How To Dissolve PVDF?

PVDF Dissolution Background

Polyvinylidene fluoride (PVDF) is a highly versatile fluoropolymer known for its exceptional chemical resistance, thermal stability, and mechanical properties. The dissolution of PVDF has been a subject of significant interest in various industrial and research applications, including membrane fabrication, polymer processing, and material science.

The challenge of dissolving PVDF stems from its unique molecular structure, which consists of alternating CH2 and CF2 groups along the polymer backbone. This structure imparts high crystallinity and strong intermolecular forces, making PVDF resistant to most common solvents. Consequently, the dissolution of PVDF requires specific conditions and solvents to overcome these inherent properties.

Historically, the dissolution of PVDF has been achieved through the use of polar aprotic solvents. These solvents, such as N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), and N-methyl-2-pyrrolidone (NMP), have been widely employed due to their ability to interact with the polar groups of PVDF and disrupt the intermolecular forces holding the polymer chains together.

The dissolution process typically involves heating the PVDF-solvent mixture to temperatures ranging from 40°C to 80°C, depending on the specific solvent and desired dissolution rate. The elevated temperature enhances the solvent's ability to penetrate the polymer structure and facilitates the disentanglement of polymer chains.

In recent years, environmental and health concerns associated with traditional polar aprotic solvents have driven research towards more sustainable alternatives. This has led to the exploration of green solvents, such as ionic liquids and deep eutectic solvents, which offer potential advantages in terms of reduced toxicity and environmental impact.

The concentration of PVDF in solution is another critical factor in the dissolution process. Typically, PVDF solutions are prepared with concentrations ranging from 5% to 20% by weight, depending on the intended application. Higher concentrations may require longer dissolution times or more aggressive solvents to achieve complete dissolution.

Understanding the dissolution behavior of PVDF is crucial for various applications, including the preparation of PVDF membranes for water treatment and gas separation, the development of PVDF-based coatings and adhesives, and the processing of PVDF for advanced materials and composites. The ability to control and optimize the dissolution process directly impacts the final properties and performance of PVDF-based products.

As research in this field continues to evolve, new techniques and solvents are being explored to enhance the efficiency and sustainability of PVDF dissolution. These advancements aim to address the growing demand for PVDF-based materials in emerging technologies while minimizing environmental impact and improving process economics.

Market Demand for PVDF Solutions

The market demand for PVDF solutions has been steadily growing across various industries due to the unique properties of Polyvinylidene Fluoride (PVDF). This versatile fluoropolymer offers excellent chemical resistance, thermal stability, and mechanical strength, making it highly sought after in sectors such as chemical processing, electronics, and renewable energy.

In the chemical processing industry, the demand for PVDF solutions is driven by the need for corrosion-resistant materials in handling aggressive chemicals and solvents. PVDF's ability to withstand harsh environments has led to its increased adoption in piping systems, tank linings, and filtration membranes. The growing emphasis on safety and longevity in chemical plants has further boosted the market for PVDF-based solutions.

The electronics sector has also witnessed a surge in demand for PVDF solutions, particularly in the production of piezoelectric sensors and transducers. PVDF's piezoelectric properties make it an ideal material for manufacturing pressure sensors, ultrasonic transducers, and other electronic components. As the Internet of Things (IoT) and smart devices continue to proliferate, the demand for PVDF in this sector is expected to rise significantly.

Renewable energy, especially the solar power industry, has emerged as a major driver for PVDF solutions. PVDF-based backsheets for photovoltaic modules offer superior weather resistance and durability, contributing to the longevity of solar panels. With the global push towards clean energy and the rapid expansion of solar installations, the demand for PVDF in this sector is projected to experience substantial growth.

The water treatment industry has also recognized the benefits of PVDF solutions, particularly in membrane filtration systems. PVDF membranes are highly effective in water purification processes, offering excellent chemical resistance and fouling resistance. As water scarcity becomes a pressing global issue, the demand for advanced filtration technologies utilizing PVDF is expected to increase.

