How to Implement PVDF in Environmentally Friendly Products?

PVDF Technology Evolution and Objectives

Polyvinylidene fluoride (PVDF) has undergone significant technological evolution since its discovery in 1948. Initially developed as a high-performance thermoplastic, PVDF has found applications in various industries due to its unique properties, including chemical resistance, thermal stability, and piezoelectric characteristics. The technology's evolution has been driven by the increasing demand for advanced materials in sectors such as electronics, energy, and environmental protection.

In recent years, the focus of PVDF technology has shifted towards its implementation in environmentally friendly products. This shift aligns with global sustainability goals and the growing awareness of environmental issues. The primary objective of current PVDF research and development is to enhance its eco-friendly attributes while maintaining its superior performance characteristics.

One of the key evolutionary trends in PVDF technology is the development of bio-based and recyclable PVDF formulations. Researchers are exploring ways to incorporate renewable resources into PVDF production, reducing reliance on petroleum-based raw materials. This approach aims to decrease the carbon footprint associated with PVDF manufacturing and improve its end-of-life recyclability.

Another significant objective in PVDF technology evolution is the optimization of its properties for specific environmental applications. For instance, PVDF membranes are being developed with enhanced filtration capabilities for water treatment and air purification systems. These advancements contribute to more efficient and sustainable environmental protection solutions.

The integration of PVDF in energy-efficient technologies is also a key focus area. Researchers are working on improving PVDF's piezoelectric properties for energy harvesting applications, such as in wearable devices and smart textiles. This development aims to create self-powered, environmentally friendly products that reduce overall energy consumption.

Furthermore, the evolution of PVDF technology includes efforts to minimize its environmental impact during production and use. This involves developing cleaner manufacturing processes, reducing harmful emissions, and improving the material's durability to extend product lifespans. The goal is to create PVDF-based products that are not only functional but also align with circular economy principles.

In conclusion, the evolution of PVDF technology and its objectives are closely tied to environmental considerations. The focus has shifted from merely exploiting PVDF's unique properties to developing sustainable, eco-friendly applications. As research progresses, the aim is to position PVDF as a key material in the creation of environmentally responsible products across various industries.

Eco-Friendly PVDF Market Analysis

The market for eco-friendly PVDF (Polyvinylidene Fluoride) products has been experiencing significant growth in recent years, driven by increasing environmental awareness and stringent regulations on sustainable materials. PVDF, known for its durability, chemical resistance, and versatility, is finding new applications in environmentally conscious industries.

The global eco-friendly PVDF market is primarily segmented into coatings, membranes, and films. In the coatings sector, PVDF is gaining traction as a sustainable alternative to traditional materials, particularly in architectural and automotive applications. The demand for PVDF-based coatings is rising due to their long-lasting properties, which reduce the need for frequent repainting and maintenance, thereby lowering the overall environmental impact.

In the membrane segment, PVDF is increasingly used in water treatment and filtration systems. The growing need for clean water solutions worldwide is driving the adoption of PVDF membranes, which offer excellent chemical resistance and fouling resistance. This application aligns well with global sustainability goals and contributes to the circular economy by enabling efficient water recycling and reuse.

The films sector is another area where eco-friendly PVDF is making strides. PVDF films are being utilized in solar panel backsheets, enhancing the durability and efficiency of photovoltaic systems. As the renewable energy sector expands, the demand for PVDF in this application is expected to grow substantially.

Geographically, North America and Europe are leading the eco-friendly PVDF market, owing to strict environmental regulations and a strong focus on sustainable development. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The market is characterized by ongoing research and development efforts to enhance the eco-friendly properties of PVDF. Manufacturers are focusing on developing bio-based precursors and improving recycling techniques to make PVDF more sustainable throughout its lifecycle. This trend is likely to open up new opportunities and applications for eco-friendly PVDF products in the coming years.

Despite the positive outlook, challenges remain in the widespread adoption of eco-friendly PVDF. The higher cost compared to conventional materials and the need for specialized processing techniques are potential barriers. However, as economies of scale improve and technology advances, these challenges are expected to diminish, further boosting market growth.

PVDF Environmental Challenges

Polyvinylidene fluoride (PVDF) has gained significant attention in various industries due to its unique properties, including chemical resistance, thermal stability, and piezoelectric characteristics. However, the implementation of PVDF in environmentally friendly products faces several challenges that need to be addressed to ensure sustainable development and minimize ecological impact.

One of the primary environmental concerns associated with PVDF is its production process. The synthesis of PVDF typically involves the use of fluorinated compounds, which can contribute to greenhouse gas emissions and ozone depletion. The manufacturing process also requires significant energy input, leading to a substantial carbon footprint. These factors pose challenges in aligning PVDF production with environmentally friendly practices and regulations.

The durability and chemical resistance of PVDF, while beneficial for many applications, present challenges in terms of biodegradability and end-of-life management. PVDF products can persist in the environment for extended periods, potentially contributing to plastic pollution. The difficulty in recycling PVDF materials further exacerbates this issue, as conventional recycling methods may not be suitable for processing PVDF waste effectively.

