How to Apply PVDF in Acoustic Transducer Innovation?

PVDF Acoustic Evolution

The evolution of PVDF (Polyvinylidene Fluoride) in acoustic transducer technology represents a significant advancement in the field of electroacoustic devices. PVDF, a piezoelectric polymer, has emerged as a versatile material for acoustic applications due to its unique properties and adaptability.

In the early stages of acoustic transducer development, traditional piezoelectric ceramics such as PZT (Lead Zirconate Titanate) dominated the field. However, the discovery of PVDF's piezoelectric properties in the late 1960s by Kawai opened up new possibilities for acoustic transducer design. This breakthrough led to the exploration of PVDF as a viable alternative to ceramic-based transducers.

The 1970s and 1980s saw intensive research into PVDF's acoustic properties and potential applications. Scientists and engineers focused on understanding the material's frequency response, sensitivity, and durability in various acoustic environments. During this period, early prototypes of PVDF-based acoustic transducers were developed, primarily for underwater sound applications and medical ultrasound imaging.

The 1990s marked a significant leap in PVDF acoustic technology with the development of copolymers and improved manufacturing techniques. The introduction of P(VDF-TrFE) copolymers enhanced the material's piezoelectric properties, leading to better performance in acoustic transducers. This period also saw the expansion of PVDF applications into air-coupled transducers and microphones.

In the 2000s, advancements in nanotechnology and material science further propelled PVDF acoustic evolution. Researchers began exploring nanocomposite PVDF materials, incorporating nanoparticles to enhance specific acoustic properties. This era also witnessed the integration of PVDF into flexible and wearable acoustic devices, opening up new avenues for consumer electronics and biomedical applications.

The past decade has seen a focus on optimizing PVDF for specific acoustic applications. Researchers have been working on tailoring the material's properties through various processing techniques, such as electrospinning and 3D printing. These advancements have led to the development of highly sensitive and directional PVDF acoustic sensors and actuators.

Recent years have witnessed a growing interest in combining PVDF with other materials and technologies to create hybrid acoustic systems. The integration of PVDF with MEMS (Micro-Electro-Mechanical Systems) technology has resulted in miniaturized, high-performance acoustic transducers for applications in IoT devices and smart sensors.

Looking ahead, the evolution of PVDF in acoustic transducers is expected to continue, with a focus on sustainability, energy harvesting capabilities, and integration with artificial intelligence for smart acoustic systems. The ongoing research in this field promises to unlock new possibilities for PVDF in next-generation acoustic transducer innovations.

Market Demand Analysis

The market demand for PVDF (Polyvinylidene Fluoride) in acoustic transducer innovation has been steadily growing, driven by the increasing need for high-performance, durable, and versatile transducer materials across various industries. PVDF's unique piezoelectric properties make it an attractive option for manufacturers seeking to enhance the capabilities of their acoustic devices.

In the medical field, there is a rising demand for PVDF-based ultrasound transducers due to their superior sensitivity and broad frequency range. These characteristics enable improved imaging quality and diagnostic accuracy in applications such as echocardiography, obstetrics, and vascular imaging. The global medical ultrasound market, which heavily relies on advanced transducer technologies, is projected to experience significant growth in the coming years.

The automotive industry represents another key market for PVDF acoustic transducers. With the increasing integration of advanced driver assistance systems (ADAS) and autonomous driving technologies, there is a growing need for reliable and high-performance ultrasonic sensors. PVDF-based transducers offer advantages in terms of durability, temperature resistance, and flexibility, making them well-suited for automotive applications such as parking assistance and collision avoidance systems.

In the consumer electronics sector, PVDF is gaining traction in the development of miniaturized acoustic transducers for smartphones, earbuds, and other portable devices. The material's flexibility and ability to be formed into thin films allow for the creation of compact yet powerful speakers and microphones. As consumers demand higher audio quality and more advanced features in their personal devices, the market for PVDF-based acoustic components is expected to expand.

The industrial sector also presents significant opportunities for PVDF acoustic transducers. In non-destructive testing (NDT) applications, PVDF-based ultrasonic sensors are valued for their ability to operate at high frequencies and their resistance to harsh environmental conditions. This makes them ideal for inspecting materials and structures in industries such as aerospace, oil and gas, and manufacturing.

