How To Melt PVDF?

PVDF Melting Background

Polyvinylidene fluoride (PVDF) is a highly versatile fluoropolymer known for its exceptional chemical resistance, thermal stability, and mechanical properties. The melting of PVDF is a crucial process in various industrial applications, including the production of films, membranes, and coatings. Understanding the background of PVDF melting is essential for optimizing processing conditions and achieving desired material properties.

PVDF was first synthesized in the 1940s by Dupont researchers, but its commercial production and widespread use began in the 1960s. The polymer's unique combination of properties, such as high dielectric strength, piezoelectricity, and resistance to UV radiation, has made it invaluable in industries ranging from electronics to chemical processing.

The melting behavior of PVDF is influenced by its molecular structure and crystallinity. PVDF typically exists in several crystalline forms, with the most common being the α, β, and γ phases. The α-phase is the most thermodynamically stable and is formed under normal processing conditions. The β-phase, which exhibits the strongest piezoelectric and ferroelectric properties, can be obtained through specific processing techniques or by applying mechanical stress to the α-phase.

The melting point of PVDF varies depending on its molecular weight and crystalline structure, but it generally falls within the range of 155-192°C (311-378°F). This relatively high melting point contributes to PVDF's excellent thermal stability and makes it suitable for applications requiring resistance to high temperatures.

Melting PVDF involves overcoming the intermolecular forces that hold the polymer chains together in the crystalline regions. As heat is applied, the polymer chains gain kinetic energy, causing them to vibrate more vigorously. This increased motion eventually overcomes the attractive forces between chains, leading to the breakdown of the crystalline structure and the transition to a molten state.

The melting process of PVDF is not instantaneous but occurs over a temperature range. This is due to the presence of crystals with varying sizes and perfection within the polymer matrix. Smaller or less perfect crystals tend to melt at lower temperatures, while larger, more perfect crystals require higher temperatures to fully melt.

Understanding the melting behavior of PVDF is crucial for processing and application development. The melting characteristics affect various properties of the final product, including mechanical strength, chemical resistance, and electrical performance. Proper control of the melting process is essential for achieving the desired crystalline structure and optimizing the material's properties for specific applications.

In recent years, research has focused on modifying PVDF's melting behavior through techniques such as blending with other polymers, incorporating nanofillers, or using nucleating agents. These approaches aim to tailor the melting characteristics and crystallization behavior to enhance specific properties or improve processability for various applications.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) melting solutions has been steadily increasing across various industries due to the unique properties and versatile applications of this thermoplastic fluoropolymer. PVDF's exceptional chemical resistance, thermal stability, and mechanical strength make it a sought-after material in sectors such as chemical processing, oil and gas, electronics, and renewable energy.

In the chemical processing industry, there is a growing need for PVDF melting techniques to produce corrosion-resistant piping, valves, and fittings. The ability to melt and shape PVDF into these components allows manufacturers to create durable and long-lasting equipment for handling aggressive chemicals and solvents. This demand is driven by the expansion of chemical manufacturing facilities and the increasing focus on safety and reliability in industrial processes.

The oil and gas sector represents another significant market for PVDF melting solutions. As exploration and production activities extend to more challenging environments, there is a rising demand for PVDF-based liners, coatings, and components that can withstand harsh conditions. The ability to melt and apply PVDF effectively is crucial for protecting equipment from corrosion and extending its operational life in offshore and onshore installations.

In the electronics industry, the miniaturization trend and the need for high-performance materials have led to increased interest in PVDF melting techniques. The polymer's piezoelectric and ferroelectric properties make it valuable for manufacturing sensors, transducers, and capacitors. As consumer electronics and IoT devices become more sophisticated, the demand for precisely melted and formed PVDF components is expected to grow.

The renewable energy sector, particularly in solar panel manufacturing, has emerged as a significant driver of PVDF melting demand. PVDF backsheets are essential for protecting solar cells from environmental factors and ensuring long-term performance. The ability to melt and extrude PVDF into thin, uniform sheets is critical for producing high-quality solar panels that can withstand decades of outdoor exposure.

