How to Optimize PVDF in Hybrid Energy Devices?

PVDF in Hybrid Energy: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a crucial material in the development of hybrid energy devices, marking a significant milestone in the evolution of energy storage and conversion technologies. The journey of PVDF in this field began with its discovery in the mid-20th century, but its potential in energy applications has only been fully recognized in recent decades. As research progressed, scientists and engineers identified PVDF's unique properties, including its high dielectric constant, excellent mechanical strength, and remarkable piezoelectric characteristics, which make it particularly suitable for hybrid energy systems.

The technological trajectory of PVDF in hybrid energy devices has been characterized by continuous improvements in material synthesis, processing techniques, and device integration. Initially, PVDF was primarily used in simple capacitor applications. However, as the demand for more efficient and versatile energy solutions grew, researchers began exploring its potential in more complex hybrid systems that combine multiple energy harvesting and storage mechanisms.

Current trends in PVDF research for hybrid energy devices focus on enhancing its performance through various optimization strategies. These include modifying the polymer structure, incorporating nanofillers, and developing novel composite materials. The goal is to improve key parameters such as energy density, power output, and cycle life, while maintaining the material's flexibility and durability.

The objectives of optimizing PVDF in hybrid energy devices are multifaceted. Primarily, researchers aim to increase the overall energy conversion efficiency of these systems. This involves improving the piezoelectric response of PVDF to mechanical stimuli, enhancing its dielectric properties for better energy storage, and optimizing its interface with other components in hybrid devices. Additionally, there is a strong focus on developing PVDF-based materials that can operate effectively across a wide range of environmental conditions, ensuring reliability and longevity in real-world applications.

Another critical objective is to make PVDF-based hybrid energy devices more cost-effective and environmentally friendly. This includes exploring sustainable production methods, reducing the use of harmful solvents in processing, and improving the recyclability of PVDF materials at the end of their lifecycle. As the world moves towards cleaner and more sustainable energy solutions, the optimization of PVDF in hybrid energy devices aligns closely with global efforts to combat climate change and reduce dependence on fossil fuels.

In conclusion, the background and objectives of optimizing PVDF in hybrid energy devices reflect a dynamic and rapidly evolving field. The journey from its initial discovery to its current status as a key material in advanced energy systems underscores the importance of continued research and development. As we look to the future, the optimization of PVDF holds promise for creating more efficient, sustainable, and versatile hybrid energy solutions that can address the world's growing energy needs.

Market Analysis for PVDF-based Hybrid Energy Devices

The market for PVDF-based hybrid energy devices is experiencing significant growth, driven by the increasing demand for efficient and sustainable energy storage solutions. PVDF (Polyvinylidene Fluoride) has emerged as a key material in hybrid energy devices due to its excellent piezoelectric properties, chemical stability, and flexibility. These characteristics make it particularly suitable for applications in energy harvesting and storage systems.

The global market for PVDF in energy-related applications is projected to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is primarily fueled by the rising adoption of renewable energy sources and the need for advanced energy storage technologies. The automotive sector, in particular, is showing a strong interest in PVDF-based hybrid energy devices for electric and hybrid vehicles, as these materials can enhance battery performance and energy efficiency.

In the consumer electronics industry, PVDF-based hybrid energy devices are gaining traction for their ability to harvest energy from ambient vibrations and convert it into usable electrical energy. This technology is being explored for powering small electronic devices and sensors, potentially reducing the reliance on traditional batteries.

The Asia-Pacific region is expected to dominate the market for PVDF-based hybrid energy devices, with China and Japan leading in terms of production and consumption. This is largely due to the robust manufacturing base in these countries and their strong focus on renewable energy technologies. North America and Europe are also significant markets, driven by stringent environmental regulations and increasing investments in clean energy solutions.

One of the key market trends is the development of nanostructured PVDF materials, which offer enhanced performance in energy harvesting and storage applications. These advanced materials are attracting attention from both academic researchers and industry players, potentially opening new avenues for market growth.

However, the market faces challenges such as the high cost of PVDF compared to alternative materials and the complexity of integrating PVDF-based components into existing energy systems. Overcoming these barriers will be crucial for wider market adoption and continued growth in the sector.

In conclusion, the market for PVDF-based hybrid energy devices shows promising growth potential, driven by technological advancements and increasing demand for efficient energy solutions. As research and development efforts continue to optimize PVDF properties and applications, the market is likely to see further expansion and diversification in the coming years.

Current Challenges in PVDF Optimization

Despite the promising potential of PVDF in hybrid energy devices, several challenges hinder its optimization. One of the primary obstacles is the limited control over PVDF's crystalline structure. The β-phase, which exhibits the highest piezoelectric and ferroelectric properties, is crucial for energy harvesting applications. However, achieving a high percentage of β-phase without compromising other material properties remains a significant challenge.

Another hurdle is the integration of PVDF with other materials in hybrid devices. The compatibility issues between PVDF and various electrodes, substrates, or other functional layers can lead to poor interfacial adhesion and reduced device performance. This challenge is particularly pronounced when attempting to create flexible or stretchable hybrid energy devices, where maintaining structural integrity under deformation is critical.

