Microelectro-mechanical systems (MEMS) microphone package device and MEMS packaging method thereof

a micro-electro-mechanical system and microphone technology, applied in the direction of solid-state device transducers, loudspeakers, electrostatic transducers of semiconductor, etc., can solve the problem of relatively large volume of the package, and achieve the effect of small volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In the invention, the Silicon MEMS microphone chip has the integrated circuit embedded in the same chip. The Silicon MEMS microphone chip in package is a single ship. The Silicon MEMS microphone chip can be adhered to the substrate by the adhesive structure for form a fully sealed space except the acoustic aperture to receive the acoustic source from the environment.

[0024]Several embodiments are provided for descriptions of the invention. However, the invention is not just limited to the provided embodiments.

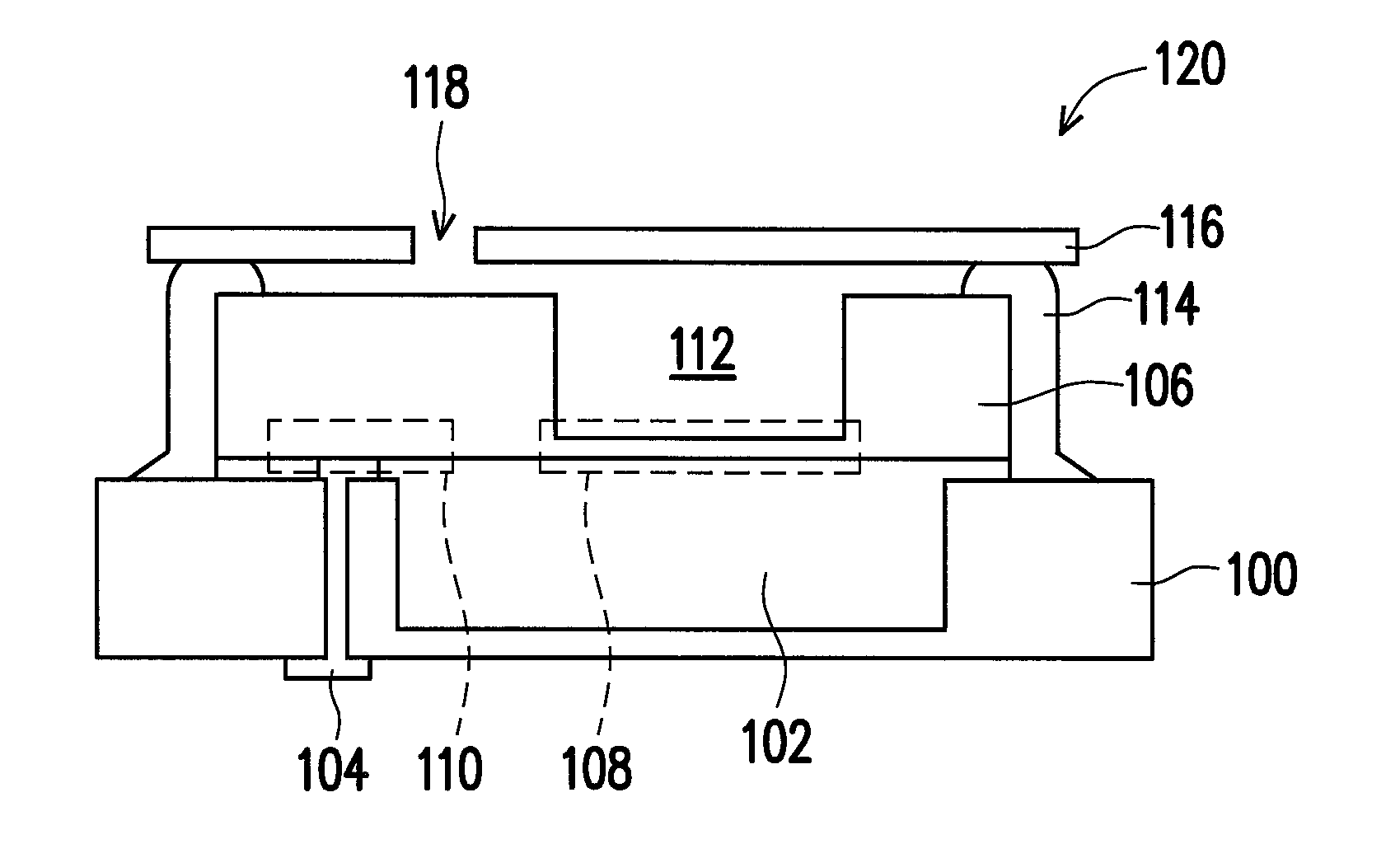

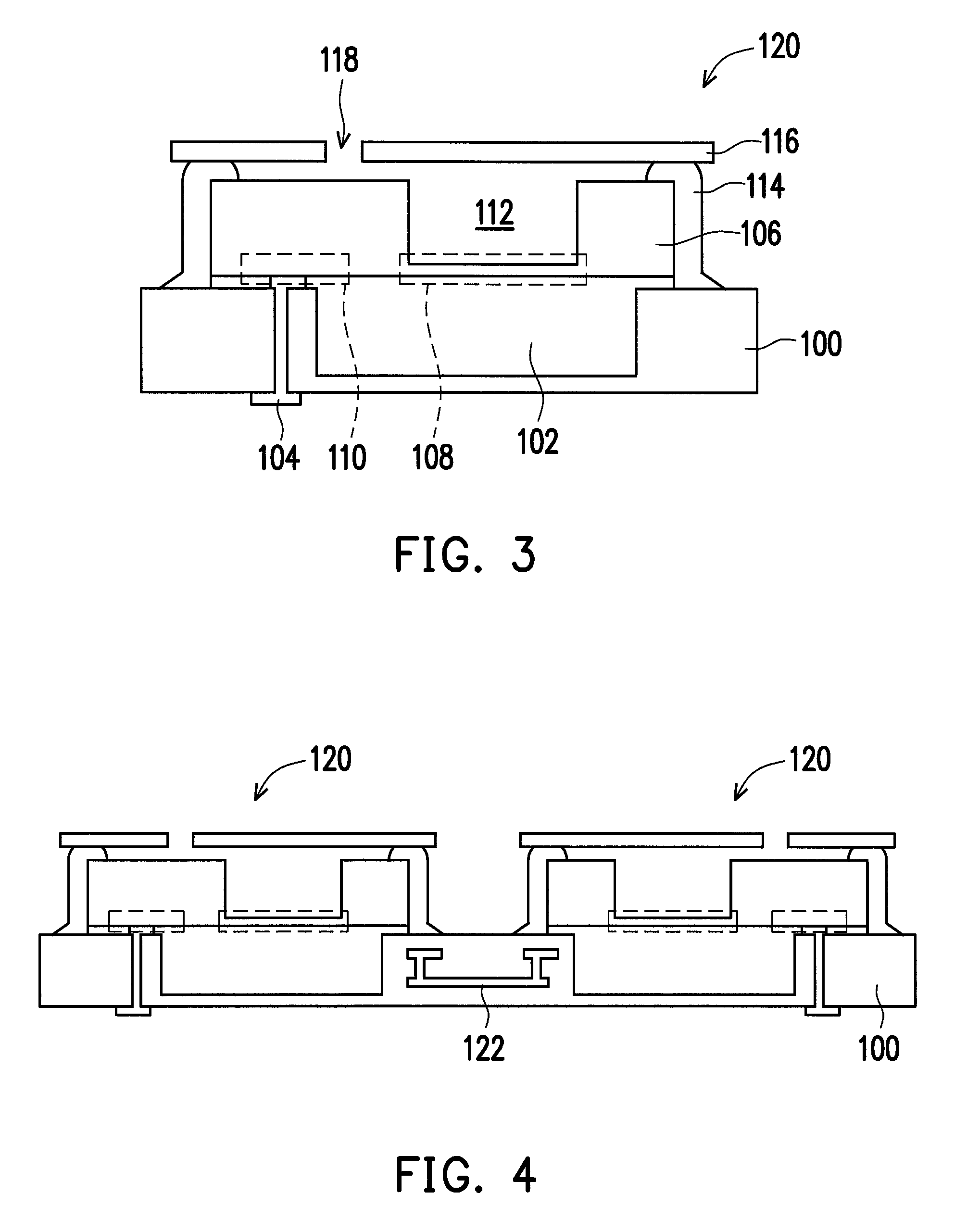

[0025]FIG. 3 is a drawing, schematically a cross-section view of a MEMS microphone package device, according to an embodiment of the invention. In FIG. 3, a MEMS microphone package device 120 includes a substrate 100 as a base. The substrate 100 has interconnection structure 104, which has multiple connection pads 104, such as metal pad, on both surfaces of the substrate. In FIG. 3, only one connection pad is shown. However, it can be understood that the interconnection st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com