How To Pole PVDF?

PVDF Poling Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in various technological applications due to its unique piezoelectric, pyroelectric, and ferroelectric properties. The process of poling PVDF is fundamental to enhancing these properties, making it a subject of significant interest in materials science and engineering. The evolution of PVDF poling techniques has been driven by the growing demand for high-performance sensors, actuators, and energy harvesting devices.

The development of PVDF poling methods can be traced back to the 1960s when researchers first discovered its piezoelectric properties. Since then, the field has witnessed substantial advancements, with various poling techniques being developed and refined. These include thermal poling, corona poling, electrode poling, and more recently, hysteresis poling and two-step poling processes. Each of these methods aims to align the dipoles within the PVDF polymer chains, thereby maximizing its electromechanical response.

The primary objective of PVDF poling research is to achieve optimal dipole alignment while minimizing material degradation and processing complexity. This involves a delicate balance between applying sufficient electric field strength and managing the thermal conditions to facilitate molecular mobility without compromising the polymer's structural integrity. Researchers are continually striving to develop more efficient and scalable poling techniques that can be applied to various PVDF forms, including thin films, fibers, and nanocomposites.

Current technological trends are pushing the boundaries of PVDF poling capabilities. There is a growing interest in developing methods that can produce uniformly poled large-area PVDF films for flexible electronics and energy harvesting applications. Additionally, researchers are exploring ways to combine poling with other processing techniques, such as stretching and annealing, to further enhance the material's properties.

The future of PVDF poling research is likely to focus on several key areas. These include the development of in-situ poling techniques for 3D-printed PVDF structures, the exploration of novel poling methods using pulsed electric fields or plasma treatments, and the integration of poling processes into roll-to-roll manufacturing for large-scale production. Furthermore, there is increasing interest in understanding and controlling the poling process at the molecular level, potentially leading to breakthroughs in achieving higher piezoelectric coefficients and more stable polarization.

As we look towards the future, the objectives of PVDF poling research are expanding beyond traditional applications. Emerging fields such as soft robotics, wearable technology, and biomedical implants are driving the need for more sophisticated and tailored poling techniques. These applications require precise control over the spatial distribution of polarization and the ability to pole complex three-dimensional structures.

Market Demand for Poled PVDF

The market demand for poled PVDF (polyvinylidene fluoride) has been steadily increasing due to its unique piezoelectric and pyroelectric properties. These characteristics make poled PVDF highly desirable in various industries, particularly in sensing and actuating applications. The global market for piezoelectric devices, which includes poled PVDF products, is projected to grow significantly in the coming years.

One of the primary drivers of market demand for poled PVDF is its widespread use in the healthcare sector. Medical ultrasound imaging systems utilize poled PVDF transducers due to their excellent sensitivity and broad bandwidth. The growing emphasis on early disease detection and non-invasive diagnostic techniques has led to increased adoption of ultrasound technology, consequently boosting the demand for poled PVDF components.

In the industrial sector, poled PVDF finds applications in vibration sensors, pressure sensors, and accelerometers. These devices are crucial for monitoring and controlling various manufacturing processes, ensuring product quality, and enhancing overall operational efficiency. As industries continue to embrace automation and smart manufacturing concepts, the demand for such sensors is expected to rise, further fueling the market for poled PVDF.

The automotive industry represents another significant market for poled PVDF. With the increasing focus on vehicle safety and driver assistance systems, there is a growing need for sensors that can detect impacts, measure tire pressure, and monitor various vehicle parameters. Poled PVDF's flexibility, durability, and ability to withstand harsh environments make it an ideal material for these applications.

In the consumer electronics sector, poled PVDF is gaining traction in the development of haptic feedback systems and touch-sensitive interfaces. As smartphones, wearables, and other portable devices become more sophisticated, the demand for advanced tactile feedback mechanisms is increasing. Poled PVDF's ability to generate precise and localized vibrations makes it a promising material for enhancing user experience in these devices.

