High efficiency, wet-base, downfired multi-pass water heater

a multi-pass, water heater technology, applied in water heaters, lighting and heating apparatus, climate sustainability, etc., can solve the problems of inability to meet the needs of water heaters. to achieve the effect of reducing the number of problems, avoiding the formation of a new type of water heater, and avoiding the formation of new types of water heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

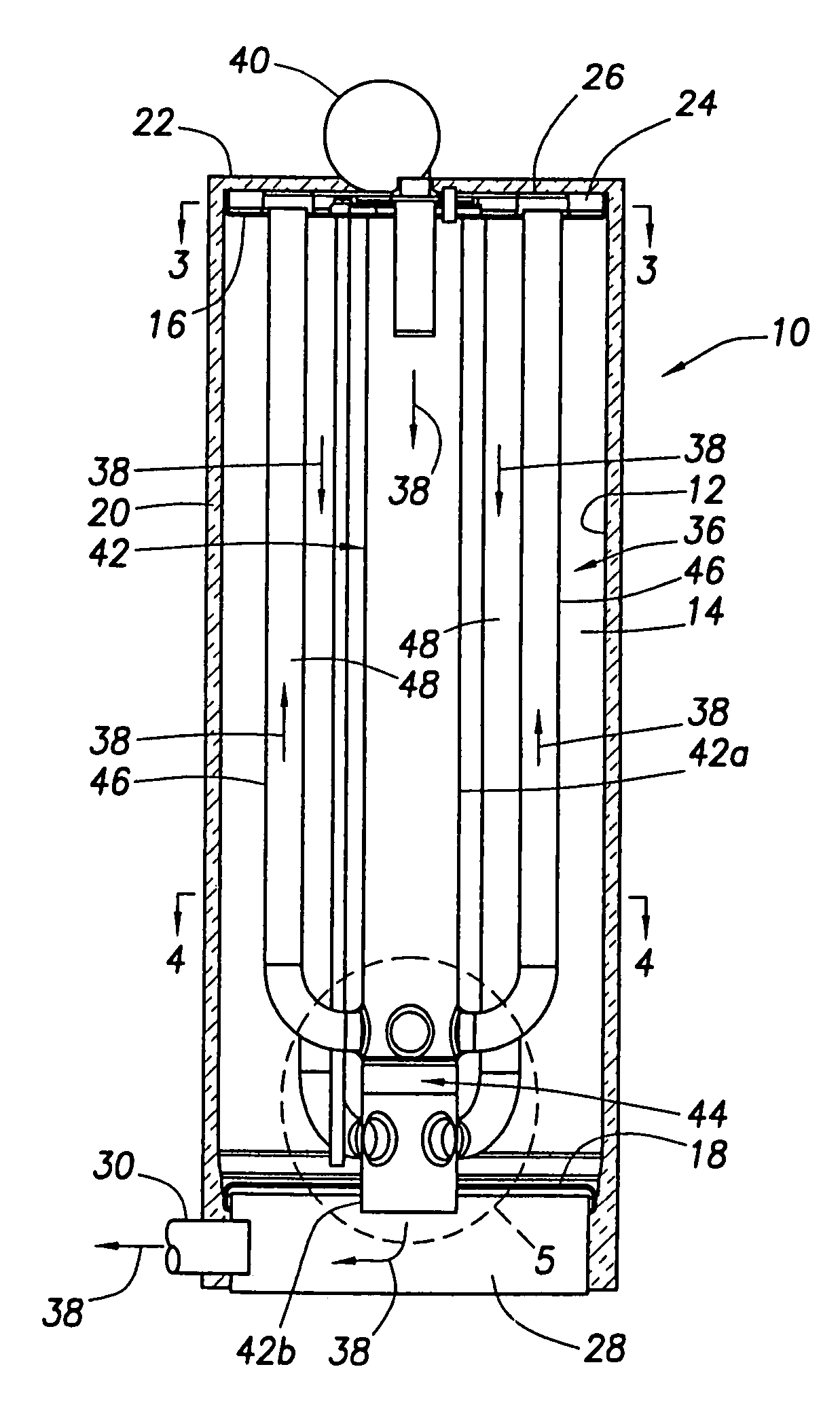

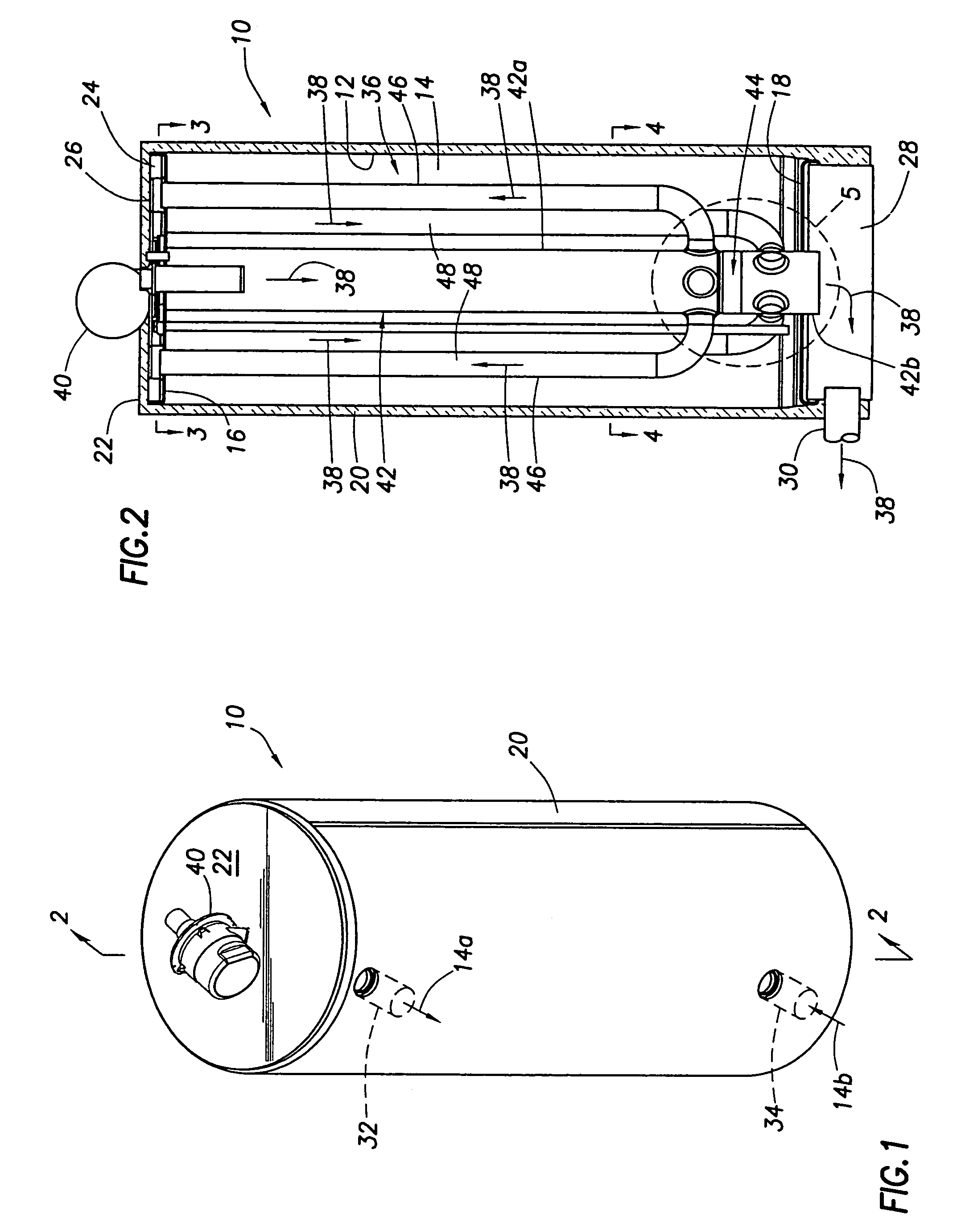