In the automotive sector, PVDF solutions are gaining traction for their use in fuel system components, electrical wire insulation, and surface coatings. The material's resistance to fuels and chemicals, combined with its durability, makes it an attractive option for manufacturers looking to enhance vehicle performance and longevity.

The aerospace industry is another sector driving the demand for PVDF solutions. The material's lightweight nature, coupled with its resistance to UV radiation and extreme temperatures, makes it suitable for various aerospace applications, including wire insulation, tubing, and composite materials for aircraft interiors.

As industries continue to seek high-performance materials that can withstand challenging environments, the market demand for PVDF solutions is expected to maintain its upward trajectory. The versatility of PVDF and its ability to be tailored for specific applications through various dissolution and processing techniques will likely open up new market opportunities across diverse sectors.

Current PVDF Dissolution Challenges

Polyvinylidene fluoride (PVDF) dissolution presents significant challenges due to its unique chemical structure and properties. The strong carbon-fluorine bonds in PVDF make it highly resistant to most common solvents, limiting its processability and potential applications. This resistance to dissolution is both a strength and a limitation, depending on the intended use of the polymer.

One of the primary challenges in dissolving PVDF is finding suitable solvents that can effectively break down its crystalline structure without degrading the polymer's properties. Traditional organic solvents often prove ineffective, necessitating the use of more aggressive or specialized solvents. This limitation restricts the range of processing techniques available for PVDF and can increase manufacturing costs.

Temperature control during dissolution is another critical challenge. PVDF typically requires elevated temperatures to facilitate dissolution, but excessive heat can lead to polymer degradation or unwanted side reactions. Balancing the need for sufficient heat to promote dissolution while avoiding thermal damage to the polymer is a delicate process that demands precise control and monitoring.

The dissolution kinetics of PVDF are complex and can vary significantly based on factors such as molecular weight, degree of crystallinity, and the presence of additives or copolymers. This variability makes it difficult to develop standardized dissolution protocols, often requiring case-by-case optimization for different PVDF grades or applications.

Environmental and safety concerns also pose challenges in PVDF dissolution. Many effective solvents for PVDF are toxic, flammable, or environmentally harmful, necessitating stringent safety measures and disposal protocols. This aspect not only impacts the practicality of certain dissolution methods but also raises regulatory and sustainability issues in industrial settings.

The incomplete dissolution of PVDF can lead to inhomogeneous solutions or gels, affecting the quality and properties of the final product. Achieving complete and uniform dissolution is crucial for applications such as membrane fabrication, coatings, and composite materials, where the polymer's performance is directly tied to its solution properties.

Scalability of PVDF dissolution processes from laboratory to industrial scale presents additional challenges. Methods that work effectively at small scales may encounter issues when scaled up, such as longer dissolution times, increased solvent consumption, or difficulties in maintaining uniform dissolution conditions across larger volumes.

Addressing these challenges requires a multifaceted approach, combining innovative solvent systems, advanced processing techniques, and a deep understanding of PVDF's physicochemical properties. Ongoing research in this area focuses on developing more efficient and environmentally friendly dissolution methods, exploring novel solvent combinations, and investigating alternative processing routes to expand the utility and applications of PVDF.

Existing PVDF Dissolution Methods

01 PVDF membrane applications

PVDF membranes are widely used in various applications due to their excellent chemical resistance and mechanical properties. They are commonly employed in water treatment, filtration systems, and separation processes. PVDF membranes can be modified to enhance their performance in specific applications, such as improving hydrophilicity or fouling resistance.- PVDF membrane applications: PVDF membranes are widely used in various applications due to their excellent chemical resistance and mechanical properties. They are commonly employed in water treatment, filtration systems, and separation processes. PVDF membranes can be modified to enhance their performance in specific applications, such as improving hydrophilicity or fouling resistance.

- PVDF in energy storage devices: PVDF is utilized in energy storage devices, particularly in lithium-ion batteries and supercapacitors. It serves as a binder material for electrode components, enhancing the stability and performance of these devices. PVDF-based separators are also developed to improve the safety and efficiency of energy storage systems.