Market analysts project that the global PVDF market, including melting applications, will continue to expand at a compound annual growth rate of over 6% in the coming years. This growth is attributed to the increasing adoption of PVDF in emerging applications such as water treatment membranes, lithium-ion battery components, and advanced coatings for architectural purposes.

The demand for innovative PVDF melting solutions is also driven by sustainability concerns and regulatory pressures. As industries seek to reduce their environmental footprint, there is a growing interest in developing more energy-efficient and environmentally friendly methods for melting and processing PVDF. This trend is likely to spur research and development efforts in optimizing melting techniques and equipment.

PVDF Melting Challenges

Polyvinylidene fluoride (PVDF) is a highly versatile fluoropolymer known for its excellent chemical resistance, thermal stability, and piezoelectric properties. However, melting PVDF presents several significant challenges due to its unique molecular structure and thermal characteristics.

One of the primary difficulties in melting PVDF is its high melting point, which typically ranges from 155°C to 192°C, depending on the specific grade and crystallinity. This high melting temperature necessitates specialized equipment capable of reaching and maintaining these elevated temperatures without degrading the polymer.

The thermal stability of PVDF is both an advantage and a challenge in the melting process. While it allows the material to withstand high temperatures, it also means that the processing window is relatively narrow. Overheating can lead to thermal degradation, resulting in the release of harmful fluorine-containing compounds and compromising the material's properties.

Another significant challenge is the tendency of PVDF to undergo thermal crosslinking during the melting process. This can lead to gel formation and increased viscosity, making it difficult to achieve a uniform melt and potentially causing processing issues in subsequent manufacturing steps.

The high melt viscosity of PVDF poses additional challenges. Even when successfully melted, the material can be difficult to flow and shape, requiring high pressures and specialized processing techniques. This characteristic can limit the range of processing methods available and increase the complexity of manufacturing processes.

Moisture sensitivity is another factor that complicates the melting of PVDF. The presence of moisture can lead to hydrolysis reactions at high temperatures, potentially degrading the polymer and affecting its properties. Thorough drying of the material before processing is often necessary to mitigate this issue.

The crystalline nature of PVDF adds another layer of complexity to the melting process. The polymer's crystalline regions require more energy to melt compared to amorphous regions, leading to non-uniform melting behavior. This can result in inconsistencies in the final product and difficulties in achieving precise control over the melting process.

Addressing these challenges often requires a combination of specialized equipment, carefully controlled processing conditions, and potentially the use of additives or copolymers to modify the melting behavior of PVDF. Researchers and manufacturers continue to explore innovative approaches to overcome these obstacles, aiming to expand the applications and processing capabilities of this valuable polymer.

Current PVDF Melting Methods

01 PVDF membrane applications

PVDF membranes are widely used in various applications due to their excellent chemical resistance, mechanical strength, and thermal stability. They are commonly employed in water treatment, filtration processes, and separation technologies. PVDF membranes can be modified to enhance their performance in specific applications, such as improving hydrophilicity or adding antimicrobial properties.- PVDF membrane applications: PVDF membranes are widely used in various applications due to their excellent chemical resistance and mechanical properties. They are commonly employed in water treatment, filtration systems, and separation processes. PVDF membranes can be modified to enhance their performance in specific applications.

- PVDF in energy storage devices: PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. It serves as a binder material for electrode components, improving the stability and performance of these devices. PVDF-based separators are also developed to enhance safety and efficiency in energy storage applications.

- PVDF composites and blends: PVDF is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or introduce new functionalities such as piezoelectric or ferroelectric properties. PVDF composites find applications in sensors, actuators, and smart materials.

- PVDF in coating technologies: PVDF-based coatings are developed for various surfaces to provide protection against corrosion, weathering, and chemical attack. These coatings are particularly useful in architectural applications, industrial equipment, and marine environments. The durability and UV resistance of PVDF coatings make them suitable for long-term exterior use.

- PVDF processing and modification techniques: Various processing and modification techniques are employed to tailor PVDF properties for specific applications. These include surface modification, blending with other polymers, incorporation of nanoparticles, and controlled crystallization. Such modifications can enhance properties like hydrophobicity, conductivity, or biocompatibility of PVDF materials.