The energy harvesting market also presents opportunities for poled PVDF applications. With the growing interest in renewable energy sources and self-powered devices, poled PVDF's piezoelectric properties can be harnessed to convert mechanical energy from vibrations or pressure into electrical energy. This capability is particularly valuable in developing autonomous sensors and low-power electronic devices for IoT applications.

As environmental concerns continue to shape industry trends, the biodegradability and recyclability of PVDF compared to other piezoelectric materials give it a competitive edge. This aspect is likely to drive further adoption in eco-conscious markets and applications where sustainability is a key consideration.

Current Challenges in PVDF Poling

Poling polyvinylidene fluoride (PVDF) remains a significant challenge in the field of piezoelectric polymers. The process of aligning dipoles within the PVDF structure to enhance its piezoelectric properties is complex and fraught with difficulties. One of the primary challenges is achieving uniform and consistent poling across the entire PVDF sample. The heterogeneous nature of polymer structures often leads to uneven dipole alignment, resulting in varying piezoelectric responses throughout the material.

Another major hurdle is the high electric field strength required for effective poling. PVDF typically requires fields in the range of 50-100 MV/m, which can lead to electrical breakdown of the material if not carefully controlled. This necessitates precise equipment and meticulous process control to avoid damaging the polymer during poling. Additionally, the high fields can induce unwanted structural changes in the PVDF, potentially altering its mechanical properties or crystalline structure.

Temperature management during the poling process presents another significant challenge. The poling efficiency is highly temperature-dependent, with optimal results typically achieved near the Curie temperature of PVDF. However, maintaining a stable and uniform temperature throughout the sample during the application of high electric fields is technically demanding. Thermal gradients can lead to non-uniform poling and potentially compromise the material's integrity.

The retention of the poled state over time, known as poling stability, is a persistent issue in PVDF applications. Environmental factors such as temperature fluctuations, mechanical stress, and exposure to electric fields can cause depolarization, gradually reducing the piezoelectric response of the material. Developing methods to enhance the long-term stability of poled PVDF remains an active area of research.

Scale-up of the poling process for industrial applications poses additional challenges. While laboratory-scale poling can be achieved with relative success, translating these methods to large-scale production while maintaining uniformity and efficiency is problematic. The design of poling equipment capable of handling larger PVDF sheets or continuous rolls while ensuring consistent field application and temperature control is a significant engineering challenge.

Furthermore, the characterization of poled PVDF presents its own set of difficulties. Accurately measuring the degree of poling and the resulting piezoelectric properties requires specialized equipment and expertise. The development of standardized, reliable, and non-destructive testing methods for poled PVDF is crucial for quality control and performance optimization in industrial settings.

Existing PVDF Poling Methods

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through the use of additives, surface treatments, or blending with other polymers.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance. This includes methods for improving membrane porosity, hydrophilicity, and fouling resistance through surface treatments, blending with other polymers, or incorporating nanoparticles.

- PVDF in energy storage applications: Utilization of PVDF in energy storage devices, particularly in lithium-ion batteries and supercapacitors. PVDF serves as a binder material for electrode components, enhancing the stability and performance of these devices. Research focuses on optimizing PVDF formulations for improved battery efficiency and longevity.

- PVDF-based piezoelectric materials: Development of PVDF and its copolymers as piezoelectric materials for various applications. This includes methods for enhancing the piezoelectric properties of PVDF through copolymerization, orientation techniques, and the addition of fillers. Applications range from sensors and actuators to energy harvesting devices.

- PVDF in water treatment and filtration: Application of PVDF membranes in water treatment and filtration processes. Research focuses on improving the performance of PVDF membranes for microfiltration, ultrafiltration, and membrane distillation. This includes strategies to enhance flux, selectivity, and antifouling properties of PVDF-based filtration systems.

- PVDF composites and blends: Development of PVDF-based composites and polymer blends to enhance specific properties or create multifunctional materials. This includes combining PVDF with other polymers, nanoparticles, or functional additives to improve mechanical, thermal, or electrical properties for various applications in electronics, coatings, and advanced materials.

