Steel piston ring

a technology of steel piston ring and chromium plating layer, which is applied in the direction of brake systems, machines/engines, transportation and packaging, etc., can solve the problems of increasing the requirements of piston ring, and increasing the cost of piston ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

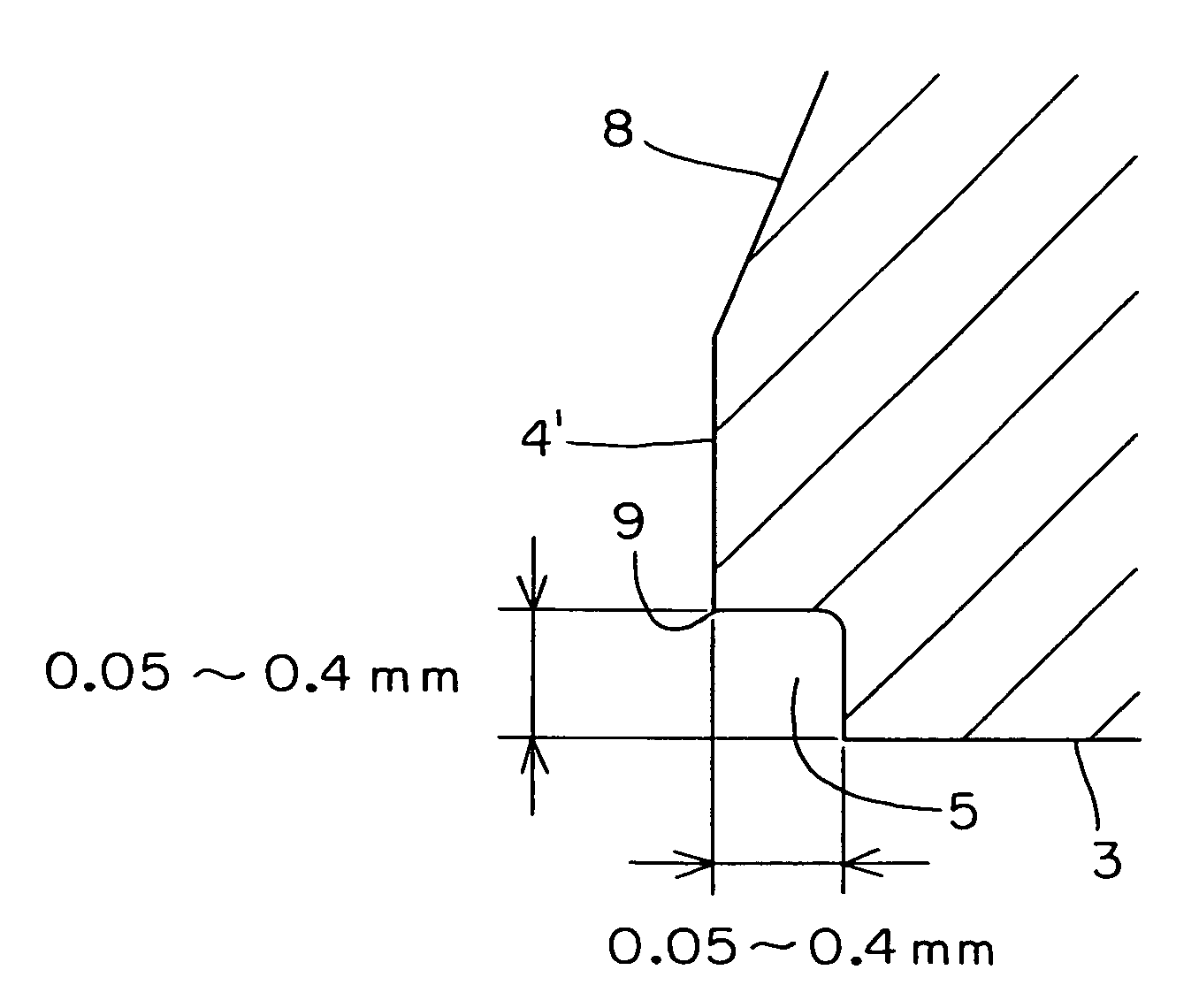

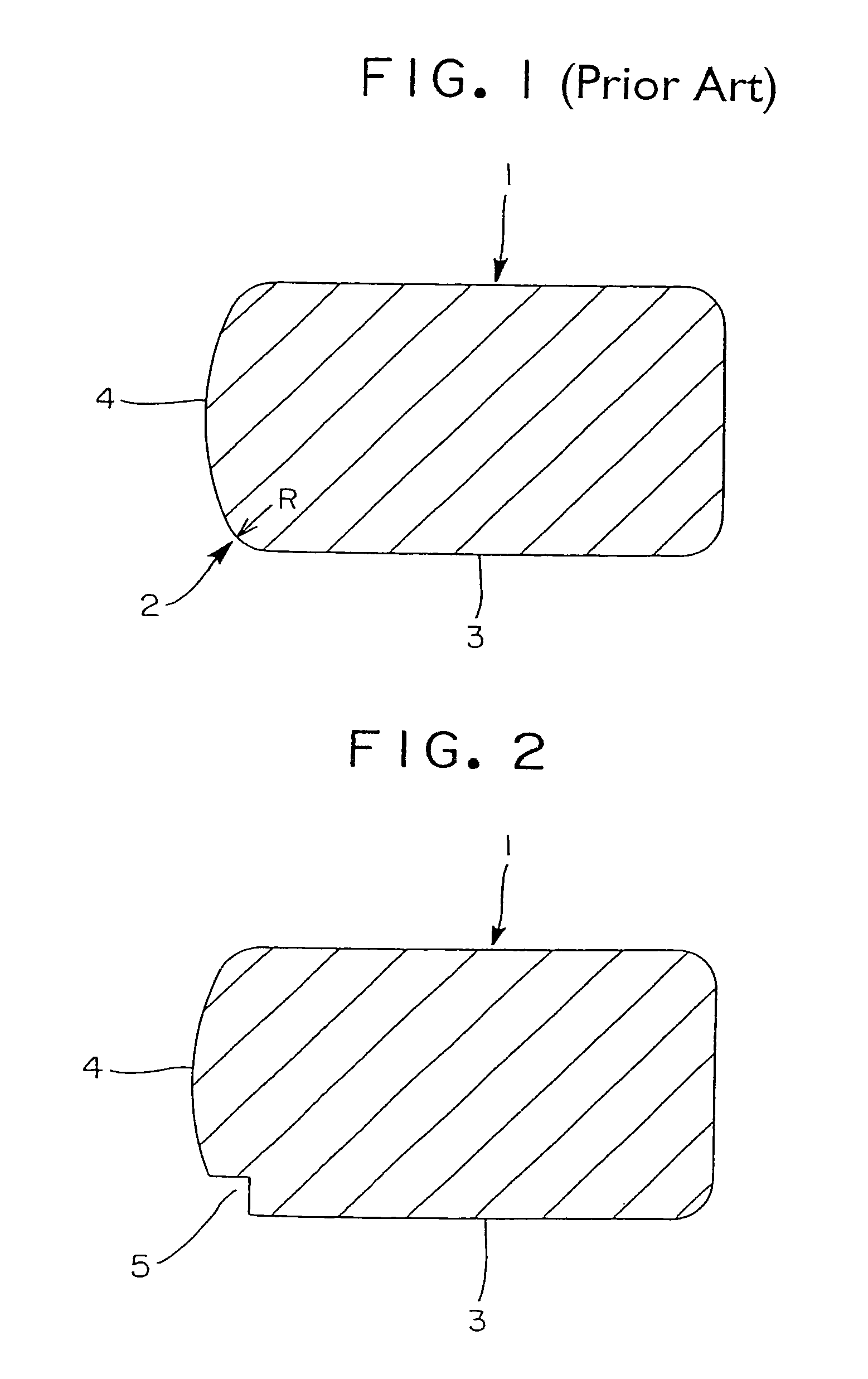

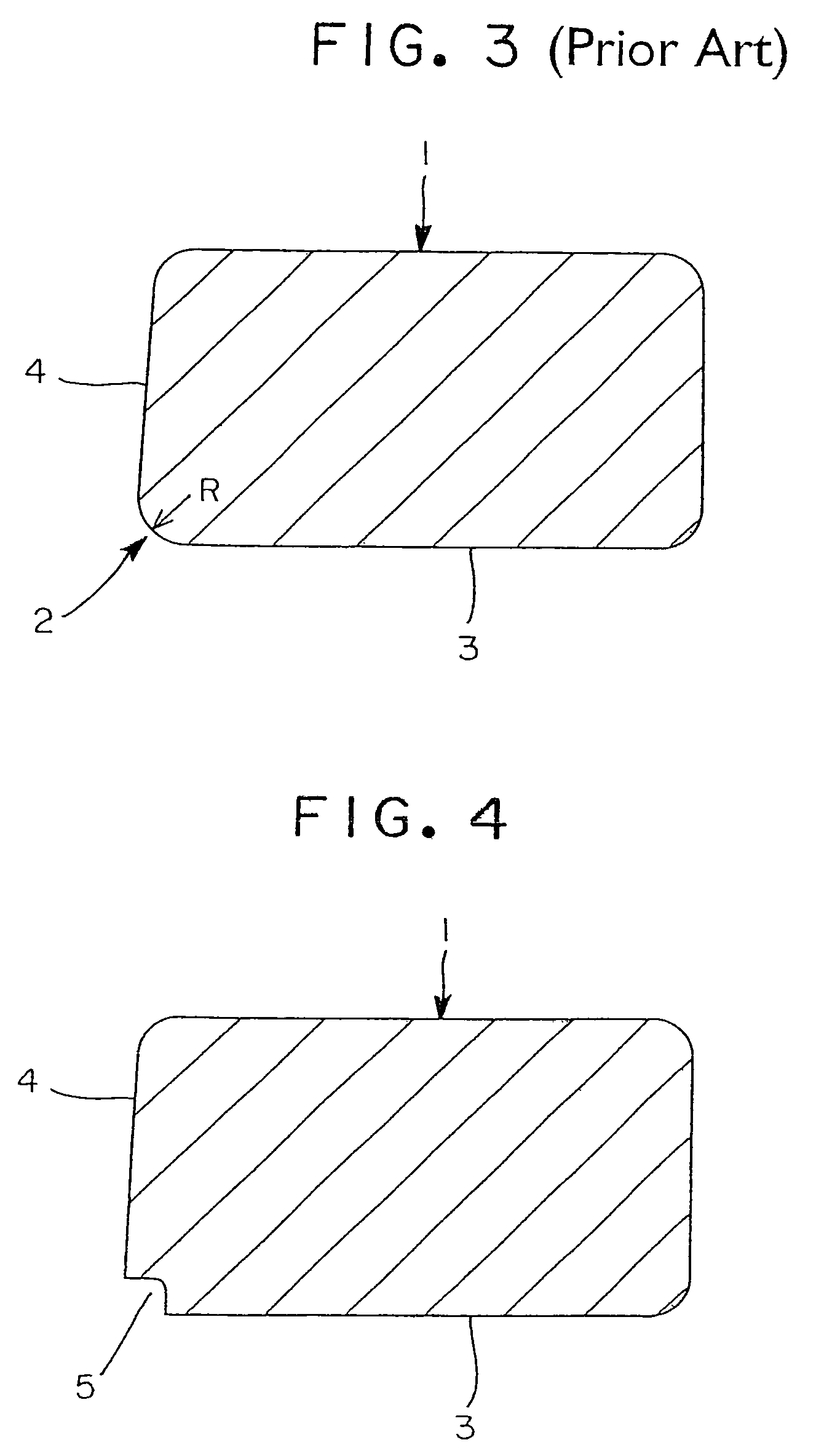

[0037]The present invention adopts a following technique to suppress a machining amount of a lower side surface 3 and an outer peripheral surface 4 of a piston ring 1 having a barrel-face or a taper-face outer peripheral sliding surface, that is, to suppress a machining amount for obtaining a corner portion 2 having a sharp edge to a small amount. That is, in the present invention, a groove 5 (see FIG. 2, FIG. 4, FIG. 5 and FIG. 7) having an approximately quadrangular cross section with a length of each side of 0.05 to 0.4 mm or a groove 6 (see FIG. 6, FIG. 8) having an approximately quarter-circular cross section with a radius of 0.05 to 0.4 mm is formed in the corner portion 2 defined by an outer peripheral sliding surface 4 and the lower-side surface 3 of the piston ring 1 by use of lathe turning or grinding process at least by removing only a portion corresponding to an round portion remaining at the corner portion 2. Here, the groove 5 is continuously extended to abutting end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com