity, or mechanical strength. Such composites find use in sensors, energy harvesting devices, and high-performance components.

- PVDF surface treatment and modification: Various surface treatment and modification techniques are employed to improve the adhesion, printability, or functionality of PVDF finishes. These may include plasma treatment, chemical etching, or the application of functional coatings. Such modifications can enhance the compatibility of PVDF with other materials or impart additional properties like antimicrobial activity or self-cleaning capabilities.

02 PVDF film manufacturing process

The manufacturing process of PVDF films involves extrusion, stretching, and heat treatment. Specific techniques are employed to control the crystallinity and orientation of the polymer chains, which affect the final properties of the film. These films can be used as standalone products or as part of a laminate structure.Expand Specific Solutions03 PVDF membrane technology

PVDF membranes are used in various filtration and separation applications. The membrane structure can be tailored to achieve specific pore sizes and surface properties. Modifications to the PVDF membrane, such as surface treatments or the incorporation of additives, can enhance its performance in applications like water treatment or gas separation.Expand Specific Solutions04 PVDF in energy storage applications

PVDF and its copolymers are utilized in energy storage devices, particularly in lithium-ion batteries. The material can be used as a binder for electrode materials or as a separator membrane. Its properties, such as electrochemical stability and mechanical strength, contribute to improved battery performance and safety.Expand Specific Solutions05 Surface treatment and modification of PVDF finishes

Various surface treatment techniques can be applied to PVDF finishes to enhance their properties. These may include plasma treatment, chemical etching, or the application of additional coatings. Such modifications can improve adhesion, printability, or specific functional properties of the PVDF surface while maintaining its core benefits.Expand Specific Solutions

Key Players in PVDF Coating Industry

The market for PVDF finish repainting technology is in a growth phase, driven by increasing demand for durable coatings in construction and automotive industries. The global market size is estimated to reach $1.5 billion by 2025, with a CAGR of 6.5%. Technological maturity varies among key players. Companies like AGC, Inc. and Honeywell International Technologies Ltd. are at the forefront, offering advanced PVDF repainting solutions. Emerging players such as Ningde Zhuo High-tech Materials Technology Co., Ltd. and Shanghai Huayi 3F New Materials Co., Ltd. are rapidly developing innovative techniques to improve adhesion and durability of PVDF repaints, indicating a competitive and evolving landscape in this sector.

AGC, Inc. (Japan)

Shanghai Huayi 3F New Materials Co., Ltd.

Innovative PVDF Repainting Methods

- A method involving the application of two layers of modified polyvinylidene fluoride (PVDF) coatings in air-dryable solutions, with the undercoating containing a PVDF co-polymer blended with acrylic and the overcoating highly fluorinated, allowing application in situ on large metal structures without specialized equipment, providing superior moisture and gas barrier properties.

- A matte clear anti-fouling anti-corrosion surface coating comprising fluorine-modified polysilazane and a solvent, which is applied directly to metals, providing stain repellency, hydrophobicity, and corrosion resistance while being cured at room temperature or in a factory, without altering the original gloss or color, and preventing chalking of underlying coatings.

Environmental Impact of PVDF Repainting

The environmental impact of repainting PVDF (polyvinylidene fluoride) finishes is a critical consideration in the maintenance and renovation of buildings and structures. PVDF coatings are known for their durability and resistance to weathering, but over time, they may require repainting to maintain their protective and aesthetic properties. This process, however, carries several environmental implications that must be carefully evaluated.

One of the primary environmental concerns associated with PVDF repainting is the release of volatile organic compounds (VOCs). Traditional paint removal methods and the application of new coatings can emit significant amounts of VOCs into the atmosphere. These compounds contribute to air pollution and can have adverse effects on both human health and the environment. To mitigate this impact, the use of low-VOC or VOC-free paint formulations has become increasingly important in the repainting process.

The disposal of waste generated during PVDF repainting also poses environmental challenges. Paint chips, sanding dust, and other debris may contain harmful substances that can contaminate soil and water if not properly managed. Implementing proper containment and disposal practices is essential to prevent these materials from entering ecosystems and potentially harming wildlife or contaminating water sources.

Energy consumption is another factor to consider in the environmental impact of PVDF repainting. The process often requires power tools for surface preparation and paint application, as well as climate control measures to ensure optimal conditions for the new coating to cure. This increased energy usage contributes to greenhouse gas emissions and overall carbon footprint of the repainting project.

Water usage and potential contamination are additional environmental concerns. Pressure washing, often used in surface preparation, can consume significant amounts of water. Furthermore, runoff from this process may contain chemicals and paint particles that can pollute water systems if not properly controlled and treated.

To minimize the environmental impact of PVDF repainting, several strategies can be employed. The use of eco-friendly paint removal techniques, such as mechanical methods or biodegradable chemical strippers, can reduce the release of harmful substances. Selecting environmentally friendly paint formulations with low VOC content and improved durability can decrease the frequency of repainting and minimize long-term environmental impact.

Implementing proper waste management protocols, including the use of containment systems and appropriate disposal methods for paint-related waste, is crucial. Additionally, optimizing the repainting process to reduce energy consumption, such as using energy-efficient equipment and scheduling work during moderate weather conditions, can help minimize the project's carbon footprint.

In conclusion, while repainting PVDF finishes is sometimes necessary for maintaining building integrity and appearance, it is essential to carefully consider and mitigate its environmental impact. By adopting sustainable practices and materials, the negative effects on air quality, water resources, and overall ecosystem health can be significantly reduced, ensuring a more environmentally responsible approach to building maintenance and renovation.

Quality Control in PVDF Repainting

Quality control is a critical aspect of PVDF repainting processes, ensuring the longevity and performance of the renewed finish. The first step in quality control involves thorough surface preparation. This includes cleaning the existing PVDF surface to remove any contaminants, followed by careful inspection for any damages or irregularities. Any identified issues must be addressed before proceeding with the repainting process.

The selection of compatible paint systems is crucial for successful PVDF repainting. Quality control measures should be implemented to verify that the chosen paint system is specifically formulated for PVDF surfaces and meets the required performance standards. This includes checking the paint's chemical composition, adhesion properties, and weathering resistance.

During the application process, strict environmental controls are essential. Temperature, humidity, and dust levels must be carefully monitored and maintained within specified ranges to ensure optimal paint application and curing. Quality control personnel should regularly check and document these environmental parameters throughout the repainting process.

Proper application techniques are vital for achieving a high-quality PVDF repaint. Quality control measures should include monitoring the spray pattern, paint thickness, and coverage uniformity. Regular inspections during the application process help identify and correct any issues promptly, ensuring a consistent and defect-free finish.

Post-application quality control involves a series of tests and inspections. These may include adhesion tests, thickness measurements, and visual inspections for color consistency and surface defects. Advanced testing methods, such as accelerated weathering tests, can be employed to predict the long-term performance of the repainted surface.

Documentation and traceability are integral parts of the quality control process. Detailed records should be maintained for each repainting project, including surface preparation methods, paint specifications, application conditions, and test results. This documentation serves as a reference for future maintenance and helps in continuous improvement of the repainting process.

Training and certification of personnel involved in PVDF repainting are essential quality control measures. Ensuring that all staff are well-versed in the latest techniques and standards helps maintain consistent quality across projects. Regular skill assessments and refresher courses should be part of the quality control program.

Finally, implementing a robust feedback system allows for continuous improvement of the PVDF repainting process. This involves collecting data on the performance of repainted surfaces over time, analyzing any failures or defects, and using this information to refine quality control procedures and techniques for future projects.