- PVDF composites and blends: PVDF is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, thermal stability, or electrical properties. PVDF composites find applications in various industries, including aerospace, automotive, and electronics.

- PVDF in piezoelectric applications: PVDF exhibits piezoelectric properties, making it suitable for use in sensors, actuators, and energy harvesting devices. The material can be processed into thin films or fibers to create flexible piezoelectric elements. These PVDF-based piezoelectric devices are used in various fields, including medical devices, wearable technology, and structural health monitoring.

- PVDF processing techniques: Various processing techniques are employed to manufacture PVDF products with specific properties and forms. These include melt processing, solution casting, electrospinning, and phase inversion. The choice of processing method affects the final properties of the PVDF material, such as crystallinity, porosity, and surface characteristics.

02 PVDF in energy storage devices

PVDF is utilized in the production of energy storage devices, particularly in lithium-ion batteries. It serves as a binder material for electrode components, improving the stability and performance of the battery. PVDF-based separators are also developed to enhance the safety and efficiency of energy storage systems.Expand Specific Solutions03 PVDF composites and blends

PVDF is often combined with other materials to create composites or blends with enhanced properties. These combinations can improve the mechanical strength, thermal stability, or electrical properties of the resulting material. PVDF composites find applications in various industries, including aerospace, automotive, and electronics.Expand Specific Solutions04 PVDF in piezoelectric applications

PVDF exhibits piezoelectric properties, making it suitable for use in sensors, actuators, and energy harvesting devices. The material can convert mechanical stress into electrical energy and vice versa. This characteristic is exploited in the development of flexible electronics, wearable devices, and vibration sensors.Expand Specific Solutions05 PVDF processing techniques

Various processing techniques are employed to manufacture PVDF products with specific properties and forms. These include solution casting, melt extrusion, electrospinning, and phase inversion. The choice of processing method affects the final properties of the PVDF material, such as crystallinity, porosity, and surface characteristics.Expand Specific Solutions

Key PVDF Manufacturers and Suppliers

The market for PVDF dissolution technology is in a growth phase, driven by increasing demand in various industries such as electronics, energy storage, and membrane manufacturing. The global PVDF market size is projected to expand significantly, with key players like Arkema France SA, Solvay China Co. Ltd., and Honeywell International Technologies Ltd. leading the field. The technology's maturity varies across applications, with established processes in some sectors and ongoing research in others. Academic institutions such as Qingdao University of Science & Technology, Fuzhou University, and Beijing University of Chemical Technology are contributing to advancements in PVDF dissolution techniques, while companies like BYD Co., Ltd. and EMD Millipore Corp. are applying these technologies in commercial products, indicating a competitive and evolving landscape.

Arkema France SA

Shanghai Huayi 3F New Materials Co., Ltd.

Innovative PVDF Solvent Systems

- Use low-boiling point solvent extraction method to separate paraffin and PVDF. Through the steps of extraction, filtration, drying and distillation recovery, high-purity PVDF is obtained, and further use polar solvents and alcohol solvents to remove impurities, and finally obtain PVDF suitable for industrial use. Refined PVDF.

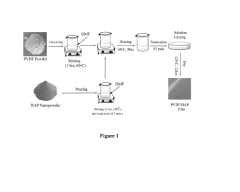

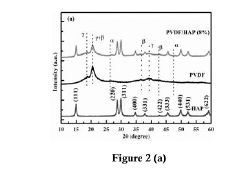

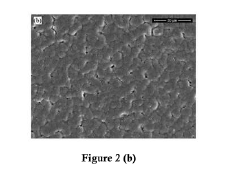

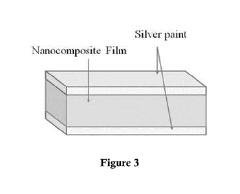

- A nanocomposite film-based capacitive energy storage device using a poly-vinylidene fluoride (PVDF) polymer matrix reinforced with hydrated antimony pentoxide (HAP) nanoparticles, synthesized through a hydroxylation process, which is coated with a silver paste electrode, offering a cost-effective and high-energy storage solution.

