Coil winding number variable type motor and coil winding number varying method for varying cooling and heating capacity of reciprocating compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

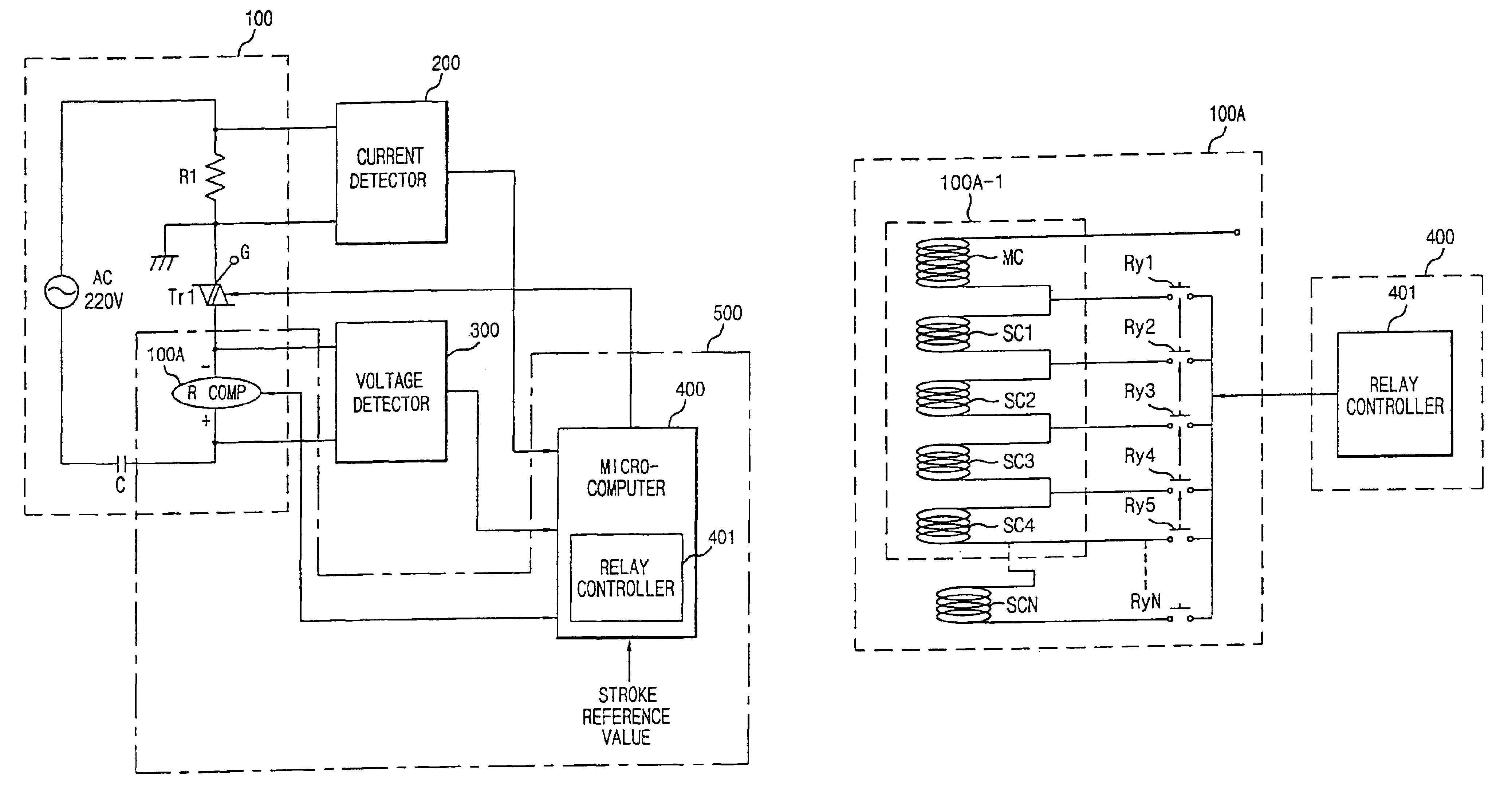

Image

Examples

Embodiment Construction

Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

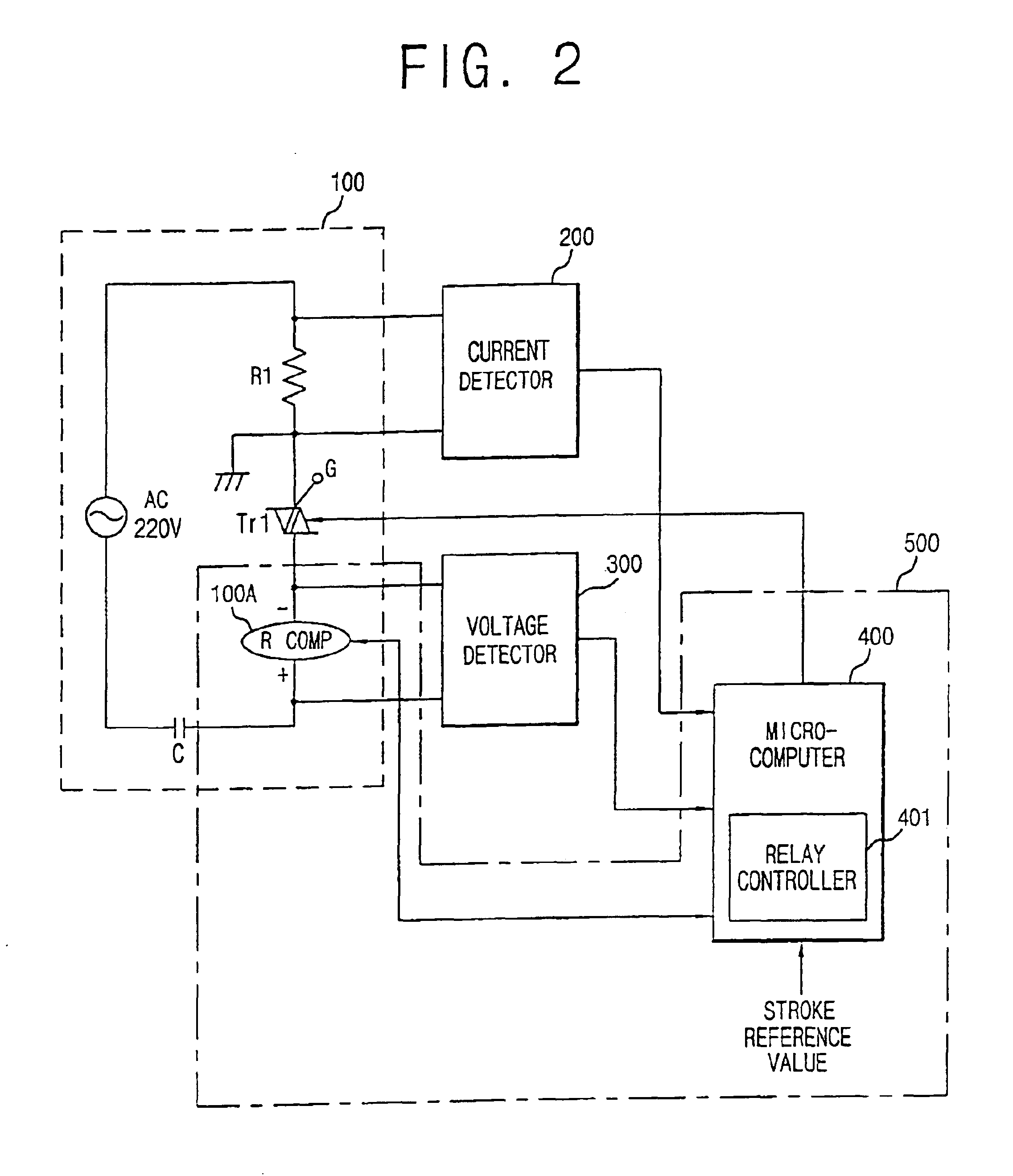

FIG. 2 is a schematic block diagram of a coil winding number variable type motor for varying a cooling and heating capacity of a reciprocating compressor in accordance with a preferred embodiment of the present invention.

First, according to an initial stroke reference value by a user, a microcomputer 400 inputs a switching signal to a switching device, that is, a triac (Tr1), performing an AC switching function, to drive a reciprocating compressor 100.

Thereafter, a current detector 200 and a voltage detector 300 detect a current and a voltage generated from the reciprocating compressor, respectively.

By using the detected current and the voltage, the microcomputer 400 compares the initial stroke reference value by the user and a stroke reference value computed during the driving of the reciprocating compressor 100, and outputs a sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com