How To Reactivate PVDF?

PVDF Reactivation Background and Objectives

Polyvinylidene fluoride (PVDF) is a highly versatile fluoropolymer that has gained significant attention in various industries due to its exceptional properties. The reactivation of PVDF has become a crucial area of research and development, driven by the need to enhance its performance and extend its lifespan in diverse applications. This technological pursuit aims to address the challenges associated with PVDF's degradation and loss of functionality over time.

The evolution of PVDF reactivation techniques can be traced back to the early 1990s when researchers first recognized the potential for improving the polymer's long-term stability. Initially, efforts focused on physical methods such as thermal treatments and mechanical stress. As the field progressed, more sophisticated approaches emerged, including chemical modifications and surface treatments, which have shown promising results in restoring PVDF's properties.

The primary objective of PVDF reactivation is to restore the material's piezoelectric, ferroelectric, and electroactive properties, which are essential for its use in sensors, actuators, and energy harvesting devices. These properties can deteriorate due to various factors, including environmental stress, mechanical fatigue, and electrical aging. By developing effective reactivation methods, researchers aim to extend the operational life of PVDF-based devices and improve their overall performance.

Another critical goal is to enhance the material's chemical resistance and thermal stability, which are vital for its applications in harsh environments such as chemical processing plants and high-temperature settings. Reactivation techniques that can restore these properties without compromising the material's structural integrity are highly sought after in the industry.

The pursuit of PVDF reactivation is also driven by sustainability concerns. As industries strive to reduce waste and maximize resource efficiency, the ability to reactivate and reuse PVDF components aligns with circular economy principles. This approach not only reduces the environmental impact but also offers significant cost savings for manufacturers and end-users.

Recent technological trends in PVDF reactivation include the exploration of nanocomposite materials, plasma treatments, and electrochemical methods. These innovative approaches aim to overcome the limitations of traditional reactivation techniques and offer more precise control over the material's properties. Additionally, there is growing interest in developing in-situ reactivation methods that can be applied without removing PVDF components from their operational settings, potentially revolutionizing maintenance practices in various industries.

As research in this field continues to advance, the ultimate aim is to develop a comprehensive understanding of the mechanisms underlying PVDF degradation and reactivation. This knowledge will pave the way for more efficient, cost-effective, and environmentally friendly reactivation processes, further expanding the applications and longevity of PVDF-based technologies across multiple sectors.

Market Demand for PVDF Reactivation

The market demand for PVDF reactivation has been steadily growing in recent years, driven by the increasing use of PVDF in various industries and the need for sustainable practices. PVDF (Polyvinylidene fluoride) is a high-performance fluoropolymer known for its excellent chemical resistance, thermal stability, and mechanical properties. It finds widespread applications in industries such as chemical processing, oil and gas, water treatment, and electronics.

As PVDF components and membranes age or become fouled during use, their performance deteriorates, leading to reduced efficiency and increased operational costs. This has created a significant market demand for effective PVDF reactivation techniques. Industries are seeking cost-effective solutions to extend the lifespan of PVDF materials, improve their performance, and reduce the need for frequent replacements.

The water treatment sector, in particular, has shown a strong demand for PVDF reactivation. PVDF membranes are extensively used in water filtration and purification systems. As these membranes become fouled over time, their filtration efficiency decreases, necessitating reactivation or replacement. The growing global focus on water scarcity and the need for efficient water treatment solutions have further amplified the demand for PVDF reactivation technologies in this sector.

In the chemical processing industry, PVDF is widely used for its exceptional chemical resistance. However, prolonged exposure to harsh chemicals can degrade PVDF components, affecting their performance and longevity. The ability to reactivate these components can significantly reduce operational costs and downtime, driving the demand for effective reactivation methods.

The oil and gas industry also presents a substantial market for PVDF reactivation. PVDF is used in various applications within this sector, including pipelines, valves, and fittings. The harsh operating conditions in oil and gas facilities can lead to the degradation of PVDF materials, creating a need for reactivation techniques to maintain their performance and extend their service life.

The electronics industry, where PVDF is used in sensors, transducers, and other components, has also shown interest in reactivation technologies. As electronic devices become more sophisticated and miniaturized, the demand for high-performance, long-lasting PVDF components has increased, along with the need for effective reactivation methods.

