Method for depositing particles onto a substrate using an alternating electric field

a technology of alternating electric field and substrate, which is applied in the direction of aerosol delivery, nuclear engineering, microcapsules, etc., can solve the problems of limited amount of electrostatic deposition, preventing the reliable deposition of a controlled mass on the substrate, and electrostatic deposition technology. achieve the effect of high mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

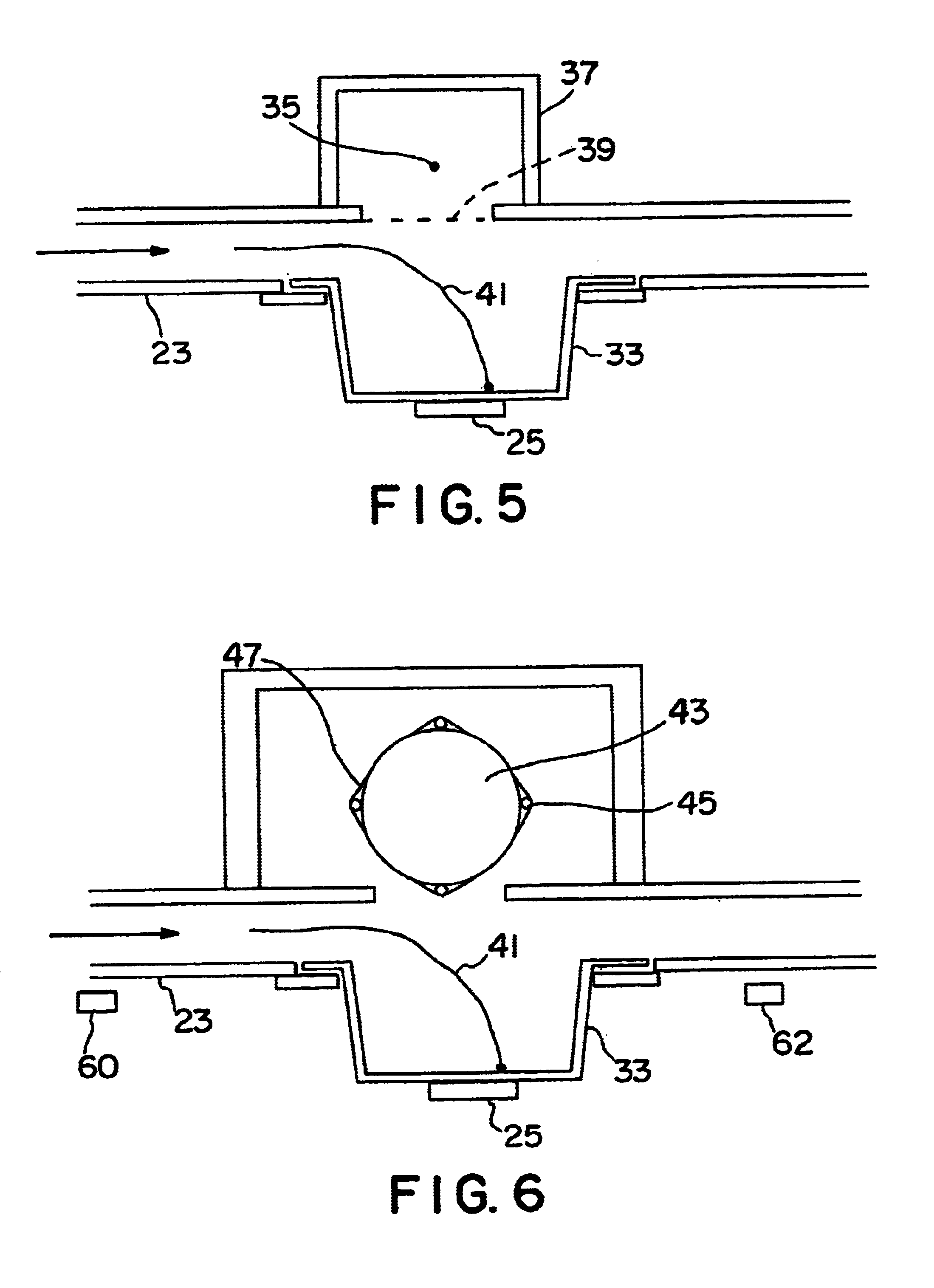

[0036]A filling device was set up according to the schematic of FIG. 6. The channel was fabricated of ¼-inch thick polycarbonate sheet. The channel width was 40-mm and its height was 6-mm. A blister pack pocket, formed of 6-mil polyvinyl chloride, having a depth of 4-mm and a diameter of 6-mm was supported on a circular electrode 25 having a diameter of 4-mm.

[0037]The charge source, consisting of glass core rod 43, spiral wire electrode 47 and four glass coated wire 45 spaced at intervals around the periphery of the core rod, was obtained from Delphax Systems, Canton, Mass. Delphax customers employ these rods in discharging (erasing) latent images on Delphax high-speed printer drums.

[0038]Spiral winding 47 was maintained at ground potential and glass coated tungsten wire 45 was excited using 2300 volt peak-to-peak ac at a frequency of 120 kHz. A Trek high voltage amplifier was employed to provide square wave switching of deposition electrode 25 at a frequency of 35 Hertz. The output...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric field | aaaaa | aaaaa |

| electric field | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com