The scalability of PVDF-based hybrid energy devices presents another major challenge. While laboratory-scale devices have shown promising results, translating these successes to large-scale, commercially viable production processes has proven difficult. Issues such as maintaining consistent film thickness, ensuring uniform properties across large areas, and developing cost-effective manufacturing techniques need to be addressed.

Furthermore, the long-term stability and reliability of PVDF in hybrid energy devices remain concerns. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can degrade PVDF's performance over time. Developing strategies to enhance the material's durability and maintain its functional properties under various operating conditions is crucial for practical applications.

The optimization of PVDF's energy harvesting efficiency is another significant challenge. While PVDF exhibits good piezoelectric properties, there is still room for improvement in terms of its energy conversion efficiency. Enhancing the material's responsiveness to mechanical stimuli and maximizing the electrical output are ongoing areas of research that require innovative approaches.

Lastly, the multifunctional nature of hybrid energy devices demands a delicate balance between different properties of PVDF. Optimizing one aspect, such as piezoelectric performance, may come at the cost of other desirable characteristics like flexibility or thermal stability. Finding the right trade-offs and developing strategies to simultaneously enhance multiple properties pose significant challenges in PVDF optimization for hybrid energy devices.

Existing PVDF Optimization Techniques

01 PVDF membrane optimization

Optimization of PVDF membranes involves improving their properties for various applications. This includes enhancing porosity, mechanical strength, and chemical resistance. Techniques such as blending with other polymers, surface modification, and controlling the crystallization process are employed to achieve desired membrane characteristics.- PVDF membrane optimization: Optimization of PVDF membranes involves improving their properties for various applications. This includes enhancing porosity, mechanical strength, and chemical resistance. Techniques such as blending with other polymers, surface modification, and controlling crystallization processes are employed to achieve desired membrane characteristics.

- PVDF-based composites for energy storage: PVDF is utilized in energy storage applications, particularly in lithium-ion batteries and supercapacitors. Optimization focuses on enhancing the dielectric properties, ionic conductivity, and electrochemical stability of PVDF-based composites. This involves incorporating various fillers, nanoparticles, or conductive materials to improve performance.

- PVDF processing techniques: Various processing techniques are employed to optimize PVDF properties. These include electrospinning for nanofiber production, solution casting for thin films, and melt processing for bulk materials. Optimization of these techniques involves controlling parameters such as temperature, solvent selection, and processing conditions to achieve desired morphology and properties.

- PVDF copolymers and blends: PVDF properties can be optimized through copolymerization or blending with other polymers. This approach allows for tailoring of characteristics such as flexibility, thermal stability, and piezoelectric properties. Common copolymers include PVDF-HFP and PVDF-TrFE, while blends may incorporate polymers like PMMA or PVA to enhance specific properties.

- Surface modification of PVDF: Surface modification techniques are employed to optimize PVDF surface properties for specific applications. These methods include plasma treatment, grafting, and chemical functionalization. Such modifications can enhance hydrophilicity, biocompatibility, or adhesion properties of PVDF materials, expanding their potential uses in various fields.

02 PVDF-based composites for energy storage

PVDF is utilized in energy storage applications, particularly in the development of advanced battery separators and electrodes. Optimization focuses on improving the electrochemical performance, thermal stability, and ionic conductivity of PVDF-based composites. This involves incorporating various additives and nanofillers to enhance the overall energy storage capabilities.Expand Specific Solutions03 PVDF processing techniques

Various processing techniques are employed to optimize PVDF properties for specific applications. These include solution casting, electrospinning, phase inversion, and melt processing. The optimization of these techniques aims to control the morphology, crystallinity, and overall performance of PVDF-based materials.Expand Specific Solutions04 PVDF copolymers and blends

The development of PVDF copolymers and blends is a key area of optimization. By incorporating other monomers or blending with compatible polymers, the properties of PVDF can be tailored for specific applications. This approach allows for the enhancement of characteristics such as flexibility, adhesion, and thermal stability.Expand Specific Solutions05 Surface modification of PVDF

Surface modification techniques are employed to optimize the surface properties of PVDF materials. These methods include plasma treatment, grafting, and chemical functionalization. The goal is to improve characteristics such as hydrophilicity, biocompatibility, and fouling resistance, particularly for membrane and coating applications.Expand Specific Solutions

Key Players in PVDF and Hybrid Energy Sector

The optimization of PVDF in hybrid energy devices is currently in a growth phase, with increasing market size and technological advancements. The global market for PVDF in energy applications is expanding, driven by the rising demand for efficient energy storage solutions. Technologically, the field is progressing rapidly, with various levels of maturity observed among key players. Companies like DuPont de Nemours, Inc. and LG Energy Solution Ltd. are at the forefront, leveraging their extensive R&D capabilities. Academic institutions such as Xi'an Jiaotong University and Nanyang Technological University are contributing significant research. State Grid Corp. of China and Samsung Electro-Mechanics Co., Ltd. are also making notable strides in practical applications, indicating a competitive and diverse landscape in PVDF optimization for hybrid energy devices.

