Microparticle carriers of maximal uptake capacity by both M cells and non-M cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

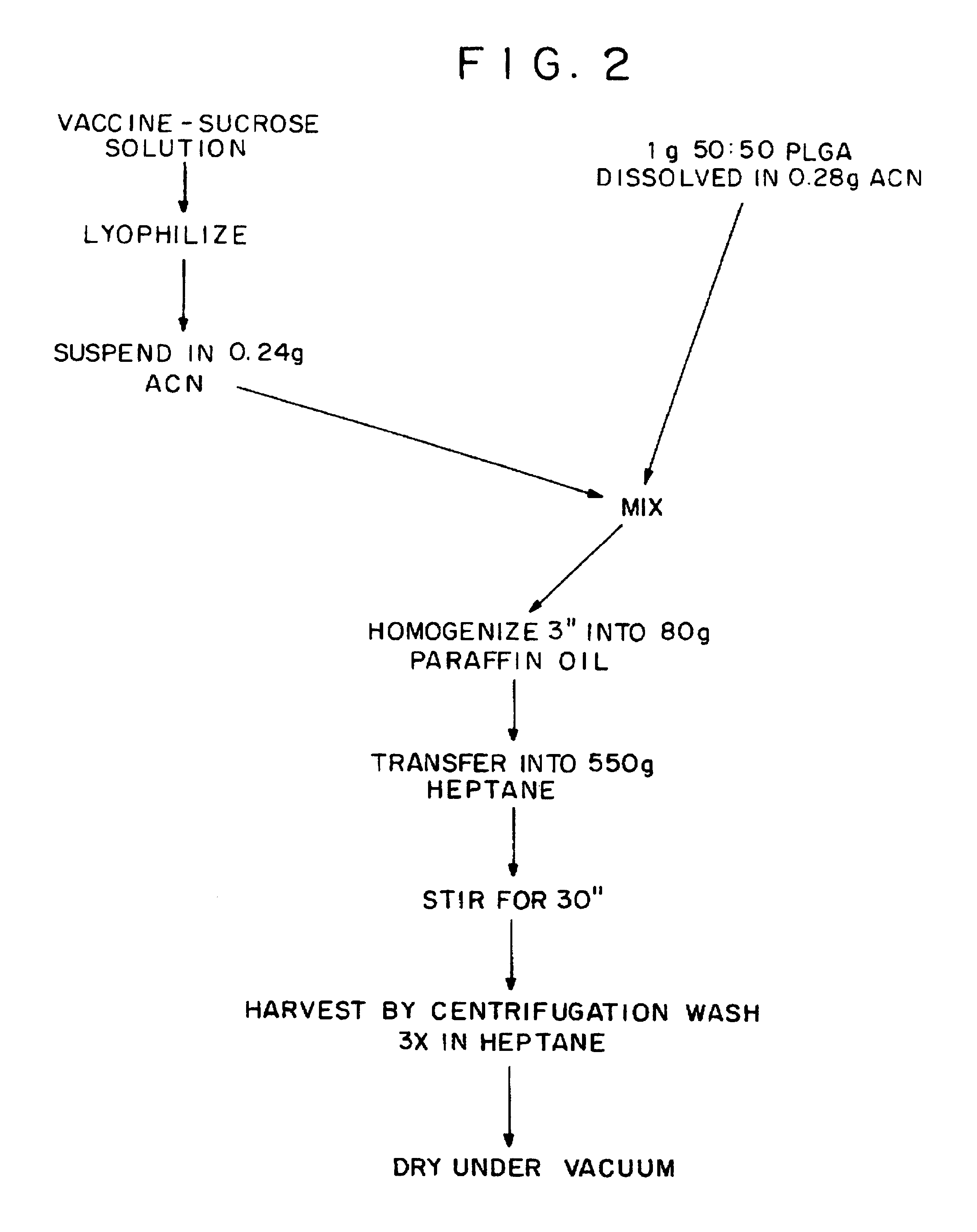

Solvent Extraction

[0039]Preparation of Freeze-Dried Antigen-Sucrose Matrix

[0040]Materials

[0041]8 ml water

[0042]80 mg sucrose

[0043]20 mg purified antigen / active

[0044]The freeze-drier is turned on and the temperature is set at −25 degrees.

Preparation of the Antigen-Sucrose Matrix

[0045]The antigen / active is placed in a 20 ml capacity plastic vial to which water and sucrose are added.

[0046]The dispersion is then flash freezed by gently swirling the vial (without the cap) in liquid nitrogen for about one half of an hour.

[0047]After about 1000 minutes the temperature is elevated to about +5 degrees for 500 minutes (8.33 hours) and then elevated to about +20 degrees for 1000 minutes (16.67 hours), and the vial is removed.

Preparation of Polymerized Lactide Glycolide (PLG) Solution

[0048]The PLG is removed from the freezer and allowed to come to room temperature.

[0049]About 2.8 g of acetonitrile is weighed into a 20 ml capacity glass vial and set aside.

[0050]After the polymer reaches room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com