02 PVDF-based composites and nanocomposites

Development of PVDF-based composite and nanocomposite materials by incorporating various fillers, nanoparticles, or other polymers to enhance specific properties such as piezoelectricity, thermal stability, or mechanical strength. These composites find applications in sensors, actuators, and energy harvesting devices.Expand Specific Solutions03 PVDF in energy storage applications

Utilization of PVDF as a binder or separator material in energy storage devices such as lithium-ion batteries and supercapacitors. PVDF's properties, including its chemical stability and ability to form porous structures, make it suitable for improving the performance and longevity of these devices.Expand Specific Solutions04 PVDF coatings and films

Development of PVDF-based coatings and films for various applications, including corrosion protection, weather resistance, and self-cleaning surfaces. These coatings and films exploit PVDF's chemical resistance, UV stability, and low surface energy to provide long-lasting protection and functionality.Expand Specific Solutions05 PVDF processing and manufacturing techniques

Advancements in processing and manufacturing techniques for PVDF, including extrusion, injection molding, and electrospinning. These methods aim to improve the efficiency of PVDF production, enhance material properties, and enable the creation of specialized PVDF forms such as nanofibers or porous structures for specific applications.Expand Specific Solutions

Key Players in PVDF Industry

The poling of PVDF is a critical process in the development of piezoelectric materials, currently in a growth phase with expanding market applications. The global PVDF market is projected to reach significant size, driven by increasing demand in various industries. Technologically, the process is moderately mature, with ongoing research for optimization. Companies like Arkema, Inc. and Arkema France SA are leading players, leveraging their expertise in polymer science. Academic institutions such as the University of Electronic Science & Technology of China and Zhejiang University contribute to advancing the technology. Emerging players like Sansan Intelligent Technology and AI Technology, Inc. are also entering the field, potentially bringing innovative approaches to PVDF poling techniques.

Murata Manufacturing Co. Ltd.

Arkema, Inc.

Core Innovations in PVDF Poling

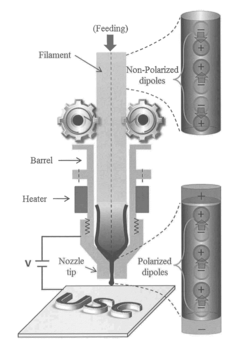

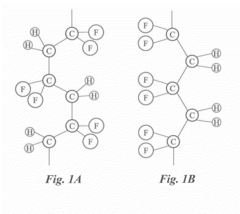

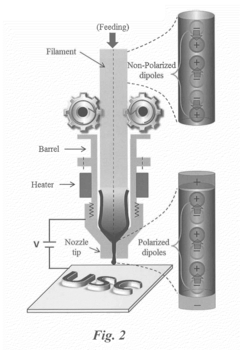

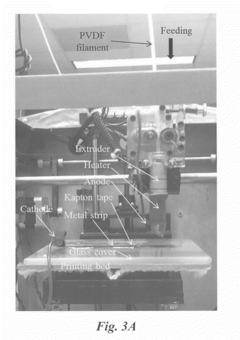

- The integration of electric poling and additive manufacturing (AM) processes to directly print piezoelectric devices from polyvinylidene fluoride (PVDF) polymeric filaments under a strong electric field, allowing for simultaneous mechanical stressing and electric poling, which aligns dipoles uniformly over a large area.

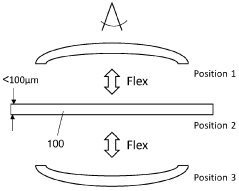

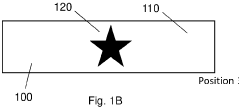

- An electrophoretic display film less than 100 μm thick, comprising a layer of electrophoretic material, a patterned piezoelectric layer with differential polarization, and a flexible, light-transmissive electrode layer, which eliminates the need for external power sources by using piezoelectric material to drive the electrophoretic medium through mechanical flexing.