The market demand for PVDF reactivation is further fueled by the growing emphasis on sustainability and circular economy principles. Companies are increasingly looking for ways to reduce waste and maximize the use of existing materials. PVDF reactivation aligns well with these objectives, offering a sustainable alternative to frequent replacements and disposal of PVDF components.

PVDF Reactivation Challenges

Polyvinylidene fluoride (PVDF) reactivation presents several significant challenges that researchers and industry professionals must address. One of the primary obstacles is the degradation of PVDF's piezoelectric properties over time, which can lead to reduced performance in various applications. This degradation is often caused by environmental factors, mechanical stress, and thermal exposure, making it crucial to develop effective reactivation methods.

A major challenge in PVDF reactivation is the need for precise control over the repoling process. The alignment of dipoles within the polymer structure is critical for maintaining its piezoelectric properties. However, achieving uniform repoling across the entire material can be difficult, especially for complex shapes or large-scale applications. This challenge is further compounded by the fact that different PVDF grades and compositions may require tailored reactivation approaches.

Another significant hurdle is the potential for structural damage during the reactivation process. High electric fields or temperatures used in some reactivation methods can lead to material breakdown, compromising the integrity and longevity of the PVDF components. Balancing the need for effective reactivation with the preservation of material properties is a delicate task that requires careful optimization.

The energy efficiency of reactivation processes also poses a challenge. Current methods often require substantial energy input, which can be costly and environmentally unfriendly. Developing more energy-efficient reactivation techniques is crucial for making the process economically viable and sustainable, especially for large-scale industrial applications.

Furthermore, the lack of standardized reactivation protocols across different industries and applications creates difficulties in ensuring consistent results. The variability in PVDF grades, processing conditions, and end-use requirements necessitates the development of adaptable reactivation methods that can be fine-tuned for specific scenarios.

The long-term stability of reactivated PVDF is another area of concern. While immediate reactivation may be achievable, ensuring that the restored properties remain stable over extended periods under various operating conditions is challenging. This requires a deep understanding of the polymer's behavior and the development of strategies to maintain its reactivated state.

Lastly, the integration of reactivation processes into existing manufacturing and maintenance workflows presents logistical challenges. Developing in-situ reactivation methods that can be applied without significant disruption to ongoing operations is a key area of research. This includes the need for non-destructive testing methods to assess the effectiveness of reactivation and to determine when reactivation is necessary.

Current PVDF Reactivation Methods

01 Chemical treatment for PVDF reactivation

Various chemical treatments can be employed to reactivate PVDF membranes. These methods may involve the use of specific solvents, acids, or bases to remove fouling agents and restore the membrane's original properties. The process often includes cleaning steps followed by chemical treatments to regenerate the membrane surface.- Chemical treatment for PVDF reactivation: Various chemical treatments can be employed to reactivate PVDF membranes. These methods may involve the use of specific solvents, acids, or bases to remove fouling agents and restore the membrane's original properties. The process often includes cleaning steps followed by chemical treatments to regenerate the membrane surface.

- Physical methods for PVDF membrane regeneration: Physical techniques can be used to reactivate PVDF membranes. These may include backwashing, ultrasonic cleaning, or mechanical scrubbing to remove contaminants from the membrane surface. Some methods may combine physical and chemical treatments for enhanced effectiveness in restoring membrane performance.

- Thermal reactivation of PVDF materials: Thermal processes can be applied to reactivate PVDF materials. This may involve controlled heating or annealing procedures to modify the polymer structure, remove impurities, or restore original properties. The temperature and duration of the thermal treatment are critical factors in achieving effective reactivation.

- Electrochemical methods for PVDF reactivation: Electrochemical techniques can be employed to reactivate PVDF membranes or materials. These methods may involve applying electrical potentials or currents to induce changes in the polymer structure or to remove fouling agents. The process can be optimized by controlling parameters such as voltage, current density, and electrolyte composition.

- Surface modification for PVDF reactivation: Surface modification techniques can be used to reactivate PVDF materials. These may include plasma treatment, grafting of functional groups, or coating with specific substances to enhance the material's properties or restore its functionality. The modified surface can improve the material's performance in various applications.