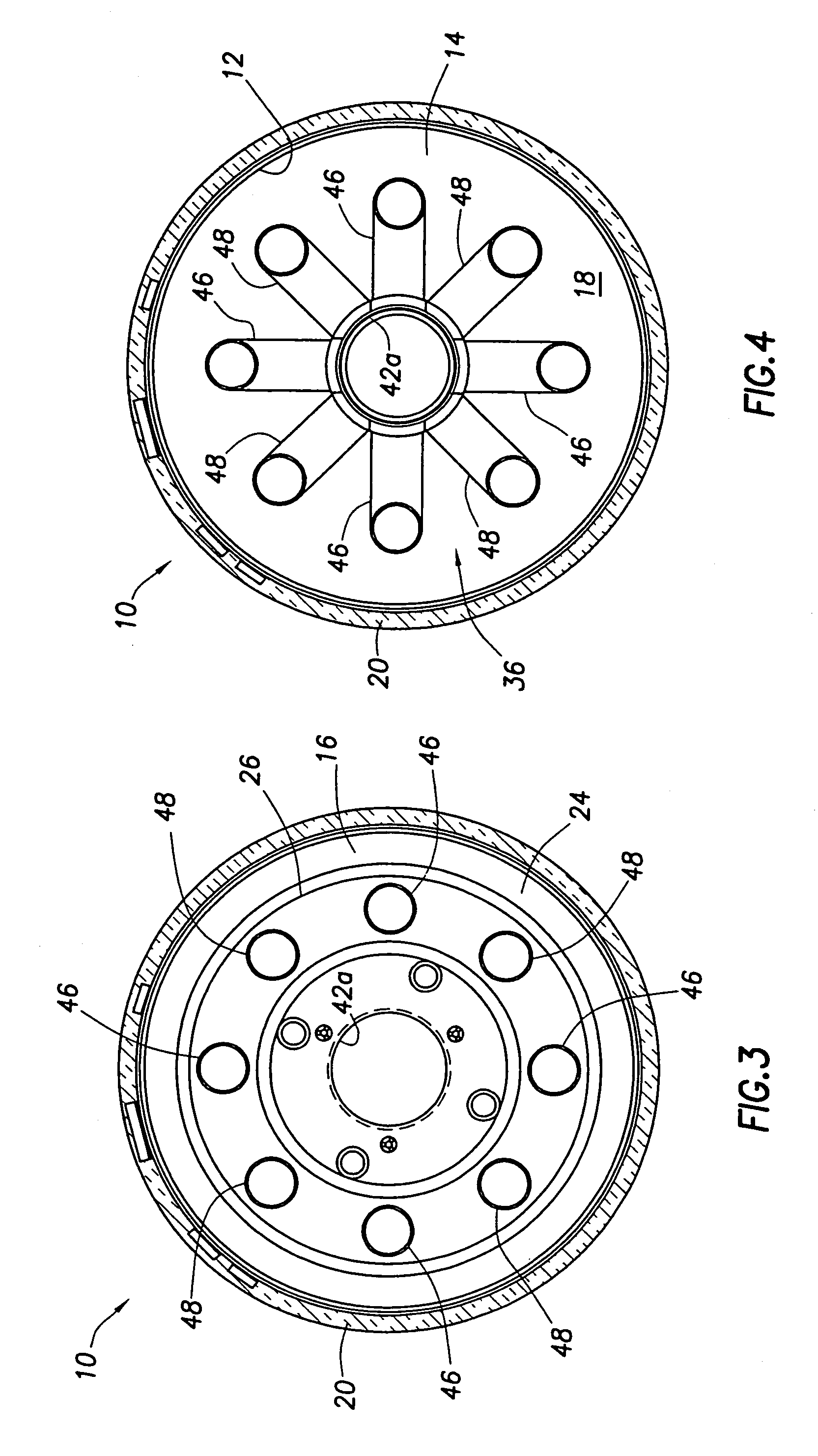

[0017]Referring initially to FIGS. 1 and 2, the present invention provides a specially designed fuel-fired heating appliance 10 which is representatively a gas-fired water heater but could alternatively be another type of fuel-fired heating apparatus such as, for example, a boiler water heater 10 representatively has a vertically elongated cylindrical configuration and includes a metal tank 12 adapted to receive and store a quantity of water 14 to be heated. Tank 12 has a top end wall 16 and a bottom end wall 18, and is disposed within an insulated jacket structure 20 having a top wall 22 spaced upwardly apart from the top end wall 16 of the tank 12.

[0018]An upper end portion of the jacket structure 20 defines a cylindrical interior space 24 above the top end wall 16 of the tank 12, and an annular plenum structure 26 extends along the top side of the tank end wall 16 within the interior space 24. For purposes later described herein, a cylindrical bottom plenum structure 28 extends d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com