02 PVDF in energy storage devices

PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. It serves as a binder material for electrode components, enhancing the stability and performance of these devices. PVDF-based separators are also developed to improve the safety and efficiency of energy storage systems.Expand Specific Solutions03 PVDF composites and blends

PVDF is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or introduce new functionalities such as piezoelectric or ferroelectric properties. PVDF composites find applications in sensors, actuators, and smart materials.Expand Specific Solutions04 PVDF processing techniques

Various processing techniques are employed to fabricate PVDF-based materials and products. These include electrospinning, solution casting, melt extrusion, and phase inversion. Each technique offers unique advantages in terms of controlling the morphology, crystallinity, and properties of the resulting PVDF structures.Expand Specific Solutions05 PVDF surface modification

Surface modification of PVDF is often performed to tailor its properties for specific applications. Techniques such as plasma treatment, grafting, and chemical modification are used to alter surface characteristics like hydrophilicity, adhesion, or biocompatibility. These modifications expand the range of applications for PVDF materials.Expand Specific Solutions

Key PVDF Manufacturers

The market for PVDF melting technology is in a growth phase, driven by increasing demand in various industries. The global PVDF market size is projected to expand significantly, with key players like Arkema, Solvay, and Kuraray leading the field. The technology's maturity varies across applications, with established processes in chemical processing and emerging innovations in advanced materials. Companies such as Evonik and Honeywell are investing in R&D to enhance PVDF melting techniques, while academic institutions like Shandong University and Fuzhou University are contributing to fundamental research. The competitive landscape is characterized by a mix of large chemical corporations and specialized materials companies, with ongoing efforts to improve efficiency and develop novel applications for melted PVDF.

Arkema France SA

Kuraray Co., Ltd.

Innovative PVDF Melting Techniques

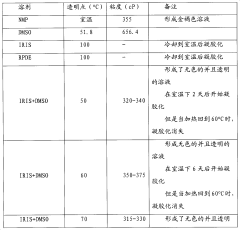

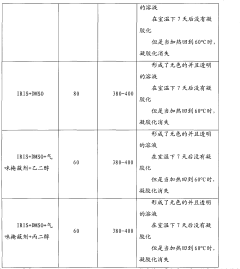

- A solvent blend containing diesters and dimethyl sulfoxide, combined with possible odor masking agents and antifreeze, is used to solubilize the fluoropolymer, resulting in a composition with a low freezing point and good solvency, avoiding the need for CMR chemicals of use.

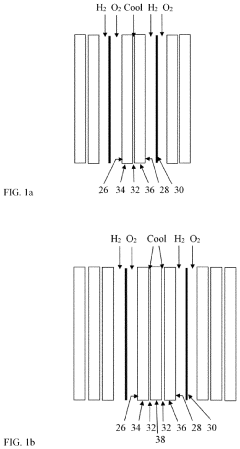

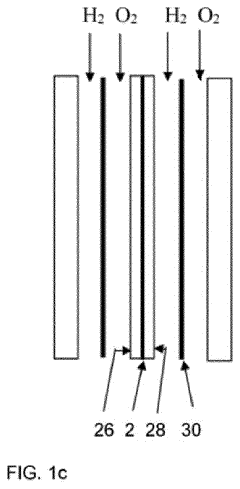

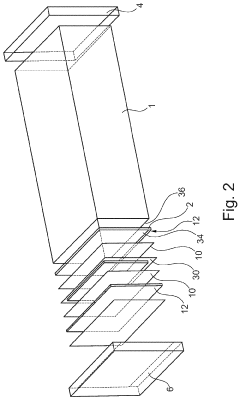

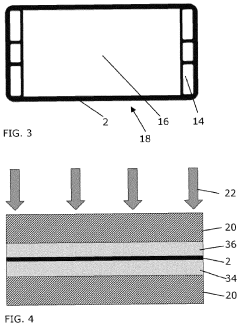

- A polymer adhesive made from thermoplastic fluoropolymers, specifically polyvinylidene difluoride (PVDF) and its co-polymers, is used to create a durable and impermeable bonding layer between plates, which is mixed with solvents and surfactants to form a homogeneous liquid mixture that can be applied at room temperature and cured under pressure, ensuring strong adhesion and thermal stability.