02 Physical methods for PVDF membrane regeneration

Physical techniques can be used to reactivate PVDF membranes. These may include backwashing, ultrasonic cleaning, or mechanical scrubbing. Such methods aim to remove accumulated foulants and restore membrane permeability without altering the chemical structure of the PVDF material.Expand Specific Solutions03 Thermal reactivation of PVDF membranes

Thermal treatments can be applied to reactivate PVDF membranes. This process may involve controlled heating and cooling cycles to remove contaminants and restore the membrane's original properties. The thermal approach can be particularly effective for certain types of fouling and may be combined with other reactivation methods.Expand Specific Solutions04 Electrochemical methods for PVDF reactivation

Electrochemical techniques can be employed to reactivate PVDF membranes. These methods may involve the application of electric current or potential to remove foulants and restore membrane performance. Electrochemical reactivation can be particularly effective for certain types of organic and inorganic fouling.Expand Specific Solutions05 Composite approaches for PVDF membrane regeneration

Composite or hybrid approaches combining multiple reactivation techniques can be used to effectively regenerate PVDF membranes. These methods may integrate chemical, physical, thermal, or electrochemical treatments in a specific sequence to achieve optimal reactivation results. The combination of different techniques can address various types of fouling and enhance overall membrane performance.Expand Specific Solutions

Key Players in PVDF Reactivation Industry

The reactivation of PVDF is a niche but growing field within the broader polymer industry. The market is in its early growth stage, with increasing demand driven by sustainability initiatives and the circular economy. While the global market size for PVDF recycling is still relatively small, it is expected to expand significantly in the coming years. Technologically, the process is moderately mature, with ongoing research to improve efficiency and scalability. Companies like China Petroleum & Chemical Corp., Shanghai Petrochemical Research Institute, and Zhejiang University are at the forefront of PVDF reactivation research, developing innovative methods and applications. Other players such as Guangdong Bangpu Recycling Technology and Hunan Bangpu Recycling Technology are also making significant contributions to advancing this technology.

China Petroleum & Chemical Corp.

Shanghai Petrochemical Research Institute of China Petroleum & Chemical Corporation

Innovative PVDF Reactivation Techniques

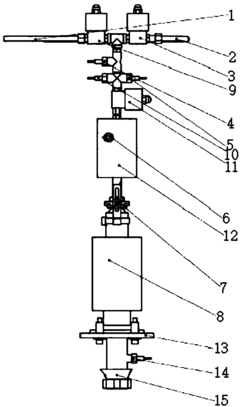

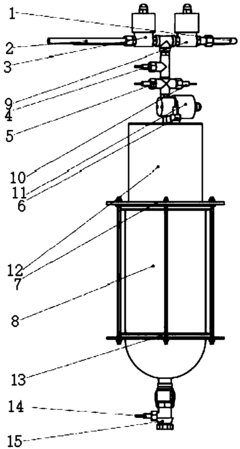

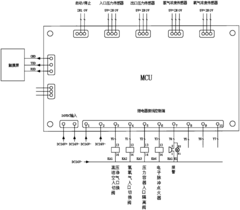

- Adopting a high-efficiency deflagration cleaning and regeneration method, through the microcontroller control system and hydrogen and oxygen deflagration, a high temperature and high pressure are formed to burn particulate matter. The high-pressure clean air and hydrogen and oxygen inlet switching valve are used, combined with pressure and gas concentration sensors, to achieve automatic control and monitoring to ensure deflagration conditions. Effectively clean DPF.

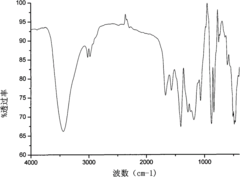

- The gamma ray co-radiation grafting method is used to carry out co-radiation grafting reaction between N-vinylpyrrolidone (NVP) monomer and polyvinylidene fluoride (PVDF) powder. By carrying out co-radiation grafting reaction in water, the reaction conditions are controlled as follows: Monomer concentration, irradiation dose and temperature to produce graft copolymers with good solubility.

Environmental Impact of PVDF Reactivation

The reactivation of PVDF (Polyvinylidene fluoride) has significant environmental implications that must be carefully considered. The process of reactivating PVDF typically involves chemical treatments or thermal methods, which can potentially release harmful substances into the environment if not properly managed.

