Strand-reinforced composite material

a composite material and strand technology, applied in the field of elastic composite materials, can solve the problems of wearer's skin, leakage of garments, rough and uncomfortable laminates,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

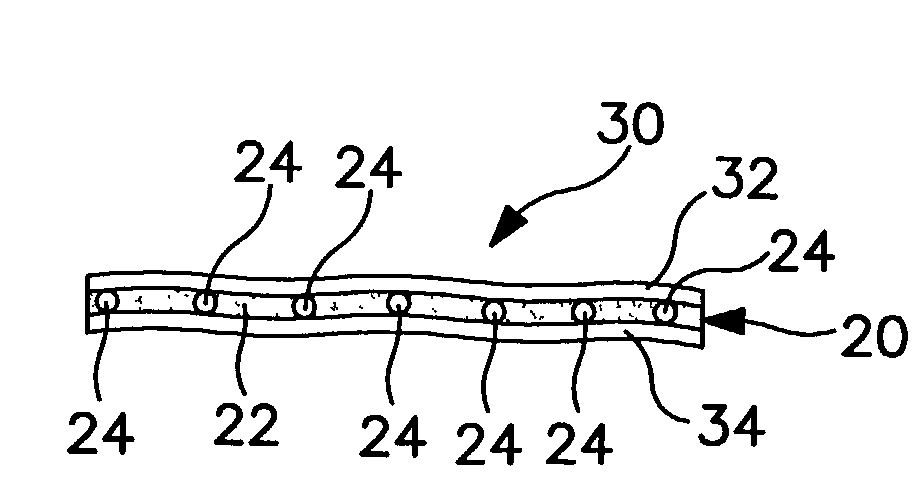

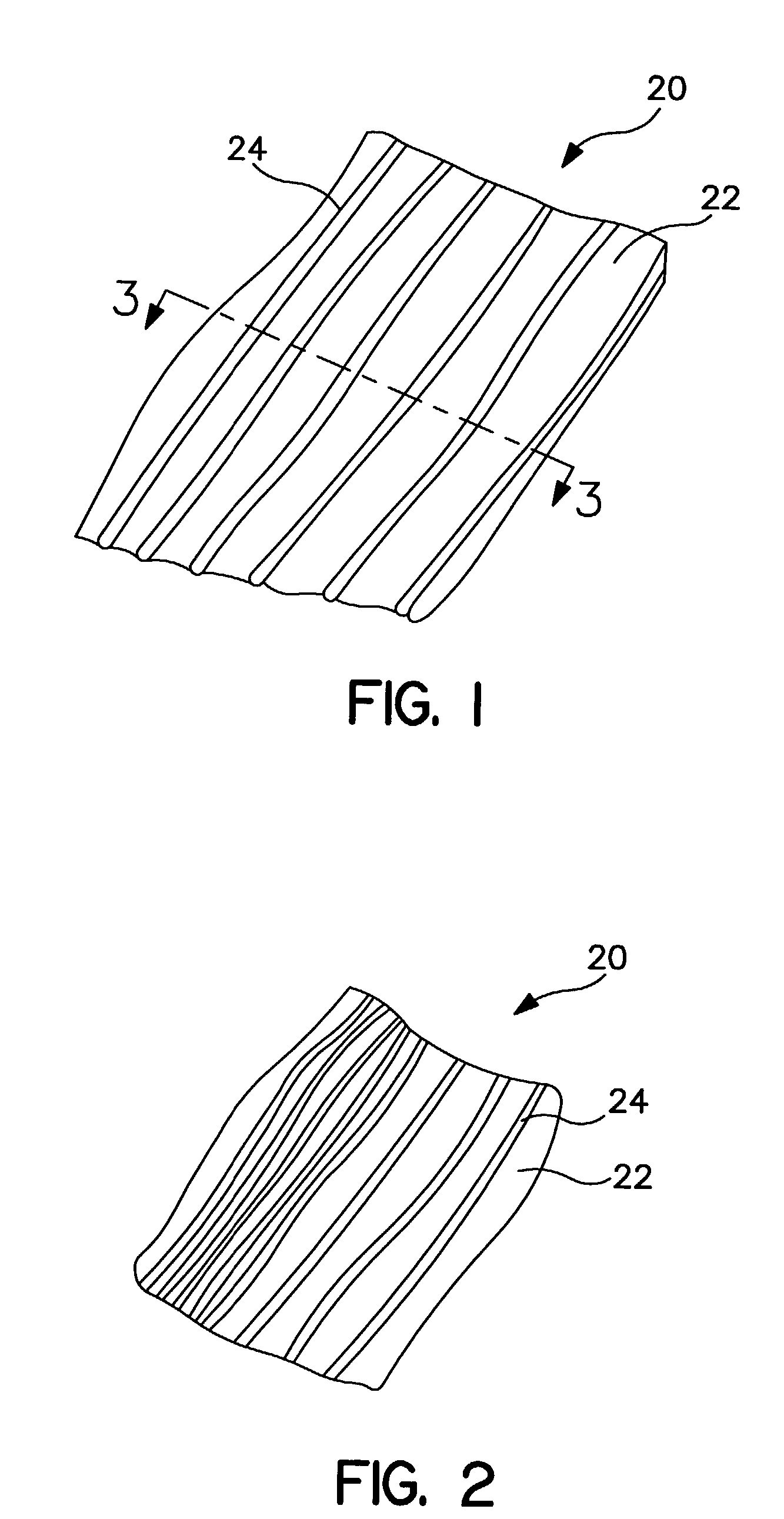

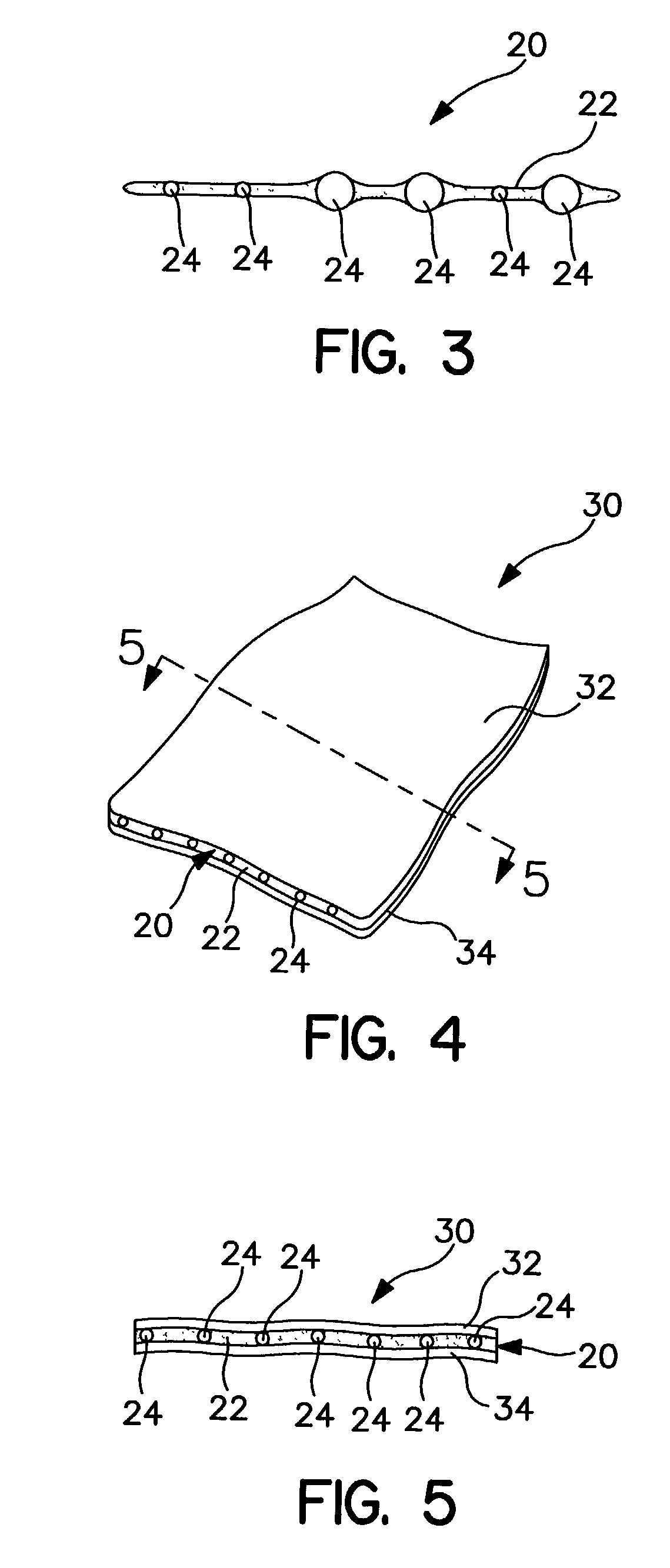

Image

Examples

example 1

[0071]In this example, a strand-reinforced laminate material (sample B) was made in accordance with the invention and the tension decay properties were compared to a control (sample A) having the same elastomeric adhesive film composition without the elastic strands. In each case, the film add-on before stretching to 800% was 80 gsm and the elastomeric adhesive film composition was a mixture of 35 wt % PICOLYTE S115 and 65% KRATON G2760, to which 10% Hercules PICOLYTE S25 was added. More particularly, the elastic adhesive film underwent process elongation of between 500% and 800%, resulting in an output basis weight of between 70 and 120 grams per square meter (gsm) before stretching onto a chill roll having a temperature of 10 to 15 degrees Celsius, from a melt tank having a temperature of up to 400 degrees Fahrenheit.

[0072]The control spunbond / film / spunbond laminate sample (sample A) was made without any reinforcing strands. The test sample (sample B) was reinforced with VFL extru...

example 2

[0076]In this example, the strand-reinforced laminate material (sample B) of Example 1 was incorporated into the leg cuff portion of a personal care garment, as indicated by the reference number 30 in FIG. 8. The “in-product” tension properties were evaluated and compared to conventional spunbonded laminates (SBL) and Lycra laminates (including Lycra strands adhered with elastic attachment adhesive). The “in-product” tension values of the elasticized laminate composite portion of the personal care garment are shown in Table 2 and were measured as follows.

[0077]The garment was extended flat on a lightbox and clamped at one end while a 1000 gram weight in the form of a bar was attached at the other end, resulting in stretching of the material in the machine direction. Two marks corresponding to a discrete gauge length value in the range of 4-7 inches were placed on the stretched elastic portion. The weight was removed and the retracted elastic laminate composite was cut out from the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com