How To Do A Dot Blot On PVDF?

Dot Blot PVDF Background

Dot blot on PVDF (polyvinylidene difluoride) is a powerful technique in molecular biology used for detecting and analyzing specific proteins or nucleic acids in complex biological samples. This method evolved from the traditional Southern and Western blotting techniques, offering a simpler and more rapid approach for qualitative and semi-quantitative analysis of biomolecules.

The dot blot technique was first introduced in the early 1980s as a simplified version of nucleic acid blotting methods. It quickly gained popularity due to its ease of use and ability to process multiple samples simultaneously. The adoption of PVDF membranes for dot blotting further enhanced the technique's capabilities, offering superior protein binding capacity and chemical resistance compared to traditional nitrocellulose membranes.

PVDF membranes were initially developed for industrial applications but found their way into biological research due to their unique properties. These membranes are characterized by their high protein binding capacity, mechanical strength, and resistance to a wide range of chemicals. These attributes make PVDF an ideal substrate for dot blot applications, particularly when dealing with low abundance proteins or small sample volumes.

The basic principle of dot blotting on PVDF involves directly spotting samples onto the membrane, followed by detection using specific antibodies or probes. This approach eliminates the need for electrophoretic separation, making it a faster alternative to traditional blotting methods. The technique has found applications in various fields, including protein expression analysis, antibody screening, and pathogen detection.

Over the years, dot blotting on PVDF has undergone several refinements and adaptations. Researchers have developed various protocols to optimize sample application, blocking, and detection steps. The introduction of automated spotting systems and imaging technologies has further improved the reproducibility and quantitative aspects of the technique.

The evolution of dot blotting on PVDF has been closely tied to advancements in membrane technology and detection methods. Modern PVDF membranes offer enhanced sensitivity and lower background noise, while developments in chemiluminescent and fluorescent detection systems have significantly improved the technique's detection limits and dynamic range.

As research demands continue to grow, dot blotting on PVDF remains a valuable tool in the molecular biology toolkit. Its simplicity, versatility, and compatibility with high-throughput screening make it an attractive option for both basic research and clinical applications. The ongoing development of novel membrane materials and detection technologies promises to further expand the capabilities and applications of this technique in the future.

Market Demand Analysis

The market demand for dot blot techniques on PVDF membranes has been steadily growing in recent years, driven by the increasing need for rapid and cost-effective protein detection methods in various research and diagnostic applications. This technique offers several advantages over traditional Western blotting, including faster processing times, lower sample volume requirements, and the ability to analyze multiple samples simultaneously.

In the biotechnology and pharmaceutical industries, dot blotting on PVDF membranes has gained significant traction for its utility in high-throughput screening of protein expression and purification processes. The technique's simplicity and efficiency make it particularly valuable in early-stage drug discovery and development, where rapid assessment of protein targets is crucial.

The academic research sector represents another major market for dot blotting on PVDF membranes. As funding for life sciences research continues to grow globally, there is an increased demand for efficient and reliable protein detection methods. Dot blotting offers researchers a quick and economical way to screen large numbers of samples, making it an attractive option for many laboratories.

Clinical diagnostics is an emerging market for dot blot techniques on PVDF membranes. The method's potential for rapid and sensitive detection of disease biomarkers has sparked interest in developing point-of-care diagnostic tools. This application is particularly relevant in resource-limited settings where quick and simple diagnostic methods are essential.

The environmental monitoring sector has also shown growing interest in dot blotting on PVDF membranes for detecting specific proteins or contaminants in water and soil samples. The technique's adaptability to field conditions and its ability to process multiple samples efficiently make it a promising tool for environmental scientists and regulatory agencies.

As the demand for personalized medicine increases, dot blotting on PVDF membranes is finding applications in biomarker discovery and validation. The technique's ability to rapidly screen patient samples for specific proteins or antibodies aligns well with the goals of precision medicine, potentially driving further market growth in this sector.

The food and beverage industry is another area where dot blotting on PVDF membranes is gaining traction, particularly for allergen detection and quality control processes. The method's sensitivity and specificity make it valuable for ensuring food safety and compliance with regulatory standards.

Overall, the market for dot blotting on PVDF membranes is expected to continue expanding as more industries recognize its potential for rapid, cost-effective protein detection. The technique's versatility and adaptability to various research and diagnostic needs position it as a valuable tool across multiple sectors, driving sustained market demand in the foreseeable future.

Current Challenges

Despite the widespread use of dot blot assays on PVDF membranes, several challenges persist in the current implementation of this technique. One of the primary issues is the inherent hydrophobicity of PVDF membranes, which can lead to inconsistent protein binding and high background noise. This hydrophobicity often necessitates pre-treatment of the membrane with methanol, adding complexity to the protocol and potentially affecting protein integrity.

Another significant challenge is the limited sensitivity of dot blot assays compared to other protein detection methods. While PVDF membranes generally offer better protein retention than nitrocellulose, the detection limit for low-abundance proteins remains a concern. This limitation can be particularly problematic when working with complex biological samples or when attempting to detect trace amounts of target proteins.