One of the primary environmental concerns is the release of fluorinated compounds during the reactivation process. These compounds, if released into the atmosphere or water systems, can persist in the environment for extended periods and may have adverse effects on ecosystems and human health. Proper containment and treatment of any emissions or effluents from the reactivation process are crucial to mitigate these risks.

The energy consumption associated with PVDF reactivation is another important environmental factor. Thermal reactivation methods, in particular, can be energy-intensive, contributing to increased carbon emissions if the energy source is not renewable. Implementing energy-efficient technologies and exploring the use of renewable energy sources for the reactivation process can help reduce the overall carbon footprint.

Water usage is also a significant consideration in PVDF reactivation. Some reactivation methods may require substantial amounts of water for cleaning or processing, potentially straining local water resources. Implementing water recycling systems and optimizing water usage in the reactivation process can help minimize this environmental impact.

The disposal of byproducts and waste materials generated during PVDF reactivation presents another environmental challenge. These materials may contain residual chemicals or contaminants that require special handling and disposal methods to prevent soil or groundwater contamination. Developing effective waste management strategies and exploring opportunities for byproduct recycling or repurposing can help reduce the environmental burden of the reactivation process.

On a positive note, the reactivation of PVDF can contribute to resource conservation by extending the lifespan of PVDF materials and reducing the need for new PVDF production. This can lead to a decrease in raw material extraction and manufacturing-related environmental impacts. Additionally, the reactivation process may present opportunities for recovering valuable materials or chemicals, further enhancing its environmental benefits.

To minimize the environmental impact of PVDF reactivation, it is essential to adopt best practices and technologies that prioritize sustainability. This includes implementing closed-loop systems to capture and treat emissions, optimizing energy and water usage, and developing more environmentally friendly reactivation methods. Ongoing research and development efforts should focus on improving the efficiency and sustainability of PVDF reactivation processes to ensure that the environmental benefits outweigh the potential risks.

Cost-Benefit Analysis of PVDF Reactivation

The cost-benefit analysis of PVDF reactivation is a crucial aspect to consider when evaluating the feasibility and economic viability of this process. PVDF (Polyvinylidene fluoride) is a valuable polymer with numerous applications in various industries, including chemical processing, electronics, and membrane technology. However, over time, PVDF membranes can become fouled or degraded, necessitating reactivation or replacement.

Reactivation of PVDF offers several potential benefits. Firstly, it can significantly extend the lifespan of PVDF membranes, reducing the frequency of replacements and associated costs. This is particularly advantageous in large-scale industrial applications where membrane replacement can be a substantial expense. Additionally, reactivation can help maintain the performance characteristics of PVDF membranes, ensuring consistent filtration efficiency and product quality.

From a cost perspective, the primary expenses associated with PVDF reactivation include the chemicals and equipment required for the process, as well as labor costs. These may involve specialized cleaning agents, pH adjusters, and potentially advanced oxidation processes. The exact costs can vary depending on the specific reactivation method chosen and the scale of the operation.

When comparing the costs of reactivation to complete replacement, several factors come into play. The initial investment in reactivation equipment and processes may be higher than simply purchasing new membranes. However, over time, the cumulative cost savings from extended membrane life can outweigh this initial outlay. It's essential to consider the frequency of reactivation needed and the number of times a membrane can be successfully reactivated before replacement becomes necessary.

Environmental benefits should also be factored into the cost-benefit analysis. Reactivation reduces waste generation by prolonging the use of existing materials, aligning with sustainability goals and potentially offering cost savings related to waste disposal. Furthermore, in regions with strict environmental regulations, the reduced waste from reactivation may translate to lower compliance costs and improved corporate image.

The economic viability of PVDF reactivation can vary depending on the specific application and industry context. In high-value, critical applications where membrane performance is crucial, the benefits of reactivation may be more pronounced. Conversely, in less demanding applications or where labor costs are high, the balance may shift towards replacement.

In conclusion, while the upfront costs of implementing PVDF reactivation processes can be significant, the long-term benefits in terms of extended membrane life, maintained performance, and reduced waste often justify the investment. A thorough cost-benefit analysis, taking into account all relevant factors specific to the application, is essential for making an informed decision on whether to pursue PVDF reactivation or opt for regular replacement.