Environmental Impact of PVDF Poling

The environmental impact of PVDF poling is a critical consideration in the development and application of this technology. The poling process, which aligns the dipoles in the PVDF material to enhance its piezoelectric properties, involves the application of high electric fields and elevated temperatures. This process can have several environmental implications that need to be carefully assessed and mitigated.

One of the primary environmental concerns associated with PVDF poling is energy consumption. The process typically requires high voltages and sustained heating, which can result in significant energy usage. This energy demand contributes to increased carbon emissions if the power source is not from renewable energy. Additionally, the production of the necessary equipment for poling, such as high-voltage power supplies and temperature-controlled chambers, also has an environmental footprint in terms of resource extraction and manufacturing emissions.

The use of chemical solvents during the PVDF film preparation and poling process is another area of environmental concern. These solvents, often volatile organic compounds (VOCs), can contribute to air pollution if not properly managed. Proper handling, recycling, and disposal of these chemicals are essential to minimize their environmental impact and comply with regulatory standards.

Furthermore, the production of PVDF itself involves fluorine-based chemistry, which can have potential environmental risks if not carefully controlled. The synthesis of PVDF monomers and the polymerization process require stringent safety measures to prevent the release of fluorinated compounds into the environment, as these can persist and accumulate in ecosystems.

The disposal of PVDF materials after their useful life is also an important environmental consideration. While PVDF is generally considered a stable and inert polymer, its resistance to degradation means it can persist in the environment for extended periods if not properly recycled or disposed of. Developing effective recycling methods for PVDF materials, especially those that have undergone poling, is crucial for reducing waste and promoting a circular economy approach.

On a positive note, the enhanced piezoelectric properties of poled PVDF enable the development of energy harvesting devices and sensors that can contribute to environmental monitoring and sustainable energy solutions. These applications can potentially offset some of the environmental costs associated with the poling process by enabling more efficient energy use and environmental protection measures in various industries.

To mitigate the environmental impact of PVDF poling, research efforts are focusing on developing more energy-efficient poling techniques, such as corona poling at room temperature or the use of localized electric fields. Additionally, the exploration of alternative, more environmentally friendly solvents and the optimization of poling parameters to reduce energy consumption are active areas of investigation.

Scalability of PVDF Poling Processes

The scalability of PVDF poling processes is a critical factor in the widespread adoption and industrial application of this technology. As the demand for piezoelectric polymers continues to grow across various sectors, including sensors, actuators, and energy harvesting devices, the ability to efficiently pole large quantities of PVDF becomes increasingly important.

Current poling methods, such as contact poling, corona poling, and electron beam poling, have demonstrated effectiveness on a laboratory scale. However, transitioning these techniques to large-scale production presents several challenges. Contact poling, while straightforward, may face limitations in uniformity when applied to larger surface areas. Corona poling offers better scalability but requires careful control of environmental conditions to ensure consistent results across larger samples.

Electron beam poling shows promise for scalability due to its ability to penetrate thicker samples and provide uniform poling throughout the material. However, the high equipment costs and specialized infrastructure required for this method may pose barriers to widespread industrial adoption.

Recent advancements in roll-to-roll processing techniques have opened new possibilities for scaling up PVDF poling. This continuous manufacturing approach allows for the poling of long sheets of PVDF film, potentially increasing production rates and reducing costs. However, maintaining uniform electric field distribution and temperature control across the entire width of the film remains a challenge.

Another avenue for improving scalability is the development of novel electrode designs and configurations. Multi-pin electrode arrays and segmented electrode systems have shown potential in enhancing the uniformity of poling over larger areas, addressing some of the limitations of traditional flat-plate electrodes.

The integration of in-line monitoring and quality control systems is crucial for ensuring consistent poling results in large-scale production. Real-time measurement of piezoelectric properties and automated adjustment of poling parameters can significantly improve process reliability and reduce waste.

As research continues, emerging techniques such as photopoling and chemical poling methods are being explored for their potential scalability advantages. These approaches may offer new pathways for efficient large-scale PVDF poling, potentially revolutionizing the manufacturing process for piezoelectric polymer devices.