Radiation hardened microcircuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

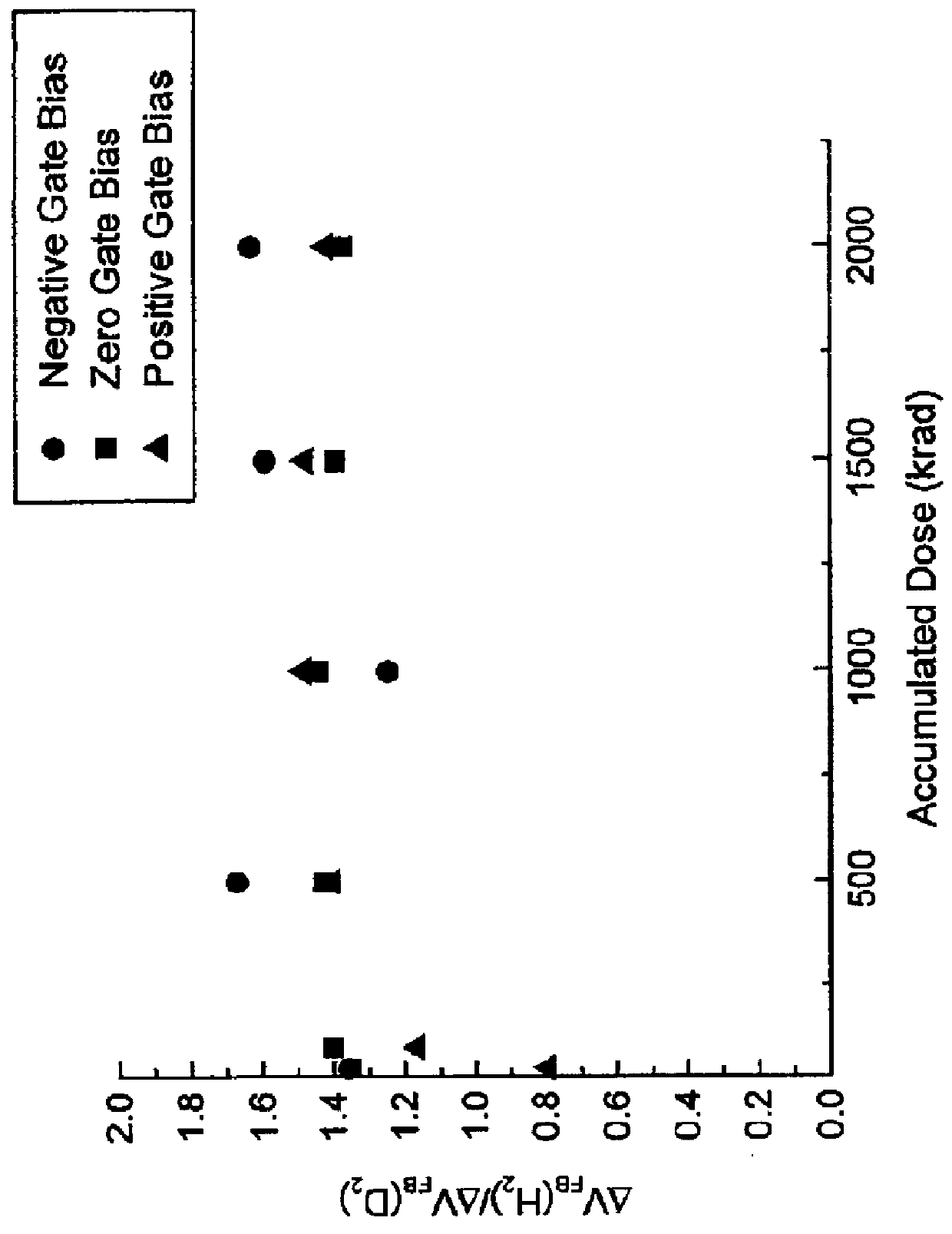

Image

Examples

Embodiment Construction

[0012]Typical silicon-based semiconductor circuits are made up of various devices, e.g., transistors, interconnect lines between the various devices, and isolating dielectrics separating the devices and interconnects from each other. Of these components, the isolating dielectrics are the most susceptible to damage from external radiation. The annealing process of the present invention significantly improves the radiation hardness of these circuits while at the same time reducing hot carrier degradation and electrical stress-induced leakage currents in the individual devices of which the circuit is partly comprised.

[0013]One aspect of the invention is the unique post-fabrication annealing process applied to the semiconductor circuit. First, the finished circuit is baked in a vacuum (−6 torr) for approximate one hour at about 500° C. to remove any hydrogen in the circuit resulting from the fabrication process. The temperature of this out-gassing anneal stage is chosen to enhance remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com