Furthermore, the growing focus on underwater acoustics and marine research has created a niche market for PVDF transducers. Their ability to operate effectively in aqueous environments and withstand high pressures makes them suitable for sonar systems, underwater communication devices, and oceanographic research equipment.

As the demand for more sophisticated and efficient acoustic transducers continues to rise across these diverse sectors, the market for PVDF-based solutions is expected to experience substantial growth. Manufacturers and researchers are likely to invest more resources in exploring novel applications and optimizing the performance of PVDF in acoustic transducer technologies to meet the evolving needs of various industries.

PVDF Challenges

Despite the promising potential of PVDF in acoustic transducer innovation, several significant challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the relatively low piezoelectric coefficient of PVDF compared to traditional ceramic materials. This limitation affects the overall sensitivity and efficiency of PVDF-based transducers, potentially compromising their performance in applications requiring high precision or power output.

Another challenge lies in the temperature sensitivity of PVDF. The material's piezoelectric properties can degrade at elevated temperatures, restricting its use in high-temperature environments or applications involving significant heat generation. This thermal instability necessitates careful consideration in transducer design and may limit PVDF's applicability in certain industrial or automotive contexts.

The manufacturing process of PVDF films presents additional hurdles. Achieving consistent film thickness and uniform polarization across large areas can be difficult, leading to variations in performance and reliability. These manufacturing inconsistencies can result in batch-to-batch variability, complicating quality control and potentially increasing production costs.

PVDF's relatively low dielectric constant poses challenges in impedance matching with electronic circuits. This mismatch can lead to signal loss and reduced efficiency in the overall transducer system. Engineers must develop specialized matching networks or signal conditioning circuits to optimize the performance of PVDF-based transducers, adding complexity to the design process.

The long-term stability and aging characteristics of PVDF remain areas of concern. Over time, the material may experience depolarization or changes in its mechanical properties, potentially affecting the transducer's performance and reliability. This necessitates extensive testing and validation to ensure consistent operation throughout the device's intended lifespan.

Integration of PVDF with other materials and components in transducer assemblies presents additional challenges. Ensuring proper bonding, minimizing interface losses, and maintaining the material's piezoelectric properties during integration processes require careful engineering and material selection. These integration issues can impact the overall performance and durability of PVDF-based acoustic transducers.

Lastly, the cost-effectiveness of PVDF in comparison to traditional piezoelectric materials remains a challenge in some applications. While PVDF offers unique advantages in flexibility and formability, its overall performance-to-cost ratio may not always be favorable, particularly in high-volume or cost-sensitive markets. Overcoming these economic barriers requires continued research into more efficient manufacturing processes and innovative design approaches to fully leverage PVDF's unique properties.

Current PVDF Solutions

01 Acoustic properties of PVDF films and membranes

PVDF films and membranes exhibit excellent acoustic properties due to their high piezoelectric response and flexibility. These materials can be used in various acoustic applications, including sensors, transducers, and sound-absorbing structures. The acoustic performance of PVDF can be further enhanced by controlling the crystalline structure and incorporating additives.- Acoustic properties of PVDF films and membranes: PVDF films and membranes exhibit excellent acoustic properties due to their unique molecular structure and piezoelectric characteristics. These materials can efficiently convert mechanical vibrations into electrical signals and vice versa, making them suitable for various acoustic applications such as sensors, transducers, and speakers.

- PVDF-based composites for enhanced acoustic performance: Composites incorporating PVDF with other materials, such as nanoparticles or conductive fillers, can significantly improve acoustic properties. These composites often demonstrate enhanced sound absorption, transmission loss, and frequency response, making them ideal for noise reduction and acoustic insulation applications.

- Acoustic metamaterials using PVDF: PVDF-based acoustic metamaterials are engineered structures that exhibit unique acoustic properties not found in natural materials. These metamaterials can manipulate sound waves in unconventional ways, such as negative refraction or acoustic cloaking, opening up new possibilities in sound control and acoustic engineering.

- PVDF in ultrasonic transducers and sensors: PVDF's piezoelectric properties make it an excellent material for ultrasonic transducers and sensors. These devices can generate and detect high-frequency sound waves, finding applications in medical imaging, non-destructive testing, and underwater acoustics.