DuPont de Nemours, Inc.

Samsung Electro-Mechanics Co., Ltd.

Innovative PVDF Formulations and Structures

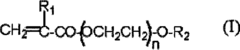

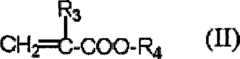

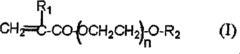

- A copolymer of a nitrile group-containing monomer, a soft and flexible oxygen-containing ethylene skeleton monomer with a long chain length, and a highly adhesive carboxyl group-containing monomer is used as a non-aqueous electrolyte-based energy device electrode. The binder resin composition optimizes the adhesion to the current collector and the swelling resistance of the electrolyte.

- A hybrid binder composition combining ethylene copolymers with halogenated polymers like PVDF, enhancing flexibility, adhesion, and processability through the formation of interpenetrating networks or polymeric blends, which can be easily processed in existing lithium ion battery systems without the need for curing agents or crosslinking.

Environmental Impact of PVDF in Energy Devices

The environmental impact of PVDF (polyvinylidene fluoride) in hybrid energy devices is a critical consideration as these technologies become more prevalent. PVDF, while offering excellent performance characteristics, presents several environmental challenges throughout its lifecycle.

During the production phase, the synthesis of PVDF involves the use of fluorine-containing compounds, which can contribute to greenhouse gas emissions if not properly managed. The manufacturing process also requires significant energy input, potentially increasing the carbon footprint of the final product. Additionally, the use of solvents in PVDF production can lead to air and water pollution if strict environmental controls are not implemented.

In the operational phase of hybrid energy devices, PVDF demonstrates high durability and chemical resistance, which contributes to the longevity of these systems. This extended lifespan can be seen as a positive environmental attribute, as it reduces the need for frequent replacements and the associated resource consumption. However, the very properties that make PVDF desirable in these applications also pose challenges for end-of-life management.

The disposal and recycling of PVDF-containing devices present significant environmental concerns. PVDF is not biodegradable and can persist in the environment for extended periods. When incinerated, it may release harmful substances, including hydrogen fluoride, which can contribute to air pollution and pose health risks. Recycling PVDF is technically challenging due to its high chemical resistance, often resulting in downcycling rather than true recycling.

Furthermore, the potential for PVDF to shed microplastics during its use in energy devices is an emerging environmental concern. These microscopic particles can enter ecosystems, potentially impacting wildlife and entering the food chain. The long-term effects of PVDF microplastics on the environment are not yet fully understood and require further research.

To mitigate these environmental impacts, several strategies are being explored. These include developing more environmentally friendly production methods for PVDF, improving end-of-life recycling technologies, and investigating bio-based alternatives that could offer similar performance with reduced environmental impact. Additionally, design for disassembly and recycling is becoming increasingly important in the development of hybrid energy devices to facilitate more effective material recovery at the end of the product's life.

In conclusion, while PVDF offers significant benefits in hybrid energy devices, its environmental impact throughout the lifecycle must be carefully managed. Balancing the performance advantages with environmental considerations will be crucial for the sustainable development of these technologies in the future.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for optimizing PVDF in hybrid energy devices are crucial for the successful implementation and commercialization of this technology. As the demand for high-performance energy storage and conversion systems continues to grow, the ability to scale up production while maintaining quality and cost-effectiveness becomes paramount.

One of the primary challenges in scaling PVDF production for hybrid energy devices is maintaining consistent material properties across large batches. The molecular weight distribution, crystallinity, and morphology of PVDF can significantly impact its performance in energy applications. To address this, manufacturers must develop robust quality control processes and implement advanced characterization techniques to ensure uniformity in large-scale production.

Another critical aspect of scalability is the development of efficient and cost-effective synthesis methods. Traditional polymerization techniques may not be suitable for high-volume production, necessitating the exploration of alternative approaches such as continuous flow reactors or microwave-assisted synthesis. These methods can potentially reduce reaction times, improve yield, and minimize waste, making them more amenable to industrial-scale manufacturing.

The processing of PVDF into functional components for hybrid energy devices also presents scalability challenges. Techniques such as electrospinning, which is often used to create high-surface-area PVDF membranes, may require significant optimization and equipment redesign to achieve high-throughput production. Similarly, the development of automated and continuous processes for film casting, coating, and patterning of PVDF materials is essential for large-scale manufacturing.

Environmental considerations and sustainability are increasingly important factors in manufacturing processes. As production scales up, it becomes crucial to implement green chemistry principles and develop recycling strategies for PVDF materials. This may involve the use of environmentally friendly solvents, the optimization of energy consumption during synthesis and processing, and the establishment of closed-loop recycling systems for production waste and end-of-life products.

The integration of PVDF components into hybrid energy devices at scale also requires careful consideration of assembly processes and quality control measures. Automated assembly lines with in-line testing and characterization capabilities can help ensure consistent performance across large production volumes. Additionally, the development of standardized interfaces and modular designs can facilitate easier integration and maintenance of PVDF components in various energy device configurations.