Another environmental challenge lies in the potential release of fluorinated compounds during the use and disposal of PVDF products. While PVDF itself is considered relatively inert, there are concerns about the potential leaching of harmful substances, particularly when exposed to extreme conditions or during degradation processes. This raises questions about the long-term environmental impact of PVDF-containing products and their potential effects on ecosystems and human health.

The use of PVDF in water treatment applications, such as membranes for filtration systems, presents a paradox. While these applications contribute to environmental protection by improving water quality, the production and disposal of PVDF membranes can have negative environmental implications. Balancing the benefits of PVDF in water treatment with its environmental footprint remains a significant challenge.

To address these environmental challenges, research efforts are focusing on developing more sustainable production methods for PVDF, including the use of green chemistry principles and renewable energy sources. Additionally, there is growing interest in exploring bio-based alternatives or modified PVDF formulations that maintain the desired properties while improving environmental compatibility.

Efforts are also being made to enhance the recyclability and end-of-life management of PVDF products. This includes developing advanced recycling technologies specifically tailored for fluoropolymers and investigating potential applications for recycled PVDF materials. Furthermore, life cycle assessments are being conducted to better understand and mitigate the environmental impact of PVDF throughout its entire lifecycle.

Green PVDF Implementation Strategies

01 PVDF membrane fabrication and modification

Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance. This includes methods for improving membrane porosity, hydrophilicity, and fouling resistance through surface treatments, blending with other polymers, or incorporating nanoparticles.- PVDF membrane fabrication and modification: Various techniques for fabricating and modifying PVDF membranes to enhance their properties and performance in applications such as filtration, separation, and energy storage. This includes methods for improving membrane porosity, hydrophilicity, and mechanical strength through surface treatments, blending with other polymers, or incorporating nanoparticles.

- PVDF-based piezoelectric and energy harvesting devices: Development of piezoelectric devices and energy harvesters using PVDF and its copolymers. These materials are utilized for their excellent piezoelectric properties to convert mechanical energy into electrical energy, with applications in sensors, actuators, and small-scale power generation systems.

- PVDF in battery and supercapacitor applications: Utilization of PVDF as a binder material in lithium-ion batteries and supercapacitors. PVDF's chemical stability, adhesion properties, and ability to form porous structures make it suitable for improving electrode performance and overall energy storage device efficiency.

- PVDF-based coatings and surface treatments: Development of PVDF-based coatings and surface treatments for various substrates to impart properties such as chemical resistance, weatherability, and self-cleaning capabilities. These coatings find applications in architecture, automotive, and industrial sectors.

- PVDF in composite materials and blends: Incorporation of PVDF into composite materials and polymer blends to create materials with enhanced properties such as improved mechanical strength, thermal stability, and chemical resistance. These composites find applications in aerospace, automotive, and industrial sectors.

02 PVDF in energy storage applications

Utilization of PVDF in energy storage devices, particularly in lithium-ion batteries and supercapacitors. PVDF is used as a binder material for electrode fabrication, separator membrane, or as a component in solid electrolytes to improve battery performance and safety.Expand Specific Solutions03 PVDF-based piezoelectric materials

Development of PVDF and its copolymers as piezoelectric materials for various applications. This includes methods for enhancing the piezoelectric properties of PVDF through copolymerization, blending, or incorporation of nanofillers, as well as fabrication techniques for piezoelectric devices.Expand Specific Solutions04 PVDF in water treatment and filtration

Application of PVDF membranes in water treatment and filtration processes. This includes the development of PVDF-based ultrafiltration and microfiltration membranes with improved antifouling properties, chemical resistance, and separation efficiency for various water purification applications.Expand Specific Solutions05 PVDF composites and blends

Creation of PVDF-based composites and blends with other materials to enhance specific properties. This includes the development of PVDF nanocomposites with improved mechanical, thermal, or electrical properties, as well as PVDF blends with other polymers for tailored performance in various applications.Expand Specific Solutions

Key PVDF Industry Players

The implementation of PVDF in environmentally friendly products is in a growth phase, with increasing market size due to rising demand for sustainable materials. The technology's maturity varies across applications, with some sectors more advanced than others. Key players like Arkema, Inc., Wanhua Chemical Group Co., Ltd., and Kureha Corp. are driving innovation in this field. Academic institutions such as Nanjing Tech University and Beijing University of Chemical Technology are contributing to research and development. The competitive landscape is diverse, with both established chemical companies and emerging specialized firms like Shandong Huaxia Shenzhou New Materials Co. Ltd. and Shanghai Huayi 3F New Materials Co., Ltd. actively participating in the market.

Arkema, Inc.

Wanhua Chemical Group Co., Ltd.