- Acoustic energy harvesting using PVDF: PVDF-based devices can be used for acoustic energy harvesting, converting ambient sound or vibrations into electrical energy. This technology has potential applications in self-powered sensors, wearable devices, and energy-efficient systems that can operate in noisy environments.

02 PVDF-based composites for improved acoustic performance

Composites incorporating PVDF and other materials, such as nanoparticles or other polymers, can enhance acoustic properties. These composites often demonstrate improved sound absorption, transmission loss, and vibration damping characteristics compared to pure PVDF. The synergistic effects of the combined materials contribute to superior acoustic performance in various applications.Expand Specific Solutions03 Acoustic metamaterials using PVDF

PVDF can be used to create acoustic metamaterials with unique properties, such as negative refractive index or extraordinary sound absorption. These metamaterials often involve structured PVDF layers or elements designed to manipulate acoustic waves in ways not possible with conventional materials. Applications include noise control, acoustic cloaking, and advanced acoustic devices.Expand Specific Solutions04 PVDF in electroacoustic transducers

PVDF's piezoelectric properties make it suitable for use in electroacoustic transducers, such as microphones and speakers. The material's high sensitivity to mechanical stress and ability to generate electrical signals in response to acoustic waves enable the development of efficient and compact acoustic devices. PVDF-based transducers often offer advantages in terms of frequency response and durability.Expand Specific Solutions05 Acoustic insulation and damping using PVDF foams

PVDF foams exhibit excellent acoustic insulation and damping properties due to their closed-cell structure and viscoelastic behavior. These foams can be used in various applications, including automotive, aerospace, and building construction, to reduce noise transmission and vibrations. The acoustic performance of PVDF foams can be tailored by controlling the foam density and cell size distribution.Expand Specific Solutions

Key Industry Players

The application of PVDF in acoustic transducer innovation is in a growth phase, with increasing market size and technological advancements. The global market for piezoelectric devices, including PVDF-based transducers, is expanding rapidly. Technologically, PVDF applications are maturing, with companies like Qualcomm, Philips, and xMEMS Labs leading in innovation. Academic institutions such as MIT, Nanyang Technological University, and Beijing University of Technology are contributing to fundamental research. Established players like General Electric and Robert Bosch are integrating PVDF technology into their product lines, while specialized firms like Measurement Specialties and Misonix are focusing on niche applications. The involvement of diverse entities indicates a competitive and evolving landscape with significant potential for further development and commercialization.

Arkema France SA

xMEMS Labs, Inc.

PVDF Patent Landscape

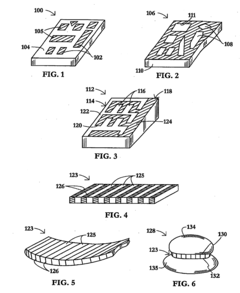

- A method involving double-sided metallization of a very long and thin PVDF tape, cutting it into unitary films, attaching these films to a smart card with a pattern of interconnections, and applying a constraining piece with notches to create a crenellated shape for improved mechanical resistance and signal emission.

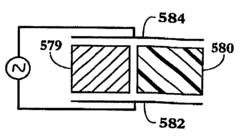

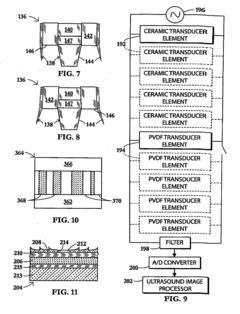

- A piezocomposite ultrasonic transducer device is developed, comprising piezoelectric ceramic elements for therapeutic high-intensity operations and polymeric elements for imaging, bonded together to form a unitary block, allowing for simultaneous therapeutic and imaging modes with improved frequency bandwidth and reduced parasitic vibrations.

Material Properties

Polyvinylidene fluoride (PVDF) is a highly versatile polymer with unique properties that make it particularly suitable for acoustic transducer applications. Its piezoelectric characteristics, coupled with its mechanical and thermal properties, position PVDF as a material of significant interest in the field of acoustic innovation.