Reproducibility is also a major hurdle in dot blot assays on PVDF. Variations in sample application, membrane wetting, and blocking efficiency can lead to inconsistent results between experiments. The manual nature of sample spotting introduces operator-dependent variability, making it difficult to achieve standardized and quantitative results across different laboratories or even within the same lab.

The choice of blocking agent presents another challenge. While PVDF membranes are compatible with a wide range of blocking solutions, selecting the optimal agent to minimize non-specific binding without interfering with the target protein-antibody interaction can be a delicate balance. Inadequate blocking can result in high background noise, while over-blocking may mask low-abundance proteins.

Cross-reactivity and non-specific binding of antibodies remain persistent issues in dot blot assays. The simplified nature of the technique, which lacks the separation step found in Western blotting, can lead to false positive results due to antibodies binding to proteins with similar epitopes. This problem is exacerbated when working with complex protein mixtures or when using polyclonal antibodies.

Quantification of dot blot results on PVDF membranes poses another challenge. Unlike Western blots, where protein size information aids in result interpretation, dot blots rely solely on signal intensity. Accurate quantification requires careful optimization of sample loading, exposure times, and image analysis techniques to ensure linearity of the signal response.

Lastly, the time-consuming nature of the dot blot procedure, particularly when dealing with multiple samples, presents a challenge in high-throughput applications. The multiple steps involved, including membrane preparation, sample application, blocking, antibody incubations, and washing, can make the process labor-intensive and time-consuming, limiting its applicability in large-scale studies or diagnostic settings.

PVDF Dot Blot Methods

01 Dot blot techniques for protein detection

Dot blot is a technique used for detecting, analyzing, and identifying proteins. It involves spotting a sample directly onto a membrane and then probing with antibodies or other detection reagents. This method is simpler and faster than Western blotting, making it useful for rapid screening of multiple samples.- Dot blot techniques for protein detection: Dot blot is a technique used for detecting, analyzing, and identifying proteins. It involves spotting protein samples directly onto a membrane and then using specific antibodies or probes for detection. This method is simpler and faster than Western blotting, making it useful for rapid screening of multiple samples.

- Automated dot blot systems: Automated systems have been developed to improve the efficiency and reproducibility of dot blot assays. These systems can handle multiple samples simultaneously, control spotting parameters, and integrate with imaging and analysis software. Automation reduces human error and increases throughput for large-scale protein studies.

- Enhanced sensitivity in dot blot assays: Various methods have been developed to enhance the sensitivity of dot blot assays. These include using specialized membranes, optimizing blocking and washing steps, employing signal amplification techniques, and developing high-affinity probes. Improved sensitivity allows for the detection of low-abundance proteins in complex samples.

- Multiplex dot blot analysis: Multiplex dot blot techniques allow for the simultaneous detection of multiple proteins in a single assay. This approach uses different labeled antibodies or probes to detect various target proteins on the same membrane. Multiplexing increases the amount of information obtained from a single experiment and reduces sample consumption.

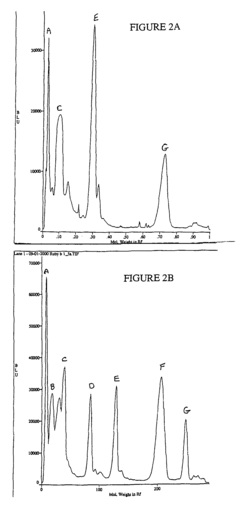

- Quantitative dot blot analysis: Quantitative dot blot methods have been developed to provide more accurate measurements of protein levels. These techniques often involve the use of internal standards, calibration curves, and specialized imaging systems. Quantitative analysis allows for the comparison of protein expression levels across different samples or experimental conditions.

02 Automated dot blot systems

Automated systems have been developed to improve the efficiency and reproducibility of dot blot assays. These systems can handle multiple samples simultaneously, control spotting volume and position, and integrate with imaging and analysis software for quantitative results.Expand Specific Solutions03 Novel detection methods for dot blots

Innovative detection methods have been introduced to enhance the sensitivity and specificity of dot blot assays. These include fluorescent probes, chemiluminescent substrates, and nanoparticle-based detection systems, which can improve signal-to-noise ratios and lower detection limits.Expand Specific Solutions04 Application of dot blots in diagnostics

Dot blot techniques have found applications in various diagnostic fields, including detection of pathogens, biomarkers for diseases, and environmental contaminants. The simplicity and speed of dot blots make them suitable for point-of-care testing and field-based diagnostics.Expand Specific Solutions05 Modifications to improve dot blot performance

Researchers have developed modifications to traditional dot blot protocols to improve performance. These include optimizing membrane types, blocking agents, and sample preparation methods to reduce background noise, increase specificity, and enhance overall assay sensitivity.Expand Specific Solutions

Key Industry Players

The dot blot technique on PVDF membranes is in a mature stage of development, with widespread adoption across research and industrial applications. The global market for PVDF membranes is substantial, driven by increasing demand in biotechnology, pharmaceuticals, and water treatment sectors. Technologically, the process is well-established, with companies like Life Technologies Corp., FUJIFILM Corp., and Alnylam Pharmaceuticals, Inc. offering advanced solutions. Academic institutions such as Zhejiang University and Fuzhou University contribute to ongoing refinements. The competitive landscape is diverse, featuring both specialized biotech firms and large chemical corporations like China Petroleum & Chemical Corp., indicating a robust and evolving market with opportunities for innovation in membrane performance and application-specific optimizations.

