Hydrofluoroethers as low temperature refrigerants

a technology of hydrofluoroethers and refrigerants, applied in the field of heat transfer media, can solve the problems of many heat transfer agents that are not considered, their toxicity, and unsuitable for commercial food handling environments, and achieve the effects of low viscosity, low temperature difference factor, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

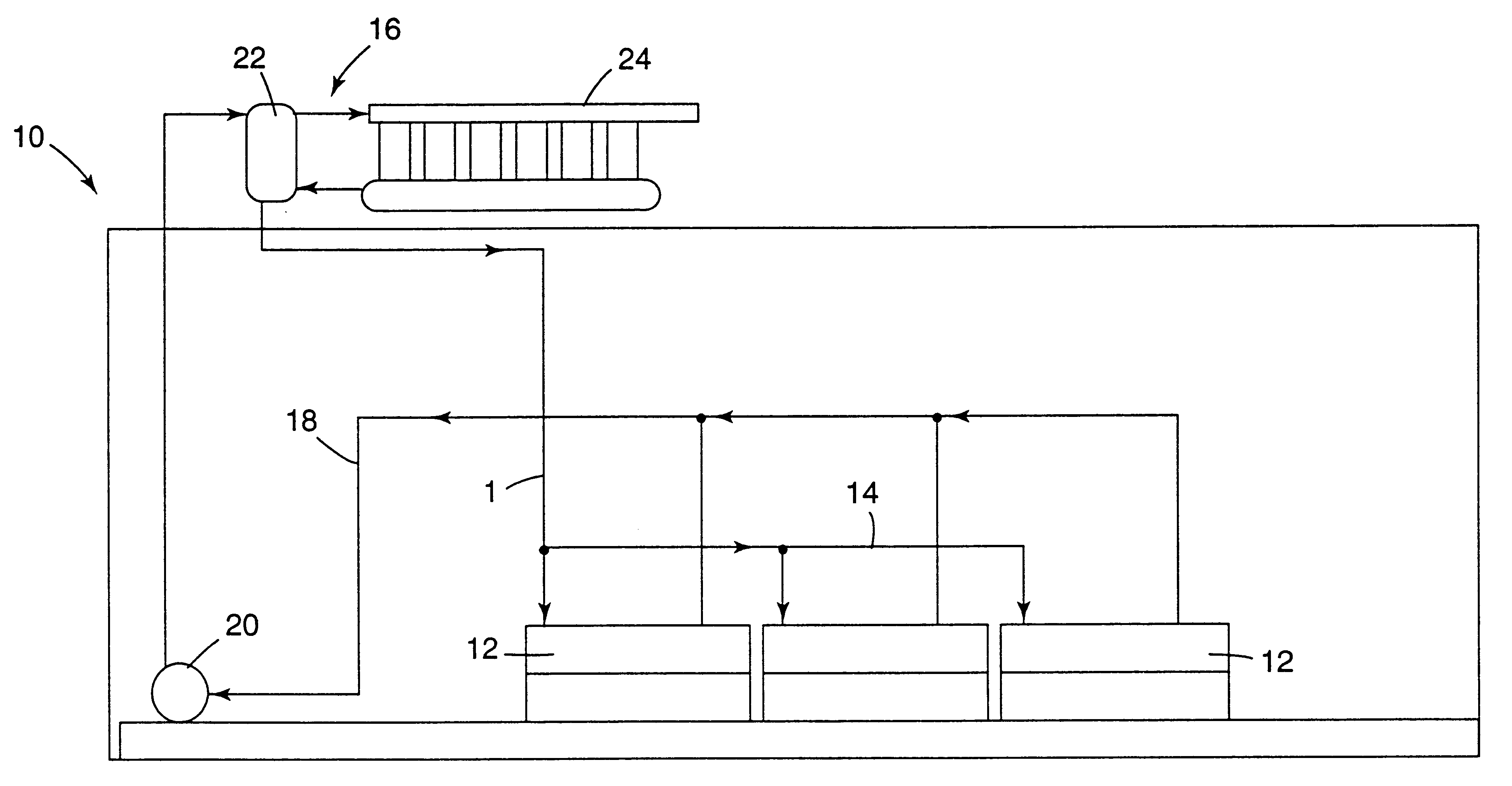

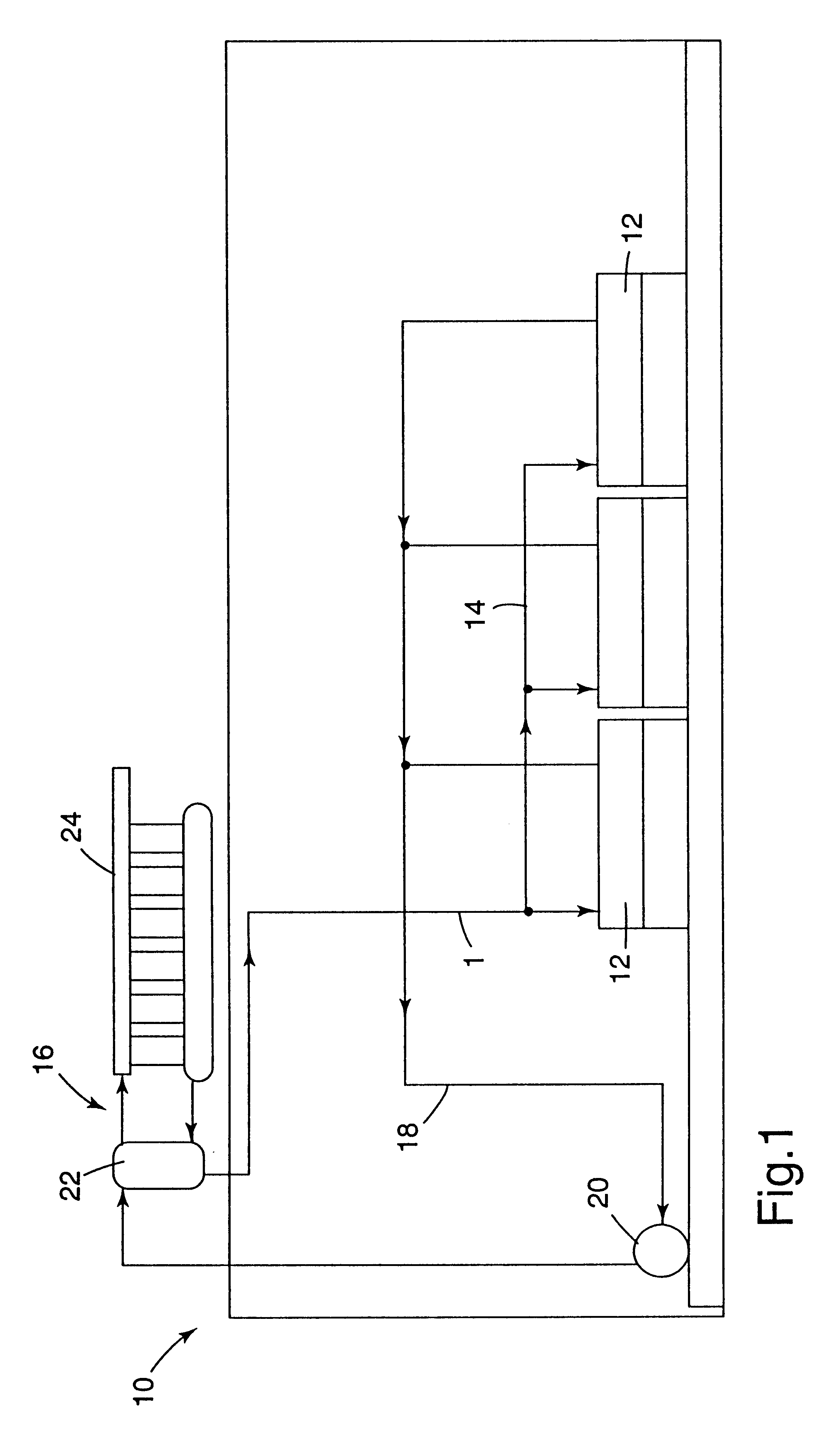

Image

Examples

