Multi-nozzle ink jet head

a multi-nozzle, ink jet technology, applied in the direction of printing, inking apparatus, etc., can solve the problems of possible contact shorting, and high load on the piezoelectric body 111, so as to achieve accurate inkjet formation and increase the strength of the ink chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[First Embodiment]

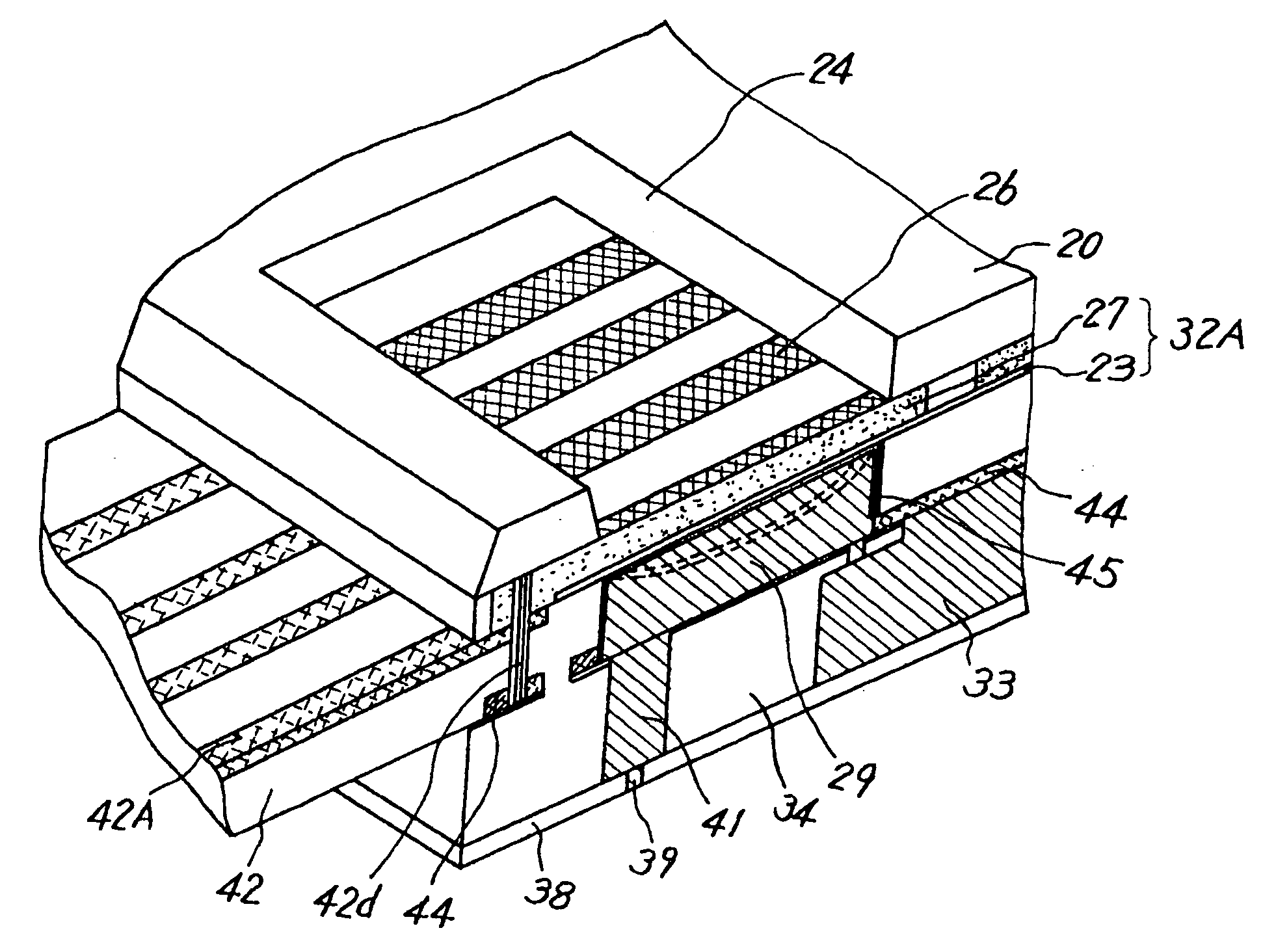

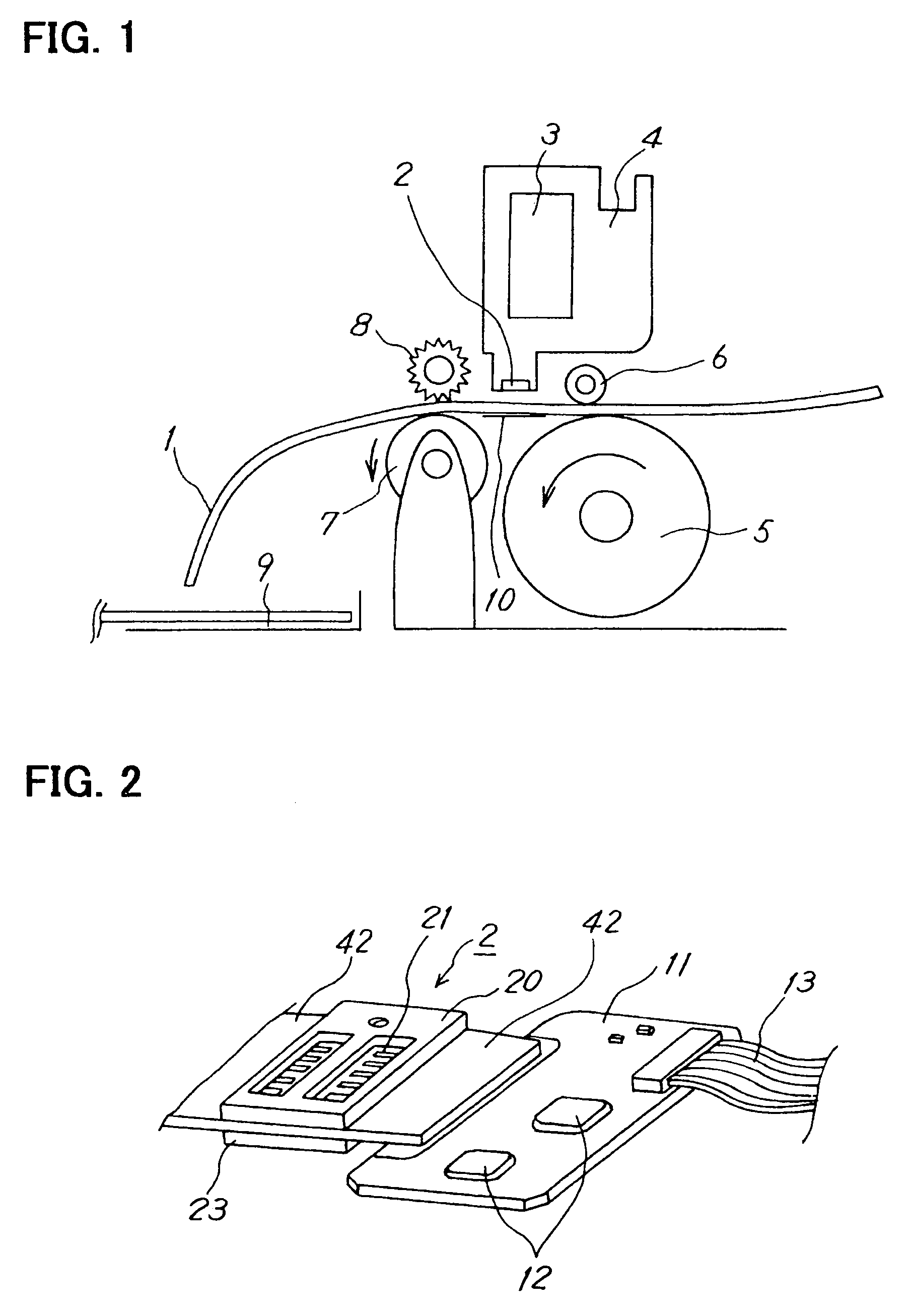

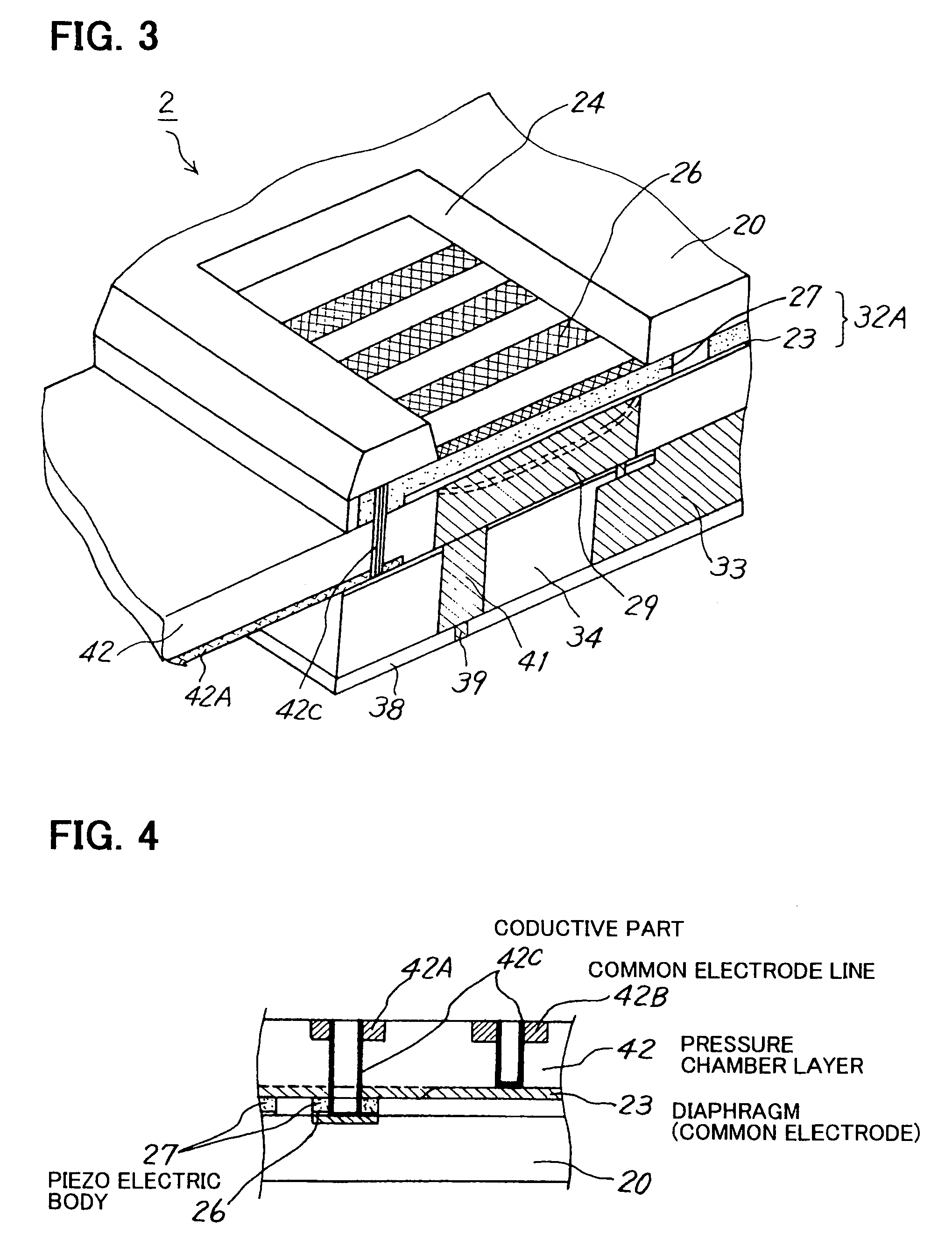

[0062]FIG. 3 is a sectioned perspective view of the ink jet head 2 of a first embodiment of the present invention, FIG. 4 is a sectional view of major parts of the head of FIG. 3, FIG. 5 is a drawing explaining the wiring patterns of the head of FIG. 3, FIGS. 7 and 8 are drawings for explaining the effects of the present invention, and FIGS. 9 to 12 consist of process diagrams for explaining a method of manufacturing the ink jet head of the first embodiment of the present invention.

[0063]As shown in FIG. 3, broadly speaking, the ink jet head 2 is constituted from a substrate 20, main body parts 42 and 34, a nozzle plate 38, ink ejection energy generating parts 32A and so on. As