Life Technologies Corp.

China Petroleum & Chemical Corp.

Innovative Techniques

- A microtiter plate without any membrane or structure in the reaction areas, made of standard plastic, is used for ELISPOT assays, where the wells are coated directly with capture antibodies, simplifying the process and reducing costs, while maintaining sensitivity and specificity.

- Development of novel fluorescent derivatization reagents with high Stokes shifts and selective binding properties that become fluorescent only when bound to aldehyde or ketone moieties, allowing for rapid and sensitive detection without the need for secondary reagents, using a covalent linkage that forms a stable adduct with the target molecules.

Quality Control

Quality control is a critical aspect of performing a dot blot on PVDF membranes to ensure reliable and reproducible results. The process begins with the careful preparation and handling of samples and reagents. It is essential to use high-quality, purified proteins or nucleic acids as samples to minimize background noise and non-specific binding. Proper storage and handling of antibodies and other detection reagents are crucial to maintain their specificity and sensitivity.

The PVDF membrane itself requires special attention during the quality control process. Before use, the membrane should be inspected for any visible defects or contamination. Pre-wetting the membrane with methanol is a crucial step to activate its surface and ensure uniform binding of proteins. Consistent and even application of samples onto the membrane is vital for accurate comparisons between different spots.

During the blocking and washing steps, it is important to use fresh, high-quality blocking agents and buffers to minimize background signal. The incubation times and temperatures for each step should be carefully controlled and optimized for the specific antibodies and detection systems being used. Proper washing techniques, including the use of appropriate detergents and sufficient washing volumes, are essential to remove unbound reagents and reduce non-specific signals.

The choice of detection method, whether chemiluminescence, colorimetric, or fluorescence-based, should be made based on the required sensitivity and the available equipment. Calibration of imaging systems and proper exposure times are crucial for obtaining accurate and quantifiable results. Including positive and negative controls on each blot is essential for validating the specificity of the antibodies and the overall performance of the assay.

To ensure reproducibility, it is advisable to perform technical replicates and, when possible, biological replicates. Standardization of protocols and the use of automated systems, where available, can help reduce variability between experiments. Proper documentation of all experimental conditions, including lot numbers of reagents and any deviations from standard protocols, is crucial for troubleshooting and future reference.

Regular maintenance and calibration of equipment used in the dot blot process, such as pipettes, imaging systems, and incubators, are essential for consistent results. Implementing a system for tracking and analyzing quality control data over time can help identify trends or issues that may affect the reliability of results. Training of personnel and periodic proficiency testing can also contribute to maintaining high standards of quality control in dot blot experiments on PVDF membranes.

Automation Potential

The automation potential for dot blot assays on PVDF membranes presents significant opportunities to enhance efficiency, reproducibility, and throughput in laboratory settings. Automated systems can streamline various steps of the dot blot process, from sample preparation to data analysis, reducing manual labor and minimizing human error.

One key area for automation is sample application. Robotic liquid handling systems can precisely dispense samples onto PVDF membranes in a uniform and consistent manner. These systems can be programmed to handle multiple samples simultaneously, increasing throughput and ensuring equal sample volumes across all dots. Advanced platforms may incorporate temperature control to maintain sample integrity during the application process.

Membrane handling and washing steps also offer automation potential. Automated membrane washers can perform consistent and thorough washing cycles, ensuring uniform background reduction across the entire membrane. These systems can be programmed for specific wash protocols, including the number of washes, duration, and buffer composition, tailored to the requirements of different dot blot assays.

Incubation steps, such as blocking and antibody binding, can be automated using specialized incubation chambers. These chambers can maintain precise temperature control and gentle agitation, optimizing reaction conditions and reducing incubation times. Automated systems may also incorporate buffer exchange capabilities, allowing for seamless transitions between different incubation steps without manual intervention.

Detection and imaging processes present another avenue for automation. Automated imaging systems can capture high-resolution images of dot blot membranes under standardized conditions, ensuring consistent results across multiple experiments. These systems may incorporate various detection modalities, such as chemiluminescence or fluorescence, and can be integrated with image analysis software for quantitative data extraction.

Data analysis and interpretation offer significant automation potential through specialized software solutions. These tools can automatically detect and quantify dot intensities, perform background subtraction, and generate standardized reports. Machine learning algorithms can be employed to improve signal detection and noise reduction, enhancing the overall sensitivity and reliability of dot blot assays.

Fully integrated automation platforms that combine multiple steps of the dot blot process are emerging. These systems can handle sample application, membrane washing, incubation, and imaging in a single, enclosed environment. Such platforms not only increase efficiency but also minimize the risk of contamination and ensure reproducibility across experiments.