How to Enhance PVDF in Flexible Display Technologies?

PVDF in Flexible Displays: Background and Objectives

Polyvinylidene fluoride (PVDF) has emerged as a promising material in the realm of flexible display technologies, offering unique properties that align with the growing demand for bendable, foldable, and rollable screens. The evolution of PVDF in this context traces back to its initial applications in piezoelectric sensors and actuators, where its electroactive properties were first harnessed. As the electronics industry shifted towards more versatile and adaptable devices, PVDF's potential in flexible displays began to garner significant attention.

The primary objective in enhancing PVDF for flexible display technologies is to optimize its mechanical, electrical, and optical properties to meet the stringent requirements of next-generation display devices. This involves improving its flexibility and durability while maintaining excellent transparency and electrical conductivity. Researchers and engineers are focusing on developing PVDF-based composites and nanostructures that can withstand repeated bending and folding without compromising performance.

One of the key technological goals is to increase the β-phase content of PVDF, which is crucial for its piezoelectric and ferroelectric properties. This phase is particularly important for touch-sensitive displays and haptic feedback systems integrated into flexible screens. Additionally, efforts are being made to enhance PVDF's compatibility with other materials used in display manufacturing, such as transparent electrodes and light-emitting layers.

The development trajectory of PVDF in flexible displays is closely tied to broader trends in consumer electronics and wearable technology. As the market demands more durable, energy-efficient, and versatile devices, PVDF's role becomes increasingly significant. The material's potential to enable thinner, lighter, and more resilient displays aligns with the industry's push towards more compact and portable devices.

Research initiatives are also exploring PVDF's potential in energy harvesting applications within flexible displays. This could lead to self-powered or energy-efficient display technologies, addressing the growing concern for sustainable and long-lasting portable devices. The integration of PVDF in flexible displays represents a convergence of materials science, electronics engineering, and consumer technology, driving innovation across multiple sectors.

As we look towards the future of display technologies, enhancing PVDF's capabilities remains a critical focus. The goal is not only to improve existing flexible display applications but also to unlock new possibilities in form factor and functionality. This ongoing research and development effort promises to reshape our interaction with digital interfaces, paving the way for more intuitive, adaptable, and seamlessly integrated display solutions in our daily lives.

Market Analysis for PVDF-Enhanced Flexible Displays

The market for PVDF-enhanced flexible displays is experiencing significant growth, driven by the increasing demand for durable and versatile display technologies across various industries. PVDF (Polyvinylidene fluoride) has emerged as a key material in flexible display manufacturing due to its exceptional properties, including high flexibility, chemical resistance, and thermal stability. These characteristics make PVDF an ideal candidate for enhancing the performance and longevity of flexible displays.

The global flexible display market is projected to expand rapidly in the coming years, with PVDF-enhanced displays playing a crucial role in this growth. The automotive sector is one of the primary drivers of this market, as car manufacturers increasingly incorporate flexible displays into their vehicle designs for improved user interfaces and enhanced aesthetics. Additionally, the consumer electronics industry continues to push the boundaries of display technology, with smartphones, tablets, and wearable devices adopting flexible displays to offer innovative form factors and improved durability.

Another significant market segment for PVDF-enhanced flexible displays is the healthcare industry. Medical devices and equipment are increasingly utilizing flexible displays for their portability and adaptability in various healthcare settings. The aerospace and defense sectors are also showing growing interest in these displays due to their ability to withstand harsh environmental conditions and provide reliable performance in critical applications.

The Asia-Pacific region, particularly countries like South Korea, Japan, and China, is expected to dominate the PVDF-enhanced flexible display market. This is primarily due to the presence of major display manufacturers and the region's strong focus on technological innovation. North America and Europe are also significant markets, driven by the adoption of advanced display technologies in automotive and consumer electronics applications.

As the demand for flexible displays continues to rise, manufacturers are investing heavily in research and development to improve PVDF-based technologies. This includes efforts to enhance the material's optical properties, increase its flexibility, and develop more efficient production processes. The market is also seeing a trend towards the integration of PVDF with other advanced materials to create hybrid solutions that offer even better performance characteristics.

Despite the positive outlook, the PVDF-enhanced flexible display market faces some challenges. These include the high production costs associated with advanced materials and manufacturing processes, as well as competition from alternative flexible display technologies. However, ongoing technological advancements and economies of scale are expected to address these challenges over time, further driving market growth and adoption across various industries.

Current Challenges in PVDF Integration

The integration of Polyvinylidene Fluoride (PVDF) in flexible display technologies faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the inherent stiffness of PVDF, which can compromise the flexibility and durability of the display. This rigidity often leads to reduced bending capabilities and potential cracking or delamination when subjected to repeated flexing.

Another critical challenge lies in the processing and manufacturing of PVDF for flexible displays. The material's high melting point and limited solubility in common solvents make it difficult to process using conventional techniques. This complicates the production of thin, uniform films required for display applications, often resulting in inconsistent thickness and surface quality.