Innovative PVDF Eco-Solutions

- The use of polyvinylidene fluoride (PVDF) as the outermost backsheet layer in photovoltaic modules, which can be coextruded, laminated, or applied as a solvent or aqueous coating, providing improved adhesion and eliminating the need for adhesive layers or surface treatments, and can be functionalized for enhanced performance.

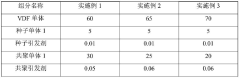

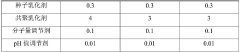

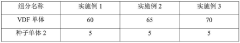

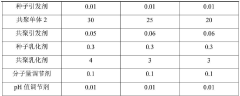

- The water-based PVDF resin dispersion emulsion is prepared using a free radical copolymerization method. A 'core-shell' structure is formed through prepolymerization of seed monomers and copolymerization of comonomers. Specific emulsifiers and initiators are combined to control the polymerization reaction conditions to achieve a stable water dispersion system.

PVDF Lifecycle Assessment

The lifecycle assessment of PVDF (Polyvinylidene Fluoride) is crucial for implementing this versatile polymer in environmentally friendly products. PVDF's lifecycle begins with the extraction of raw materials, primarily vinylidene fluoride monomer, which is derived from chlorodifluoromethane. The production process involves polymerization, typically through emulsion or suspension methods, followed by various finishing steps to achieve the desired form and properties.

During the manufacturing phase, energy consumption and potential emissions are key considerations. PVDF production requires significant energy input, particularly for polymerization and drying processes. However, advancements in manufacturing technologies have led to more efficient production methods, reducing overall energy requirements and minimizing waste generation.

The use phase of PVDF products is characterized by their long lifespan and durability. PVDF's resistance to chemicals, UV radiation, and weathering contributes to extended product life, reducing the need for frequent replacements. This longevity is particularly beneficial in applications such as architectural coatings, solar panel components, and water treatment membranes, where prolonged performance is essential for sustainability.

End-of-life considerations for PVDF products present both challenges and opportunities. While PVDF is not biodegradable, it is recyclable through mechanical and chemical processes. Mechanical recycling involves grinding and reprocessing PVDF waste into new products, while chemical recycling can break down PVDF into its constituent monomers for reuse in new polymer production. However, the collection and sorting of PVDF waste remain significant hurdles in achieving widespread recycling.

The environmental impact of PVDF throughout its lifecycle is a complex issue. While its production does involve fluorine-based chemicals and energy-intensive processes, the polymer's durability and performance in various applications can offset these initial environmental costs. For instance, PVDF's use in energy-efficient building materials and renewable energy technologies contributes to long-term environmental benefits.

To enhance the environmental profile of PVDF, ongoing research focuses on developing bio-based alternatives for raw materials, improving production efficiencies, and advancing recycling technologies. These efforts aim to create a more circular economy for PVDF, reducing its overall environmental footprint while maintaining its valuable properties for sustainable applications.

Regulatory Framework for Eco-PVDF Products

The regulatory framework for eco-PVDF products is a critical aspect of implementing PVDF in environmentally friendly applications. As governments and international organizations increasingly prioritize sustainability, manufacturers must navigate a complex landscape of regulations and standards.

At the global level, the United Nations Environment Programme (UNEP) has established guidelines for sustainable production and consumption, which indirectly influence the development of eco-PVDF products. These guidelines emphasize the importance of life cycle assessments and the reduction of environmental impacts throughout the product's lifespan.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation plays a significant role in governing the use of PVDF in eco-friendly products. REACH requires manufacturers to register chemicals and demonstrate their safe use, which has led to increased scrutiny of PVDF and its potential environmental impacts.

The EU's Restriction of Hazardous Substances (RoHS) Directive also affects the implementation of PVDF in certain applications, particularly in electronic and electrical equipment. While PVDF itself is not currently restricted under RoHS, manufacturers must ensure that any additives or processing aids used in eco-PVDF products comply with the directive's requirements.

In the United States, the Environmental Protection Agency (EPA) regulates the use of fluoropolymers, including PVDF, under the Toxic Substances Control Act (TSCA). The EPA has implemented a PFAS Action Plan, which includes increased monitoring and potential restrictions on per- and polyfluoroalkyl substances, a category that encompasses some PVDF precursors.

Many countries have adopted eco-labeling schemes that set criteria for environmentally friendly products. For instance, the EU Ecolabel and the Nordic Swan Ecolabel have specific requirements for various product categories that may incorporate PVDF. Manufacturers seeking to use these labels must demonstrate compliance with stringent environmental criteria.

The International Organization for Standardization (ISO) has developed several standards relevant to eco-PVDF products, including ISO 14001 for environmental management systems and ISO 14040 for life cycle assessment. These standards provide a framework for companies to evaluate and improve the environmental performance of their PVDF-based products.

As the regulatory landscape continues to evolve, manufacturers must stay informed about emerging regulations and proactively adapt their production processes and product designs. This may involve investing in research and development to find more sustainable alternatives or improving the recyclability and end-of-life management of PVDF products.