Environmental Impact of PVDF Solvents

The use of solvents to dissolve PVDF has significant environmental implications that warrant careful consideration. Traditional solvents for PVDF, such as N,N-dimethylformamide (DMF) and N-methyl-2-pyrrolidone (NMP), are known to pose environmental risks due to their toxicity and persistence in ecosystems. These solvents can contaminate water sources and soil, potentially harming aquatic life and vegetation. Moreover, their production and disposal contribute to air pollution and greenhouse gas emissions.

Recent research has focused on developing more environmentally friendly alternatives to dissolve PVDF. Green solvents, such as dimethyl sulfoxide (DMSO) and triethyl phosphate (TEP), have shown promise in reducing the environmental impact of PVDF processing. These solvents exhibit lower toxicity and improved biodegradability compared to conventional options. However, their effectiveness in dissolving PVDF may vary, necessitating further optimization of dissolution processes.

The environmental impact of PVDF solvents extends beyond their immediate use. The production of these solvents often involves energy-intensive processes and the use of petrochemical feedstocks, contributing to carbon emissions and resource depletion. Additionally, the disposal of waste solvents and PVDF solutions presents challenges in terms of proper treatment and potential environmental contamination.

Efforts to mitigate the environmental impact of PVDF solvents include the development of solvent recovery and recycling systems. These technologies aim to reduce the overall consumption of solvents and minimize waste generation. Furthermore, research into solvent-free or low-solvent processing methods for PVDF, such as melt processing or supercritical CO2 techniques, offers potential alternatives that could significantly reduce the reliance on environmentally harmful solvents.

The regulatory landscape surrounding PVDF solvents is evolving, with increasing pressure to phase out the most hazardous options. This has led to a growing emphasis on green chemistry principles in the development of new solvents and processing methods for PVDF. As environmental concerns continue to shape industrial practices, the search for sustainable solutions to dissolve PVDF remains a critical area of research and development in materials science and environmental engineering.

PVDF Dissolution Safety Protocols

When working with Polyvinylidene Fluoride (PVDF), proper safety protocols are essential to protect personnel and the environment. PVDF dissolution typically involves the use of strong solvents, which can pose significant health and safety risks if not handled correctly. Implementing comprehensive safety measures is crucial throughout the dissolution process.

Personal protective equipment (PPE) is the first line of defense. Laboratory personnel must wear appropriate PPE, including chemical-resistant gloves, safety goggles, and lab coats. Depending on the specific solvents used, respiratory protection may also be necessary. It is vital to consult the Safety Data Sheets (SDS) for all chemicals involved to determine the appropriate level of protection required.

Proper ventilation is critical when dissolving PVDF. All dissolution procedures should be conducted in a fume hood to prevent the accumulation of potentially harmful vapors. The fume hood should be inspected regularly to ensure proper functioning, and the sash should be kept at the appropriate height during use.

Chemical storage and handling practices are equally important. Solvents used for PVDF dissolution should be stored in appropriate containers in a well-ventilated area, away from sources of heat or ignition. When transferring solvents or dissolved PVDF solutions, use secondary containment to prevent spills and leaks.

Emergency response procedures must be in place and clearly communicated to all laboratory personnel. This includes the location and proper use of eyewash stations, safety showers, and fire extinguishers. A spill kit suitable for the specific solvents used should be readily available, and staff should be trained in its use.

Waste management is a crucial aspect of PVDF dissolution safety. Proper disposal methods for both liquid and solid waste must be established and followed. This may include neutralization, filtration, or other treatment processes before disposal, depending on local regulations and the specific chemicals involved.

Regular safety training and refresher courses should be provided to all personnel working with PVDF dissolution processes. This training should cover proper handling techniques, emergency procedures, and the importance of maintaining a clean and organized workspace to minimize accidents.

Lastly, implementing a robust system for documenting and reviewing safety incidents or near-misses can help identify areas for improvement in safety protocols. Regular safety audits and inspections should be conducted to ensure compliance with established procedures and to address any emerging safety concerns in the PVDF dissolution process.