Manifold for a pile configured battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

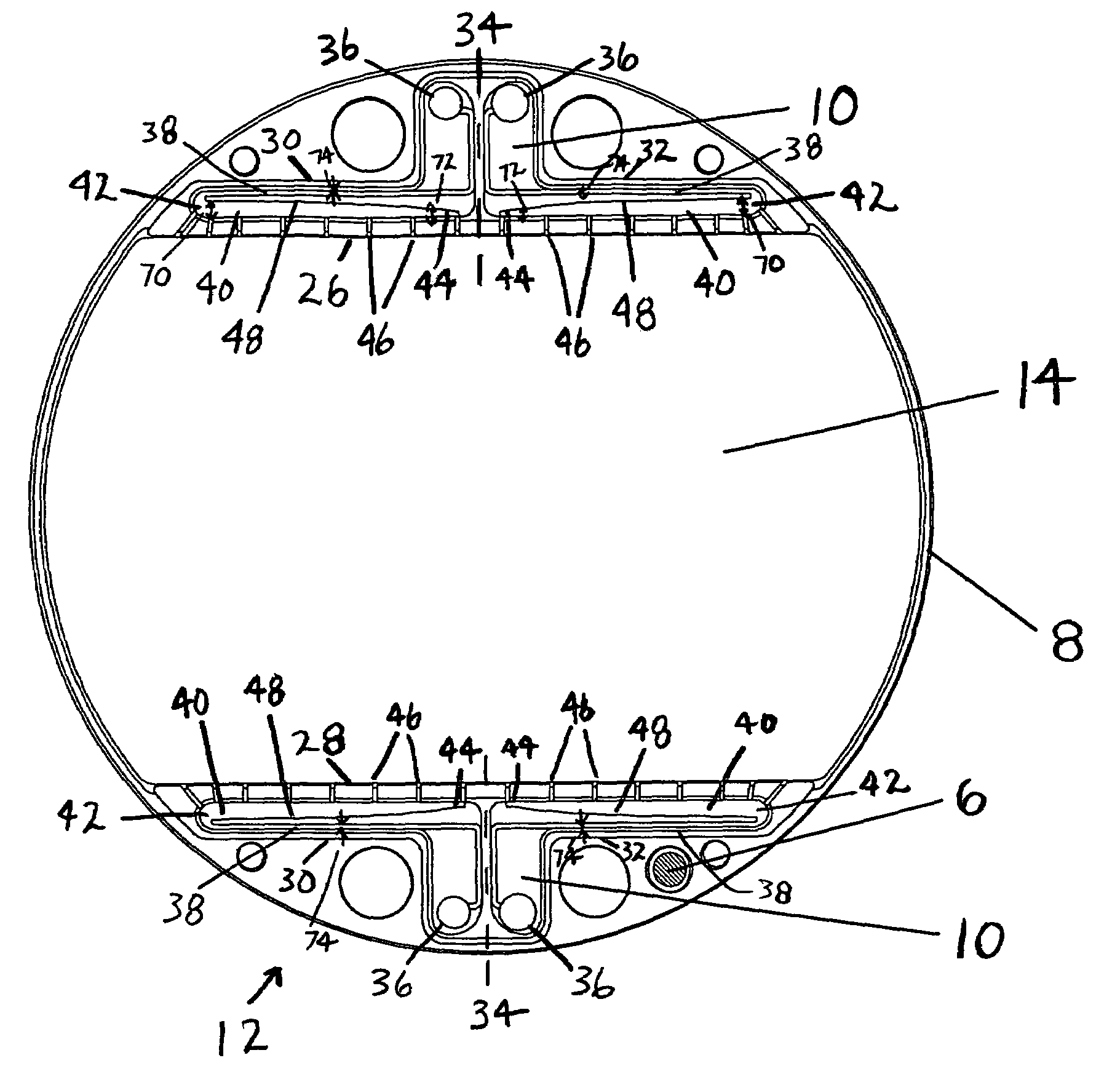

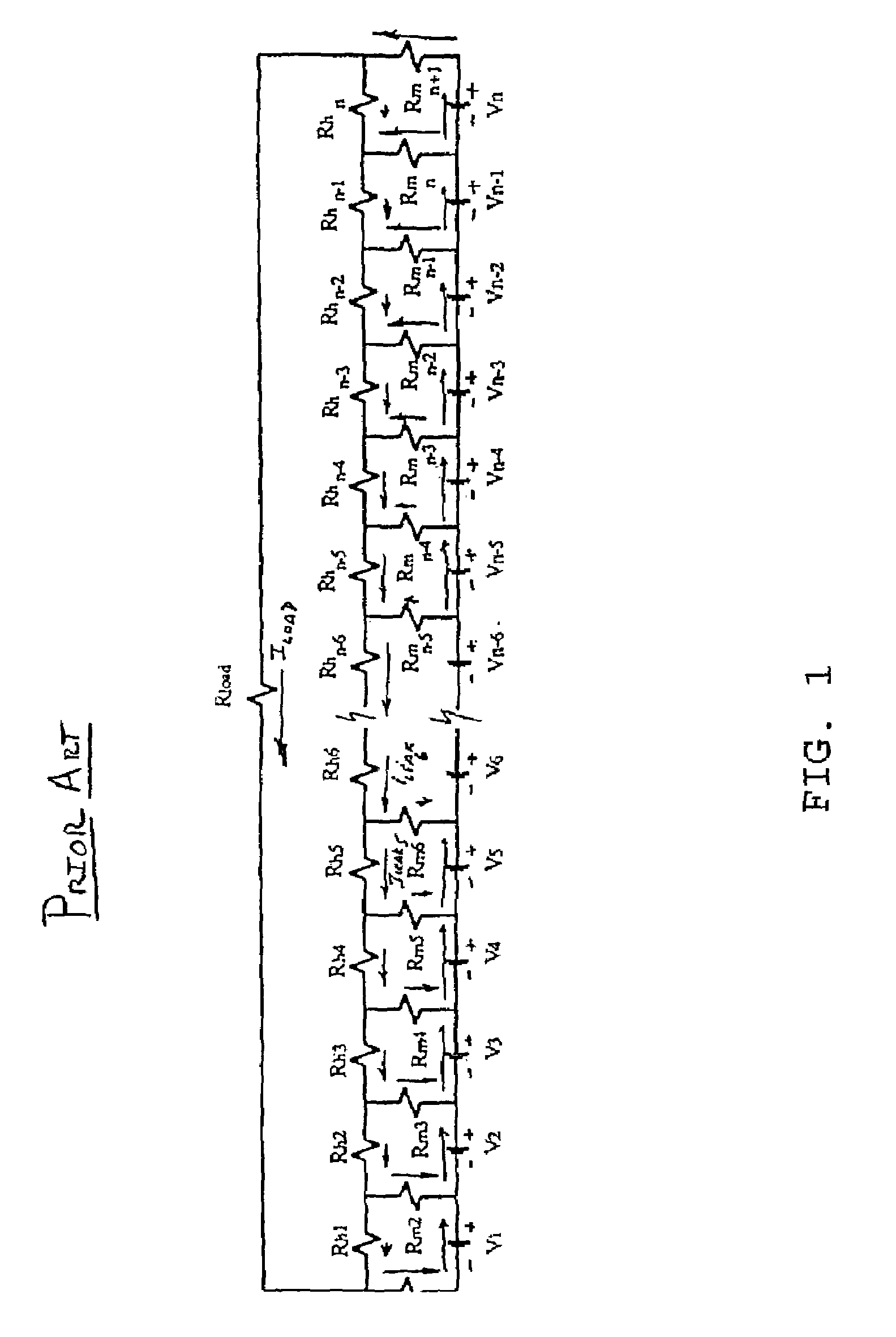

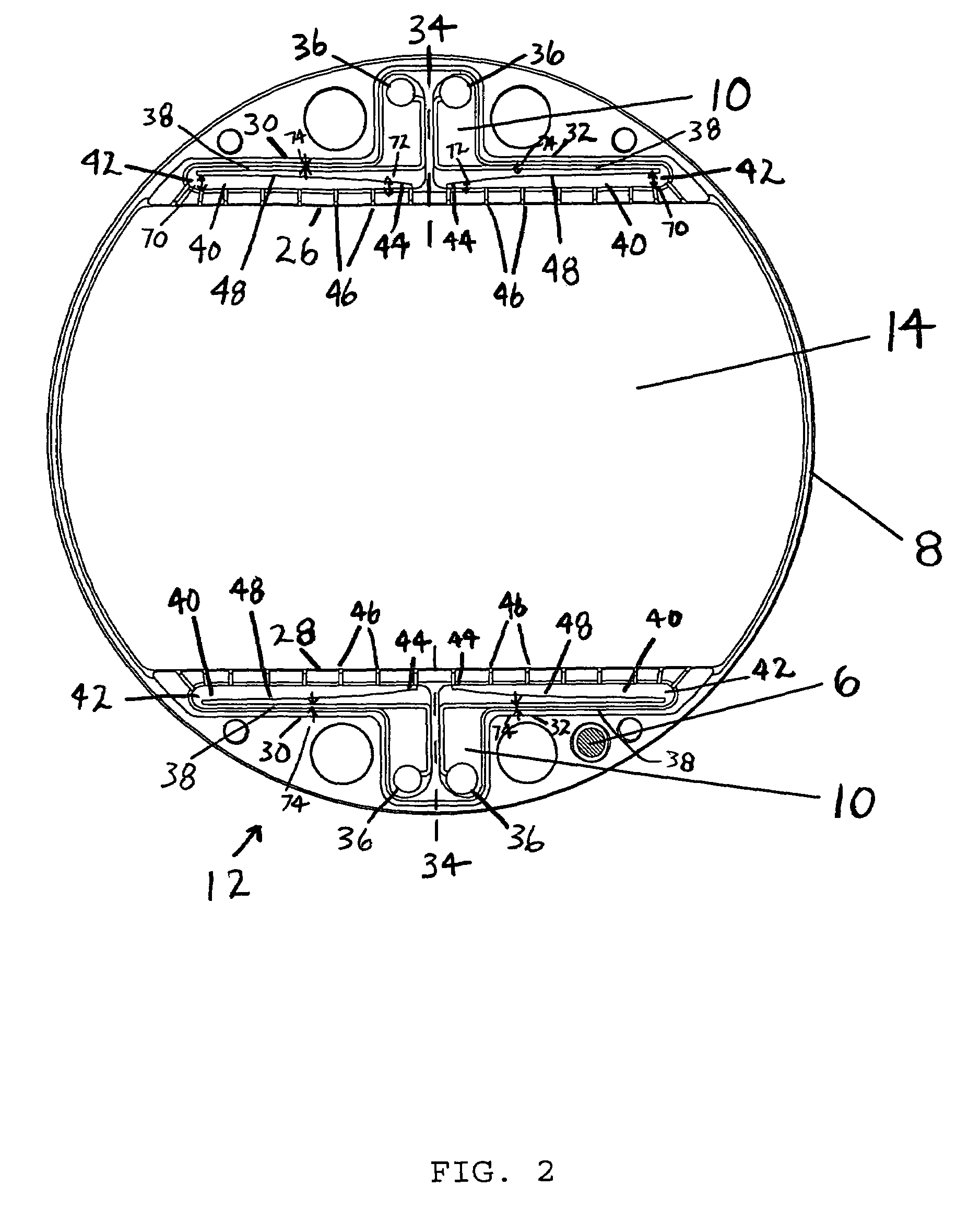

[0028]The invention, as embodied herein, comprises an improved method of fabricating and discharging a pile configured battery which utilizes an electrically conductive flowing aqueous electrolyte. This is accomplished by use of a single piece hydraulic manifold plate which decouples the hydraulic performance parameters of the manifold from the electrical performance parameters. The manifold plate comprises a configuration of hydraulic feed channels and distribution headers which separately account for electrical resistive effects and fluid viscous and dynamic pressure effects. Implementation of such manifold plates allow for improved energy conversion efficiency as well as utilization of multiple dissimilar fluids in a single battery cartridge cell discharge at greatly reduced complexity and cost.

[0029]Many high rate, pile configured, batteries consist of over 200 cells electrically connected in series and hydraulically connected in parallel, mandating common electrolyte paths to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com