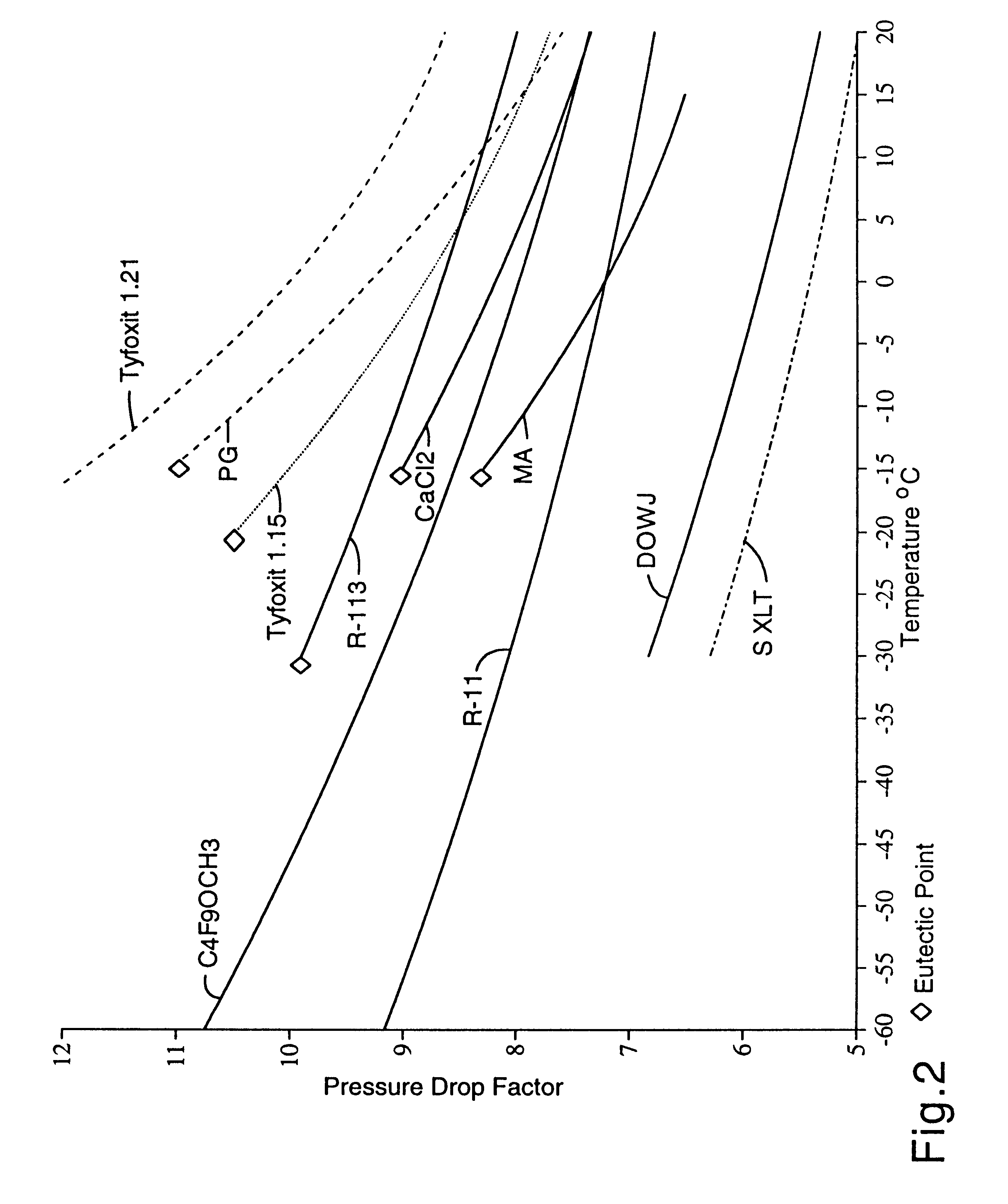

examples 1-4

illustrate the improved performance characteristics of the heat transfer media of the present invention, compared to prior art heat transfer media.

example 1

The thermal conductivities of C.sub.4 F.sub.9 OC.sub.2 H.sub.5, C.sub.4 F.sub.9 OCH.sub.3, C.sub.3 F.sub.7 OCH.sub.3, and C.sub.6 F.sub.14 were determined using a transient hot-wire thermal conductivity cell over the temperature range of -50.degree. C. to +50.degree. C., according to ASTM D 2717-86. A platinum wire was used in the measurements. The wire was 20 cm in length, 0.17 mm in diameter, and had a resistance of 120 .OMEGA. at 20.degree. C. The thermal conductivities are set forth in Tables 1-4.

example 2

The densities of the fluids of Example 1 were determined from 0.degree. C. to +50.degree. C. using a using a Mettier-Parr Model DMA45 densitometer. For temperatures below 0.degree. C., densities were determined by extrapolation of the measured densities with a linear curve fit. The densities are set forth in Tables 1-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com