Hybrid cycle rotary engine

a rotary engine and hybrid technology, applied in the field of hybrid cycle rotary engine, can solve the problems of too low maximum efficiency, difficult and costly control, and polluted hcci cycle engine, and achieve the effect of increasing the pressure and enhancing the formation of turbulen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

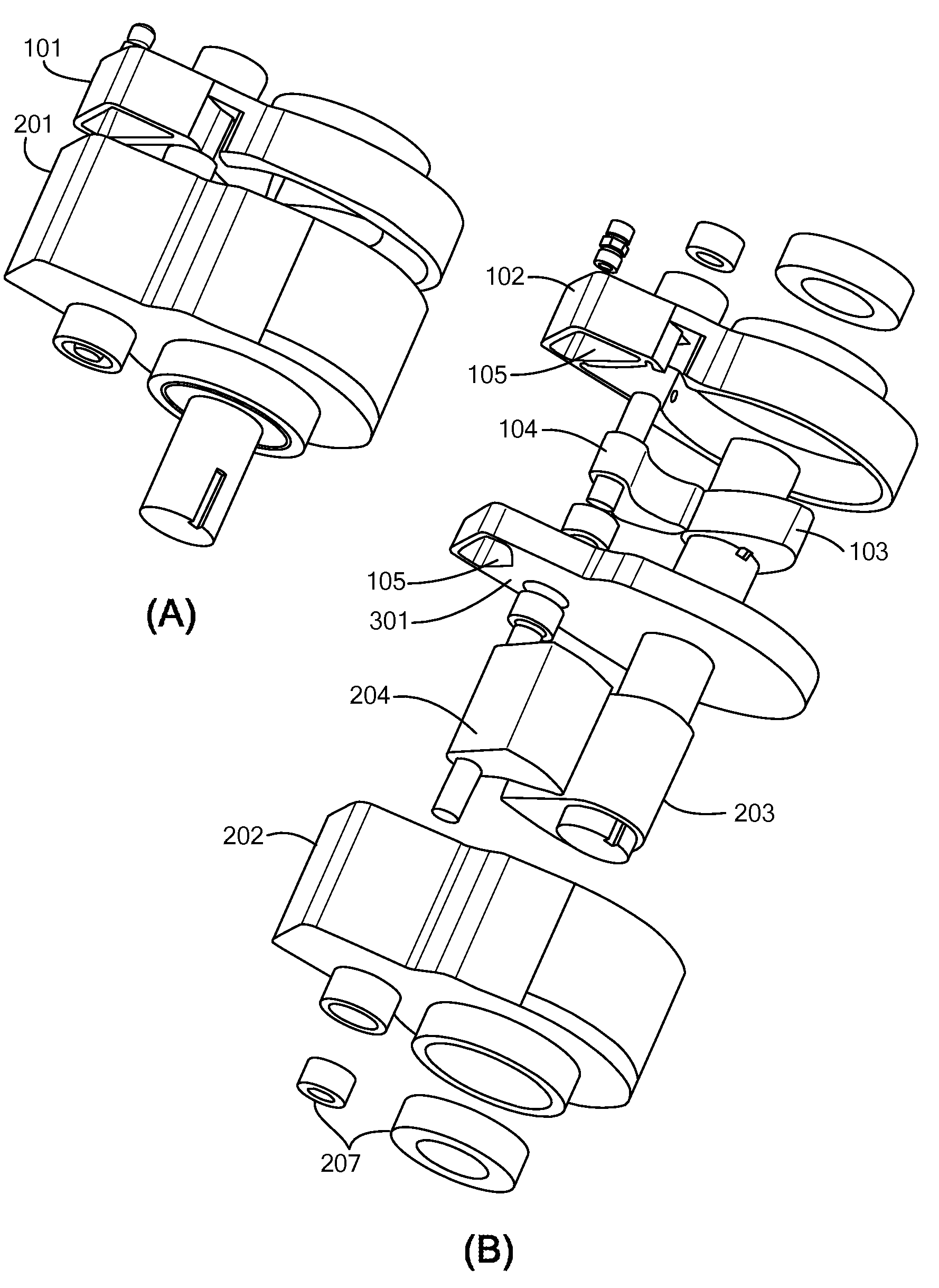

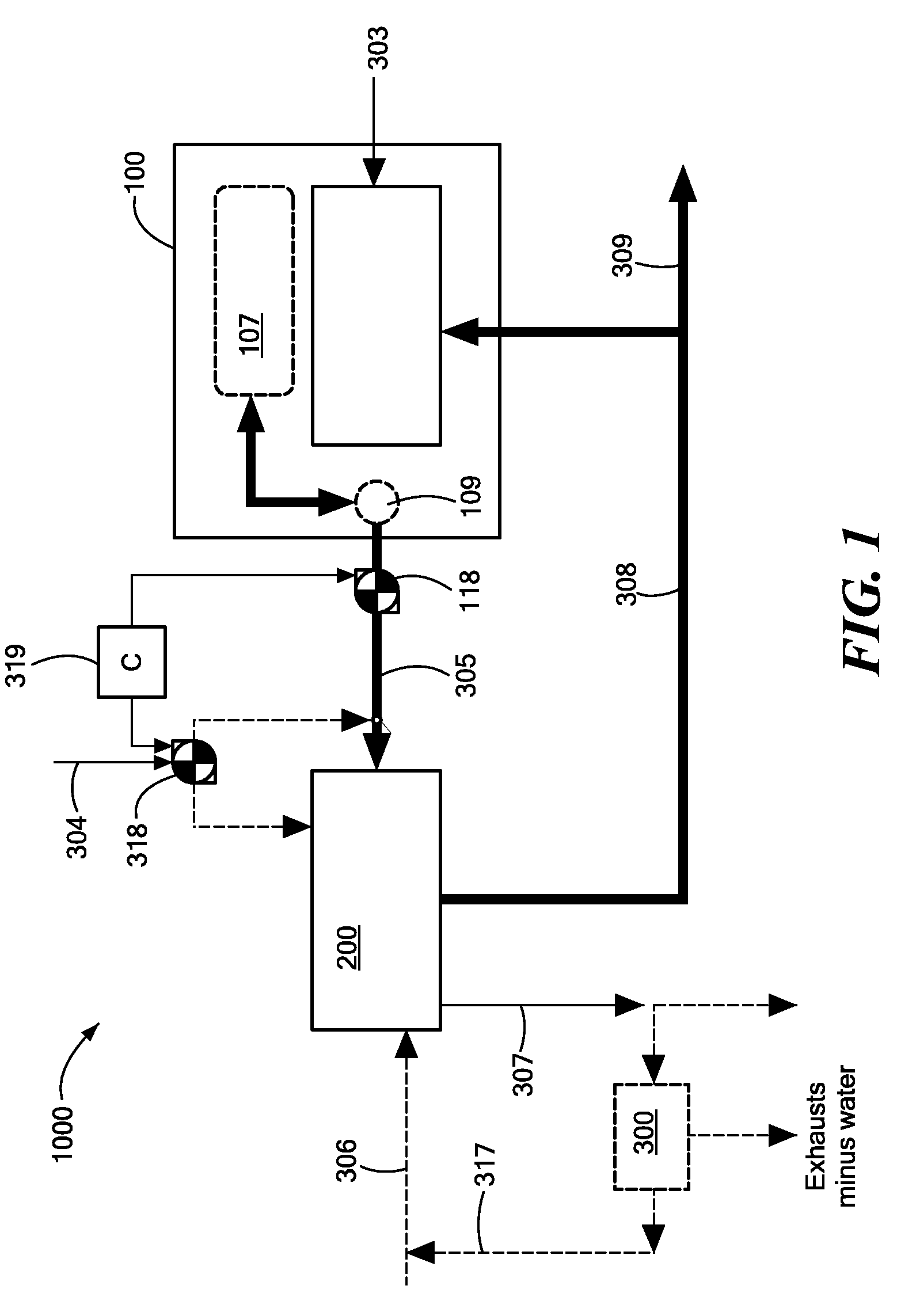

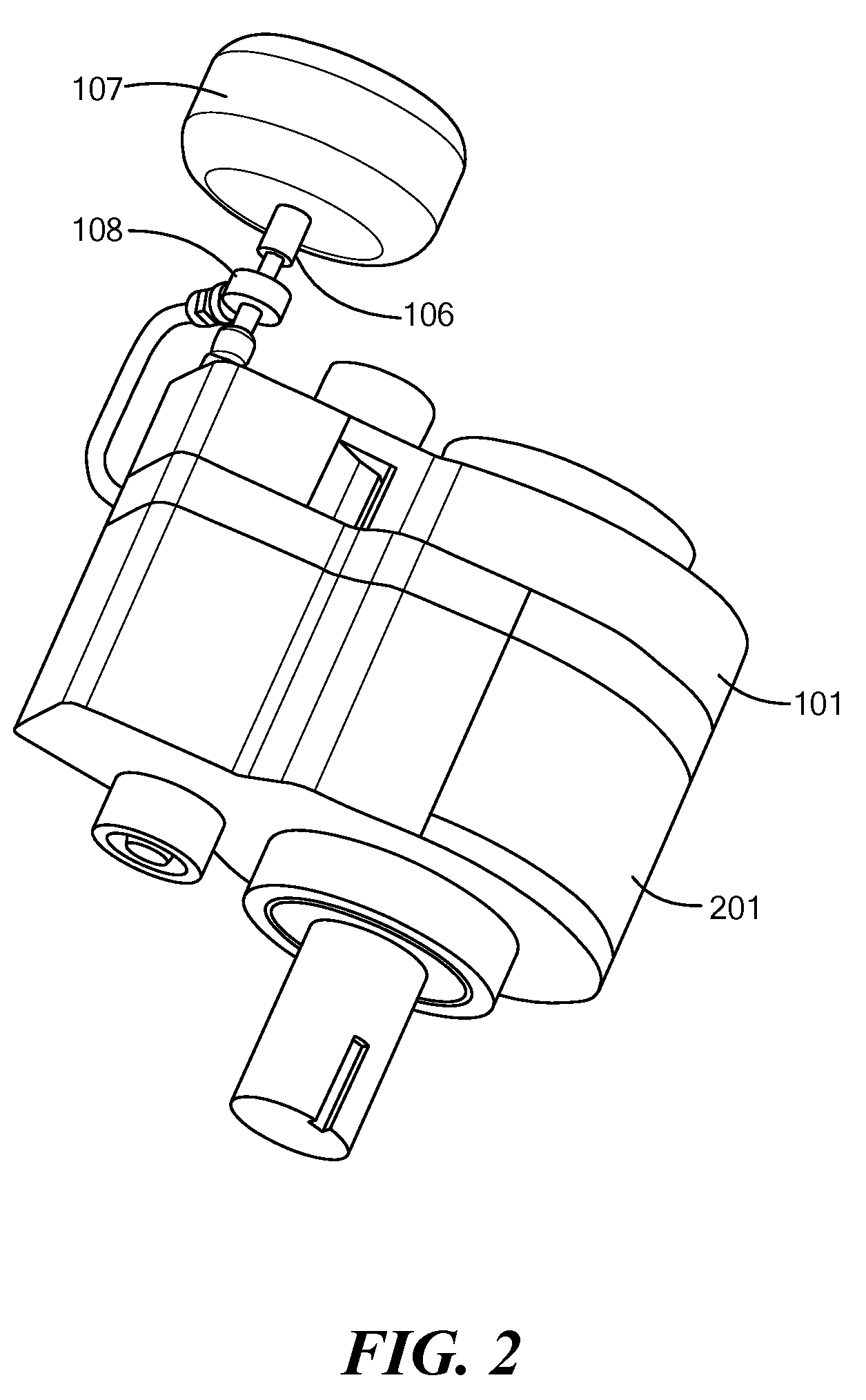

Method used

Image

Examples

Embodiment Construction

[0053]Definitions. As used in this description and the accompanying claims, the following terms shall have the meanings indicated, unless the context otherwise requires:

[0054]“Sealing contact” of two members shall mean that the members have sufficient proximity directly, or via one or more sealing components, so as to have acceptably small leakage between the two members. A sealing contact can be intermittent when the members are not always proximate to one another.

[0055]A port is “coupled” to a chamber when at least some of the time during a cycle it is in communication with the chamber.

[0056]A full “reciprocation cycle” of a rocker that reciprocates between seated position and a maximum unseated position includes 360 degrees of travel of the main shaft, wherein travel from one of such positions to the other of such positions amounts to 180 degrees of travel of the main shaft.

[0057]The “working medium” describes the various substances which may usefully injected into the working ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com