Environmental Impact of PVDF Melting

The melting process of Polyvinylidene Fluoride (PVDF) has significant environmental implications that warrant careful consideration. During the melting of PVDF, which typically occurs at temperatures between 160°C and 180°C, various environmental concerns arise. One primary issue is the potential release of harmful emissions, particularly hydrogen fluoride (HF), a toxic and corrosive gas. The production of HF can occur if PVDF is heated beyond its thermal stability limit or if it comes into contact with moisture during the melting process.

These emissions not only pose risks to human health but also contribute to air pollution and potential damage to the ozone layer. To mitigate these environmental impacts, proper ventilation systems and emission control technologies must be implemented in facilities where PVDF melting occurs. Additionally, the energy consumption required for the melting process contributes to greenhouse gas emissions, especially if the energy source is not renewable.

Water pollution is another environmental concern associated with PVDF melting. Cooling water used in the process may become contaminated with fluoride compounds, requiring proper treatment before discharge. If not managed correctly, this can lead to the contamination of water bodies and harm aquatic ecosystems.

The disposal of PVDF waste generated during the melting process also presents environmental challenges. While PVDF is recyclable, the recycling process itself can be energy-intensive and may produce additional emissions. Improper disposal of PVDF waste in landfills can lead to soil contamination and potential leaching of fluoride compounds into groundwater.

To address these environmental concerns, several strategies can be employed. The use of closed-loop systems for melting PVDF can significantly reduce emissions and minimize waste. Implementing energy-efficient melting technologies and utilizing renewable energy sources can help decrease the carbon footprint associated with the process. Furthermore, developing and adopting more environmentally friendly alternatives to PVDF or improving its recyclability can contribute to long-term sustainability in industries that rely on this material.

Research into green chemistry approaches for PVDF processing is ongoing, with efforts focused on developing less harmful additives and more eco-friendly production methods. These advancements aim to reduce the environmental impact of PVDF melting while maintaining the material's desirable properties for various applications.

PVDF Melting Safety Protocols

When melting PVDF (Polyvinylidene Fluoride), strict safety protocols must be followed to ensure the protection of personnel and equipment. The melting process typically occurs at temperatures between 170°C and 230°C, depending on the specific grade of PVDF. Due to the high temperatures involved, proper personal protective equipment (PPE) is essential. This includes heat-resistant gloves, safety goggles, and flame-resistant clothing.

Adequate ventilation is crucial during the melting process. PVDF can release hydrogen fluoride gas when overheated, which is highly toxic and corrosive. Therefore, the melting should be performed in a well-ventilated area or under a fume hood. It is advisable to install gas detection systems to monitor for any potential release of harmful vapors.

Temperature control is a critical aspect of PVDF melting safety. The use of precise temperature-controlled equipment, such as extruders or injection molding machines, is necessary to prevent overheating. Regular calibration and maintenance of these devices ensure accurate temperature readings and consistent performance. It is important to avoid rapid temperature changes, as thermal shock can lead to material degradation or equipment damage.

Fire safety measures are paramount when working with molten PVDF. The material is combustible at high temperatures, so fire extinguishing equipment should be readily available. Class D fire extinguishers, specifically designed for combustible metals, are recommended. Additionally, implementing a hot work permit system for any operations involving open flames or high heat sources in the vicinity of PVDF processing areas can help prevent accidents.

Proper material handling and storage procedures are essential components of PVDF melting safety protocols. PVDF should be stored in a cool, dry place away from direct sunlight and heat sources. Before melting, the material should be dried according to manufacturer specifications to remove any moisture, which can cause processing issues and potentially dangerous steam formation during melting.

Emergency response planning is a crucial element of PVDF melting safety. This includes establishing clear evacuation procedures, designating emergency assembly points, and training personnel in first aid specific to thermal burns and chemical exposure. Regular safety drills and updates to emergency protocols ensure that all staff members are prepared to respond effectively in case of an incident.

Lastly, comprehensive documentation and record-keeping of all safety procedures, incidents, and near-misses are essential for continuous improvement of safety protocols. Regular safety audits and reviews of melting processes can help identify potential hazards and implement preventive measures, ensuring the ongoing safety of PVDF melting operations.