will be described later, the main body part 42 has a laminated structure including an insulating layer and wiring parts, and the main body part 42 also constitutes a pressure chamber forming part, with a plurality of pressure chambers (ink chambers) 29 being formed inside thereof. The main b...

second embodiment

[Second Embodiment]

[0096]FIG. 13 is a sectioned perspective view of the head of a second embodiment of the present invention, FIG. 14 is a sectional view of connecting parts in FIG. 13, FIG. 15 is an enlarged view of FIG. 14, FIG. 16 is a drawing for explaining the operation of the head, and FIGS. 17 and 18 consist of explanatory drawings of a manufacturing process of the head.

[0097]The present embodiment is an improvement of the head of FIG. 3, and elements the same as ones shown in FIG. 3 are represented by the same reference numerals. As shown in FIGS. 13 and 14, the wiring patterns 42A and 42B are formed on the front surface (substrate 20 side) of the pressure chamber forming member (FPC) 42. Moreover, a metal mask 44 for forming the pressure chambers 29 is provided on the FPC 42. This metal mask 44 fulfills a role of reinforcing the pressure chamber walls. Furthermore, metal layers 45 are plated onto the wall surfaces of the pressure chambers 29, thus electrically connecting th...

third embodiment

[Third Embodiment]

[0104]FIG. 19 is a drawing of the constitution of the head of a third embodiment of the present invention; elements the same as ones shown in FIG. 2 and FIG. 6 are represented by the same reference numerals.

[0105]In this embodiment, driving circuits 12, connectors 71, and reinforcing plates 70 are provided on an FPC, which is the pressure chamber forming member 42 described above. As a result, because the driving circuits 12 are joined directly to the head itself, the contact process for the wiring becomes unnecessary, and moreover the cost can be reduced. Moreover, when manufacturing the head, the state of each of the elements can be inspected using the circuits, and hence temporary connection for the inspection is not necessary, which is very effective for reducing the cost of inspection.

[0106]The present invention was described above through embodiments; however, various modifications are possible within the scope of the purport of the present invention, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com