Method for producing a shielding case

a shielding case and shielding technology, applied in the direction of manual label dispensers, lamination, coatings, etc., can solve the problems of limited mechanical properties, high conductivity, difficult to achieve the optimal compromise between high elasticity, high conductivity and lowest possible material cost, and difficult to achieve the optimal compromise between high elasticity, high conductivity and low material cost. , to achieve the effect of shielding even gaps, reducing the deformation and elastic return force of the profile section, and reducing the deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

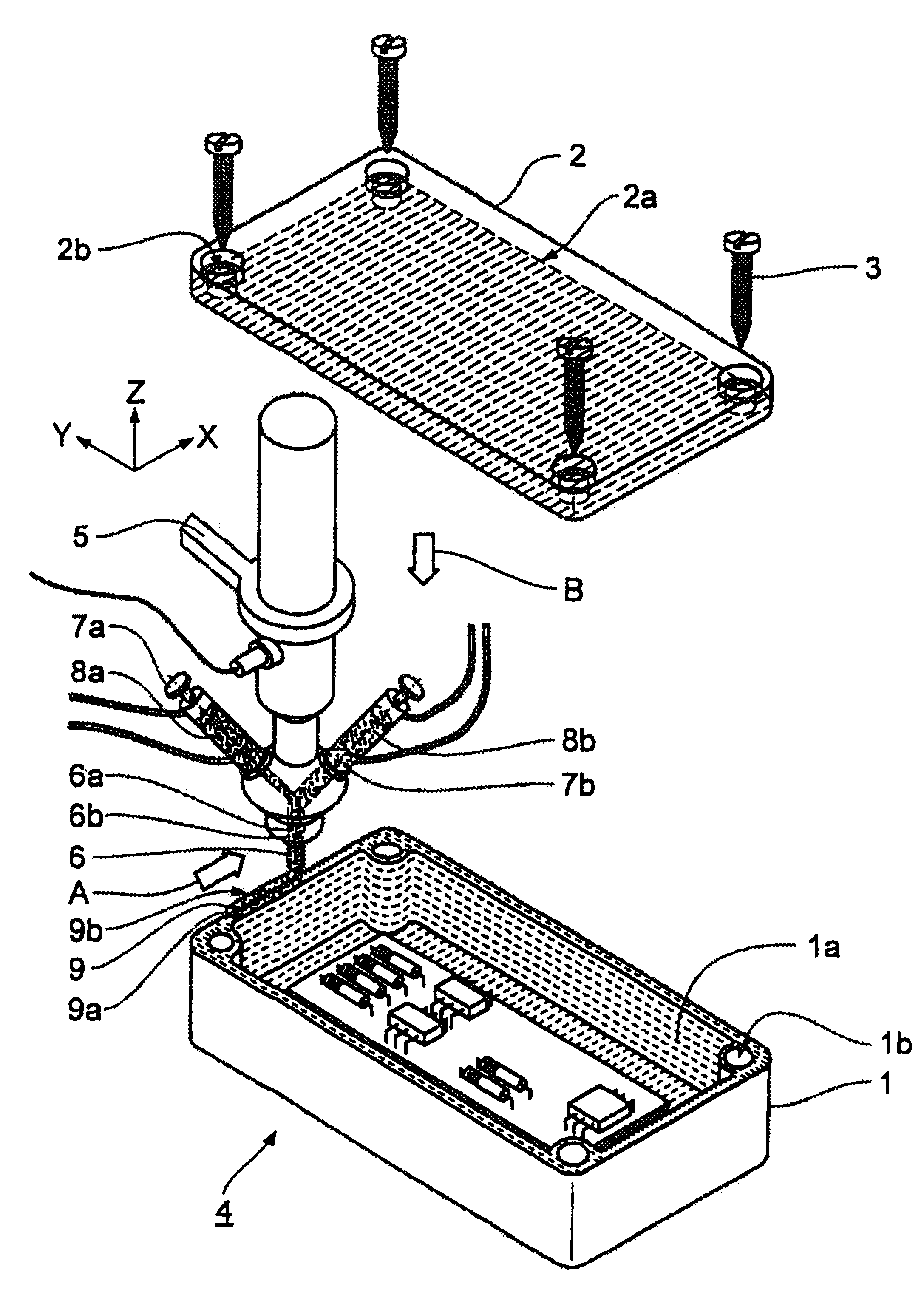

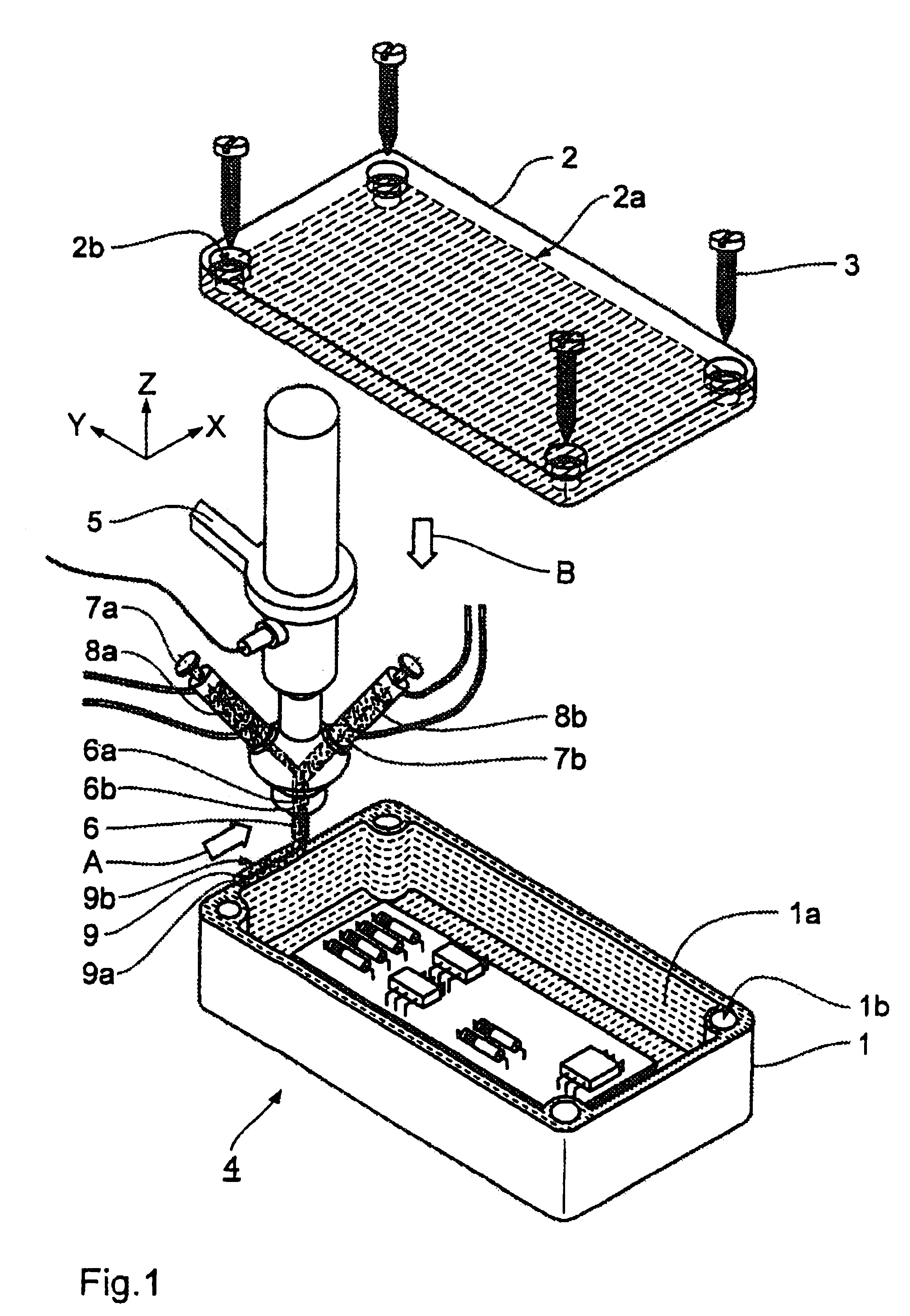

[0029]FIG. 1 is a diagrammatic view showing the principle of a casing bottom portion 1 and a casing cover 2 of injection-moulded plastic material for an electronic device (in practice for example a mobile telephone), which are both provided with an inside metallisation layer 1a and 2a respectively. Formed in both casing portions 1, 2 are screw holes 1b and 2b respectively. wWherein the screw holes 1b in the casing bottom portion are provided for partially self-tappingly screwing in self-tapping screws 3 while the screw holes 2b in the cover each have a countersink for accommodating the screw head of the respective screws 3. This screw connection permits the device casing 4 to be opened and re-closed repeatedly if required.

[0030]The Figure diagrammatically shows the way in which an arm 5 of a coordinate-controlled handling device (not shown overall as such) guides an applicator needle 6 having two concentrically extending passages or ducts 6a, 6b, with hose connections 7a, 7b for fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com