Fiber stuffing and fluffing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

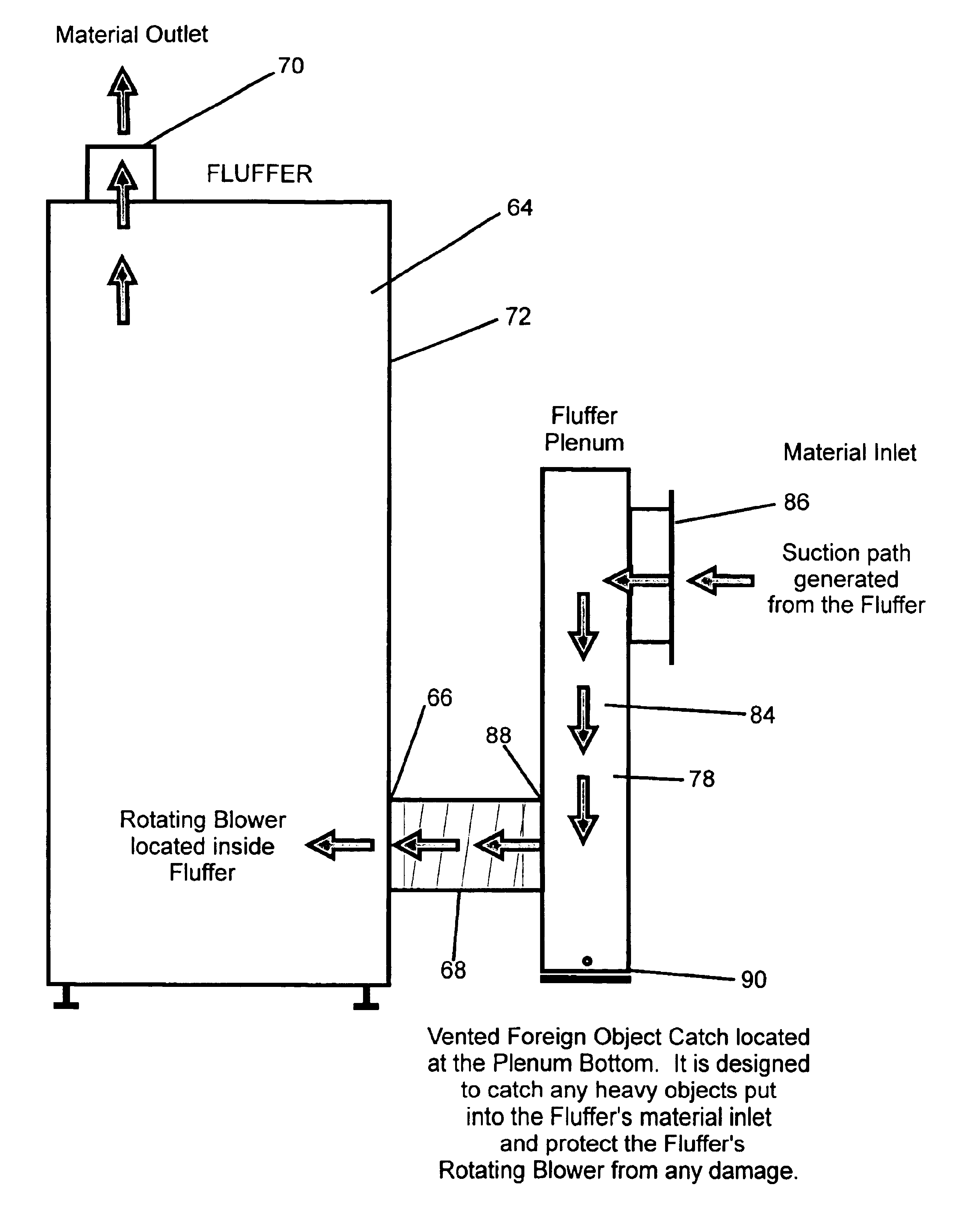

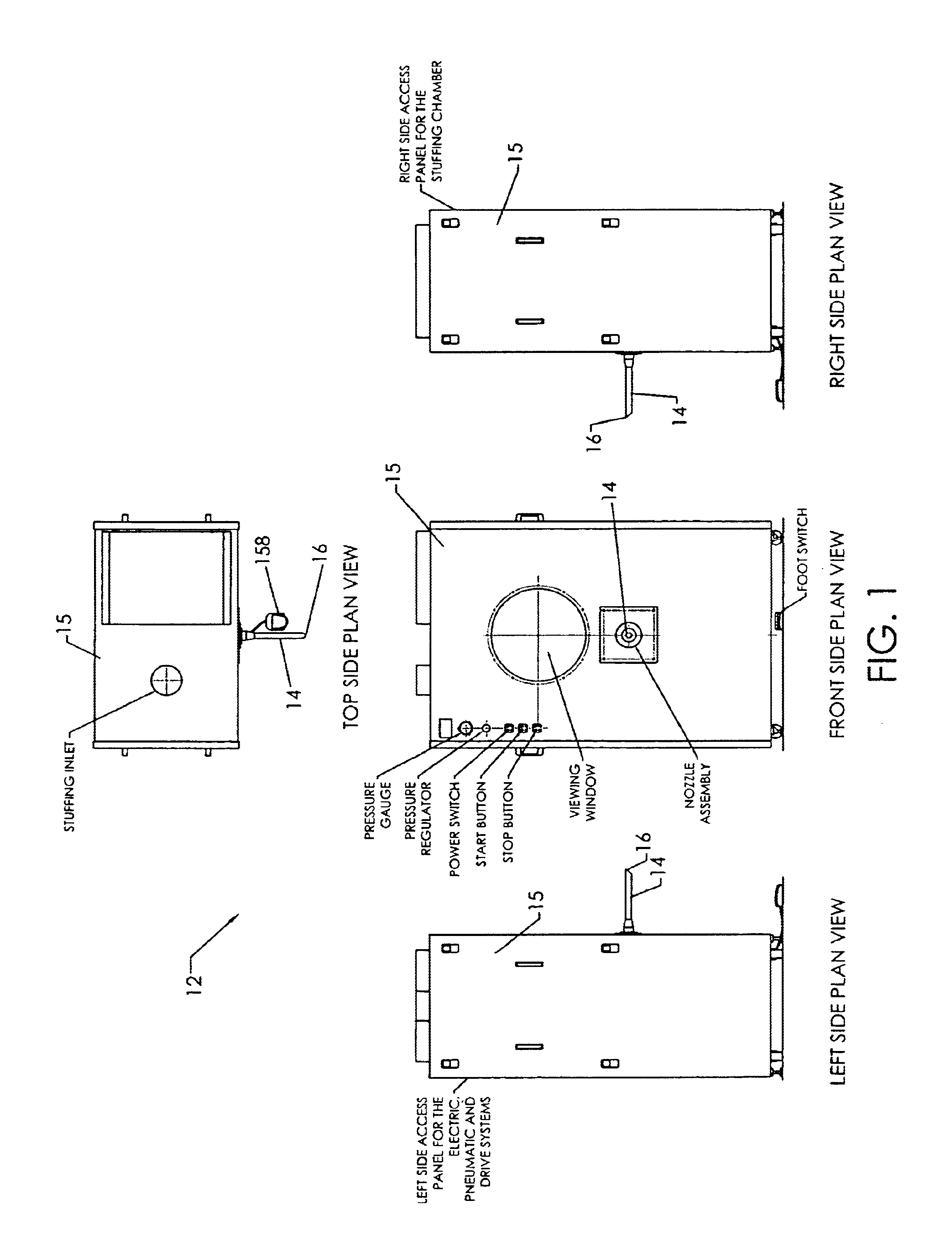

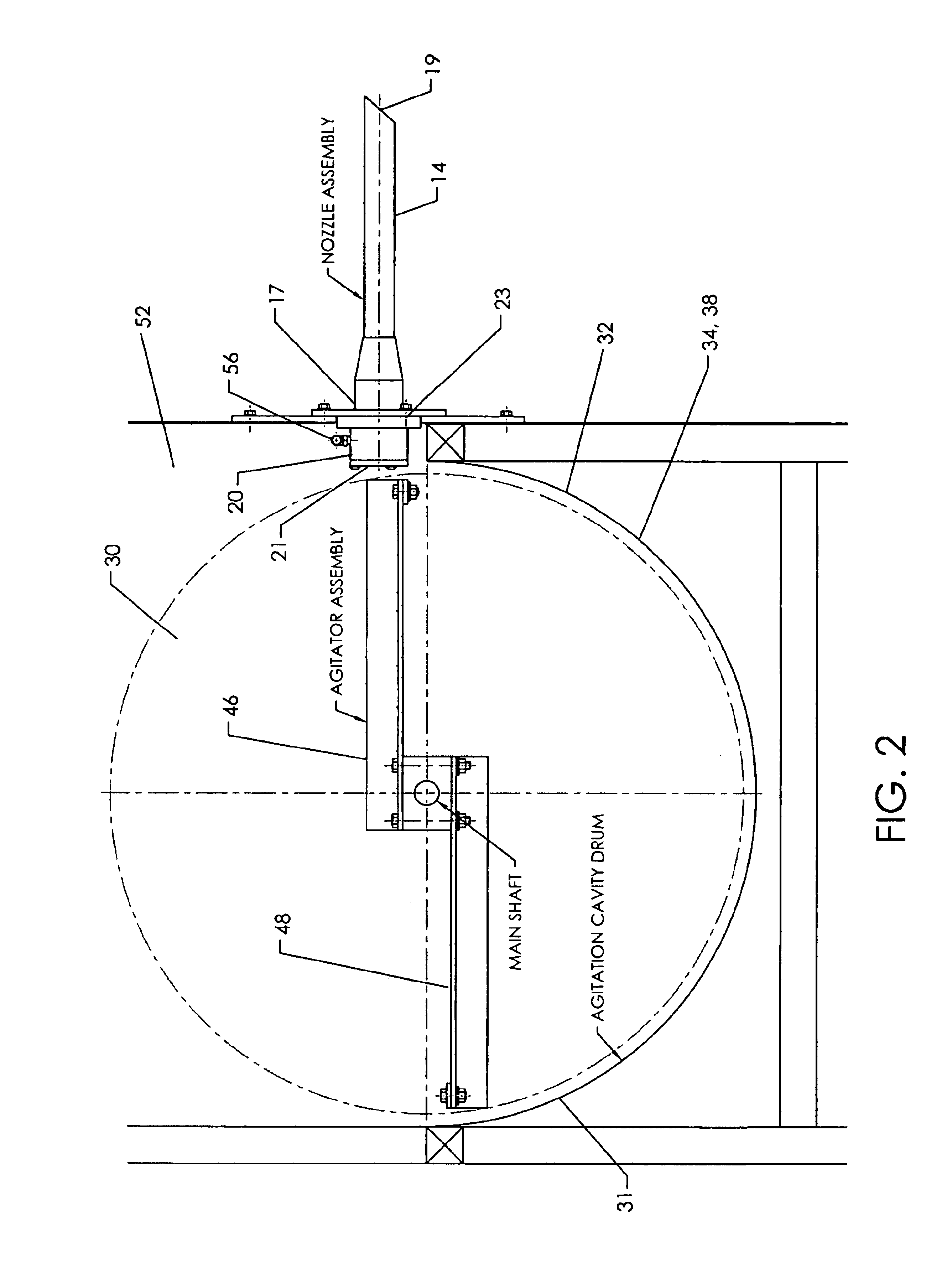

Referring now to the drawings, there is shown in the figures stand alone embodiments of the fiber stuffing and fluffing machine showing the fluffer and stuffer and associated components and circuitry of the present art and integrated embodiments along with associated components and circuitry. The drawings show the fiber stuffing and fluffing machine 10 comprising in an embodiment a stuffing machine 12 having a stuffing nozzle 14, an agitation cavity 30, a control system 50, a pressurized air supply 56, and activation switches 158, 160, 162, 164, and a fluffing machine 64 having a housing 72 and blower 74, a plenum 78, and a blast gate valve 92. All of the aforementioned uniquely formed and combined with further described portions of the apparatus to provide the useful features herein described. An embodiment of the present art combines the stuffing machine 12, fluffing machine 64, and a compressed air source 56 into a single stand alone machine.

The invention first comprises a stuffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com