The piezoelectric properties of PVDF, while beneficial in certain applications, can pose challenges in display technologies. Uncontrolled piezoelectric responses may lead to unwanted electrical noise or interference, potentially affecting the display's performance and image quality. Mitigating these effects without compromising the material's other desirable properties remains a significant hurdle.

Adhesion issues between PVDF and other layers in the display stack present another major challenge. The low surface energy of PVDF can result in poor bonding with adjacent materials, leading to delamination and reduced device longevity. This necessitates the development of specialized adhesion promotion techniques or interface materials, adding complexity to the manufacturing process.

Thermal management is a further concern in PVDF integration. The material's relatively low thermal conductivity can lead to heat accumulation in flexible displays, potentially causing performance degradation or even device failure. Addressing this issue without compromising the display's flexibility or increasing its thickness significantly is a delicate balancing act.

Lastly, the long-term stability and reliability of PVDF in flexible display environments remain uncertain. Exposure to varying environmental conditions, including temperature fluctuations, humidity, and UV radiation, can potentially degrade the material's properties over time. Ensuring consistent performance and longevity under real-world usage scenarios is crucial for the commercial viability of PVDF-based flexible displays.

Overcoming these challenges requires a multidisciplinary approach, combining materials science, chemical engineering, and display technology expertise. Innovations in PVDF formulation, processing techniques, and integration methods are necessary to fully harness its potential in flexible display applications.

Existing PVDF Enhancement Techniques

01 Modification of PVDF polymer structure

Enhancing PVDF properties through structural modifications, such as copolymerization or blending with other polymers. This can improve mechanical strength, thermal stability, and chemical resistance of the material.- Modification of PVDF polymer structure: Enhancing PVDF properties through structural modifications, such as copolymerization or blending with other polymers. This can improve mechanical strength, thermal stability, and chemical resistance of the material.

- Surface treatment techniques: Applying various surface treatments to PVDF films or membranes to enhance their properties. These treatments can include plasma treatment, chemical etching, or grafting of functional groups to improve adhesion, wettability, or selectivity.

- Incorporation of nanofillers: Adding nanofillers such as carbon nanotubes, graphene, or metal oxide nanoparticles to PVDF to create nanocomposites. This can enhance mechanical, electrical, and thermal properties of the material.

- Electrospinning for PVDF fiber production: Utilizing electrospinning techniques to produce PVDF nanofibers with enhanced properties. This method can create high surface area fibers with improved piezoelectric and ferroelectric properties.

- PVDF-based energy harvesting devices: Developing PVDF-based materials for energy harvesting applications, such as piezoelectric generators or triboelectric nanogenerators. This involves optimizing the material's piezoelectric properties and device design for improved energy conversion efficiency.

02 Surface treatment and functionalization

Applying various surface treatments or functionalization techniques to PVDF to enhance its properties. This can include plasma treatment, chemical etching, or grafting of functional groups to improve adhesion, wettability, or specific interactions with other materials.Expand Specific Solutions03 Incorporation of nanofillers or additives

Adding nanofillers or specific additives to PVDF to enhance its properties. This can include nanoparticles, carbon nanotubes, or other nanomaterials to improve mechanical, electrical, or thermal properties of the polymer.Expand Specific Solutions04 Processing techniques for PVDF enhancement

Utilizing advanced processing techniques to enhance PVDF properties. This can include methods such as electrospinning, solution casting, or melt processing to control the crystallinity, morphology, and overall performance of the material.Expand Specific Solutions05 PVDF-based composite materials

Developing PVDF-based composite materials by combining PVDF with other polymers, fibers, or reinforcing agents. This approach can lead to synergistic effects, enhancing mechanical, thermal, or electrical properties beyond those of pure PVDF.Expand Specific Solutions

Key Players in PVDF and Flexible Display Sector

The flexible display technology market, focusing on PVDF enhancement, is in a growth phase with increasing market size and technological advancements. Major players like BOE Technology, LG Display, and Samsung Display are driving innovation in this field. The market is characterized by intense competition and rapid technological evolution, with companies like Arkema and LG Chem contributing to material development. The technology's maturity is progressing, evidenced by ongoing research and development efforts from institutions such as the Industrial Technology Research Institute and universities. As the demand for flexible displays grows across various industries, companies are investing heavily in improving PVDF properties to enhance display performance and durability.

BOE Technology Group Co., Ltd.

LG Display Co., Ltd.

Breakthrough PVDF Innovations for Displays

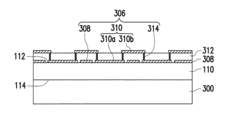

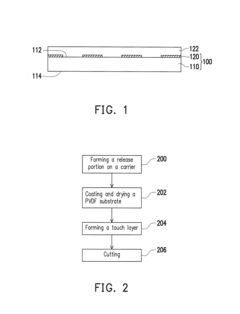

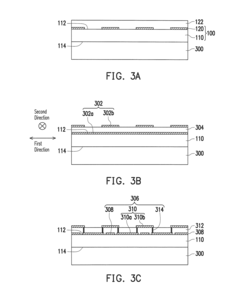

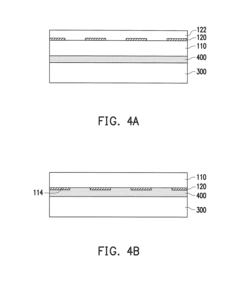

- A touch panel comprising a PVDF substrate with an inorganic nano-modified material dispersion, where the touch electrode structure is disposed on at least one surface of the PVDF substrate, and optionally a passivation layer or functional film is used to enhance optical properties and tactile feedback.

