Fork level indicator for lift trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

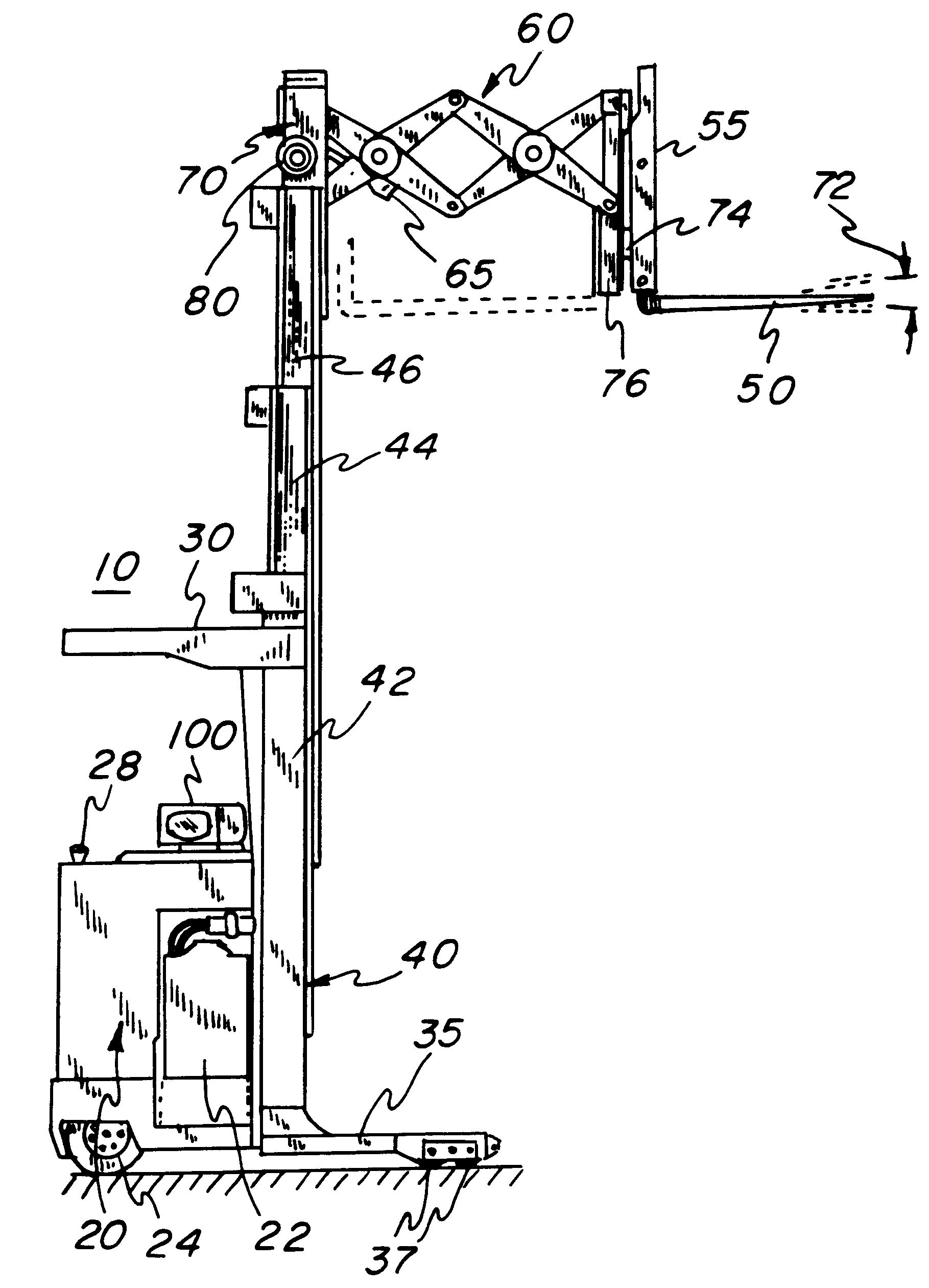

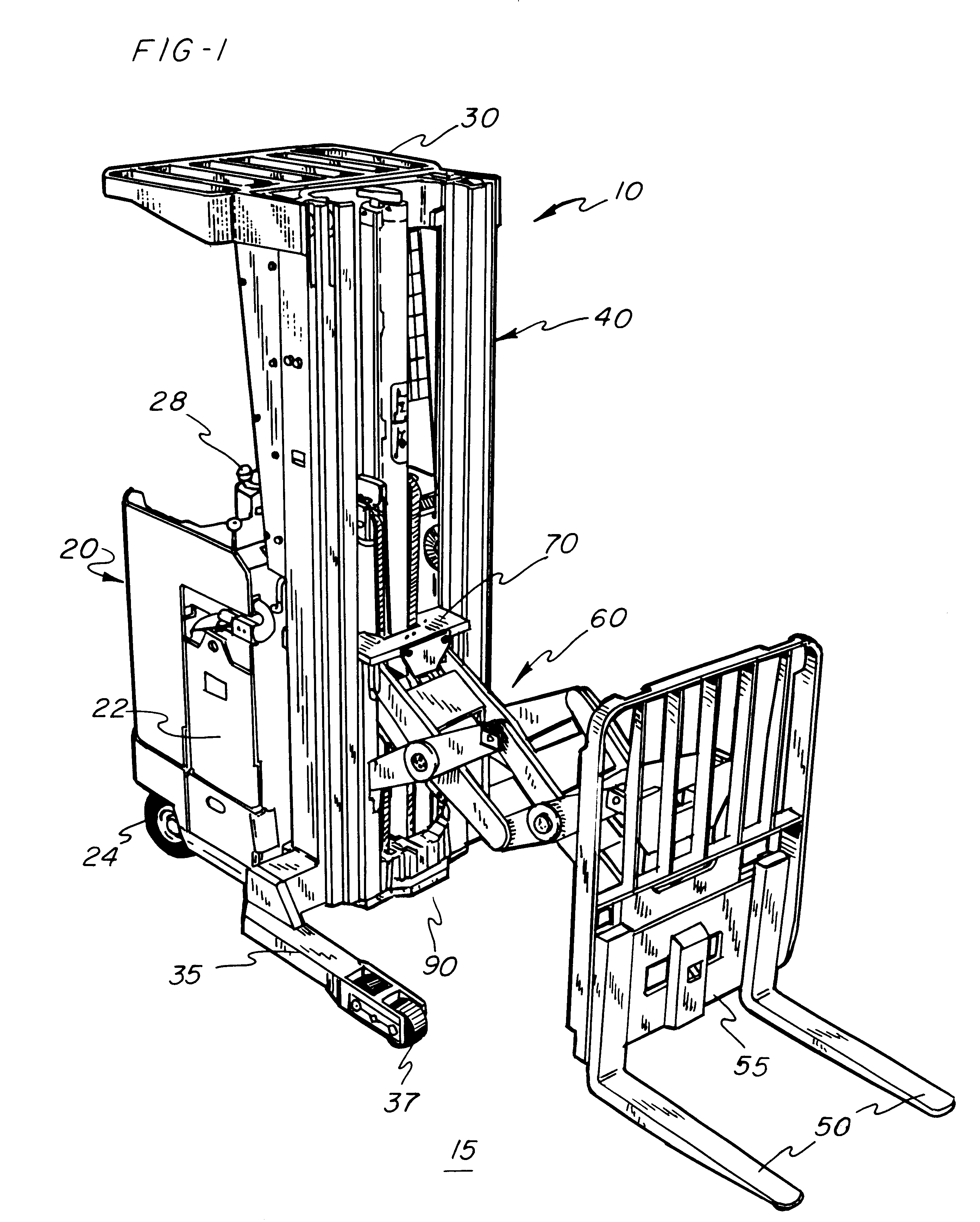

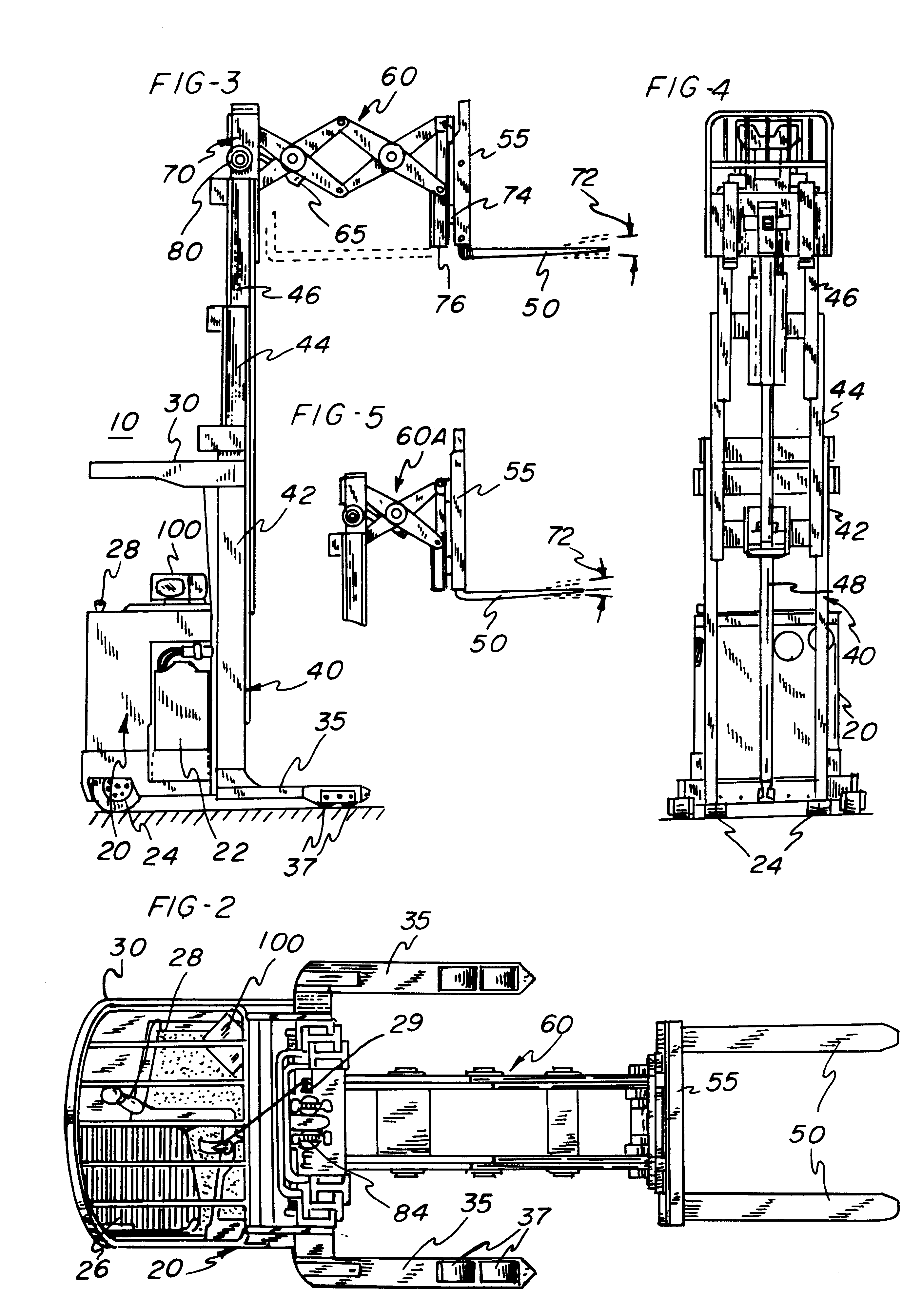

Referring now to the drawings, and particularly to FIGS. 1-5, a self propelled rider-reach lift truck 10 is illustrated as one type of materials handling truck which may incorporate the present invention. The lift truck shown is a model RD 3000 Series truck manufactured by Crown Equipment Corporation, the assignee of the present invention. It is to be understood, however, that other fork lift trucks could also incorporate the present invention, such as Crown models FC, RC, RR, SC and W fork lift trucks.

The truck 10, which operates on floor 15, includes a body 20 that contains a battery 22 supplying power to the truck and various other components, such as electric traction motors (not shown) connected to steerable wheels 24 and hydraulic motors (not shown) which supply hydraulic pressure to fork lift cylinders, as will be explained. An operator's compartment 26 is included on the body 20, along with steering control 28 and control handle 29, which controls the operation of various fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com