PVDF exhibits strong piezoelectric properties, allowing it to convert mechanical stress into electrical signals and vice versa. This property is crucial for acoustic transducers, enabling the material to efficiently transform sound waves into electrical signals or electrical impulses into sound. The piezoelectric effect in PVDF is notably strong compared to many other polymers, making it an excellent choice for sensitive acoustic applications.

The mechanical properties of PVDF further enhance its suitability for acoustic transducers. It possesses high flexibility and durability, allowing for the creation of thin, lightweight, and conformable transducer elements. This flexibility enables the design of transducers that can adapt to various shapes and surfaces, expanding the potential applications in areas such as wearable acoustic devices or curved surface sensors.

PVDF's thermal stability is another significant advantage. It maintains its properties over a wide temperature range, ensuring consistent performance in diverse environmental conditions. This stability is crucial for acoustic transducers that may be exposed to temperature variations during operation.

The material's chemical resistance is noteworthy, providing protection against many solvents, acids, and bases. This characteristic enhances the longevity and reliability of PVDF-based acoustic transducers, particularly in harsh or corrosive environments.

PVDF also demonstrates excellent acoustic impedance matching with water and human tissue. This property is particularly valuable in medical ultrasound applications, allowing for efficient transmission of acoustic waves between the transducer and the medium being examined.

The processability of PVDF is another key attribute. It can be easily formed into various shapes and structures, including thin films, which are ideal for many acoustic transducer designs. This versatility in processing allows for the creation of complex transducer geometries and arrays, enabling advanced acoustic imaging and sensing capabilities.

Furthermore, PVDF exhibits a broad frequency response, making it suitable for a wide range of acoustic applications, from low-frequency vibration sensing to high-frequency ultrasound imaging. This broad bandwidth capability enhances the material's versatility in different acoustic transducer innovations.

Manufacturing Processes

The manufacturing processes for applying PVDF in acoustic transducer innovation are critical to achieving optimal performance and reliability. The primary methods include solution casting, melt extrusion, and electrospinning, each offering unique advantages for different applications.

Solution casting is widely used for producing thin PVDF films with controlled thickness and uniformity. This process involves dissolving PVDF powder in a suitable solvent, such as dimethylformamide (DMF) or N-methyl-2-pyrrolidone (NMP), followed by casting the solution onto a flat surface and allowing the solvent to evaporate. The resulting film can be further processed through stretching and poling to enhance its piezoelectric properties.

Melt extrusion is another common technique for manufacturing PVDF films and fibers. In this process, PVDF pellets are heated above their melting point and forced through a die to create continuous sheets or fibers. This method is particularly suitable for producing thicker films and three-dimensional structures. Post-processing steps, such as uniaxial or biaxial stretching, are often employed to improve the crystallinity and piezoelectric response of the extruded PVDF.

Electrospinning has gained significant attention for fabricating PVDF nanofibers with high surface area and porosity. This technique involves applying a high voltage to a polymer solution, creating a jet that is drawn into ultrafine fibers as it travels towards a grounded collector. Electrospun PVDF nanofibers exhibit enhanced piezoelectric properties due to their unique morphology and preferential crystal orientation.

For acoustic transducer applications, precision in manufacturing is crucial. Advanced techniques such as photolithography and micro-molding are employed to create intricate patterns and structures in PVDF films. These processes enable the fabrication of miniaturized transducers with complex geometries, essential for high-frequency ultrasound applications.

Surface modification techniques play a vital role in optimizing the performance of PVDF-based acoustic transducers. Plasma treatment, for instance, can alter the surface chemistry and improve adhesion between PVDF and electrode materials. Additionally, the incorporation of nanoparticles or other functional materials during the manufacturing process can enhance the piezoelectric response and tailor the acoustic properties of the transducer.

Quality control measures are integral to the manufacturing process. In-line monitoring techniques, such as Fourier-transform infrared spectroscopy (FTIR) and X-ray diffraction (XRD), are employed to ensure consistent crystal structure and phase composition. Electrical characterization, including impedance analysis and piezoelectric coefficient measurements, is performed to verify the transducer's performance.

The choice of manufacturing process and subsequent treatments significantly influence the final properties of PVDF-based acoustic transducers. Ongoing research focuses on developing novel manufacturing techniques to further enhance the piezoelectric properties and expand the application range of PVDF in acoustic transducer innovation.