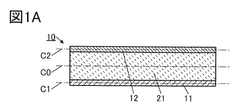

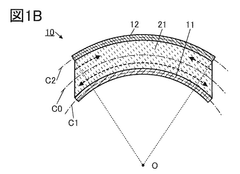

- A display device configuration with a display panel comprising a first and second film bonded by a viscoelastic adhesive layer, which has a lower bending elastic modulus than the tensile modulus, allowing for curvature without expanding or contracting, and a protective cover with a combination of flat and curved surfaces to enhance durability and reliability.

Environmental Impact of PVDF in Displays

The environmental impact of PVDF (Polyvinylidene Fluoride) in flexible display technologies is a critical consideration as the industry moves towards more sustainable practices. PVDF, while offering excellent performance characteristics, presents several environmental challenges throughout its lifecycle.

During the production phase, the synthesis of PVDF involves the use of fluorine-containing compounds, which can contribute to greenhouse gas emissions if not properly managed. The manufacturing process also requires significant energy input, potentially increasing the carbon footprint of display production. Additionally, the use of solvents in PVDF processing can lead to air and water pollution if strict control measures are not implemented.

In the usage phase, PVDF-based flexible displays generally demonstrate good durability and longevity, which can reduce the frequency of device replacement and associated electronic waste. However, the material's resistance to degradation, while beneficial for product lifespan, poses challenges for end-of-life management.

The disposal and recycling of PVDF-containing displays present significant environmental concerns. PVDF is not biodegradable and can persist in the environment for extended periods. When incinerated, it may release harmful substances, including hydrogen fluoride, which can contribute to air pollution and pose health risks. Recycling PVDF from flexible displays is technically challenging due to its integration with other materials and components, often resulting in downcycling or landfilling.

To mitigate these environmental impacts, research is focusing on developing more eco-friendly alternatives and improving PVDF's recyclability. Efforts are being made to optimize production processes to reduce energy consumption and minimize the use of harmful chemicals. Some researchers are exploring bio-based or more easily recyclable polymers that could potentially replace PVDF in certain applications.

The industry is also investigating advanced recycling technologies specifically designed for flexible displays containing PVDF. These include chemical recycling methods that can break down the polymer into its constituent monomers, allowing for the regeneration of high-quality PVDF. Additionally, design for disassembly strategies are being implemented to facilitate easier separation of PVDF from other display components at the end of the product's life.

As environmental regulations become more stringent, manufacturers are increasingly required to consider the full lifecycle impact of their products. This has led to increased investment in life cycle assessment (LCA) studies for PVDF-based displays, aiming to identify hotspots for environmental improvement and guide the development of more sustainable flexible display technologies.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for enhancing PVDF in flexible display technologies are crucial for the successful implementation and widespread adoption of this innovative material. As the demand for flexible displays continues to grow, the ability to produce PVDF-enhanced components at scale becomes increasingly important.

One of the primary challenges in scaling up PVDF production for flexible displays is maintaining consistent quality across large batches. The piezoelectric properties of PVDF, which are essential for its performance in flexible displays, can be sensitive to variations in manufacturing processes. To address this, manufacturers are developing advanced quality control systems that utilize real-time monitoring and machine learning algorithms to detect and correct deviations in the production process.

Another key consideration is the integration of PVDF into existing flexible display manufacturing lines. Many current production facilities are optimized for other materials, such as OLED or LCD components. Adapting these lines to incorporate PVDF may require significant retooling and process modifications. Manufacturers are exploring modular production systems that allow for easier integration of PVDF-related steps without disrupting the entire production flow.

The cost-effectiveness of PVDF production at scale is also a critical factor. While PVDF offers superior performance in flexible displays, it must be economically viable to compete with alternative materials. Researchers are investigating new synthesis methods and precursor materials that could reduce production costs. Additionally, economies of scale are expected to play a significant role in driving down costs as production volumes increase.

Environmental considerations in PVDF manufacturing are becoming increasingly important. The production of PVDF traditionally involves fluorine-based chemicals, which can have environmental impacts. Sustainable manufacturing practices, such as closed-loop systems for chemical recycling and the use of greener solvents, are being developed to mitigate these concerns and ensure compliance with evolving environmental regulations.

Lastly, the scalability of PVDF production must also consider the supply chain for raw materials. As demand for PVDF in flexible displays grows, securing a stable and sufficient supply of high-quality precursors becomes crucial. Manufacturers are forming strategic partnerships with suppliers and exploring alternative sources to ensure a robust supply chain that can support large-scale production.